1.

1. Safety instructios

· Please observe: This operation manual contains all necessary information.

Please read carefully to avoid damages and faults. All Rapid pieces of

equipment are checked carefully before delivery for their perfect composition

and function. In case of improper use all rights to claim under guarantee are

void.

· Make sure that only skilled staff is working with this device in order to prevent

damages and accidents caused by improper use.

· Environmental conditions i.e. humidity, low temperatures, sunlight and

contamination may damage device.

· Before using the device make sure that it is not contaminated to prevent any

injury. Avoid any contamination of device as well as of environment. In case of

any contamination during operation of device take care that it is immediately

and professionally removed.

· Always wear safety cloths respecting the applicable regulations for accident

prevention

· Only use this device conforming to its purpose and function. Improper use can

cause severe injuries.

· Caution – moving parts, sharp edges, hot machine parts or exhausting steam

can cause severe injuries.

· Before use always check the device for damages and leaks. In case of any

damage or leak make sure that it is repaired professionally before use.

Operation of defect device may cause severe injuries.

· In case of any sign of damage or malfunction during operation of device stop

device immediately to prevent injuries. Before next use make sure that the

device professionally repaired.

· Take care that in case of an accident all emergency measures are on hand

CONTENTS Seite

1. Safety Instructions 2

2. General advice 3

3. Technical data 3

4. Description 3

5. Assembling / Installation 3

6. Spare parts and accessories 4

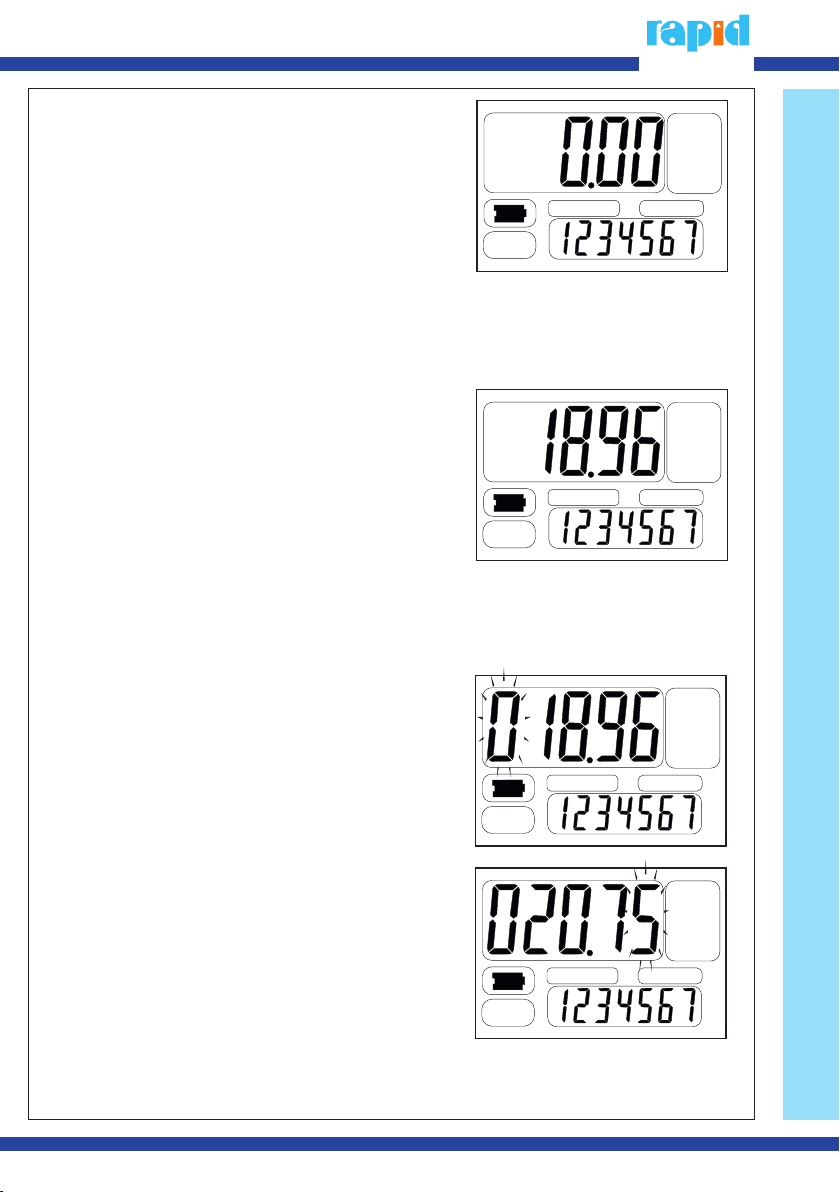

7. Operation 4

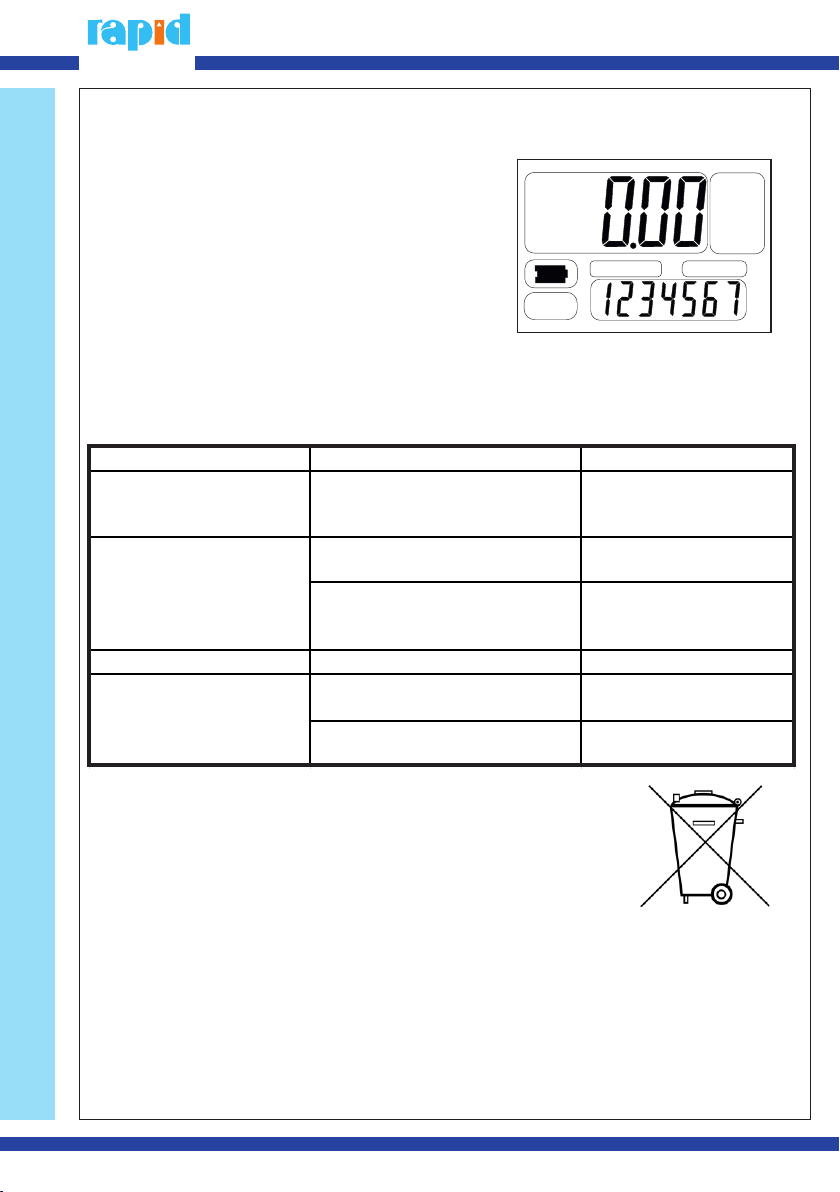

8. Maintanance and trouble shooting 4

9. Disposal 4

10. Warranty 4

OPERATION MANUAL

+49 (6158) 92980-0

2