TFP2272

Page 7 of 10

Installation

The TYCO AQUAMIST Red-E Mist

Supply Skid must be installed in accor-

dance with this section. For success-

ful performance, the entire Red-E Mist

Supply Skid must be installed in a loca-

tion within a temperature range of 40°F

to 130°F (4°C to 54°C).

NOTE: The following items are not

included when purchasing the AQUA-

MIST Red-E Mist Supply Skid and must

be purchased separately:

• 1-1/2 Inch Nitrogen Discharge Piping

• 1-1/2 Inch Water Discharge Piping

• Nitrogen Drain

• 1-1/2 Inch Wye connector (required

in 1200 Gallon (4542 Liter) systems)

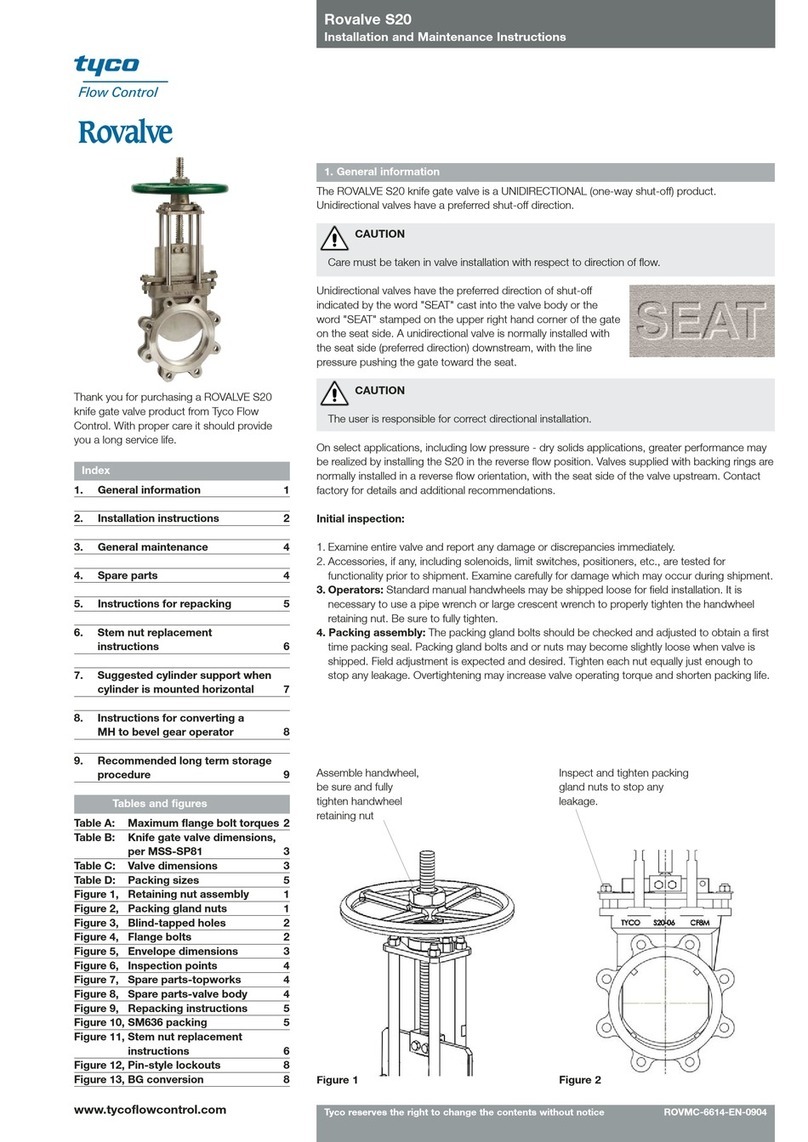

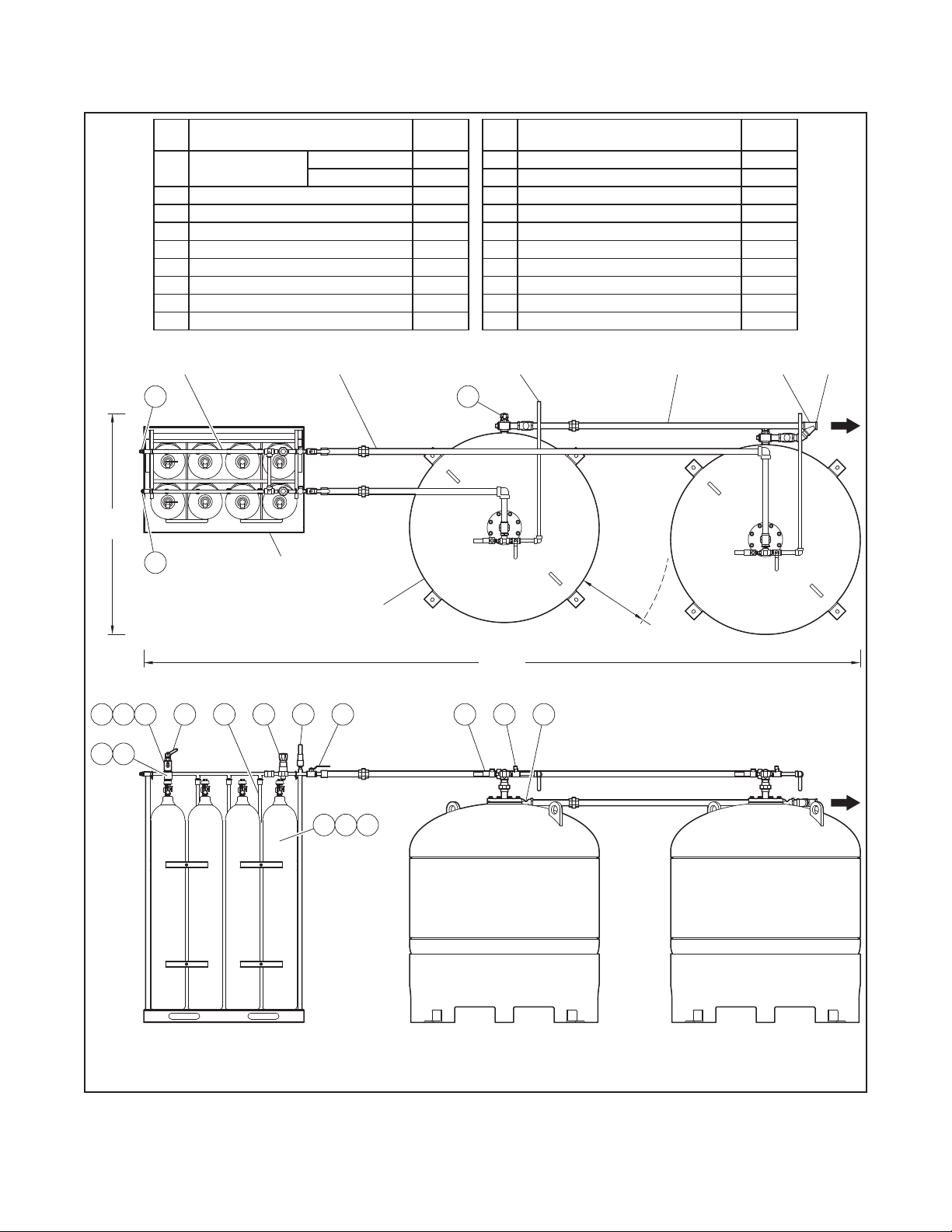

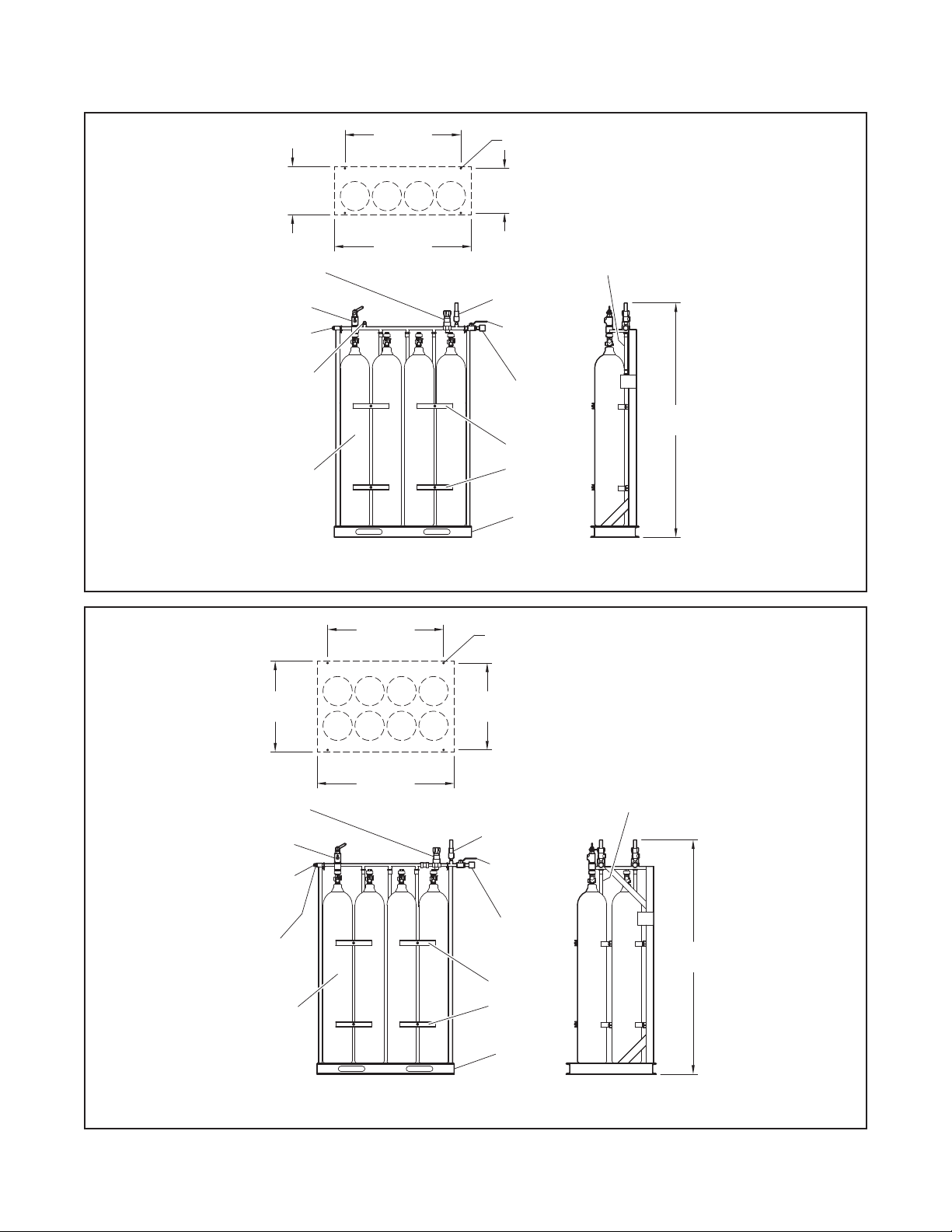

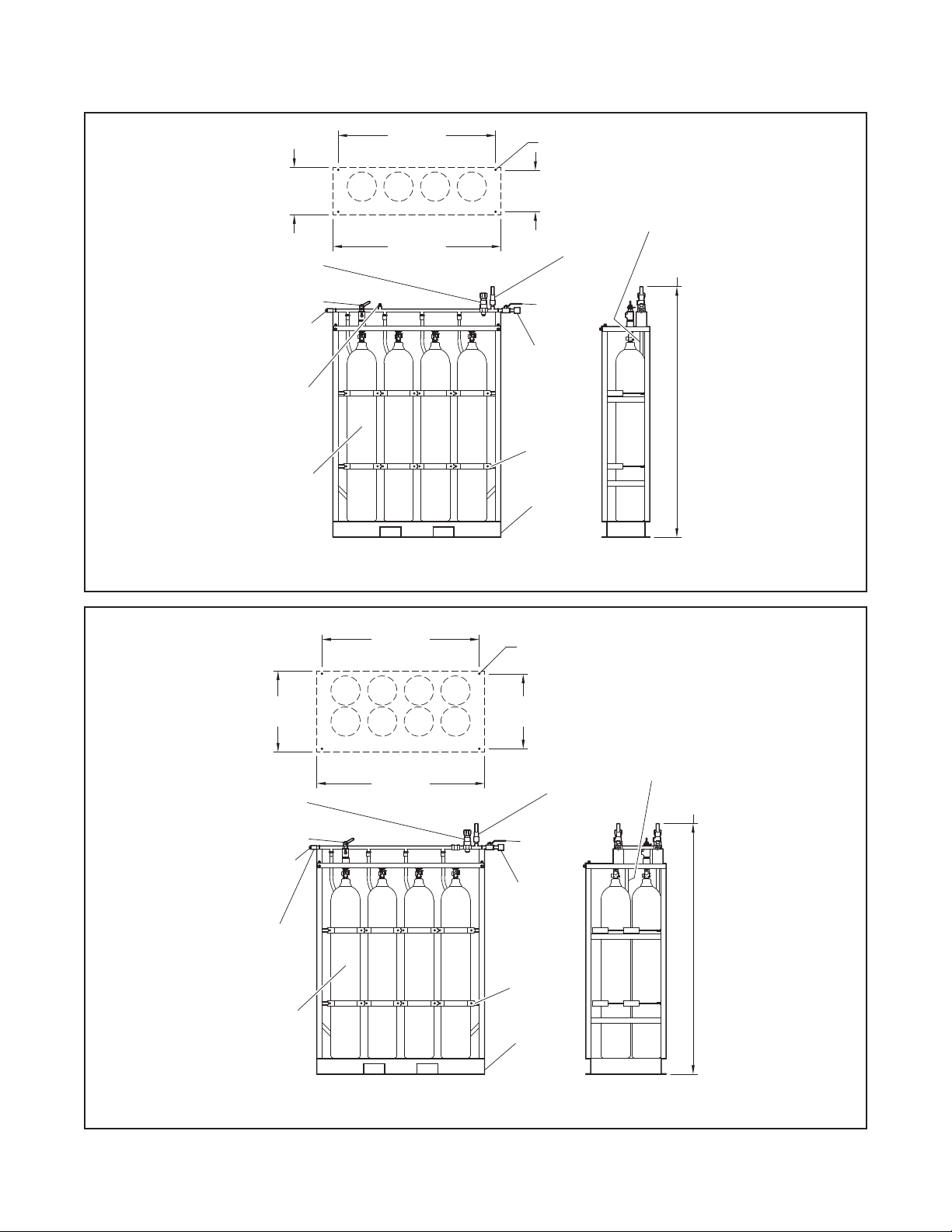

Nitrogen Supply Skid

The Nitrogen Supply Skid should

be located in an area with adequate

space to ensure access to all service-

able components. The skid must be

securely mounted or otherwise fas-

tened on a smooth, level, hard surface

capable of supporting the full weight

of the unit.

The weight of a 4 cylinder Nitrogen

Supply Skid is 1360 lbs. (617 kg) and

the weight of an 8 cylinder Nitrogen

Supply Skid is 2425 lbs. (1100 kg).

In cases where it is necessary to bring

the Nitrogen Supply Skid in through

openings with limited height, the high

pressure nitrogen manifold may be

removed. Remove the 1/4 inch (6,35

mm) U-bolts and lift the manifold off

the rack. After the Skid is located in its

final location, the high pressure mani-

fold must be re-installed in the proper

orientation by securing with the original

U-bolts with the lock washers and nuts.

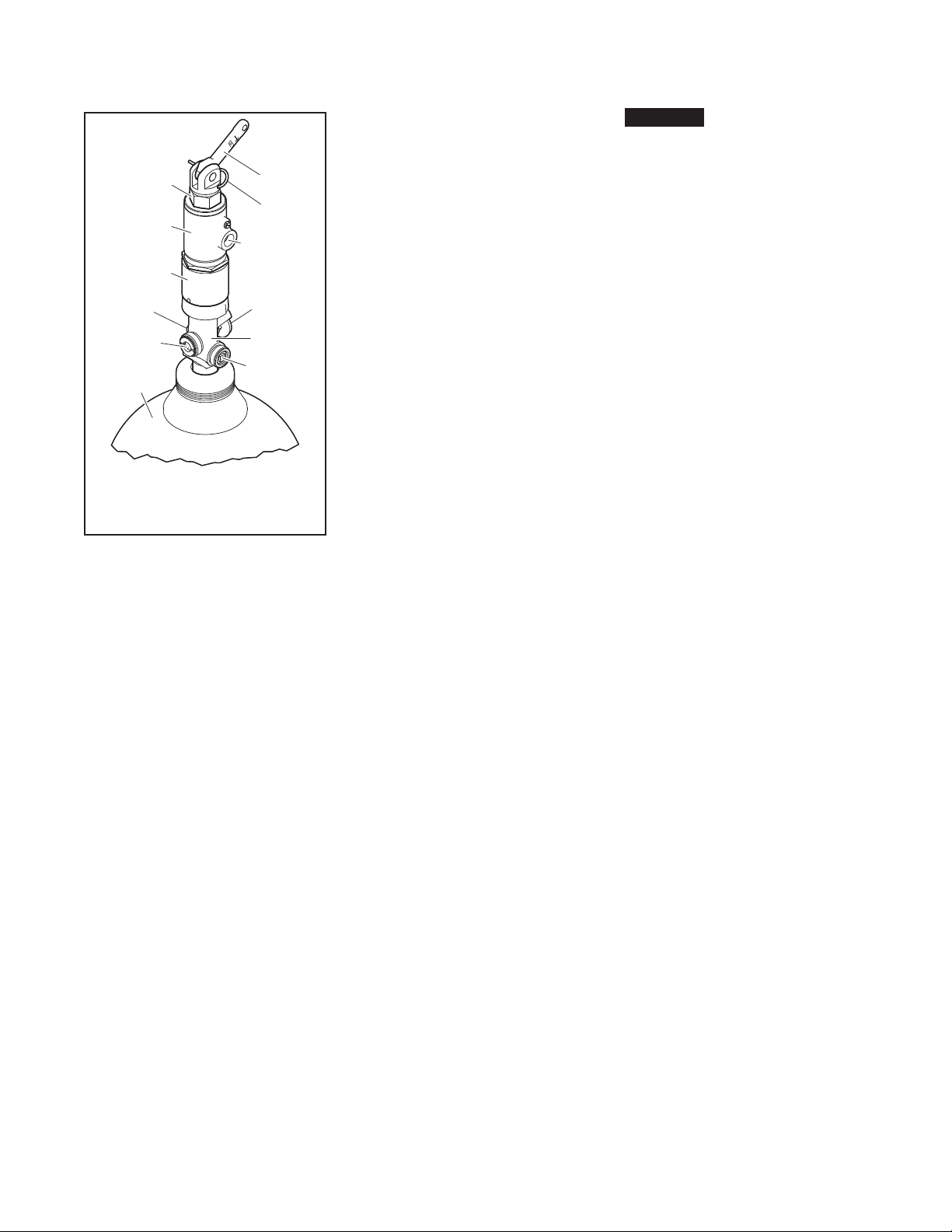

Once the Nitrogen Supply Skid is

installed, the shipping caps can be

removed from the cylinders. Then

the Flexible Discharge Bends can be

installed onto the discharge port of the

CV-98 valve. Hand tighten, then tighten

one quarter of a turn with a wrench

(Ref. Figure 7 to locate the Outlet).

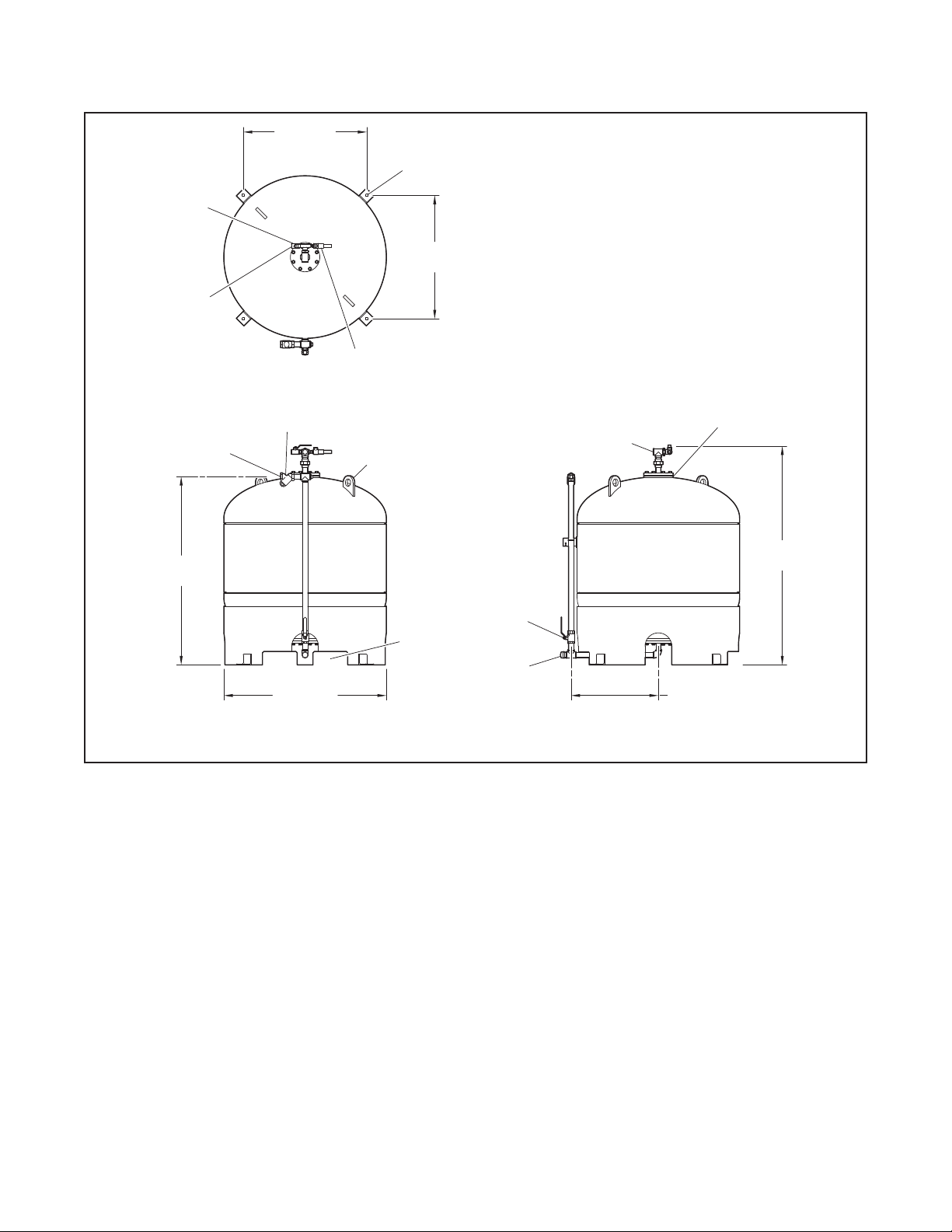

Water Supply Tank Assembly

The water supply tanks should be

installed so that they can be easily

refilled after use. Tanks must be

installed indoors or inside of a weather-

proof enclosure where operation tem-

perature limits are maintained. Secure

the tanks to the floor using four fasten-

ers through the mounting feet on the

water tank. Tanks should be spaced

at least 24 inches (0,61 m) apart to

allow for access during installation,

operation, and servicing procedures.

Ensure that the floor is strong enough

to support the weight of the water

tanks. The approximate weight of one

600 gallon (2271 liter) water tank filled is

7500 lbs. (3402 kg), approximate 2500

lbs. (1133 kg) when empty.

Nitrogen Discharge Piping

Each Nitrogen Discharge Connection

from the Nitrogen Supply Skid must be

piped to the inlet of a Water Tank Nitro-

gen Supply Connector using 1-1/2 inch

(3,81 cm) Schedule 40 Stainless 316

pipe. The connection must be made of

less than 19 feet (5,79 m) of pipe with

no more than three 90 degree elbows

and three unions.

Water Tank Discharge Piping

It is necessary to pipe the discharge of

the two water tanks together in a 1200

Gallon (4542 Liter) skid. The piping can

be completed using the same pipe as

the rest of the system. It is recom-

mended to complete the piping with

a Wye connecter to reduce the fric-

tion loss of the converging flows. (Ref.

Figure 1) Regardless of piping configu-

rations, hydraulic calculations must be

completed to include all of the pipe and

fittings from both tank assemblies.

Water Tank Nitrogen Drain Valve

Discharge Piping

The high velocity of nitrogen through

the Water Tank Nitrogen Drain Valves

when emptying a discharged system

can cause damaging levels of sound,

and the large volume of nitrogen can

deplete the oxygen concentration

inside a room where it is being dis-

pensed. It is recommended to pipe the

discharge from the Water Tank Nitro-

gen Drain Valves into an area where

high sound levels are acceptable and

where the nitrogen can be vented to

the outside.

Piping

Pipe, tube, and nipples are to have the

burrs and fins removed after cutting.

Apply pipe thread sealant to male

threads only. When using TEFLON tape

or paste sealant, do not apply the tape

or sealant any closer than one thread

from the inlet of any pipe connection.

Prior to installation, each pipe or tube

section is to be swabbed internally by

running a clean rag, sponge, or other

absorbent material, through the pipe

or tube as needed to meet the internal

cleanliness requirements of NFPA 750,

Standard on Water Mist Fire Protection

Systems.

Hangers

Selection and installation of the piping

system hangers on all piping added

to the TYCO AQUAMIST Red-E Mist

Supply Skid must be in accordance

with the specifications of NFPA 13,

Standard for the Installation of Sprin-

kler Systems, and NFPA 750, Standard

on Water Mist Fire Protection Systems.

Install FM Approved pipe hangers in

accordance with good piping practices

as well as the following standards:

•

Refer to ASME B31.1, “Power Piping

Code,” and any appropriate local

codes and standards

•

A hanger should be installed

between ttings when the ttings

are more than 2 ft. (0,6 m) apart.

Setting the

Skid for Service

Use the following procedure when

setting the system for service the first

time, or after service which involves

complete draining of the system:

Step 1. Test HF Electric Actuator and

Booster Actuator.

When testing the HF Electric Actuator

and Booster Actuator they must not be

installed on the CV-98 cylinder valve. If

installed, testing the electronic detec-

tion system will cause actuation and

discharge of the system. In order to

properly test the electric detection and

actuation, attach the Booster Actuator

to the HF Electric Actuator and ener-

gize the release circuit.

When the HF Electric Actuator/Booster

Actuator is actuated correctly, the

piston in the bottom of the actua-

tors will be locked in the down posi-

tion. Reset the HF Electric Actuator

and Booster Actuator by following the

instructions in the Skid Reset after Dis-

charge section.

Step 2. Install HF Electric Actuator and

Booster Actuator.

The Actuator Stack can be installed on

any of the four or eight nitrogen cylin-

ders on the Nitrogen Supply Skid (Ref.

Figure 7). To install the actuator stack,

make sure that the Booster Actuator

is set to the armed position. This can

be confirmed by visually checking the

position of the top and bottom pins.

When in the set position, the top pin

will be approximately flush with the

top of the actuator. The bottom pin will

be flush with the inside surface of the

actuator.

If the Booster Actuator requires setting,

use the Arming Tool and follow the

instructions listed in the Skid Reset

after Discharge section. Then, hand-

tighten the actuator onto the cylinder

valve. Next, make certain that the HF

Electric Actuator is in the armed posi-

tion. When in the set position, the top

pin will be flush with the actuator.

If the Electric Actuator requires reset-

ting, use the Arming Tool and follow the

instructions listed in the System Reset

after Discharge section. Then hand-