Envirotainer CryoSure X1 User manual

X1, X2, X5, X11

Doc No. UM-CRYO-3030

Version 2

www.envirotainer.com

CryoSure®systems

User Manual

Doc No:

UM-CRYO-3030

Revision:

2

State:

Released

Release Date:

2021-12-01

Approved By:

hanst

Record of revision

RECORD OF REVISION

VER. NO. REVISION

2REVISED:

•1.1 Overview,Table 1 Product specification:

• Relocated info of amount of vials, and added additional info in new chapter

1.1.1 Payload.

• Renamed table 1 from “Measurements and weight” to “Product specification”.

• Updated product specification data.

•1.4 Contact: New chapter.

•2.2 Symbols on the CryoSure® system.

• Removed UN3373 information. Only applicable for customer when adding bio-

logical substance category B.

• Added UN3481 information. If system is equipped by Envirotainer with a track-

er, the safety sticker will be added from the start.

•3.3 Monitor the autonomy duration left on your CryoSure® system replaces

chapter “Remaining dry ice time” which required an user to weigh the system.

• General editorial improvements:

• Clarified/changed wording.

• The word “vessel” was changed to either dewar or ®system.

• The word “data logger” was changed to tracker.

• Changed header from “Returning of empty product” to 3.2.4 Returning of

the system.

• Updated front page illustration.

• Updated illustration in 1.2 Technical details.

Doc No:

UM-CRYO-3030

Revision:

2

State:

Released

Release Date:

2021-12-01

Approved By:

hanst

TABLE OF CONTENTS

1. INTRODUCTION.......................................................................................................................... 1

1.1 Overview .................................................................................................................................1

1.1.1 Payload......................................................................................................................2

1.2 Technical details.......................................................................................................................3

1.3 Intended use............................................................................................................................4

1.4 Contact....................................................................................................................................4

1.5 Operating conditions.................................................................................................................4

2. SAFETY......................................................................................................................................... 5

2.1 Shipping regulations .................................................................................................................5

2.2 Symbols on the CryoSure® system............................................................................................5

2.3 Cleanliness of product ..............................................................................................................5

3. USING THE CRYOSURE® SYSTEM....................................................................................... 6

3.1 Preparing a shipment................................................................................................................6

3.2 Operating instructions...............................................................................................................6

3.2.1 Product loading...........................................................................................................7

3.2.2 Shipping of loaded product ..........................................................................................9

3.2.3 Product unloading .....................................................................................................10

3.2.4 Returning of the system............................................................................................. 11

3.3 Monitor the autonomy duration left on your CryoSure® system ..................................................12

Doc No:

UM-CRYO-3030

Revision:

2

State:

Released

Release Date:

2021-12-01

Approved By:

hanst

Intentionally left blank

Doc No:

UM-CRYO-3030

Revision:

2

State:

Released

Release Date:

2021-12-01

Approved By:

hanst

1. Introduction

1. INTRODUCTION

The CryoSure®system is designed for global shipping and storage of pharmaceutical products, clinical trial

materials, vaccines, cell & gene therapy, biospecimens and specialty medicines that are required to be kept

below -70°C (-94°F).

The CryoSure®system uses a unique patented technology combined with dry ice. It is a reusable shipping

system which offers both mechanical protection of the shipped product and maintains load space temperature

below -70°C (-94°F) (average between -74°C and -80°C / -101°F and -112°F).

• Maintains temperature control consistently below -70°C (-94°F)

• Suitable for any destination, domestic or international, and by ground or air, covering the entire shipment

duration including delays and customs without the need to re-charge

• Provides mechanical protection during transport by ground or air

The CryoSure®system comes in four different sizes, with product space volume from 1 L to 10.8 L. The

temperature control duration is intended to last throughout the shipment without recharging.

These systems will be pre-charged with dry ice at an Envirotainer facility and be delivered to a second location

where temperature-sensitive materials can be loaded into the dewar for transit or storage.

1.1 OVERVIEW

The CryoSure®product line consist of four different sizes.

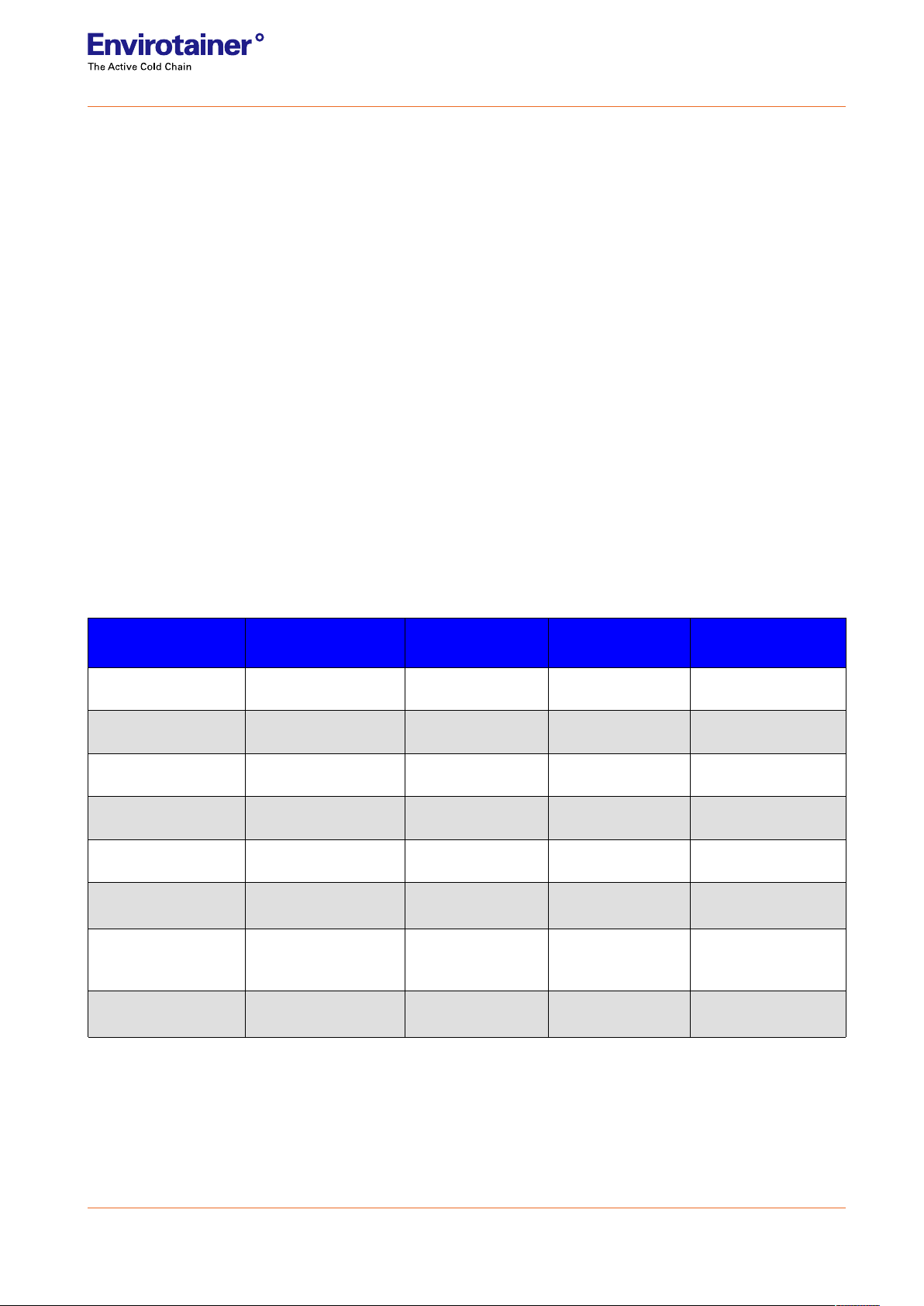

Table 1 Product specification

CryoSure°

system

X1 X2 X5 X11

Autonomous

duration* >8 days >21 days >13 days >15 days

Average

sublimation rate 0,0055 kg / hour 0,0063 kg / hour 0,010 kg / hour 0,012 kg / hour

Payload opening Ø 9 cm

(Ø 3.5ʺ)

Ø 9 cm

(Ø 3.5ʺ)

Ø 15.2 cm

(Ø 6ʺ)

Ø 21,3 cm

(Ø 8.4ʺ)

Dry-ice payload 1,2 kg

(2.5 lb.)

3,5 kg

(7.7 lb.)

3,2 kg

(7.2 lb.)

5,5 kg

(12 lb.)

Product payload 1 L

(33.7 oz.)

1.6 L

(55 oz.)

5 L

(170.3 oz.)

11.1 L

(376.3 oz.)

Product space

(DxH)

8,1 x 19,5 cm

(3.2ʺ x 7.7ʺ)

8,1 x 31,9 cm

(3.2ʺ x 12.6ʺ)

14,3 x 31,5 cm

(5.6ʺ x 12.4ʺ)

20,7 x 33,2 cm

(8.1ʺ x 13.1ʺ)

Outer dimensions

of box (WxLxH)

27,5 x 27,5 x 42,4 cm

(10.8ʺ x 10.8ʺ x 16.7ʺ)

30 x 30 x 59 cm

(11.8ʺ x 11.8ʺ x

23.2ʺ)

33,8 x 33,8 x 59 cm

(13.3ʺ x 13.3ʺ x

23.2ʺ)

45,7 x 45,7 x 63,5 cm

(18ʺ x 18ʺ x 25ʺ)

Total weight

(excl. product load)

4,8 kg

(10.6 lb.)

9,9 kg

(21.7 lb.)

11,3 kg

(24.8 lb.)

16,8 kg

(37 lb.)

* When exposed to ISTA 7D summer profile

1 (14)

Doc No:

UM-CRYO-3030

Revision:

2

State:

Released

Release Date:

2021-12-01

Approved By:

hanst

1.1.1 Payload

1.1.1 PAYLOAD

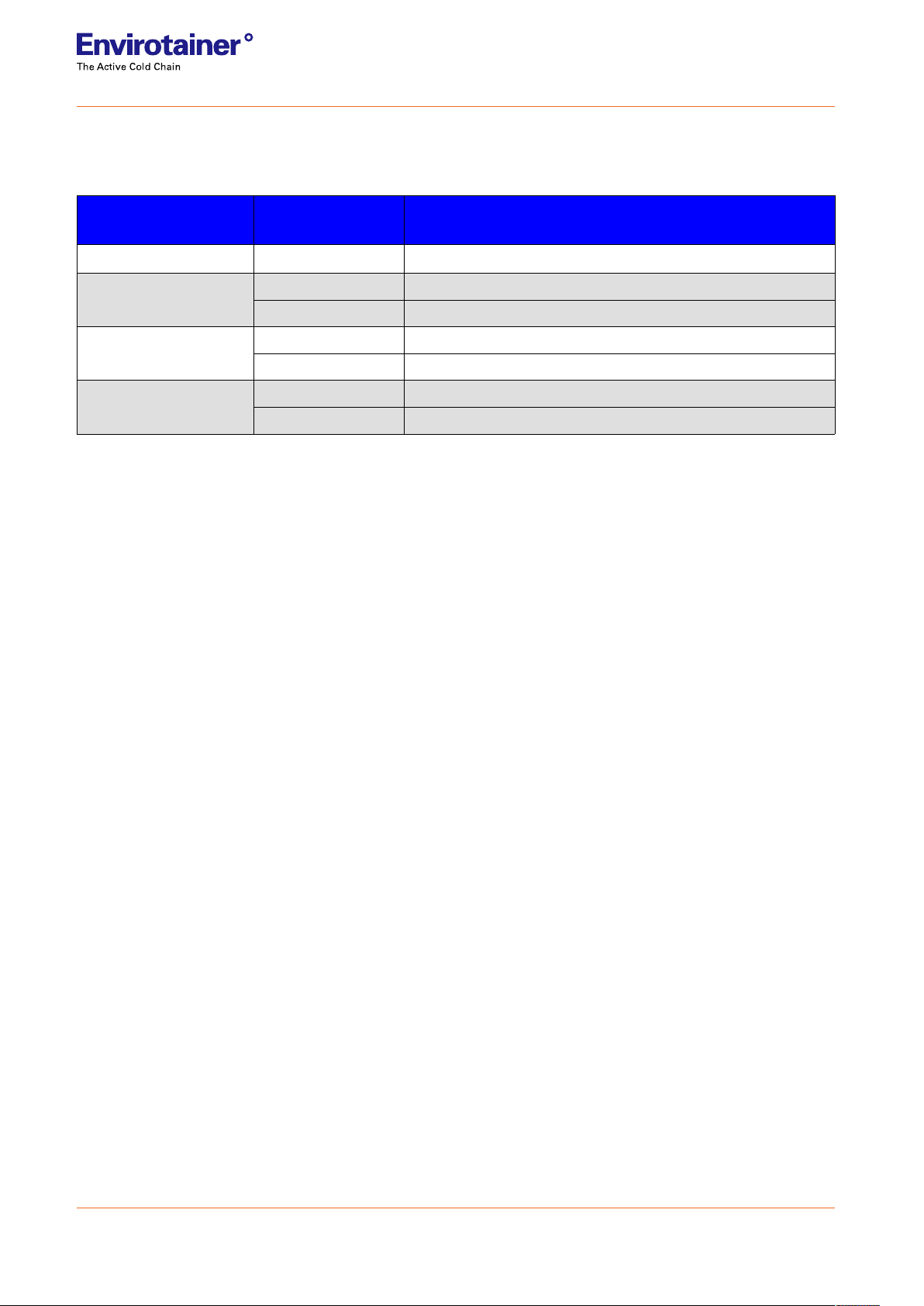

Table 2 Vials configuration

CryoSure®

version # of 2 mL vials 2 mL vials configuration

CryoSure®X1 20 Canister holding 2 bags; 10 vials/bag

CryoSure®X2 80 Canister holding 16 canes without sleeves; 5 vials/cane

70 Canister holding 14 canes with sleeves; 5 vials/cane

CryoSure®X5 300 Canister holding 60 canes without sleeves; 5 vials/cane

200 2 boxes oriented vertically; 100 vials/box

CryoSure®X11 600 120 canes without sleeves in bags; 5 vials/cane

500 Rack holding 5 boxes; 100 vials/box

2 (14)

Doc No:

UM-CRYO-3030

Revision:

2

State:

Released

Release Date:

2021-12-01

Approved By:

hanst

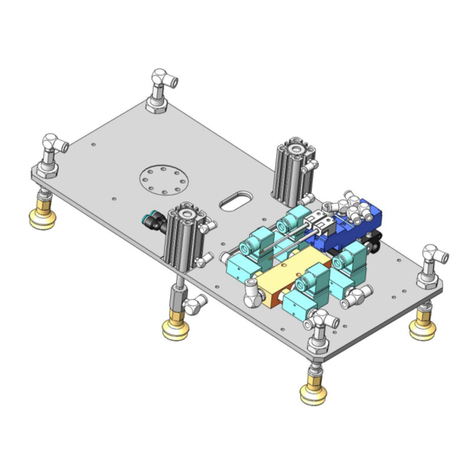

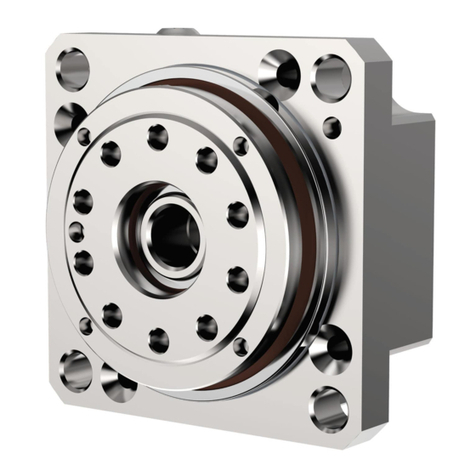

1.2 Technical details

1.2 TECHNICAL DETAILS

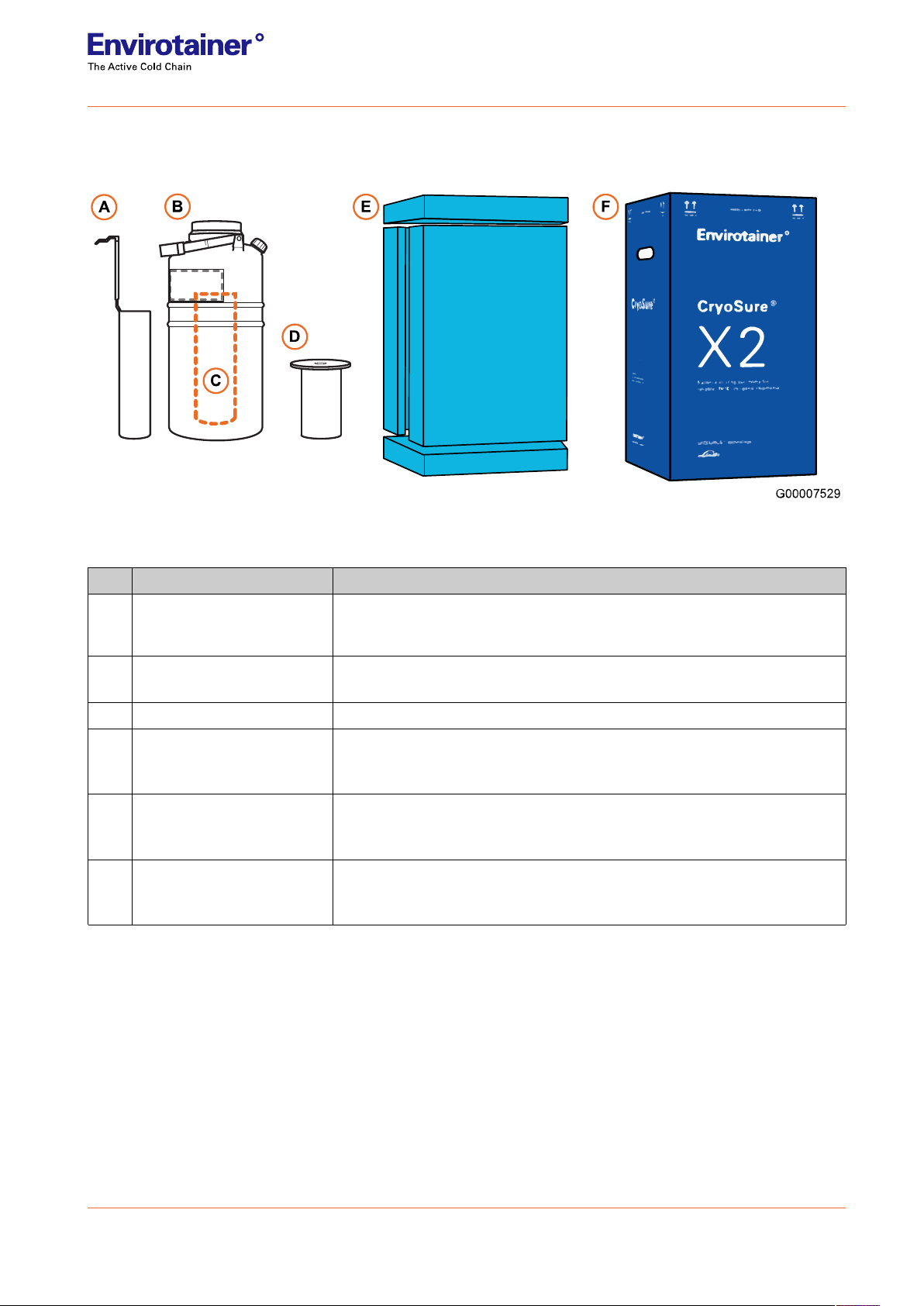

A complete CryoSure®system is comprised of the following components:

Fig. 1 The CryoSure®system.

Table 3 CryoSure®system features

Pos Name Description

AProduct holder

(standard for X2 or X5)

Cylindrical stainless-steel container with handle for loading materials into,

removing materials from, or holding materials within the storage zone of

the dewar

BDewar Insulated aluminum container that holds the dry ice refrigerant and

material to be preserved

CProduct space To place product holder in

DInsulating lid

Cap and insulating cork used to close the dewar opening while allowing

carbon dioxide vapor from sublimating dry ice inside the dewar to still

vent freely outside the dewar

EFoam inserts

Reusable packaging positioned between the dewar and cardboard box

that protects the dewar from handling damage:

(one (1) bottom, one (1) top, and two (2) side pieces)

FCardboard box

External packaging

Shipping, safety, and regulatory labels are applied to the exterior of the

cardboard box as appropriate

3 (14)

Doc No:

UM-CRYO-3030

Revision:

2

State:

Released

Release Date:

2021-12-01

Approved By:

hanst

1.3 Intended use

1.3 INTENDED USE

Pre-charged CryoSure®systems are delivered with dry ice already loaded inside. In normal operation, users are

never required to handle dry ice.

The CryoSure®system is designed for global shipping and storage of pharmaceutical products, clinical trial

materials, vaccines, cell & gene therapy, biospecimens and specialty medicines that are required to be kept

below -70°C (-94°F).

The CryoSure®system offers both mechanical protection of the shipped product and maintains load space

temperature below -70°C (-94°F) throughout the shipping duration.

Refer to 2. Safety.

IMPORTANT!

Biological materials used with the CryoSure®systems are limited to Biological Substance Category B

materials specified under UN 3373 and exceptions defined in IATA 3.6.2.2.3.

No pathogenic Category A materials (UN 2814, UN 2900) or medical or clinical wastes (UN 3291) shall

be used with the CryoSure®systems.

1.4 CONTACT

For contact information to our operations centers, refer to www.envirotainer.com.

For questions regarding this manual or the CryoSure®systems, send an e-mail to support@envirotainer.com.

1.5 OPERATING CONDITIONS

Ambient temperatures, humidity, improper orientation of system and mechanical shock does not impact the

CryoSure®system temperature levels.

4 (14)

Doc No:

UM-CRYO-3030

Revision:

2

State:

Released

Release Date:

2021-12-01

Approved By:

hanst

2. Safety

2. SAFETY

• Read the manual before handling and operating the CryoSure®system.

• Read the Safety Data Sheet for dry ice (UN1845).

• Pay attention to warning stickers and texts attached to the CryoSure®system.

2.1 SHIPPING REGULATIONS

The United States Department of Transportation (DOT) and related international government agencies regulate

shipments containing dry ice and biological materials. In addition, the International Air Transport Association

(IATA) maintains standards that guide airline polices regarding dry ice and biological material shipments. Users

of a pre-charged CryoSure®system should review and follow all appropriate government and carrier

requirements for labeling and packaging shipments containing dry ice or biological materials.

2.2 SYMBOLS ON THE CRYOSURE®SYSTEM

Fig. 2

IMPORTANT!

UN1845 (Dry ice) is solidified carbon dioxide. At atmospheric pressure, dry ice sublimates to carbon dioxide

vapor at approximately -78.5°C (-109.3°F). Dry ice is very cold, and contact with dry ice or areas cooled by

dry ice can cause frostbite. The CryoSure®pre-charged system is delivered with dry ice already loaded inside.

In normal operation, it should not be necessary for users of a pre-charged CryoSure®system to handle dry

ice. The interior spaces and surfaces of a pre-charged dewar are very cold, and users are advised to wear

appropriate gloves when interacting with the interior of the dewar or items recently removed from the interior.

The carbon dioxide evolved by sublimation of dry ice can create potentially hazardous carbon dioxide-

enriched and/or oxygen-deficient atmospheres. Users of dry ice or dry ice-containing systems are

recommended to evaluate the potential for atmospheric hazards in their working environment and take

appropriate steps to address such hazards (for example, by using air monitoring devices and adequate

ventilation).

UN3481 Lithium ion batteries contained in equipment or packed with equipment. If the CryoSure®system is

equipped with a tracker, a safety sticker will be added by Envirotainer° to the system. Any other tracker or

data logger added to the system by the customer, containing Lithium batteries, must be equally declared.

2.3 CLEANLINESS OF PRODUCT

The CryoSure®system is cleaned using VIRKON™ solution and Isopropyl alcohol according to Envirotainer

instruction SOP-ENV-0229 and SOP-ENV-0234.

5 (14)

Doc No:

UM-CRYO-3030

Revision:

2

State:

Released

Release Date:

2021-12-01

Approved By:

hanst

3. Using the CryoSure®system

3. USING THE CRYOSURE®SYSTEM

3.1 PREPARING A SHIPMENT

It is recommended to have the product pre-conditioned to -70°C (-94°F) or below -78.5°C (-109.3°F) for the

CryoSure®system to operate within the specified temperature regulating duration. Using the CryoSure®to cool

the product will reduce the temperature regulating duration.

3.2 OPERATING INSTRUCTIONS

1. Product loading, 3.2.1 Product loading.

2. Shipping CryoSure®system, 3.2.2 Shipping of loaded product.

• Remove old labels and documents.

• Prepare new labels and documents for cardboard box.

3. Receiving CryoSure®system and removing products, 3.2.3 Product unloading.

4. Returning/shipping CryoSure®system to Envirotainer/new destination, 3.2.4 Returning of the system.

• Remove any biological product materials and associated packaging from the dewar.

• Remove old labels and documents.

• Prepare new labels and documents for cardboard box.

6 (14)

Doc No:

UM-CRYO-3030

Revision:

2

State:

Released

Release Date:

2021-12-01

Approved By:

hanst

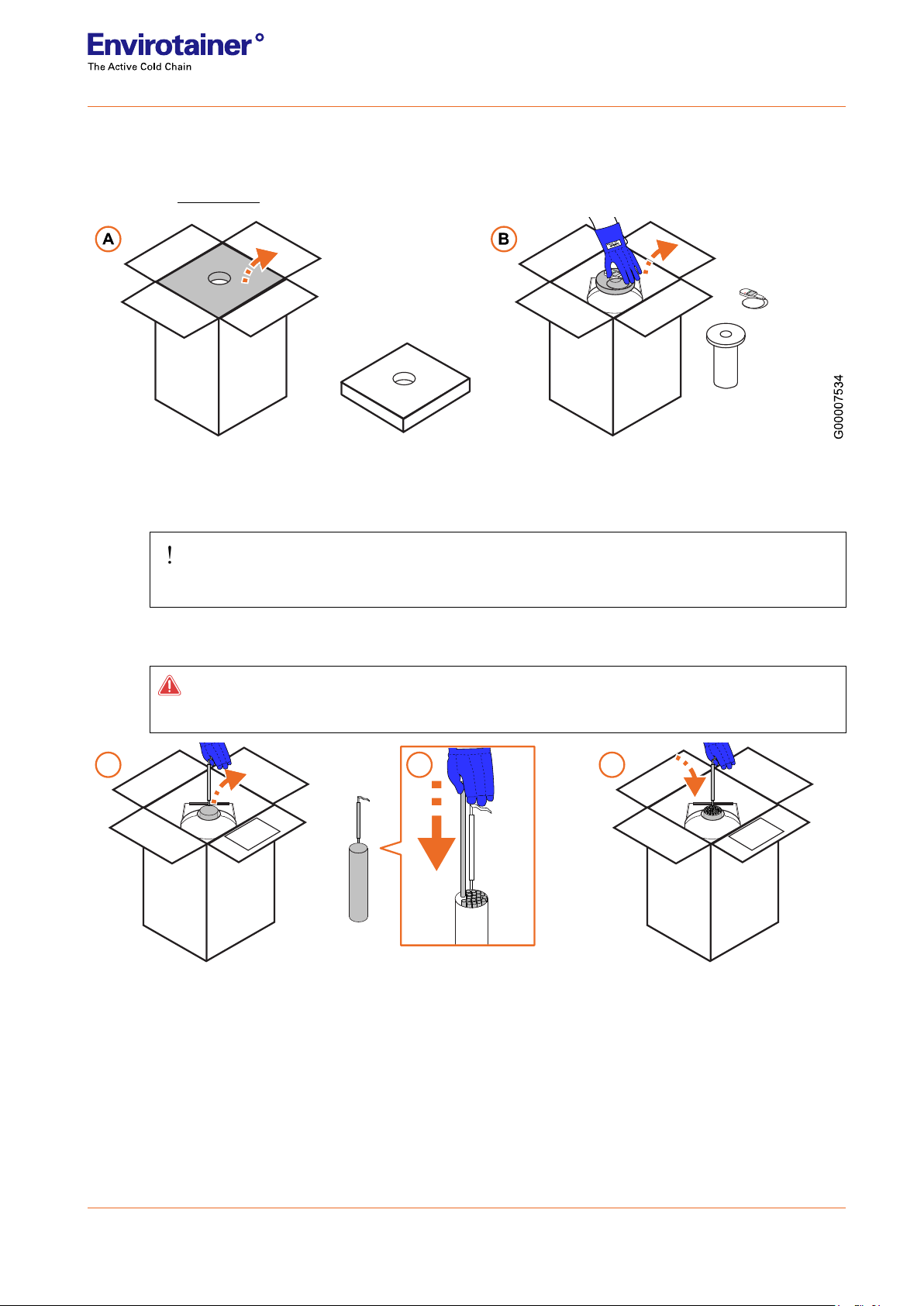

3.2.1 Product loading

3.2.1 PRODUCT LOADING

1. Inspect the outer packaging. If the cardboard box is too worn for use, contact Envirotainer for support.

Refer to 1.4 Contact

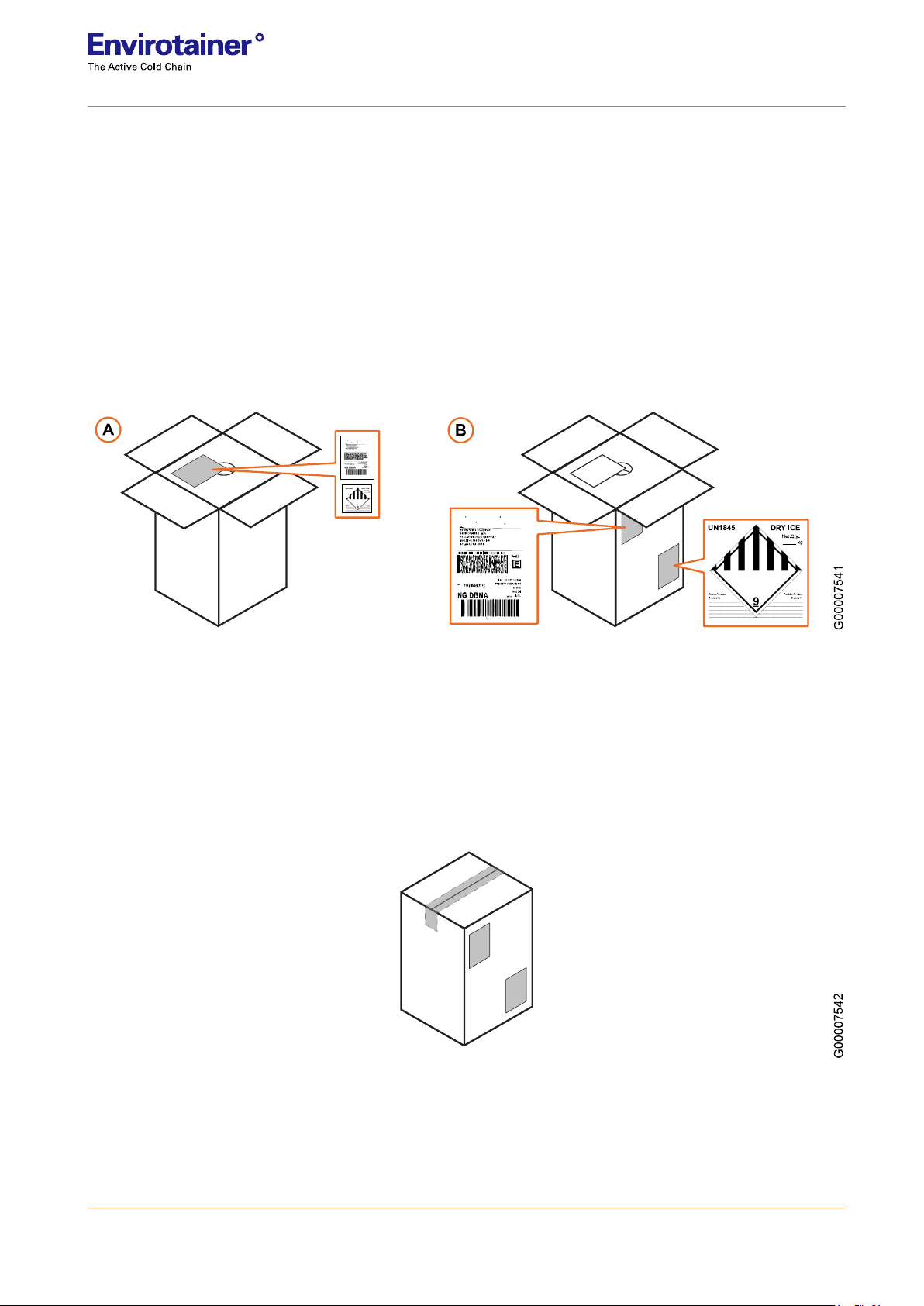

Fig. 3

2. Opening the box:

2a. Open the box and set aside the top foam.

IMPORTANT!

DO NOT DISCARD THE FOAM

2b. Wearing safety gloves, remove the lid. Place the lid to one side, together with the tracker and probe (if

any).

DANGER!

DO NOT DISCARD THE LID

Fig. 4

3. Loading the product:

3a. Lift the product holder by its handle and remove it from the dewar.

3b. Load the product into the product holder. Follow all applicable government and carrier requirements for

packaging the product.

3c. Lift the product holder into the dewar.

→

A C

G 00007532

B

7 (14)

Doc No:

UM-CRYO-3030

Revision:

2

State:

Released

Release Date:

2021-12-01

Approved By:

hanst

3.2.2 Shipping of loaded product

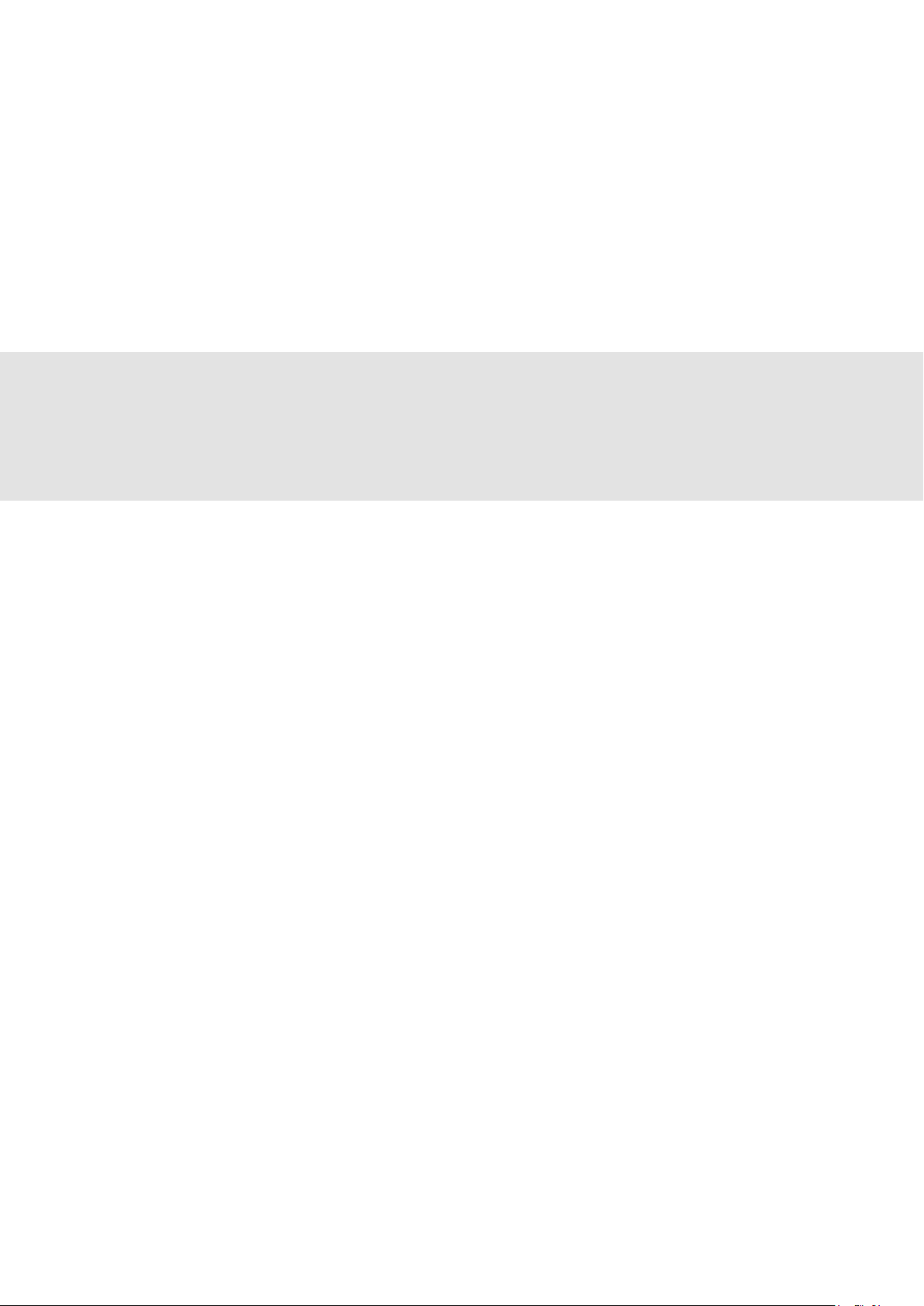

3.2.2 SHIPPING OF LOADED PRODUCT

IMPORTANT!

After the dewar has been loaded with product and properly packaged with all required components, labels

need to be applied to the exterior of the cardboard box in accordance with government

(e.g., US DOT, EU ADR) regulations and carrier (e.g., IATA) requirements.

Please ensure that all needed documents according to the correspondent regulations are on hand (for

example shippers declaration, pro forma invoices and packing lists).

1. Remove or cover all labels on the cardboard box:

• the label of the parcel carrier

• the dangerous goods label (UN1845) where you are notified as consignee

Fig. 6

2. Apply the labels to the exterior of the box in accordance with government regulations and carrier

requirements.

3. Ensure that the following documents are in the folder:

• original shipper’s declaration (according to US DOT, EU ADR or IATA regulations)

• original pro-forma invoice

• original packing list

4. Close and seal the cardboard box with a clear tape.

5. Take necessary steps in order to inform selected carrier that the parcel is ready for pick-up.

9 (14)

Doc No:

UM-CRYO-3030

Revision:

2

State:

Released

Release Date:

2021-12-01

Approved By:

hanst

3.2.3 Product unloading

3.2.3 PRODUCT UNLOADING

Fig. 7

1. Unpacking:

1a. Open the box and set aside the top foam.

IMPORTANT!

DO NOT DISCARD THE FOAM

1b. Wearing safety gloves, remove lid. Place the lid to one side.

CAUTION!

DO NOT DISCARD THE LID

Fig. 8

2. Unloading product:

2a. Lift the product holder by its handle and remove it from the dewar.

2b. Remove the product from the product holder. Store or use the product as defined by procedures.

3. Prepare the next shipment.

• If loading new product into the dewar, follow step 3b and onwards of the 3.2.1 Product loading

procedure to prepare the shipment.

• If sending the CryoSure®system to its next destination, follow step 3c and onwards of the 3.2.1 Product

loading procedure to prepare the shipment.

10 (14)

Doc No:

UM-CRYO-3030

Revision:

2

State:

Released

Release Date:

2021-12-01

Approved By:

hanst

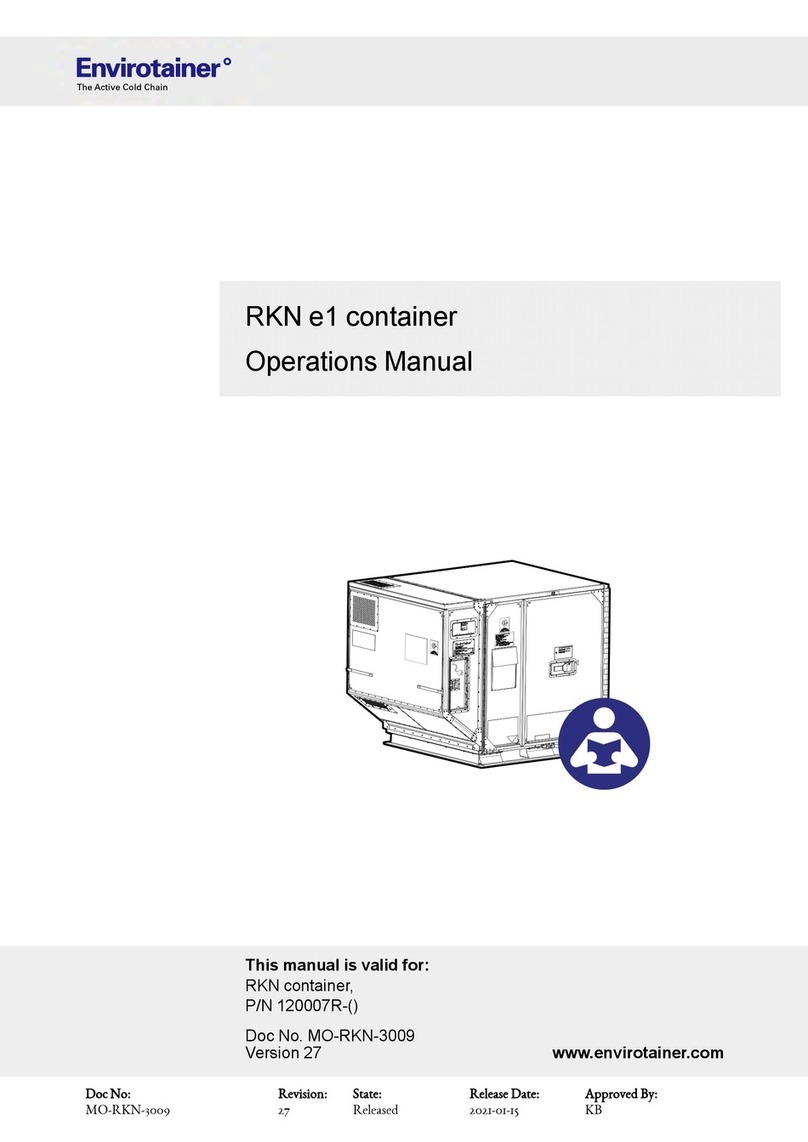

3.2.4 Returning of the system

3.2.4 RETURNING OF THE SYSTEM

If you have booked a pick-up service from Envirotainer, a prepaid shipping return label is included in a folder on

the inside of the cardboard box.

If you have not pre-booked the pick-up service, contact Envirotainer support to place an order for the service.

Otherwise, follow steps 1and 2below to prepare the CryoSure®system for return.

1. Remove any biological product materials and associated packaging from the dewar.

2. Remove or cover all labels on the cardboard box:

• the label of the parcel carrier

• the dangerous goods label (UN1845) where you are notified as consignee

• the dangerous goods label (UN 3373)

Fig. 9

3. Preparing the documents and labels.

3a. Remove the folder “Return” from the cardboard box. In the folder you find the pre-printed labels you

need for returning the CryoSure®product:

• the pre-paid label of the parcel carrier, where you are notified as Sender

• the dangerous goods label (UN1845), where you are notified as Shipper

3b. Peel and apply both labels and put them on the cardboard box.

Fig. 10

4. Close the cardboard box, and seal with a clear tape.

5. Inform Envirotainer that the CryoSure®system is ready for pick-up.

Upon your advice, Envirotainer arranges with the parcel carrier a pick-up.

11 (14)

Doc No:

UM-CRYO-3030

Revision:

2

State:

Released

Release Date:

2021-12-01

Approved By:

hanst

3.3 Monitor the autonomy duration left on your CryoSure®system

3.3 MONITOR THE AUTONOMY DURATION LEFT ON YOUR CRYOSURE®

SYSTEM

Every time a CryoSure®system is released, a unique QR code sticker is printed and placed on the outside of

the cardboard box. By scanning the QR code with your smartphone, you will get access to the DuraWatch®

service which provide information about this unique shipment, including how many days and hours of cooling

capacity is remaining.

In addition to cooling capacity remaining, DuraWatch®also provides:

• Contact details to schedule pickup of the CryoSure®system

• Shipping route information

• Product details (dewar dimension and other measurements)

• User Manual

The QR code can be scanned by anyone handling the CryoSure®system and not only the customer placing the

CryoSure®orders. However, information in DuraWatch®is non-sensitive. For any detailed information around a

CryoSure®order you still need to login to the Envirotainer Portal.

12 (14)

Doc No:

UM-CRYO-3030

Revision:

2

State:

Released

Release Date:

2021-12-01

Approved By:

hanst

Intentionally left blank

13 (14)

Doc No:

UM-CRYO-3030

Revision:

2

State:

Released

Release Date:

2021-12-01

Approved By:

hanst

Envirotainer AB

www.envirotainer.com

Doc No:

UM-CRYO-3030

Revision:

2

State:

Released

Release Date:

2021-12-01

Approved By:

hanst

This manual suits for next models

3

Table of contents

Other Envirotainer Industrial Equipment manuals

Envirotainer

Envirotainer RKN e1 User manual

Envirotainer

Envirotainer RKN e1 User manual

Envirotainer

Envirotainer RAP e2 User manual

Envirotainer

Envirotainer RKN t2 User manual

Envirotainer

Envirotainer Releye RLP 160020R User manual

Envirotainer

Envirotainer RKN e1 User manual

Envirotainer

Envirotainer RKN t2 User manual

Popular Industrial Equipment manuals by other brands

SSP

SSP EDI Series operating manual

STOKVIS ENERGY SYSTEMS

STOKVIS ENERGY SYSTEMS ECONOPLATE E3 Series Installation, operation & maintenance documentation

Rapid

Rapid AB-Z Operation manual

Baileigh

Baileigh BB-7216M Operator's manual

ABB

ABB HT579538 Operation manual

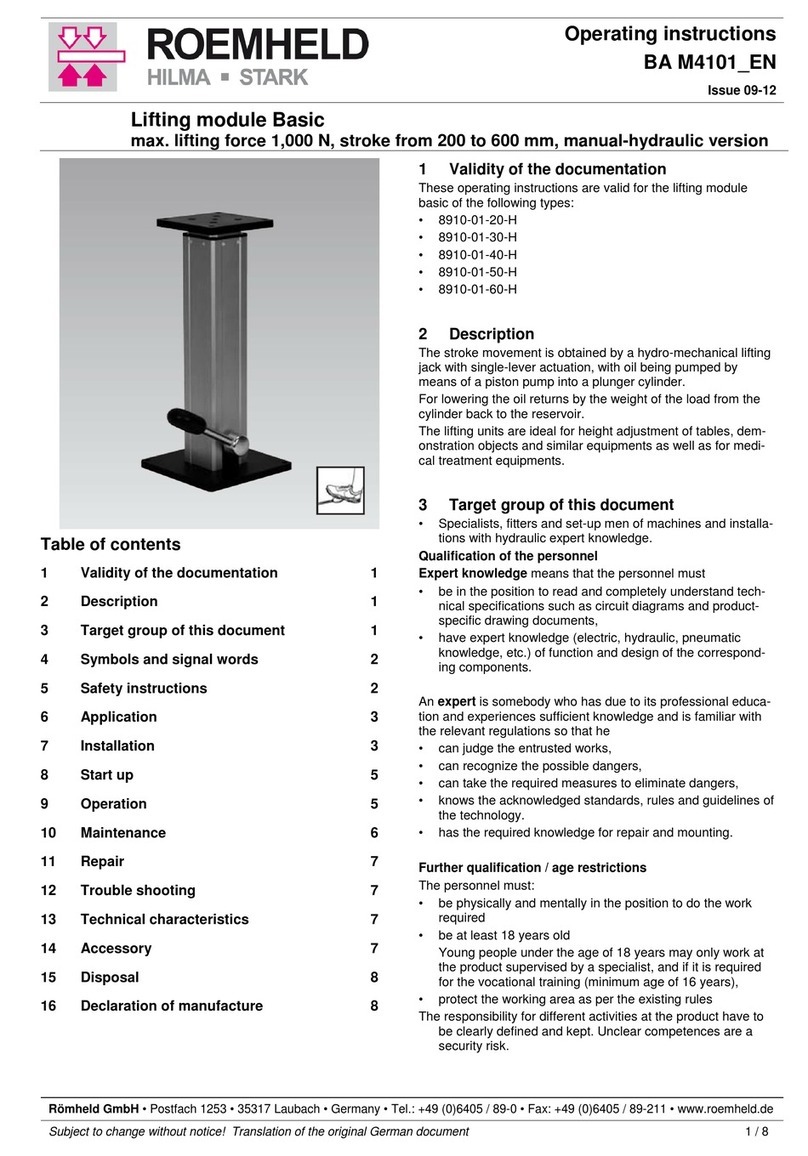

Roemheld

Roemheld 8910-01-20-H operating instructions