SSP EDI Series User manual

Table of Contents

Version 1.0

March 2019

EDI B | EDI C | EDI D | EDI E

Stop button | Emergency stop/Emergency stop button

EN Operating Manual

SSP Safety System Products GmbH & Co. KG

Max-Planck-Str. 21

D-78549 Spaichingen

www.safety-products.de

3 Installation ...............................................3

3.1 General installations notes .........................................3

3.2 Installation of the build-in version EDI Slimline housing ....................3

4 Technical data .............................................4

4.1 Switch elements .................................................4

5 Commissioning and Maintenance ..............................5

5.1 Function Test ...................................................5

5.2 Periodic inspection ...............................................5

5.3 Behavior in the event of a malfunction ................................5

6 Disassembly and Disposal ....................................5

6.1 Removal.......................................................5

6.2 Disposal .......................................................5

7 Electrical connection........................................5

7.1 Pin assignment..................................................5

8 Declaration of Conformity....................................6

8.1 EC conformity regulations..........................................6

1 About This Document .......................................2

1.1 Function.......................................................2

1.2 Safety instruction for the authorized skilled personnel......................2

1.3 Symbols .......................................................2

1.4 Scope of application ..............................................2

1.5 Attention: Safety Instructions .......................................2

1.6 Attention: Incorrect use............................................2

1.7 Liability Disclaimer ...............................................2

2 Product Description.........................................2

2.1 Intended Use ...................................................2

2.2 Design types....................................................2

2.3 Scope of application and mode of action...............................2

2.4 Product characteristics ............................................2

2.5 Dimensions.....................................................2

2.6 Scope of Supply .................................................3

2.7 Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

This operating manual is a translation of the original

operating manual.All rights,errors and changes reserved.

Depending on features of your device, description of

optional functions in the form of additional sheets will

be provided as a complement to this operating manual.

2

1. About This Document

1.1 Function

This operating manual provides all necessary information for the assembly, installation,safe

operation and disassembly of the emergency stop/emergency stop button EDI.The operating

manual must always be readable and available during the operating life of the device.

Read the operating manual carefully before using the device. Always hand this operating

manual over to future owners and users of the device. Add any supplement received from

the manufacturer to the operating manual.

1.2 Safety instruction for the authorized skilled personnel.

The tasks described in this operating manual may only be carried out by trained skilled

personnel authorized by the plant owner. You must read and understand the operating

manual before starting the EDI.Familiarize yourself with the applicable rules and regulations

relating to industrial safety and accident prevention. National and international legislation

apply to assembly, installation and regular technical inspections.

1.3 Symbols

Caution

If the warnings are not observed, faults or malfunctions as well as injury to

persons and/or damage of the machines can occur.

Information

Helpful additional information

1.4 Scope of application

The emergency stop/emergency off buttons EDI are electromechanical switching devices for

the protection of persons working with or near machines.They are used to stop/shut down

machines and plants in order to avoid or reduce arising or existing dangers to persons as

well as damages to the machine or workpieces. The manufacturer of the plant or machine

is responsible for ensuring the correct overall function of the system.

1.5 Attention: Safety Instructions

Observe the safety instructions in the operating manual, which are identified by an above

symbol for caution or warning. Follow national installation, safety and accident prevention

regulations. For additional technical information refer to SSP data sheets or visit our website

at www.safety-products.de.

All information is supplied without liability. We reserve the right to make technical mod-

ifications for reasons of improvement. No remaining risks are known, if the safety notes

and instructions regarding assembly, installation, operation and maintenance are followed.

Disconnect the plant and the device from the power supply before starting installation.

Emergency stop/emergency off buttons are used to protect personnel. Improper installation

or manipulation may cause serious injury to persons and must not be bypassed, removed

or otherwise rendered ineffective.

1.6 Attention: Incorrect use

Danger to persons or damages to parts of machines or installations can arise as a result of

inappropriate or incorrect use or manipulation of the process guard locking.

The emergency stop/emergency off function must not be used as a substitute for protective

measures or other safety functions, but should be designed as a supplementary protective

measure. Furthermore, the effectiveness of protective devices or devices with other safety

functions must not be impaired. Using his risk analysis, the designer must ensure that the

emergency stop/emergency off button in combination with the controller reaches the required

safety level (SIL, SILCL or PL).

1.7 Liability Disclaimer

We accept no liability for damages or operational malfunctions resulting from improper

installation or failure to comply with this operating manual. No other liability is accepted

by the manufacturer for damages resulting from use of spare parts or accessories, which

have not been approved by the manufacturer.Any unauthorized repairs,reconstructions and

modifications are not permitted for safety reasons and rule out liability of the manufacturer

for resulting damages.

2. Product Description

2.1 Intended Use

The device can only be used in industrial applications.

2.2 Design types

The EDI emergency stop/emergency off button in slimline housing with an M12 connector

(according to EN 61076-2-101) is available in various versions.

• Emergency stop button, not illuminable

• Emergency stop button, illuminable

• Emergency stop button, not illuminable with reset button, illuminable

• Operational unit with 2 buttons, illuminable red/green

• Operational unit with reset button, illuminable

This operating manual is valid for the following design types:

EDI B7B emergency stop button illuminated white 8-pole SP-G-61-000-01

EDI B7 emergency stop button standard 4-pole SP-G-61-000-02

EDI B7S stop button black head 4-pole SP-G-61-000-03

EDI C7 emergency stop button + reset button illuminated 8-pole SP-G-61-000-04

EDI E1B operational unit, 2 buttons - illuminated red/green 8-pole SP-G-61-000-05

EDI D1B operational unit with reset button illuminated 4-pole SP-G-61-000-09

2.3 Scope of application and mode of action

National and international legislation apply to assembly,commissioning and regular technical

inspections, in particular

• Machinery Directive 2006/42/EC

• Low Voltage Directive 2014/30/EU

• Safety regulations

• Accident prevention regulations & safety rules

Manufacturers and operators of machines with emergency stop/emergency off buttons are

responsible for observing the operating manual as well as applicable safety regulations

and rules.

For intended use, the relevant requirements for the installation and operation of emergency

stop/emergency off buttons must be observed.

• EN 60204-1:2006

• EN 13849-1/-2:2008

• EN ISO 13850:2015 (D)

2.4 Product characteristics

Built-in version or surface-mounted version with two-part surface-mounting housing.

Unlocking by rotary movement to the left or right or only to the right.

Connection of the contact blocks via spring-loaded terminal (quick connection), screw

connection or M12 plug connector.

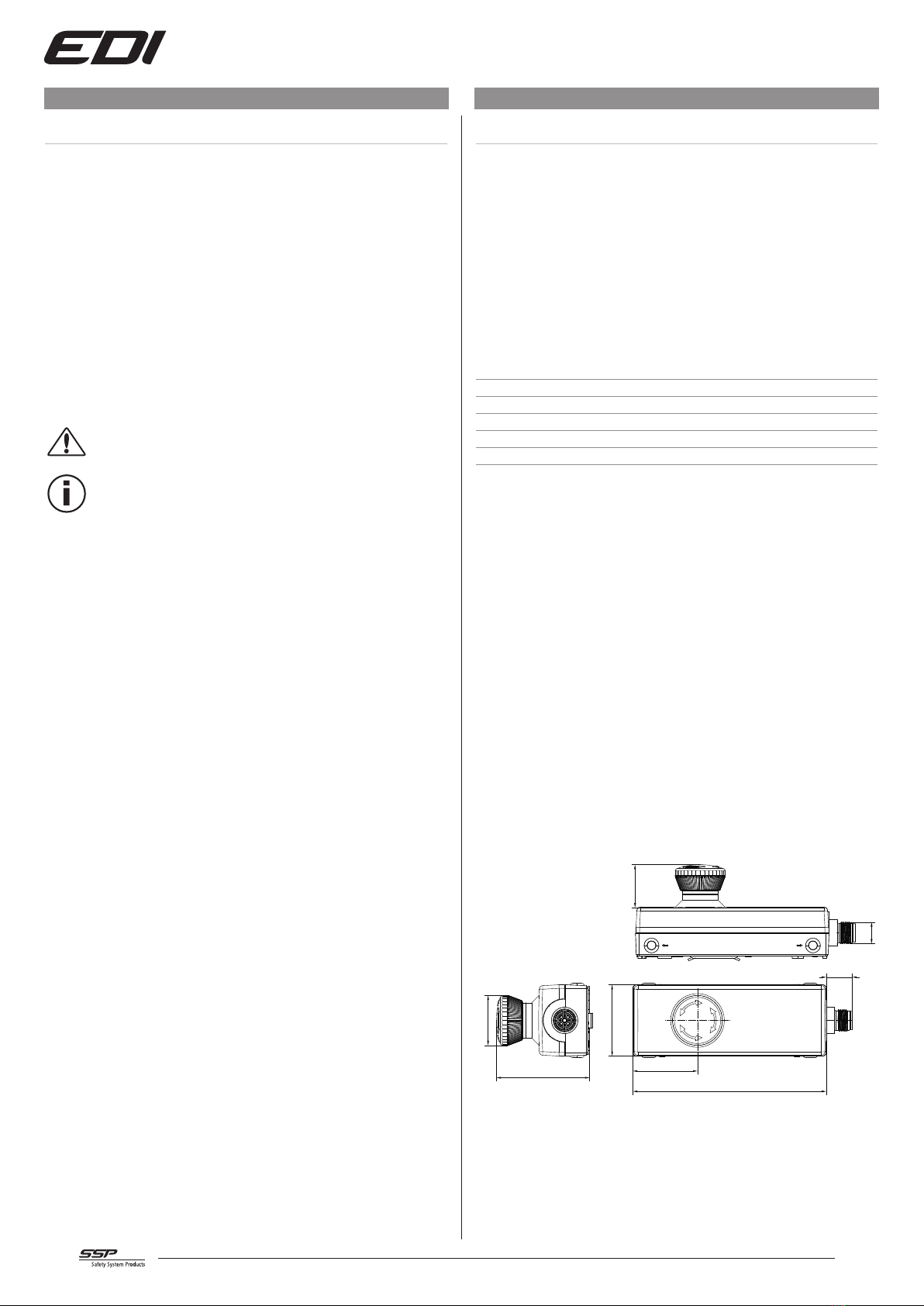

2.5 Dimensions

Dimensions in mm

108,6

40

36,3

14,6

24

M12

52,3

Ø28

EDI B7, EDI B7B

3

40

36

72

M12

20

14,5

52

Ø28

Ø28

EDI C7

36,3

108,6

14,6

40

36,3

Ø29

28,7

M12

EDI D1B

36

108,6

36

40

14,6

36,16

Ø29

28,6

M12

EDI E1B

2.6 Scope of Supply

• Emergency stop button in slimline housing and M12 plug connection

• Holding bracket

• EDI C7, D1B: Reset button, button cap & identification plate

• EDI E1B: Operating button, button cap red & green

2.7 Functions

• Confirm: Press the emergency stop button

• Unlock: Turn the emergency stop button

• Reset: Press the reset button (depending on the application)

• Two operating elements (depending on the application)

3. Installation

3.1 General installations notes

Make sure that emergency stop/emergency off button is mounted

at an easily accessible location.

The installation may only be carried out by authorized skilled personnel.

3.2 Installation of the build-in version EDI Slimline housing

The emergency stop button is intended for vertical or horizontal installation. Install the

emergency stop button as shown in the illustration.

• Tighten the holding bracket.

• Attach the housing to the side of the retaining spring, pull against the spring pressure

and press on the housing. The housing engages.

• Connect the M12 connection cable to the connector plug.

Wall installation Profile installation

4

4. Technical data

4.1 Switch elements

Item name EDI B7

SP-G-61-000-02

EDI B7B

SP-G-61-000-01

EDI C7

SP-G-61-000-04

EDI E1B

SP-G-61-000-05

EDI D1B

SP-G-61-000-09

Protection class (EN 60529) IP 65

Protection class (EN 61140) III

Operating ambient temperature –25 … +70°C

Storage temperature –25 … +80°C

Switch elements (EN 60947-5-1) 2 direct openings

2 direct openings

1 NO contact

Reset button

1 NO contact each 1 NO contact

Reset button

B10d value (EN ISO 13849-1) 250.000 switching cycles

MTTFd (mean time to failure, EN ISO 13849-1) 6849 (with switching frequency C = 1/d)

Electrical/mechanical service life (at +20°C)

Emergency stop buttons

Reset button

50.000 switching cycles (at rated load)

– 1 × 106switching cycles 1 × 106switching cycles

Max. bounce time < 10 mS

Min. direct opening path 3 mm

Data according to UL508

Utilisation category (EN 60947-5-1) DC13 DC13

Rated operating current Ie (EN 60947-5-1) 2 A 2 A

Rated operating voltage Ue 24 V DC (EN 60947-5-1) 24 V DC 24 V DC

Operating voltage 1 … 30 V DC 1 ... 36 V DC

Operating current 1 … 100 mA 1 ... 250 mA

Maximum switching capacity 250 mW

Housing material PBT (polybutylene terephthalate)

Contact material AgNi AgNi, gold plated 5 µm AgNi

Lighting connection emergency stop button

Operating voltage max 30V AC / DC

Operating current 4 mA (-24V AC)

Lighting connection reset button, operating button

Operating voltage max 30V AC / DC

Operating current 14 mA (at 24V DC)

5

5. Commissioning and Maintenance

5.1 Function Test

• Mechanical inspection:Emergency stop/emergency off button engages upon confirmation

• Electrical inspection: The machine stops or switches off upon confirmation of the

emergency stop/emergency off button.

Note

Damaged or defective devices must not be put into operation!

5.2 Periodic inspection

The inspection interval shall be determined by the machine designer on the basis of the risk

assessment. However, it is recommended that the emergency stop/emergency off button

is triggered at least once a year by the responsible safety officer for test purposes and to

check the correct function.

• mechanical and electrical function test in accordance with Step 5.1

• safe attachment

• manipulation and damage visible

• no loose wire connections

5.3 Behavior in the event of a malfunction

Note

Mechanical overload or external force can damage and impair the function of

the emergency stop button.

• Correct the error.

• Do a function test in accordance with Step 5.1.

6. Disassembly and Disposal

6.1 Removal

The EDI emergency stop/emergency off button must only be dismantled when the power

is disconnected.

6.2 Disposal

The EDI emergency stop/emergency off button must be disposed of properly in accordance

with national and local regulations.

7. Electrical connection

7.1 Pin assignment

Pin Assignment

EDI B7

1

4

3

2

1/2 NC contact 1 (emergen-

cy stop)

3/4 NC contact 2 (emergen-

cy stop)

EDI B7B

1

6

4

2

87

5

3

1/2 NC contact 1 (emergen-

cy stop)

3/4 NC contact 2 (emergen-

cy stop)

5 + LED (emergency stop)

6 - LED (emergency stop)

7/8 not assigned

EDI C7

1

6

4

2

87

5

3

1/2 NC contact 1 (emergen-

cy stop)

3/4 NC contact 2 (emergen-

cy stop)

5/6 Reset button

7 + LED reset button

8 - LED reset button

EDI E1B

1

4

3

2

1/2 NO contact

3/4 NC contact

EDI D1B

1

4

3

2

1/2x NO contact

3 + LED reset button

4 - LED reset button

6

8. Declaration of Conformity

8.1 EC conformity regulations

EDI emergency stop/emergency off button

Authorized representative: Johann Aulila

SSP Safety System Products GmbH & Co. KG

Max-Planck Str. 21, 78549 Spaichingen, Germany

www.safety-products.de

Date: October 2016

The designated products comply with the regulations of the directives:

• Machinery Directive 2006/42/EC

Applied standards:

• EN 60947-5-1: 2004

• EN 60947-5-5: 1997 + A1:2005 + A11:2013

• EN ISO 13850: 2015 (D)

Note

Signed EC Declaration of Conformity is available at the SSP website:

www.safety-products.de

SSP Safety System Products GmbH & Co. KG

Max-Planck-Straße 21

78549 Spaichingen, Germany

+49 7424 98 049-0

info@ssp.de.com

www.safety-products.de

This manual suits for next models

14

Table of contents

Other SSP Industrial Equipment manuals