Eoslift E20V User manual

E20V

Operating Instructions

Scale

Pallet

Truck

Hotline: 400-626-9090

Tel: +86 573 8622 9999

Fax: +86 573 8622 2900

Esteemed users:

For proper and safe operation of the products, before

using the products, be sure to read the operating

instructions carefully and retain them properly for

future reference.

The operator needs to have proficient operation skills.

The operator has responsibility to carefully understand

the performance and safety rules of the pallet truck.

If you have any doubts during the application, please

don't hesitate to contact Eoslift.

E20V Series Scale Pallet Trucks

Ⅰ.Technical parameters 01

Ⅱ. Safety rules 02

Ⅲ.Installation of handles 03

Ⅳ.Adjusting the finger grip handle 04

Table of contents

Ⅵ.Appendix 13

Ⅶ.Troubleshooting 14

Ⅸ.Parts list 17

Ⅴ.Operating instruction

05

Ⅷ.Transport, loading, test run and storage 16

E20V Series Scale Pallet Trucks

Technical parameters

01 02

Safety rules

Rated capacity

Load center

Dead-weight

Wheel material

Maximum error

Maximum fork height

Minimum fork height

Steering wheel

Load-bearing wheel

Overall fork width

Fork length

Length of the truck

Minimum turning radius

Type of battery

Battery capacity

Model E20V

kg

mm

mm

mm

mm

mm

mm

mm

kg

mm

mm

mAh

2000

600

130

PU/NYLON

0.05

190/200

75/85

Φ180×50

Φ80×70

560/685

1150/1220

1580/1650

1325/1395

Button cells

2x900

H

H1

B

L

L1

R

The pallet truck is only applicable to indoor use and the application environment must meet the following

conditions:

Free from rainwater or corrosion of harmful gases;

Room temperature of -20°C~+40°C;

Relative ambient humidity <90%;

and Requirements for ground: hard, anti-skid and level without barriers.

Before using the pallet truck, the operator must read the operating instructions and the warning labels on

the truck body carefully.

Do not use this truck on the muddy ground.

Do not operate the pallet truck unless you are fully familiar with it and have been authorized to do so.

Do not operate the pallet truck unless you have carefully checked its condition. Pay special attention to the

wheels, the handle assemblies, the truck frame, the unloading plate, etc. To pull the truck, always move the

finger grip control handle into the middle position. This makes the handle easier to move and reduces the

rebounce of the handle by the small piston. This also preserves the hydraulic seals and the piston

components. A long service life can be expected.

Do not carry or lift passengers.

The operator shall wear safety shoes and gloves for protection.

While the goods are being transported, all people should stay 600mm away from the truck frame.

Overload is prohibited.

Do not use the truck in a potentially flammable and explosive atmosphere.

Do not use the truck as a vehicle jack.

Do not use the truck during strong wind forces.

Do not use the truck on places insufficiently illuminated.

Under special conditions or in special locations, the operator should be careful while operating the pallet

truck.

E20V Series Scale Pallet Trucks

%

Installation of handles

03 04

Adjusting the finger grip handle

1.Make sure the chain on the handle

is in this position shown in the picture.

2.Push the handle shaft through the

holes,Fix it with the spring pin.

3.Put the chain through the hole on the shaft.

4.Fix the chain in the slot of the

unloading plate.

5.Pull the shaft from the hole. Then

the assembly is complete.

On the handle of this pallet truck, you can find finger grip control handle(1-1) which can be regulated in

three positions :

Lifting-set the control handle at lower position

Middle position: set the control handle at middle position

Lowering: set the control handle at upper position. The handle moves back to the middle position when

released.

1

2

3

However if the truck cannot operate normally under three positions, you can adjust them according to the

following steps:

①If the forks elevate while pumping in the Middle position, turn the adjusting nut (2-4) on the adjusting bolt

(2-3) or screw (2-6) clockwise until pumping action does not raise the forks and the finger grip control handle

works properly Middle position .

1-1

Upper

Middle

Lower

2-3

2-4

2-6

E20V Series Scale Pallet Trucks

② If the forks descend while pumping in the Middle position, turn the screw(2-6) or nut(2-6) counter

clockwise until the forks stop descending.

③ If the forks do not descend when the finger grip control handle (1-1) is in the Lowering position, turn

the nut (2-4) or screw (2-6) clockwise until raising the control handle lowers the forks. Then check the

Middle position according to items and ② to make sure the nut (2-4) and screw(2-6) are in the proper①

position.

④ If the forks do not elevate when the finger grip control handle is in the Lifting position, turn the nut

(2-4) or screw (2-6) counterclockwise until the forks elevate. Then check the function of the Lowering

position and Middle position according to items ,②and③ is normal.①

IP 53

1.Using the Scale Pallet Truck

The truck shall be correctly used to ensure accurate weighing. The following conditions are prohibited in

the application.

Operating Instructions

05 06

2.Normal weighing mode

2.1Operating panel

Figure 2-1 Operating panel in Normal Weighing Mode

Weight display

Unit of measurement

Battery level

Zero

On/Off back light

Unit switching

Backlight cursor

Dynamic cursor

Tare cursor

Net weight cursor

Zero cursor

1

2

3

4

5

6

7

8

9

10

11

Note: Abbreviations for the following keys:

Zero key--“0”key

Tare removal key--“T”key

Unit switch key - “U” key

ON/OFF key - “P” key

TARE

E20V Series Scale Pallet Trucks

07 08

2.2 Display

If any cargo is placed on the frame, its weight will be displayed after 1 second; once “ dynamic cursor”

disappears, value as displayed on the screen will be the weight of the cargo.

2.3 Key function.

Display function

Zero key (“ 0” ) ---Reset instrument readings within the permissible range.

Tare removal key ( “T” )---Current weight is taken as the tare weight for tare removal based

on the gross weight; whereas the instrument is to be switched over to the net weight for

display. Recover the tare weight as deducted at the net weight, and switch the instrument

to the gross weight for display.

Unit switch key ( “U” )---It is for cyclic switching of measurement unit among KG, T, OZ and

LB, representing “ kilogram” , “ ton” , “ ounce” and “ pound” respectively.

ON/OFF key (“ P”) ---Once this key is pressed and held for 2 seconds under ON status, “ -----”

is to be displayed on the screen before power-off; press the key for a while to turn on the back

light in the back light mode. Press the key for a while for start-u

Combination key function

“U” key + “0” key - Factory reset

“U” key + “T” key - enter the parameter setting mode

①

②

3.Parameter setting mode

3.1Operating panel

Figure 3-1 Operating panel in parameter setting mode

1Input value

Calibration unit

Input cursor

Option selection

Option confirmation

Location switching

Option cancellation

2

3

4

5

6

7

Press “ U” key and “ T” key simultaneously in normal display mode to enter the parameter setting mode when

“SETUP” is displayed on the screen. The function of the individual key is as follows:

“0” key - option selection

Press “ T” key to confirm entry into parameter setting mode; press “ U” key to cancel parameter setting

to enter normal display mode.

Operating Instructions E20V Series Scale Pallet Trucks

“T” key - option confirmation.

“U” key——option cancellation

“P” key - digit switching in calibration mode.

09 10

3.2Default unit setting

Default unit of the system is kilogram (KG).

The first option in parameter setting mode is default unit setting; when “ UNIT” is displayed on the screen,

press “ T” key to confirm entry into unit setting mode; press “U” key for cancellation to proceed with next

setting.

Once default unit setting is confirmed, press “0”key repeatedly for cyclic switching among the units as

displayed on the right side of screen: “ KG” , “ T” , “ OZ” and “ LB” , representing “kilogram” , “ ton” ,

“ ounce” and “ pound” respectively; press “ T” key to confirm the setting, and proceed with next setting.

3.3Back light mode setting

Default back light mode of the system is OFF; shortly press “ P” key to turn on the back light when back

light cursor is displayed on the screen in back light mode.

Once default unit setup is completed, proceed with setting of back light; when “ BLMOD”is displayed on

the screen, press “ T” key to confirm back light mode setting; press “U” key for cancellation to proceed

with next setting.

Once back light mode setting is confirmed, press “ 0” key for cyclic switching of items displayed on the

screen; “ BL ON” and “ BL OFF” refer to Back Light On and Off respectively; press “T” key to confirm

setting, and proceed with next setting.

3.4Auto Power-off Time Setting

Default auto power-off time of the system is 5 minutes when cargoes remain unchanged.

Proceed with auto power-off time setting once back light mode setting is completed; when “ POWTM” is

displayed on the screen, press “ T” key to confirm entry into auto power-off time setting; press “ U” key

for cancellation to proceed with next setting.

Once auto power-off time setup is confirmed, press “ 0”key for cyclic switching among 1-9, representing

auto power-off time (in minute); press “ T” key to confirm the setup, and proceed with next setup.

1. Press “U” key and “T” key simultaneously

for Setup mode in normal mode.

4.Calibration

Operating Instructions E20V Series Scale Pallet Trucks

2 .Press the “T” key to enter the setup

mode

3. Press the “U” key to skip the “unit

settings”

4. Press the “U ” key to skip the “back

light setting”

5. Press the “U” key to skip the “power

-off time setting”

6. Make sure that here is no cargo on

the frame, and Press “T” key to confirm

calibration.

11 12

7-1. Press “0”key to input values. 7-2. Press “ P " key to adjust the input

digit bit.

25kg

5.Battery replacement

Diagram for disassembly of battery cover

Battery holder

Battery cover

1

2

The instrument uses 2 CR2447 button cells.

As shown in the Figure, slide down instrument battery cover to remove the used battery for replacement;

put the new battery into the battery holder, and then close the battery cover.

6.Routine maintenance

Please check the oil level every six months and change the oil every twelve months. 32 # hydraulic oil is

recommended, with total volume of about 0.5 liters.

Replace the battery in time if power monitoring icon as displayed is blank or data displayed is

indistinct.

It is better not to put the instrument into prolonged outdoor operation in case of rain and snow;

prolonged exposure of instrument to the sunshine is strictly prohibited.

It is applicable to clean the instrument shell with soft and clean cloth in combination with routine

washing solvent; never use industrial solvent for cleaning or directly spray it on the instrument

surface.

It is recommended that users check the instrument and sensor regularly to ensure its accuracy

during use.

7-3. Press “0”key to input value of

corresponding digit bit.

7-4. Example: Calibration with 25KG

counterweight.

8. Complete input, and Press “T” key

for confirmation.

9. Calibration is deemed to be completed

once “CALOK” is displayed on the screen.

E20V Series Scale Pallet Trucks

Operating Instructions

13 14

Item

Description of items displayed on the screen

BLMOD

CALBN

CALOK

CANCEL

FAIL

OUTRG

PMODE

POWTIME

RESET

SS CK

SS OK

SSERR

SETUP

TARE

TR ER

UNTARE

UNIT

ZERO

ZR ER

Backlight mode setting

Calibration

Calibration OK

Cancel parameter setting

Plant calibration failed

Out of range

Plant calibration mode

Auto power-off time setting

Factory reset

Sensor check

Sensor OK

Sensor error

Parameter setting

Tare removal

Tare removal error

Untare

Unit setting

Zero

Zero error

Troubleshooting

1.System halt

This product has received strict testing before delivery and no system halt will occur under

normal conditions. Please remove the battery, and refit it again to recover its normal operation

in case of system halt.

2.Start-up failure

2.1Turn off the power supply. Disassemble the gauge outfit, and use a voltmeter to measure

battery voltage; if the voltage is below 3.5V, it means that battery voltage is extremely low,

which may result in start-up failure; replace the old battery with new one in this case.

2.2Disassemble the gauge outfit, and use a voltmeter to measure battery voltage; if the

voltage is over 3.5V, just check if the red-black connecting line between battery module and

instrument panel is disconnected.

2.3Other problems. Please contact professionals for testing of panel if power supply is normal.

3.Abnormal display

3.1If the sensor is proved to be normal through test, just press the unit switching key to see if

the data displayed is normal.

3.2Sensor connection: If display of instrument reading is abnormal, just turn off the instrument

and turn on it again to check screen display; if “SSERR” is displayed on the screen following

display of “SS CK”, it means that connection of sensor is abnormal; in this case, it is necessary

to check if connection between the sensor and instrument panel is normal before contacting

professionals to check if sensor output is normal.

3.3Calibration: If abnormal data is still displayed by the instrument following unit switching,

just use “unit switching” and “tare removal” in combination to enter the parameter setting mode,

and recalibrate at the final setting option (for details, please refer to page 10).

4.Truck failure

The forks cannot

be lifted to max.

height

The hydraulic oil is

insufficient

The hydraulic oil has

impurities

Adjusting nut(2-4) or

adjusting screw(2-6) in

wrong positions

Air enters into the cylinder

Seals damaged

1

2

Fault Possible cause Action

No.

Appendix

Description

E20V Series Scale Pallet Trucks

The forks cannot

be lifted

The hydraulic oil is

insufficient Add the hydraulic oil

Add the hydraulic oil

Change hydraulic oil

Adjust nut(2-4) or adjusting

screw(2-6)

Put the finger grip handle in

the upper position and press

the handle dozens of times

Replace the damaged seals

with new seals

15 16

Note: Do not attempt to repair the pallet truck unless you are trained in the professions.

Piston rod or the frame is

deformed resulting from

overloading or cargo

slanting to one side

The forks was kept in raised

position for extended period

of time, then the piston rod

is exposed to the air and gets

rusted , which blocks the

motion of the piston

Adjusting nut(2-4) or

adjusting screw(2-6) in

wrong positions

The forks cannot

be lowered

Seals damaged

Parts damaged

5

The forks

descended without

operation

3

4Oil leakage

The handle shall be detached before loading the truck.

The handle should be fixed stably in case sliding and damages and transported by fork truck or crane.

Before shipment, the operator should first check the truck weight, in order to choose the right crane.

When the truck is unloaded, the operator shall look out for safety around to ensure slow landing of the

truck.

If the truck is transported with the forklift truck, the forklift shall lift and lower it slowly to keep the balance

of the truck.

The truck shall be commissioned according to the following function tests: steering, traveling, braking

and combined functions with rated capacity.

When a truck is inoperative, the cargoes (if applicable) shall be removed with proper tools, the truck

shall be transported out of the working zone with a proper way.

When the truck will be shut down and in storage for a long time, the storage environment shall be kept

dry and clean, with forks lowered to their lowest position.

If the truck has to be transported for a long distance, it should be packed in the wooden pallet in order

to avoid collision during transportation.

Replace the related parts of

the cylinder or the frame with

new ones

Keep the forks at the lowest

position while not in use, and

keep piston rods lubricated in

time

Adjust nut(2-4) or adjusting

screw(2-6)

Replace the damaged

seals with new seals

Replace the damaged

parts with new parts

Impurities in the oil cause

the valve to be unable to

close tightly

Seals damaged

Adjusting nut(2-4) or

adjusting screw(2-6) in

wrong positions

Change hydraulic oil

Replace the damaged

seals with new seals

Adjust nut(2-4) or

adjusting screw(2-6)

Troubleshooting Transport, loading, test run and storage E20V Series Scale Pallet Trucks

17 18

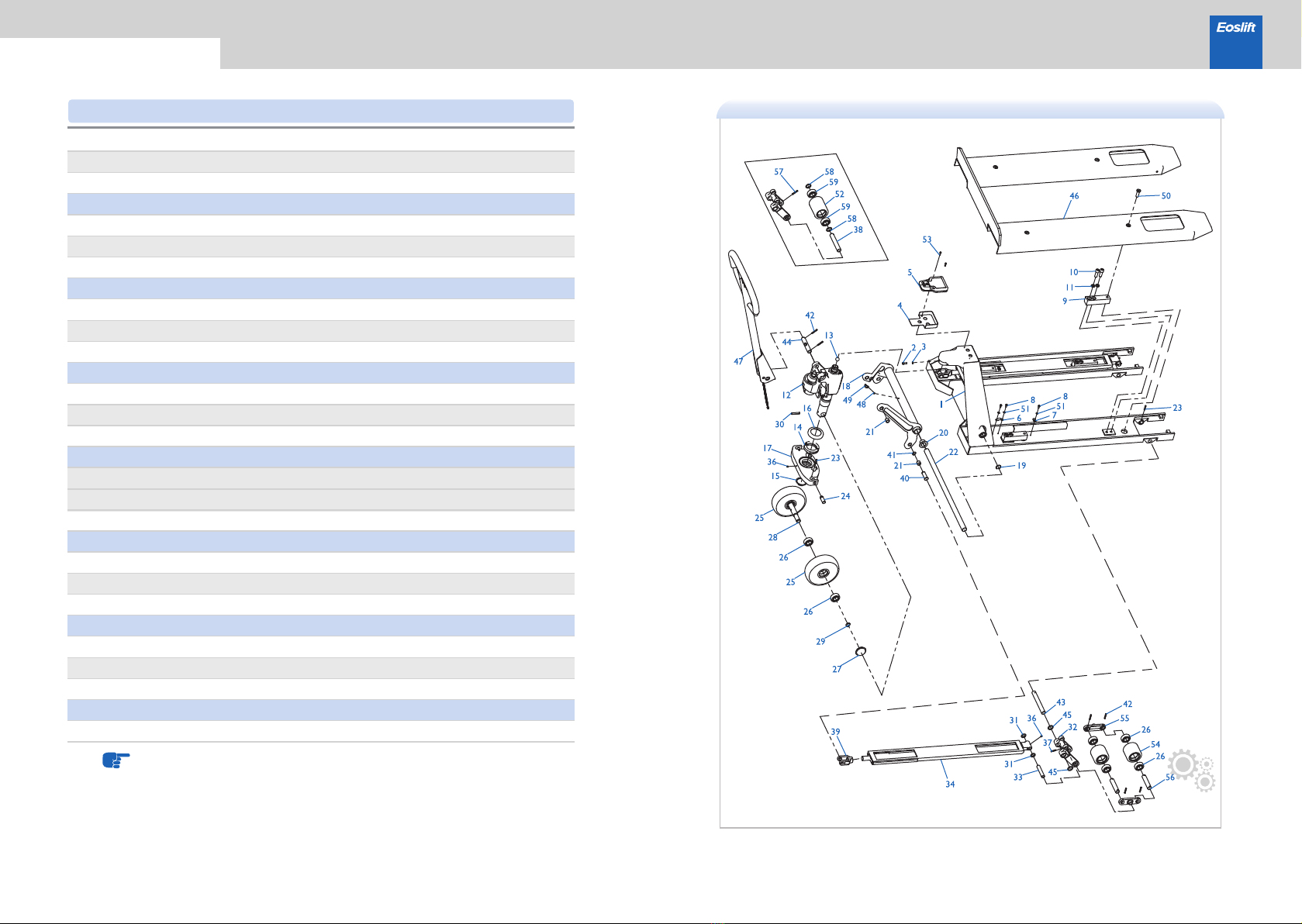

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

WC02000192

WC02000207

WC02000204

WC04000001

WC04000002

WC01000006

WC02000194

WC02000209

WC02000193

WC02000208

WC02000006

WC02000007

WC02000011

WC02000160

WC02000120

WC02000013

WC02000082

WC02000005

WC02000205

WC02000022

WC02000010

WC02000195

WC02000196

WC02000075

WC02000019

WC02000018

WE06000002

WE06000003

WE06000001

WC02000024

WC02000025

WC02000027

WC02000026

WC02000028

Frame (560 × 1150), 5012

Frame (685 × 1220), 5012

Metal protective shell (E20V), 5012

ValueScale outfit assembly

Cylinder assembly, galvanized

Left push rod (560 × 1150), 5012

Left push rod (685 × 1220), 5012

Right push rod (560 × 1150), 5012

Right push rod (685 × 1220), 5012

Small wheel carrier, black

Rocker, galvanized

Wheel shaft, galvanized

Nylon wheel φ74 × 70, white

Long shaft(540)

Long shaft(685)

Connecting rod assembly (540), black

Connecting rod assembly (685), black

Push rod connecting shaft, galvanized

Shaft

Washer, galvanized

Washer

JB7940.4, Push-fit type grease nipple 6

Connecting bracket, galvanized

Sliding bearing 29×25×25

Sliding bearing 18×16×15

GB3452.1,O-ring φ5×1.8

GB301, thrust ball bearing 51111

1

1

1

4

1

1

1

2

4

4

4

1

1

12

2

2

4

4

3

1

2

4

10

2

4

1

1

1

Gb308, Steel ball S18

GB894.1,Circlip for shaft 52,blackening

Dust cover, galvanized

Bolt pin 2, galvanized

Bolt pin, galvanized

Connecting base, galvanized

GB894.1,Circlip for shaft 16,blackening

Fork cover(560 × 1150), 5012

Fork cover(685 × 1220), 5012

Bowl-shaped concave washer for sensor

Bowl-shaped convex washer for sensor

Screw, M12 × 60

GB893.1,Circlip for hole 25,blackening

Nylon wheel φ180 × 50, white

Big wheel shaft, galvanized

GB894.1,Circlip for shaft 20,blackening

Big wheel cover, black

Big wheel cover, white

Connecting shaft, galvanized

Handle, black

Iron cable clip

R type cable clip6.5

GB95,Plain washer 5,galvanized

GB95,Plain washer 5,galvanized

Washer 53 × 31.8 × 3.5

WC02000020

WE07000003

WC02000015

WC02000012

WC02000014

WC02000190

WE07000002

WE03000001

WE05000001

WE03000009

WE03000007

WE05000006

WC02000191

WC02000206

WC02000202

WC02000198

WC02000201

WE07000001

WC02000199

WC02000078

WC02000017

WE07000004

WC02000016

WC02000076

WE06000004

WC02000004

WC02000003

WC02000200

WC02000197

WE03000006

WE05000004

WE05000004

WC02000774

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

1

1

1

2

2

2

2

1

1

2

8

8

1

4

4

4

2

2

1

2

2

1

1

1

2

2

6

4

2

4

E20V Series Scale Pallet Trucks

1TA pressure sensor 1TA assembly,

cable length: 130cm

Iron-core PU wheel φ74 × 70,

bright red PU, black iron core

GB276,Deep groove ball bearing 6204,

two-side shielded

GB879.1,Spring type straight pin 5×26,

blackening

GB879.1,Spring type straight pin 5×28,

blackening

GB879.1,Spring type straight pin 5×32,

blackening

JB7940.2, Angle hydraulic grease

nipple M6

GB70.1, Hexagon socket head cap screw

M6 × 16, galvanized

GB93,Normal type spring lock washer 6,

galvanized

GB70.1, Hexagon socket head cap screw

M4×16, galvanized

GB70.1, Hexagon socket head cap screw

M12×35, galvanized

GB93,Normal type spring lock washer 12,

galvanized

Aluminium-core PU wheelφ180×50,

bright red PU

GB879.1,Spring type straight pin 8×45,

blackening

GB818,Pan head screw with cross recess

M5×12,galvanized

Parts list · Frame(85)

Qty.

NO. Parts number Description Qty.

NO. Parts number Description

19 20

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

WC02000851

WE03000001

WE05000001

WC02000204

WC04000001

WC02000200

WC02000197

WE03000006

WC04000002

WE03000007

WE05000006

WC01000011

WC02000020

WC02000028

WE07000003

WC02000015

WC02000018

WC02000205

WE07000001

WC02000024

WC02000025

WC02000082

WE06000003

WC02000014

WC02000199

WC02000078

WC02000022

WC02000016

WC02000076

WC02000017

WE07000004

WE06000004

WC02000196

WC02000846

Frame, 5012

Metal protective shell (E20V), 5012

ValueScale outfit assembly

Iron cable clip

R type cable clip 6.5

Pressure sensor

Cylinder assembly, galvanized

GB308, Steel ball S18

GB301, thrust ball bearing 51111

GB894.1,Circlip for shaft 52,blackening

Dust cover, galvanized

Connecting bracket, galvanized

Connecting rod assembly, black

GB893.1,Circlip for hole 25,blackening

Sliding bearing 29×25×25

Sliding bearing 18×16×15

Long shaft

Bolt pin, galvanized

Nylon wheel φ180 × 50, white

Big wheel cover, black

Big wheel cover, white

Big wheel shaft, galvanized

GB894.1,Circlip for shaft 20,blackening

Washer, galvanized

Small wheel carrier, black

E20V Series Scale Pallet Trucks

GB818,Pan head screw with cross recess

M5×12,galvanized

GB70.1, Hexagon socket head cap screw

M6 × 16, galvanized

GB93,Normal type spring lock washer 6,

galvanized

GB70.1, Hexagon socket head cap screw

M12×35, galvanized

GB93,Normal type spring lock washer

12, galvanized

GB879.1,Spring type straight pin

5×28,blackening

Aluminium-core PU wheelφ180×50,

bright red PU

GB276,Deep groove ball bearing 6204,

two-side shielded

GB879.1,Spring type straight pin 8×45,

blackening

Qty.

NO. Parts number Description

Parts list · Frame(85) Parts list · Frame(75)

1

1

1

1

1

2

2

6

4

8

8

1

1

1

1

1

1

1

2

2

4

1

4

2

2

10

2

1

2

1

4

2

21 22

E20V Series Scale Pallet Trucks

Push rod connecting shaft, galvanized

Right push rod, 5012

Left push rod, 5012

JB7940.4, Push-fit type grease nipple 6

Single wheel shaft, galvanized

Connecting base, galvanized

Bolt pin 2, galvanized

GB894.1,Circlip for shaft 16,blackening

Shaft

Connecting shaft, galvanized

Washer

Fork cover, 5012

Handle, black

GB3452.1,O-ring φ5×1.8

Screw, M12 × 40

GB95,Plain washer 5,galvanized

Nylon wheel φ74 × 93, white

Nylon wheel φ74 × 70, white

Rocker, galvanized

Wheel shaft, galvanized

Washer

WC02000010

WC02000850

WC02000849

WC02000019

WE06000002

WC02000073

WC02000190

WC02000012

WE07000002

WE06000001

WC02000195

WC02000004

WC02000075

WC02000218

WC02000003

WC02000027

WC02000026

WC02000847

WE05000004

WC02000074

WC02000118

WE03000009

WC02000160

WC02000120

WC02000007

WC02000011

WE06000001

WC02000075

WC02000022

33

34

35

36

37

38*

39

40

41

42

43

44

45

46

47

48

49

50

51

52*

53

54

55

56

57*

58*

59*

2

1

1

3

2

2

2

2

2

10

2

1

4

1

1

1

1

4

6

2

2

2

2

2

2

4

4

GB879.1,Spring type straight pin

5×26,blackening

GB879.1,Spring type straight pin

5×32,blackening

Iron-core PU wheel φ74 × 70, bright red PU,

black iron core

JB7940.2, Angle hydraulic grease nipple M6

Iron-core PU wheel φ74 × 93, bright red PU,

black iron core

GB879.1,Spring type straight pin 5×32,

blackening

GB276,Deep groove ball bearing 6204,

two-side shielded

GB70.1, Hexagon socket head cap screw

M4×16, galvanized

Note:Marked with "*"are single wheel parts

Qty.

NO. Parts number Description

Parts list · Frame(75)

23 24

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

WC02000170

WC02000157

WC02000060

WC02000036

WC02000061

WC02000059

WC02000058

WC02000035

WC02000045

WC02000046

WC02000038

WC02000071

WC02000037

WC02000044

WC02000039

WC02000064

WC02000063

WC02000042

WC02000041

WC02000043

WC02000040

WC02000049

WE06000005

WE03000003

WE04000003

WC01000046

Valve body welded(75), galvanized

Valve body welded(85), galvanized

GB982, Combination sealing gasket 10

Screw

Seal ring UHS35

GB3452.1,O-ringφ34.5×3.55

Dustproof ring DH35

Piston rod

Safety valve spool

Pressure adjusting spring

Pressure adjusting screw

GB3452.1,O-ring φ11.2×2.65

Screw plug

Copper gasket

Pump body

Seal ring UHS18

Dustproof ring DH18

Spring cover

Pump core

Pressure spring

Pin

Unloading plate, galvanized

Integrated valve assembly

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

E20V Series Scale Pallet Trucks

GB879.1,Spring type straight pin

8×50,blackening

Gb73, Slotted set screws with flat point

M8 × 20, galvanized

GB6172.1, Hexagon thin nut M8,

galvanized

Qty.

NO. Parts number Description

Parts list· Cylinder

2625

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

WC02000051

WC02000065

WC02000067

WC02000053

WC02000066

WC02000050

WC02000052

WC02000054

WC02000069

WC02000070

WE06000006

WC02000055

WC02000062

WC02000048

WE03000002

WC02000056

WC02000057

WC02000047

WC02000068

Push pin sleeve

GB3452.1,O-ringφ15.2×2.4

GB3452.1,O-ringφ8×1.8

Return valve sleeve

GB3452.1,O-ringφ9.5×1.8

Stem

Unloading spring

O-ring retainer Ⅱ

GB308,Steel ball S7

Liquid inlet valve sleeve

GB117, Copper taper pin 2 × 5

O-ring retainerI

GB3452.1,O-ringφ13.2×2.4

Spring leaf

Boost valve spool

Spool spring

Blind nut

GB3452.1,O-ring φ21.2×2.65

1

1

2

1

1

1

1

1

1

1

2

1

1

1

1

1

1

1

1

E20V Series Scale Pallet Trucks

GB818,Pan head screw with cross recess

M2×2,galvanized

Qty.

NO. Parts number Description

Parts list · Integrated valve

28

27

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

WJ10800014

WJ10800015

WJ10800016

WJ10800011

WJ10800006

WJ10800003

WJ10800004

WJ10800020

WJ10800002

WJ10800008

WJ10800012

WJ10800013

WJ10800018

WJ10800019

WJ10800005

WJ10800017

WJ10800009

WJ10800010

Handle welded

Clamping roller

Roller pin

Finger grip handle

Spring type pin (5)

Spring type pin (6)

Spring type pin (7)

Locking nut

Spring type pin (9)

Positioning plate

Connecting sheet of pull rod

Pull rod

Chain

Adjusting bolt

Spring type pin (15)

Bushing

Torsion spring

Plastic roller

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

E20V Series Scale Pallet Trucks

Qty.

NO. Parts number Description

Parts list· Handle

Table of contents

Other Eoslift Forklift manuals