Eoslift S10 User manual

S10/15

Hotline: 400-626-9090

Tel: +86 573 8622 9999

Fax: +86 573 8622 2900

Operating Instructions

Semi-electric

Pallet

Stacker

For proper and safe operation of the products,

before using the products, be sure to read the

operating instructions carefully and retain them

properly for future reference.

The operator needs to have proficient operation

skills. The operator has responsibility to carefully

understand the performance and safety rules of

the pallet stacker. If you have any doubts during

the application, please don't hesitate to contact

Eoslift.

Esteemed users:

S10/15 Series Semi-electric Pallet Stackers

S10/15 Series Semi-electric Pallet Stackers

Ⅰ.Technical parameters 01

Ⅱ. Safe operating rules 02

Ⅲ.Maintenance 04

Ⅳ.Batteries 05

Table of contents

Ⅵ.Transport, loading, test run and storage 07

Ⅶ.Troubleshooting 08

Ⅷ.Electrical circuit diagram 10

Ⅴ.Control panel

06

Ⅸ.Parts list 11

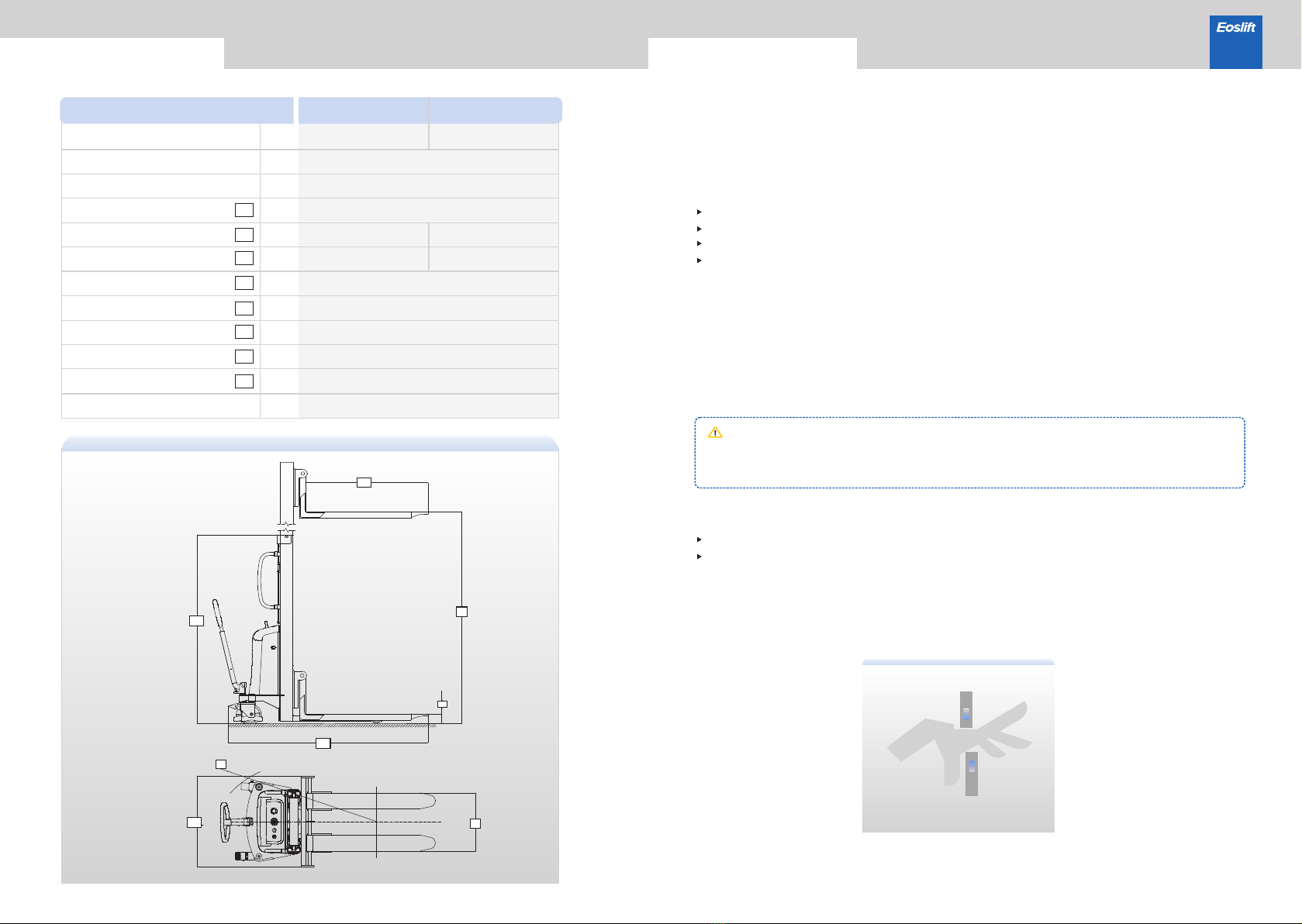

01 02

Rated capacity

Load center

Dead-weight

Minimum fork height

Maximum fork height

Lowered Mast Height

Fork length

Overall fork width

Length of the stacker

Width of the stacker

Minimum turning radius

Battery

1500

600

340-412

85

1600/2500/3000/3500

2030/1870/2030/2280

1150

540/330-830

1800

745/864

1350

12/120

kg

mm

kg

mm

mm

mm

mm

mm

mm

mm

mm

V/Ah

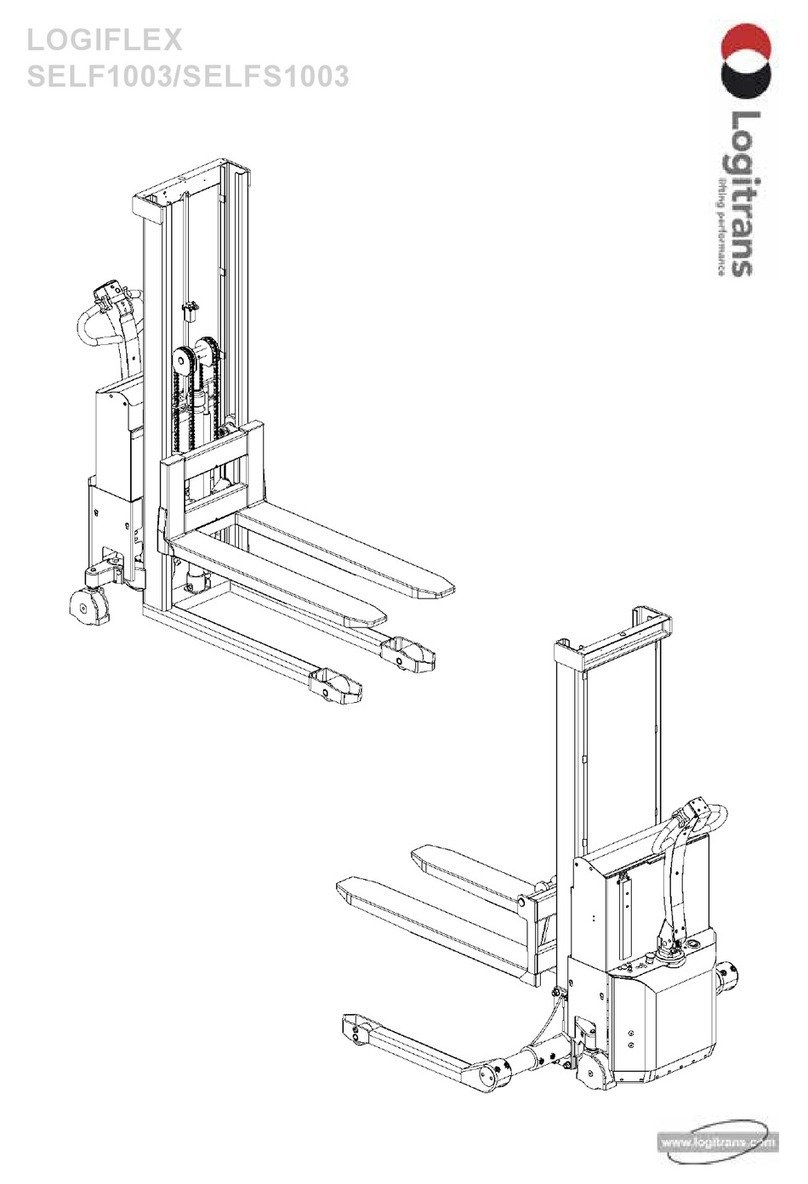

Figure 1

2000

2000

1530

5. Safety devices and warning signs

Safety devices, warning signs and the above safety precautions must be given enough attention to.

When handling the goods, the fork height must not exceed 300mm.

6. Operation protection

Hands and feet shall be kept far away from moving parts, such as frame, chains, forks and wheels to

prevent pinching hands.

H1

H

L

B

B2

R

L1

2.

Free from rainwater or corrosion of harmful gases;

Room temperature of -20°C~+40°C;

Relative ambient humidity <90%;

Requirements for ground: hard, anti-skid and level without barriers.

The stacker is only applicable to indoor use and the application environment must meet the

following conditions:

1. Requirements for operator

The stacker must be operated by persons trained in operation.The operator shall be able to carry out

operation demonstration of moving and controlling goods for users, and he or she is responsible for the

stacker. Unauthorized persons are not allowed to operate the stacker. Do not carry or lift passengers.

Unauthorized persons must leave the hazardous area. Whenever a situation causes possible harm to

persons, the operator must give a warning. If the unauthorized persons still stay in the hazardous area

after the waring is given, the operator must immediately stop the operation of the stacker.

Warning

4. Hazardous area

The hazardous area usually refers to the area where the stacker or its lifting device (e.g. forks, attachments)

will pose threat to persons during their operation or lifting process. Typically, this range extends to the

area where goods or stacker accessories are lowered.

3. Faults and defects

If stacker failure or defects occur, immediately notify the management personnel. If the stacker is not safe

for operation (such as wheel worn or brake failed, etc.), please stop using it before it is fully repaired.

L

H

H2

H1

L1

B2 B

R

S10/15 Series Semi-electric Pallet Stackers

Technical parameters

Model S15S10

Safe operating rules

H2

03 04

Maintenance

7. Stable operation

Travel of stacker shall be stable, avoiding sharp turns and sudden start.

8. Loose or unstable stacking of goods or overloaded cargoes are prohibited.

Loose or unstable stacking of goods will cause falling of goods, or even turnover.

9. Other safety requirements

Do not use this stacker on the muddy ground.

Do not operate the stacker unless you have carefully checked its condition. Pay special attention

to the wheels, the handle assemblies, the frame, the chains, etc.

The operator shall wear safety shoes and gloves for protection.

Do not use the stacker in a potentially flammable and explosive atmosphere.

Do not use the stacker as a vehicle jack.

Do not use the stacker during strong wind forces.

Do not use the stacker on places insufficiently illuminated.

Do not use the stacker on a slopping ground.

The weight of goods should be distributed evenly on the two forks, do not use only one fork. The

center of gravity of goods beyond the two forks is forbidden.

The stacker shall be charged in places properly ventilated and far away from the fire.

Stacker should be parked on a smooth place, with its brake pressed, power turned off and the

forks lowered to the min. height.

Stop using the stacker without guarding plate.

Under special conditions or in special locations, the operator should be careful while operating

the stacker.

No modifications or alterations to the parts of the stacker, especially the safety device shall be made

without permission. All original spare parts have been checked by the quality inspection departments.

To ensure the safety and reliability of the stacker operation, only the manufacturer's spare parts can be

used. Replaced parts, such as batteries and waste oil, must be disposed in accordance with the

appropriate environmental protection rules.

Only customer service persons specially trained by our company can carry out maintenance of the

truck. Thoroughly standardized maintenance is the most important preconditions to ensure stable

and reliable operation performance of the stacker. Neglect of regular maintenance could result in

failure and malfunction of the truck and poses a potential threat to the safety of the staff and

operation.

Warning

1. Hydraulic oil

Please check the oil level every six months and change the oil every twelve months. 32 # hydraulic

oil is recommended, with total volume of about 4.0 liters.

2. Routine maintenance

It is necessary to check and maintain the stacker daily for sound application. Special attention should

be paid to:

(1)The wheels, the axles, as foreign bodies may block the wheels and axles,

(2) The fork and the frame which may be deformed. and

(3) If the battery voltage is normal. The forks should be unloaded and lowered in the lowest position

when the job is over.

3. Lubrication

Use motor oil or grease to lubricate all movable parts.

4. Maintenance of battery

Keep all nuts tight, dry and clean. Each wiring terminal and cable joints must be tightened and coated

with clean grease. The exposed wiring terminals and binding posts of the battery must be covered with

insulated cover.

Figure 2

Safe operating rules S10/15 Series Semi-electric Pallet Stackers

Battery

05 06

12V, 120Ah lead-acid storage batteries are used in this series of stackers.

The storage battery shall be placed in the special anti-spilling case which should be fixed with

bolts.

The storage battery cannot be overturned when installing and moving it in case the acid liquor

spills out.

Keep power off when the stacker is not in use.

1. Battery power system

When the left two segments of the battery indicator flash, please charge the battery.

Please check the level of battery electrolyte every week, if the electrolyte is not enough, add

some distilled water or electrolyte.

The stacker shall be charged in places properly ventilated and far away from the fire.

If the stacker will be not in use for long time, charge it fully for storage and charge it once every

month.

Do not use the stacker when it is charged.

2. Battery charging

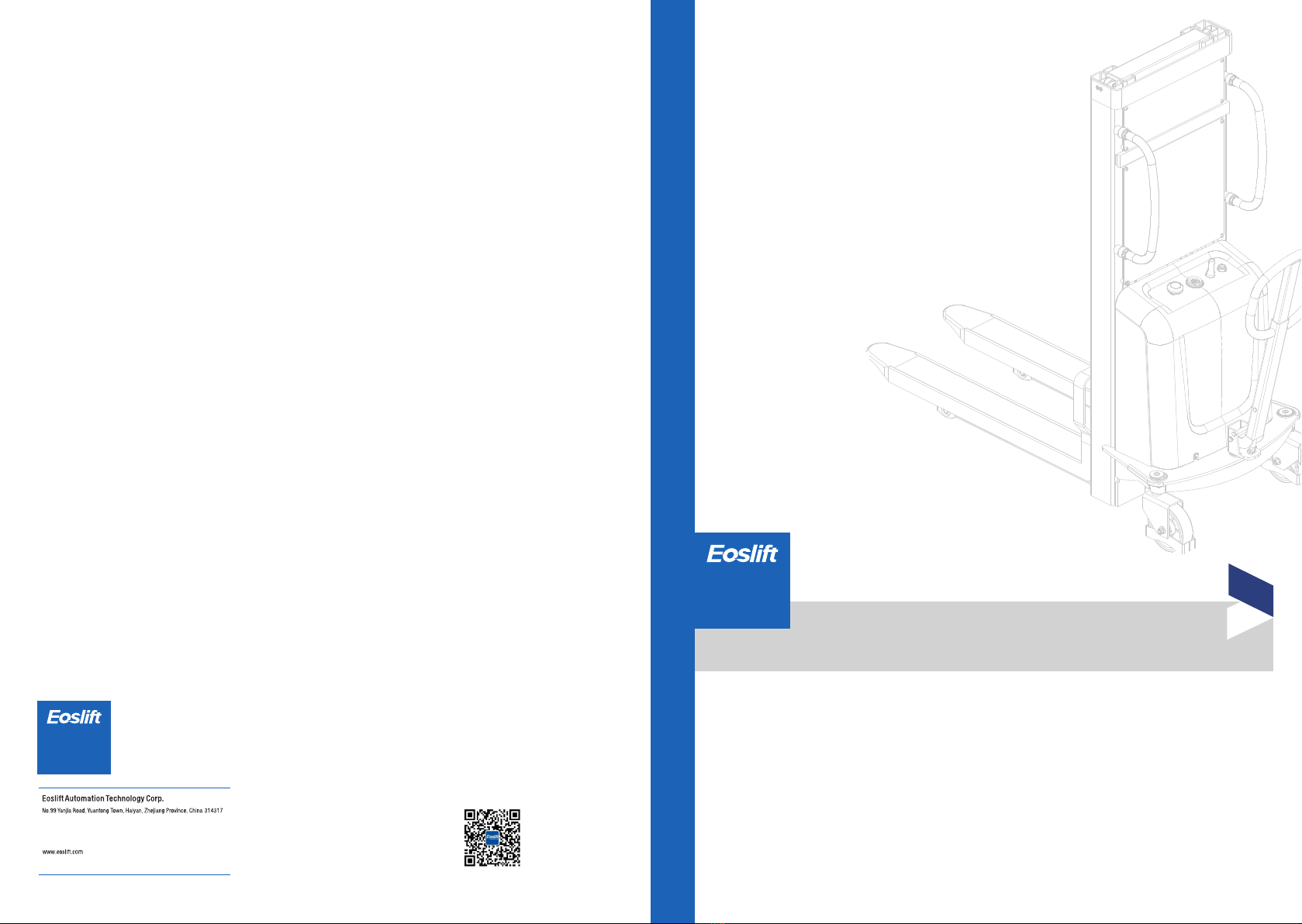

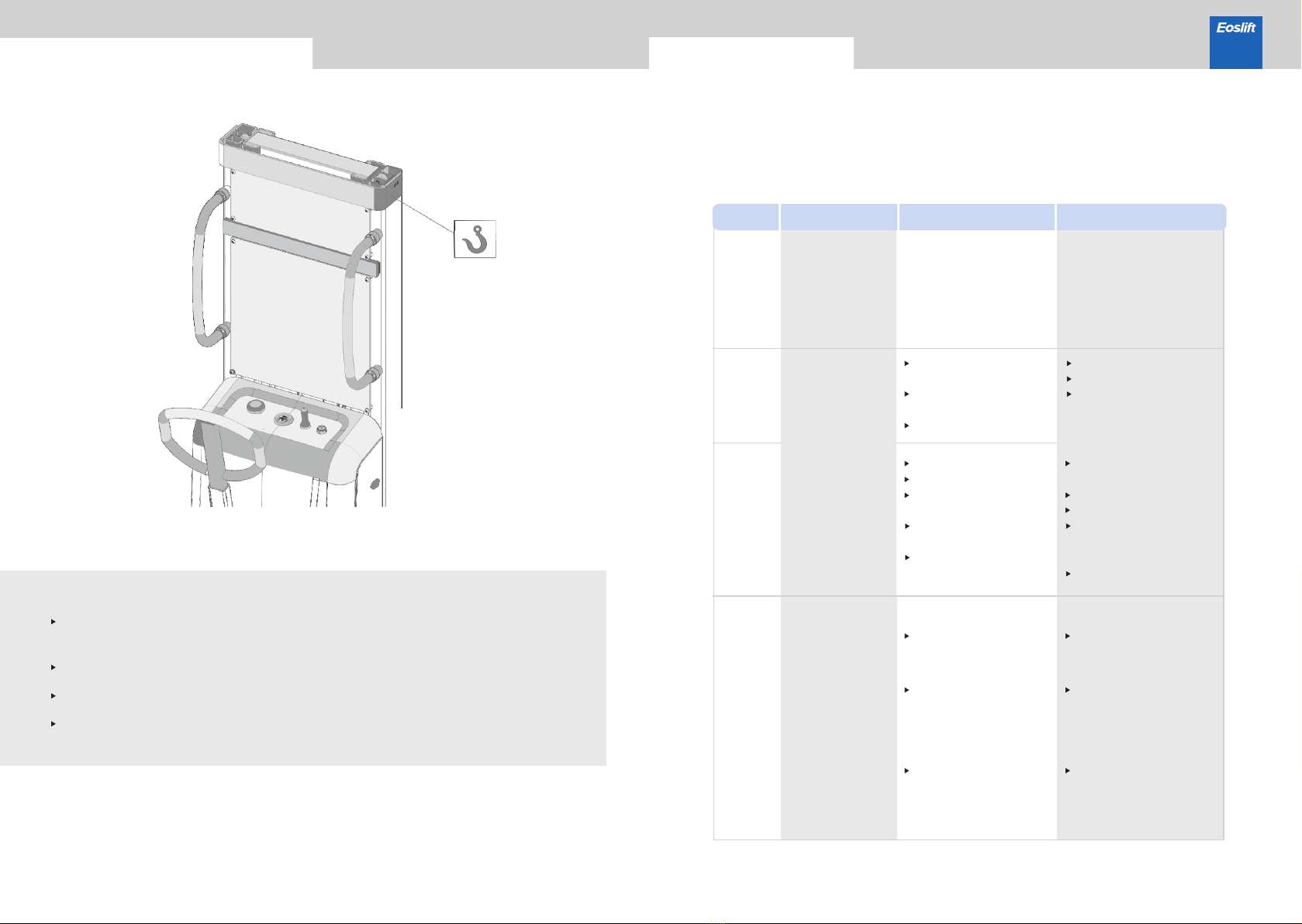

Control panel

① Emergency stop switch

When you press down this switch, it will switch off the power of the stacker, and then if you turn it

clockwise, it will switch on the power.

② Control handle of pum

This handle controls the lifting and lowering of the forks.

③ Battery indicator

It is a battery indicator with 10 segment color LED bar graph display. When the battery level is

too low, the left two segments of LED bar graph display will flash to give an alarm.

⑤ Charger socket

④ Key switch

When you turn this switch clockwise, it will switch on the power. When you turn this switch

counterclockwise, it will switch off the power. Before leaving the stacker, fully lowered its forks

and take out the key switch.

Emergency stop switch

Pump control handle

Figure 3

Battery indicator

Key switch

Charger socket

S10/15 Series Semi-electric Pallet Stackers

Transport, loading, test run and storage

07 08

Before loading, the operator shall check the stacker weight to choose the suitable hoisting

equipment.When the stacker is unloaded, the operator shall look out for safety around to ensure

safe landing of the stacker.

The stacker shall be commissioned according to the following function tests: steering, traveling,

braking and combined functions with rated capacity.

When a stacker is inoperative, the loads (if applicable) shall be removed with a proper tools, the

stacker shall be transported out of the working zone with a proper way.

When the stacker will be shut down and in storage for a long time, the storage environment shall

be kept dry and clean, with forks lowered to their lowest position.

As shown in Figure 4, when the stacker is transported by hoisting equipment, lifting points are on

both sides of the stacker.

Troubleshooting

This chapter enables the user to identify and rectifies basic faults and the effects of incorrect operation.

When trying to locate a fault, proceed in the order shown in the table below. If, after carrying out the

following remedial action listed in “actions”, the stacker cannot be restored to operation, contact the

manufacturer’s after-sale service department. Additional troubleshooting must only be performed by

the manufacturer’s specialist service engineers. The manufacturer's customer service department is

specially trained to carry out these operations.

1

The forks cannot

be lifted to max.

height

2The forks cannot

be lifted

3

The motor of the

pump station

cannot operate

4The forks cannot

be lowered

The hydraulic oil is

insufficient

Add the hydraulic oil

The piston rod or the frame is

deformed resulting from

overloading or cargo slanting

to one side

The forks was kept in raised

position for extended period

of time, then the piston rod is

exposed to the air and gets

rusted , which blocks the

motion of the piston

The relief valve of the hydraulic

pump station cannot be opened

due to wear or damage

Replace the related parts of

the cylinder or the frame with

new ones

Keep the forks at the lowest

position while not in use, and

keep piston rods lubricated in

time

Replace the relief valve of the

hydraulic pump station

Replace the switch

damaged with a new switch

Charge the battery

Tighten the connectors

Replace the damaged

contactor with a new

contactor

Repair or replace it.

Lifting switch is damaged

Battery voltage is too low

The connectors of the

power line are loose

The motor contactor is

damaged

Motor is damaged

The hydraulic oil is

insufficient

The hydraulic oil has

impurities

Seals damaged

Add the hydraulic oil

Change hydraulic oil

Replace the damaged

seals with new seals

Figure 4

Fault Possible cause ActionNo.

S10/15 Series Semi-electric Pallet Stackers

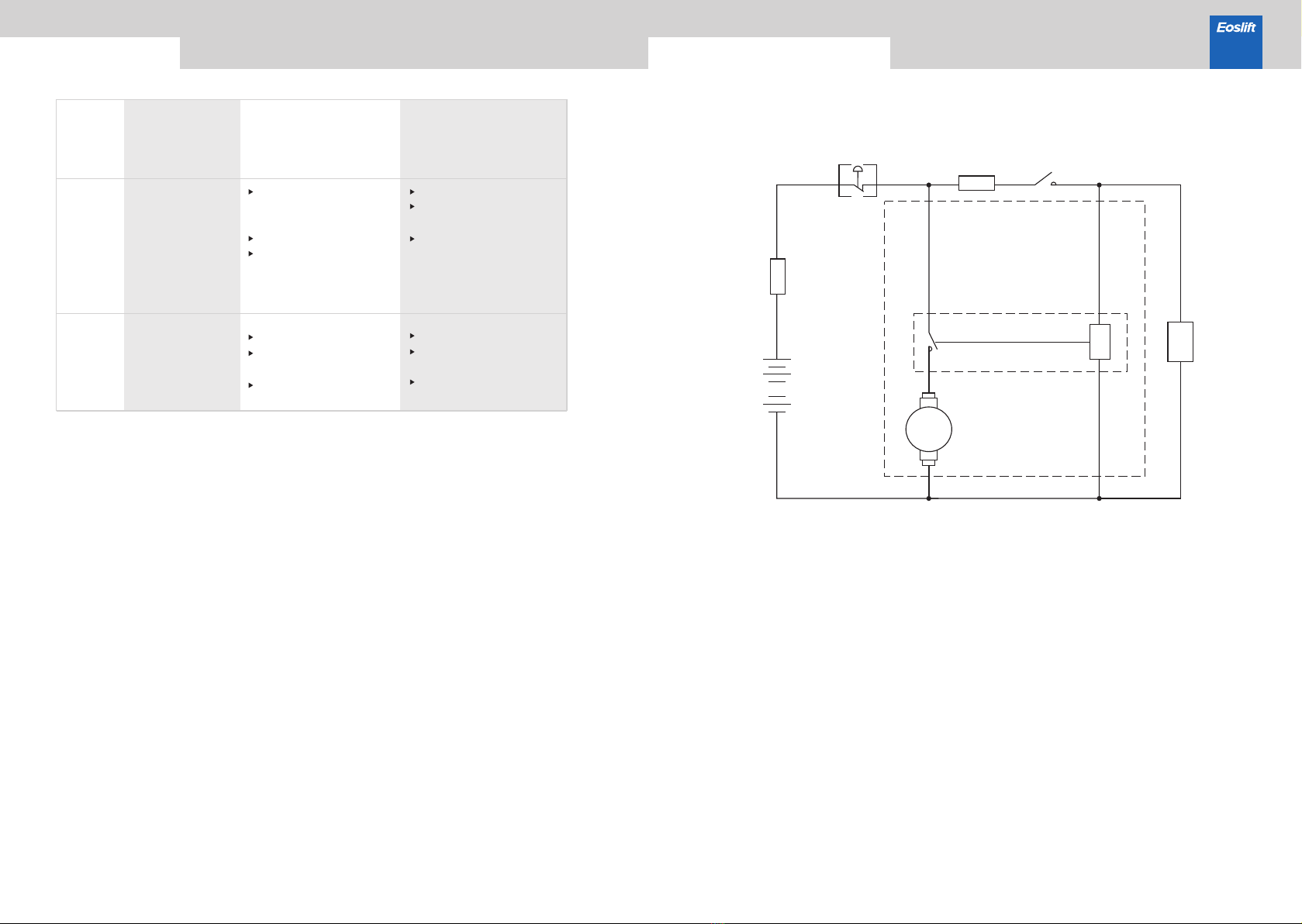

09 10

Troubleshooting Electrical circuit diagram

Emergency stop switch

FU2 20A Key switch

FU1 300A

B+

B-

24V battery unit

M

Battery indicator

M

5Oil leakage Seals damaged Replace the damaged

seals with new seals

6

The forks

descended without

operation

Impurities in the oil cause

the valve to be unable to

close tightly

Seals damaged

The relief valve of the

hydraulic pump station is

damaged.

7Battery cannot be

charged

Battery damage

Charging plug becomes

loose

Charger damage

Change hydraulic oil

Replace the damaged

seals with new seals

Replace the relief valve

of the hydraulic pump

station

Replace the battery

Tighten the plug

Repair or replace it

S10/15 Series Semi-electric Pallet Stackers

Parts list· Guide wheel,with brake S10/15 Series Semi-electric Pallet Stackers

11 12

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

WC02000237

WC02000234

WC02000243

WC02000244

WC02000245

WC02000240

WC02000238

WC02000241

WC02000242

WC02000239

WC02000235

WC02000236

WC02000226

WC02000285

WC02000435

WE05000010

WC02000225

WC02000224

WE03000013

WC02000022

WE03000018

WE05000006

WE04000011

WE07000009

Universal wheel bracket,with brake,black

Big wheel shaft sleeve 1

Sprocket

Backing ring

Wheel shaft cover

Compressions spring

Brake lining, galvanized

Brake pedal

Brake pedal shaft

Shoulder screw

Big wheel shaft sleeve 2

Key

Nylon wheelφ180×50(flower-shape wheel)

Nylon wheelφ180×50(plane wheel)

GB95,Plain washer 24,galvanized

GB297,Tapered Roller Bearings 30205

GB6170,Hexagon nut M12,galvanized

GB894.1,Circlip for shaft 12,blackening

1

2

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

2

1

1

1

2

Iron-core PU wheel φ180×50, bright red PU,

black iron core

GB276,Deep groove ball bearing 6205,

two-side shielded

GB2673,Hexagon lobular socket countersunk head

screw M10×16,galvanized

GB276,Deep groove ball bearing 6204,

two-side shielded

GB70.1, Hexagon socket head cap screw

M12×100, galvanized

GB93,Normal type spring lock washer 12,

galvanized

NO. Parts number Description Qty.

S10/15 Series Semi-electric Pallet Stackers

13 14

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

WC02000821

WC02000818

WC02000822

WC02000817

WC02000244

WC02000819

WC02000248

WC02000236

WC02000820

WC02000243

WC02000224

WE05000010

WE06000018

WE07000002

WE07000019

Handle holder, welded

Pivot Ⅱ

Handle lever welded

Pivot Ⅰ

Backing ring

Pivot Ⅲ

Gas spring

Key

Pivot Ⅳ

Sprocket

Deep groove ball bearing

Plain washer

Cotter pin

Circlip for shaft

Circlip for shaft

1

1

1

1

1

1

1

1

1

1

2

1

2

1

1

1

2

3

4

5

6

7

8

9

10

11

12

13

WC02000246

WC02000022

WC02000234

WC02000226

WC02000285

WC02000435

WC02000235

WE03000018

WE05000006

WE04000011

WC02000245

WE05000010

WC02000225

WC02000224

WE03000013

Guide wheel bracket,black

Big wheel shaft sleeve 1

Nylon wheelφ180×50(flower-shape wheel)

Nylon wheelφ180×50(plane wheel)

Big wheel shaft sleeve 2

GB6170,Hexagon nut M12,galvanized

Wheel shaft cover

GB95,Plain washer 24,galvanized

GB297,Tapered Roller Bearings 30205

1

2

2

1

1

1

1

1

1

1

1

1

1

GB276,Deep groove ball bearing 6204,

two-side shielded

Iron-core PU wheel φ180×50, bright red PU,

black iron core

GB70.1, Hexagon socket head cap screw

M12×100, galvanized

GB93,Normal type spring lock washer 12,

galvanized

GB276,Deep groove ball bearing 6205,

two-side shielded

GB2673,Hexagon lobular socket countersunk head

screw M10×16,galvanized

Parts list· Guide wheel Parts list· Handle assemblies

Qty.

NO. Parts number Description Qty.

NO. Parts number Description

15 16

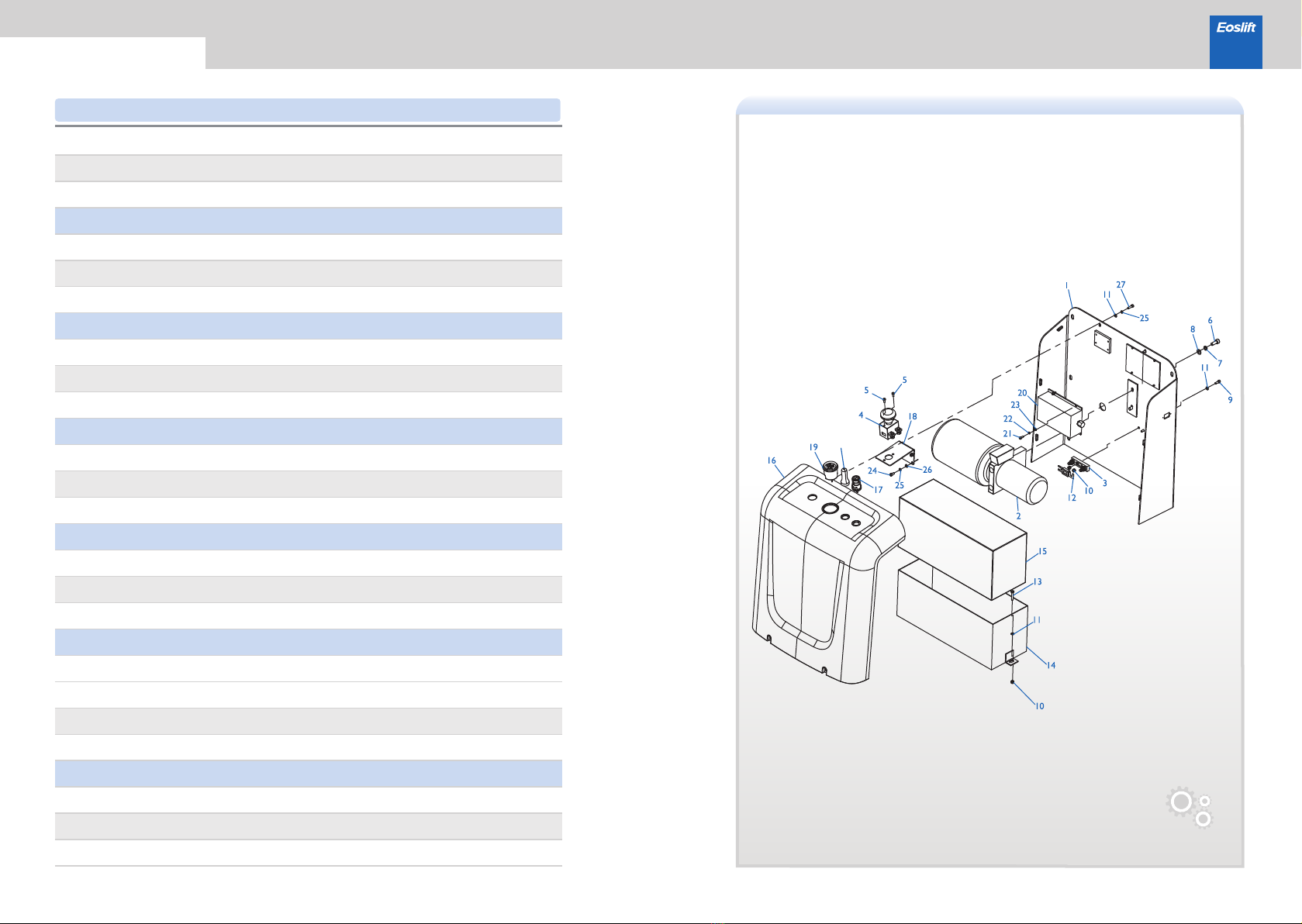

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

WC02000815

WC02000269

WC04000022

WC04000020

WE03000006

WE03000004

WE05000002

WE05000009

WE03000001

WE04000017

WE05000003

WC04000011

WE01000003

WC02000255

WC02000268

WC02000814

WC04000058

WC02000816

WC04000013

WC04000069

WE03000034

WE05000016

WE05000004

WE03000035

WE05000001

WE05000003

WE03000021

WC04000071

Electrical box welded

Hydraulic pump station

Fuse connecting holder

Emergency stop switch ZJK250A

Pan head screw with cross recess

Hexagon socket head cap screw

Spring lock washer

Plain washer

Hexagon socket head cap screw

Hexagon locking nut

Plain washer

Fuses

Bolt

Battery box

Battery

Housing

Key switch

Emergency stop switch support,welded

Battery indicator

Hexagon socket head cap screw

Spring lock washer

Plain washer

Hexagon socket head cap screw

Spring lock washer

Plain washer

Hexagon socket head cap screw

Cross switch

1

1

1

1

2

2

2

2

2

4

6

1

2

1

1

1

1

1

1

1

4

4

4

4

6

4

2

1

28

Parts list· Motor box S10/15 Series Semi-electric Pallet Stackers

CZC7-300W, built-in charger

(conforming to European Standards)

NO. Parts number Description Qty.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

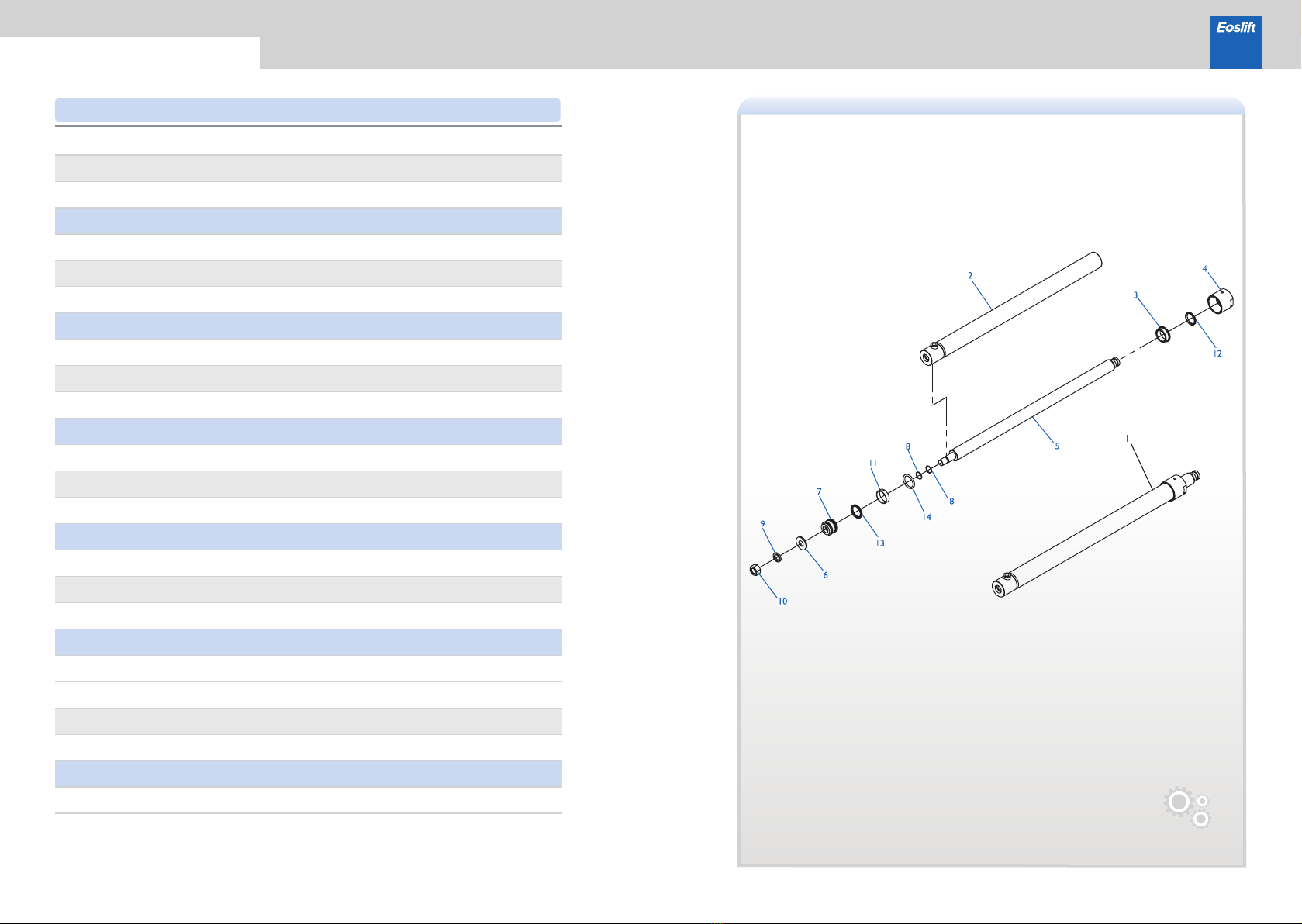

WC01000015

WC01000019

WC01000016

WC01000017

WC01000018

WC02000233

WC02000333

WC02000305

WC02000303

WC02000312

WC02000275

WC02000272

WC02000271

WC02000334

WC02000306

WC02000304

WC02000313

WC02000274

WC02000273

WC02000279

WE05000011

WE04000018

WC02000278

WC02000276

WC02000280

WC02000277

Cylinder assembly (1.6m), black

Cylinder assembly (2.0m), black

Cylinder assembly (2.5m), black

Cylinder assembly (3.0m), black

Cylinder assembly (3.5m), black

Cylinder weldment (1.6m), black

Cylinder weldment (2.0m), black

Cylinder weldment (2.5m), black

Cylinder weldment (3.0m), black

Cylinder weldment (3.5m), black

Guide sleeve

Cap, galvanized

Piston rod(1.6m)

Piston rod(2.0m)

Piston rod(2.5m)

Piston rod(3.0m)

Piston rod(3.5m)

Washer, galvanized

Piston

GB3452.1,O-ring φ26.2×2.4

GB6171,Hexagon nut M24×1.5,galvanized

ZS50 Guide ring 50×55×14.8

DH45 Dustproof ring 45×53×6.5

UHS45 Sealing ring 45×56×7

GB3452.1,O-ring φ50.8×3.1

1

1

1

1

1

1

1

2

1

1

1

1

1

1

Parts list· Cylinder assembly S10/15 Series Semi-electric Pallet Stackers

GB93,Normal type spring lock washer 24,

galvanized

17 18

NO. Parts number Description Qty.

Parts list· Top beam assembly S10/15 Series Semi-electric Pallet Stackers

19 20

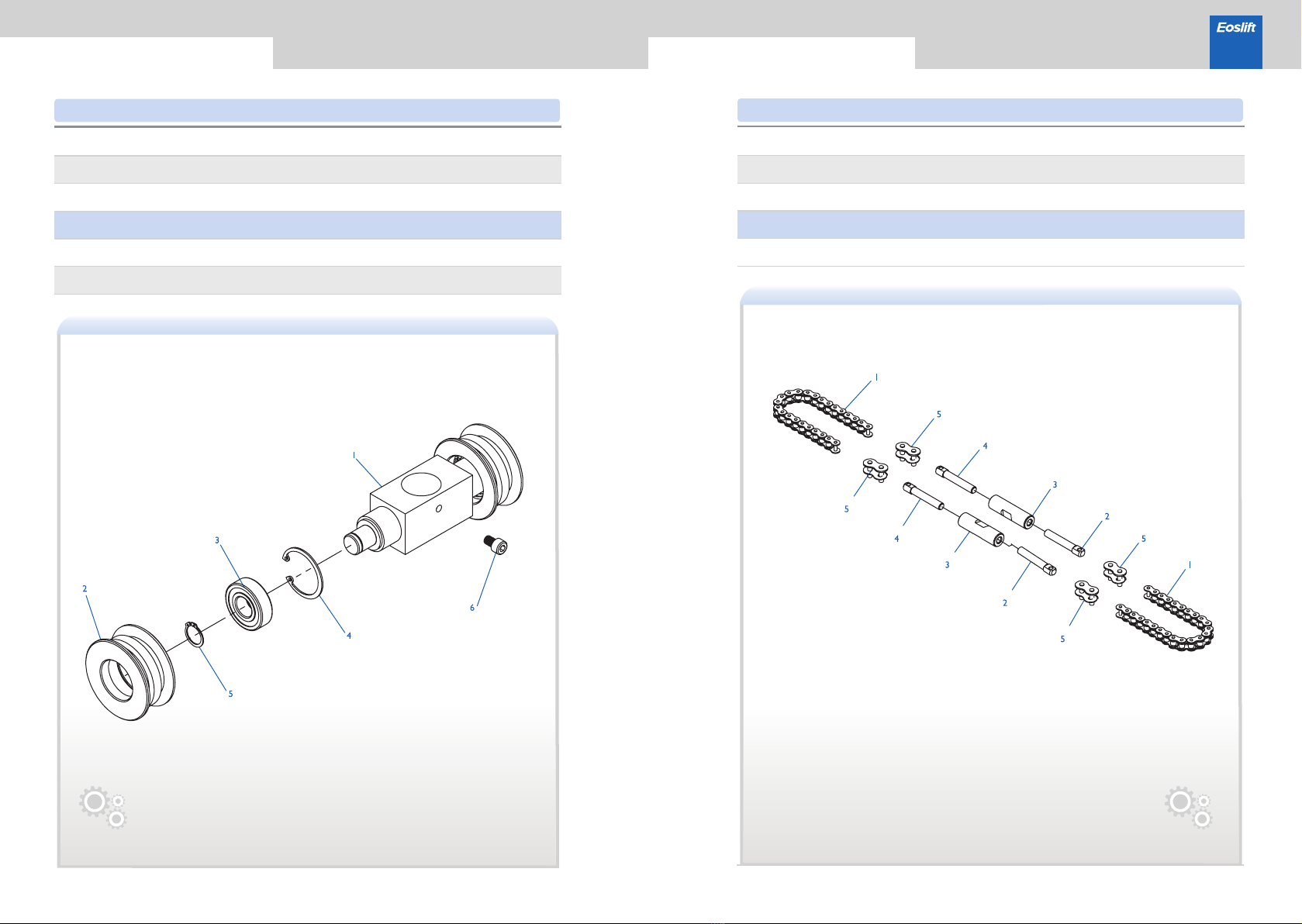

1

2

3

4

5

6

WC02000256

WC02000317

WC02000022

WE07000006

WE07000004

WE03000017

Top shaft, galvanized

Sprocket (leaf chain)

GB893.1,Circlip for hole 47,blackening

GB894.1,Circlip for shaft 20,blackening

1

2

2

2

2

1

1

2

3

4

5

WC02000219

WC02000263

WC02000262

WC02000265

WC02000220

Chain

Threaded rod (right)

Threaded rod sleeve

Threaded rod (left)

Single-row roller chain CL connector 08A-1

2

2

2

2

4

Parts list· Steering chain

GB70.1,Hexagon socket head cap screw

M8×12,galvanized

GB276,Deep groove ball bearing 6204,

two-side shielded

NO. Parts number Description Qty.

NO. Parts number Description Qty.

Parts list· Leaf chain S10/15 Series Semi-electric Pallet Stackers

Parts list· Single frame

21 22

1

2

3

4

5

6

7

8

9

10

WC02000314

WC02000332

WC02000321

WC02000325

WC02000326

WJ11900006

WJ11900008

WJ11900009

WJ11900011

WJ11900012

WJ11900013

WJ11900015

WJ11900003

WJ11900001

WJ11900005

WJ11900004

WJ11900002

WJ11900016

Leaf chain, 68 links (1.6m)

Leaf chain, 88 links (2.0m)

Leaf chain, 90 links (2.5m)

Leaf chain, 102 links (3.0m)

Leaf chain, 116 links (3.5m)

LH1223 long end connector

Leaf chain, 68 links (1.6m)

Leaf chain, 88 links (2.0m)

Leaf chain, 90 links (2.5m)

Leaf chain, 102 links (3.0m)

Leaf chain, 116 links (3.5m)

Chain pivot

GB91, Cotter pin 2 × 16

GB91, Cotter pin 3.2 × 32

Spherical nut

GB6171, nut M14 × 1.5 × 12.8

GB91, Cotter pin 2 × 32

Chain shackle

2

2

2

2

2

2

2

2

2

2

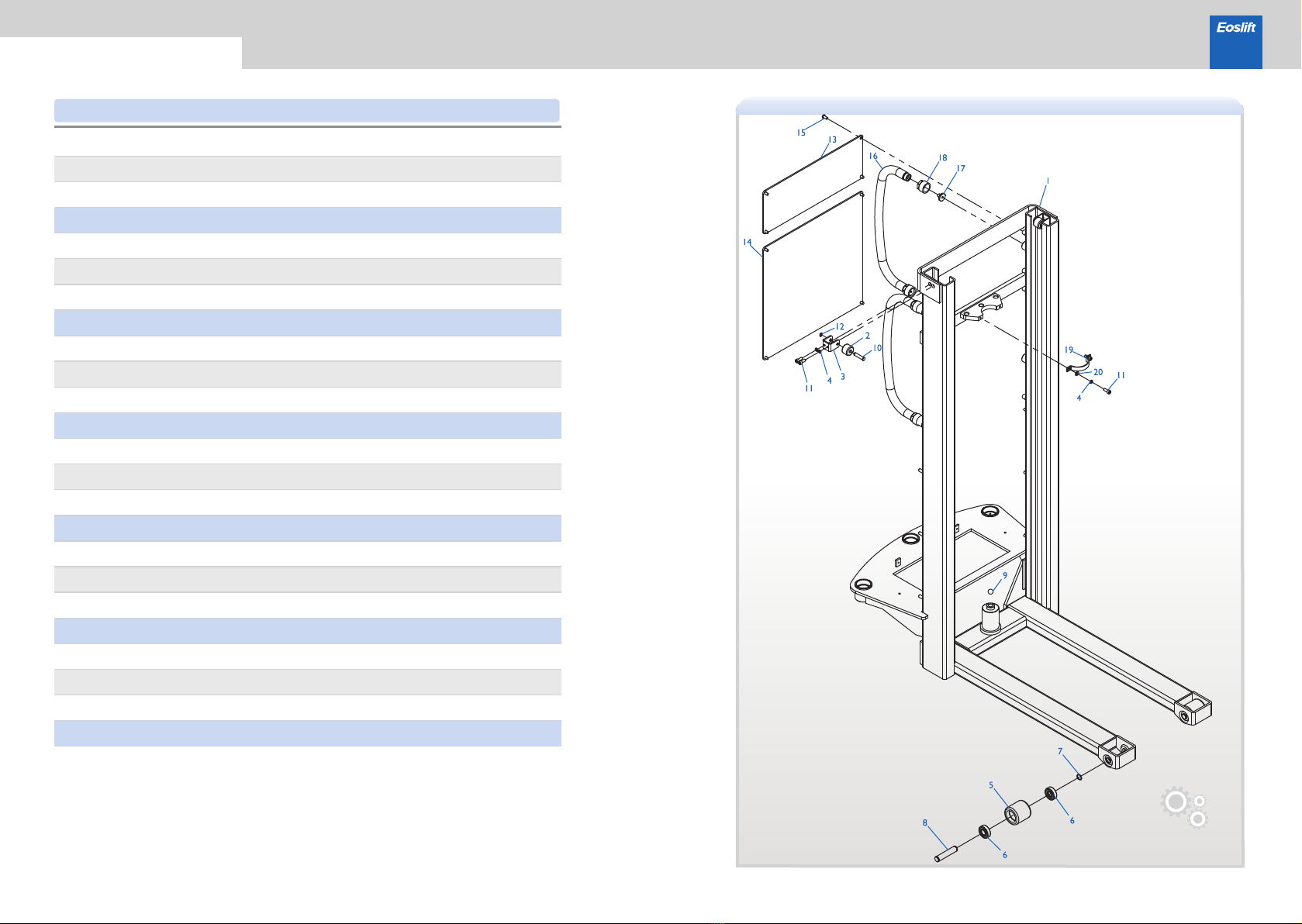

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

WC02000899

WE03000014

WE04000015

WC02000227

WC02000259

WC02000022

WE07000004

WC02000264

WE04000014

WE04000013

WE01000002

WE05000005

WE05000008

WE04000008

WE05000002

WE05000009

WE04000009

WC02000020

WC02000898

WE97000031

External frame,5012(1.5t)

Hexagon socket head cap screw

Hexagon locking nut

Iron-core PU wheel

Front wheel shaft

Deep groove ball bearing

Circlip for shaft

Locking ring

Acorn nut--sssembling type

Acorn nut--sssembling type

M10 × 50 bolt

Spring lock washer

Plain washer

Hexagon nut

Spring lock washer

Plain washer

Hexagon nut

Steel ball

Glass baffle

Hexagon socket button head screw

1

4

4

2

2

2

4

1

2

1

1

2

2

2

1

1

1

1

1

6

NO. Parts number Description Qty.

NO. Parts number Description Qty.

NOTE:For the 1.5t and 2.0t models

Parts list· Single frame S10/15 Series Semi-electric Pallet Stackers

Parts list· Movable fork assy

2423

1

2

3

4

5

6

7

8

9

10

11

WC02000319

WE03000019

WE07000007

WC02000224

WE07000010

WC02000231

WC02000232

WC02000283

WE07000011

WC02000282

WC02000284

Fork guide plate bracket(1.5t), black

GB893.1,Circlip for hole 52,blackening

GB894.1,Circlip for shaft 25,blackening

Iron wheel

Iron wheel cap

Shaft (830) galvanized

GB894.1,Circlip for shaft 32,blackening

Fork assembly (1150), black

Adjusting screw,galvanized

1

8

4

4

4

4

4

1

2

2

2

Gb77, Hexagon socket set screw with flat point

M12×20,galvanized

GB276,Deep groove ball bearing 6205,

two-side shielded

NO. Parts number Description Qty.

NOTE:For single mast models

Parts list· External frame S10/15 Series Semi-electric Pallet Stackers

25 26

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

WC02000830

WC02000876

WC02000904

WC02000293

WC02000294

WE05000005

WC02000227

WC02000022

WE07000004

WC02000259

WC02000020

WC02000295

WE03000014

WE07000008

WC02000865

WC02000866

WC02000875

WC02000903

WE97000031

WC02000862

WC02000863

WC02000864

WC02000867

WE05000008

External frame,5012(1.5t,2.5m)

External frame,5012(1.5t,3.0m)

External frame,5012(1.5t,3.5m)

Upper guide wheel

Upper guide bracket

Spring lock washer

Iron-core PU wheel

Deep groove ball bearing

Circlip for shaft

Front wheel shaft

Steel ball

Pivot

Hexagon socket head cap screw

Circlip for shaft

Glass baffleⅠ(2.5m/3.0m/3.5m)

Glass baffleⅡ(2.5m)

Glass baffleⅡ(3.0m)

Glass baffleⅡ(3.5m)

Hexagon socket button head screw

Handrail

Fixing screws for handrails

Connecting nuts for handrail

Cylinder coupling

Plain washer

1

1

1

2

2

6

2

4

4

2

1

2

6

2

1

1

1

1

8

2

4

4

1

2

NO. Parts number Description Qty.

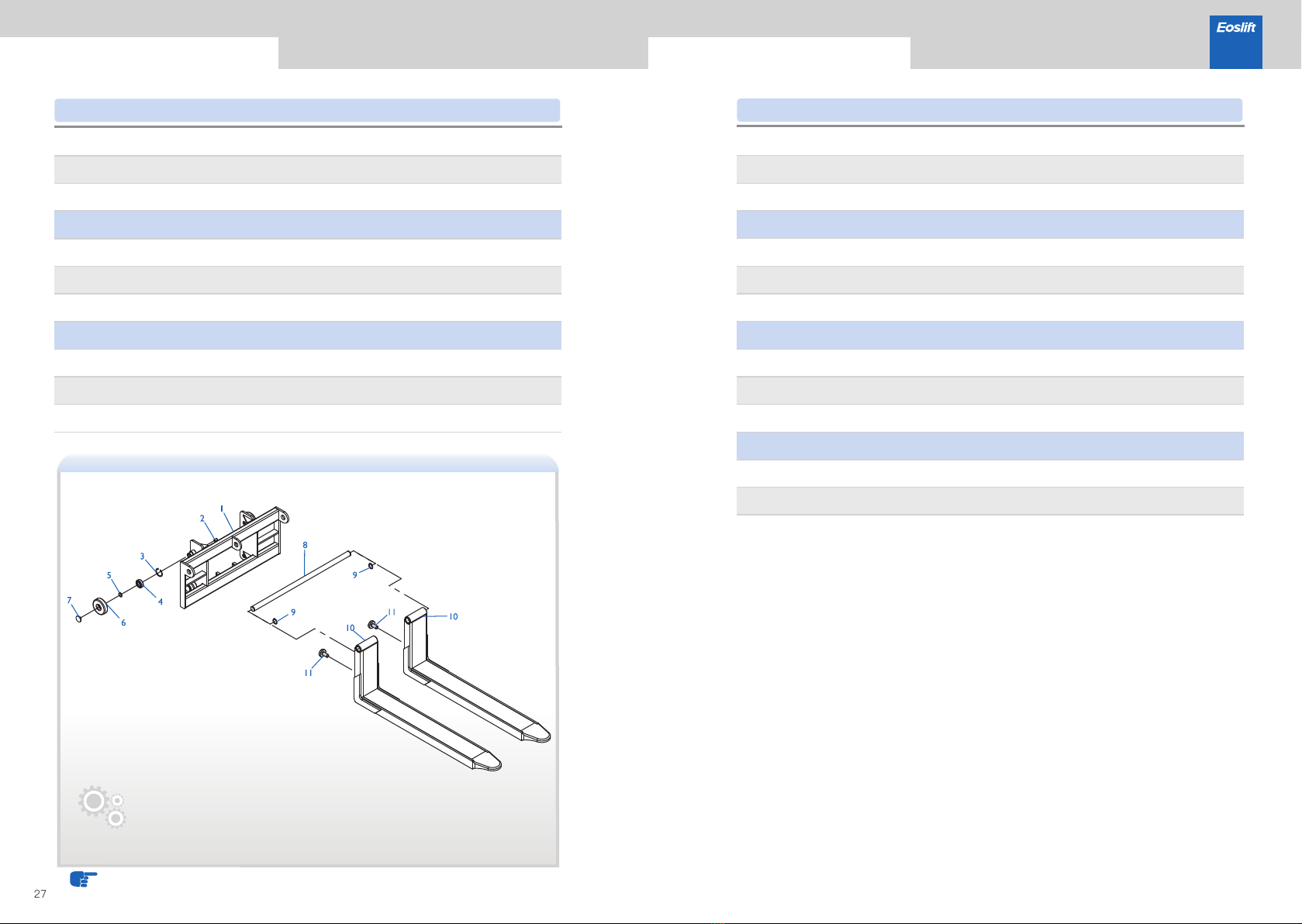

Parts list· Movable fork assy S10/15 Series Semi-electric Pallet Stackers

27 28

1

2

3

4

5

6

7

8

9

10

11

WC02000323

WE03000019

WE07000007

WC02000224

WE07000010

WC02000231

WC02000232

WC02000283

WE07000011

WC02000282

WC02000284

Fork guide plate bracket, black(1.5t/2.0t)

GB893.1,Circlip for hole 52,blackening

GB894.1,Circlip for shaft 25,blackening

Iron wheel

Iron wheel cap

Shaft (830) galvanized

GB894.1,Circlip for shaft 32,blackening

Fork assembly (1150), black

Adjusting screw,galvanized

1

8

4

4

4

4

4

1

2

2

2

1

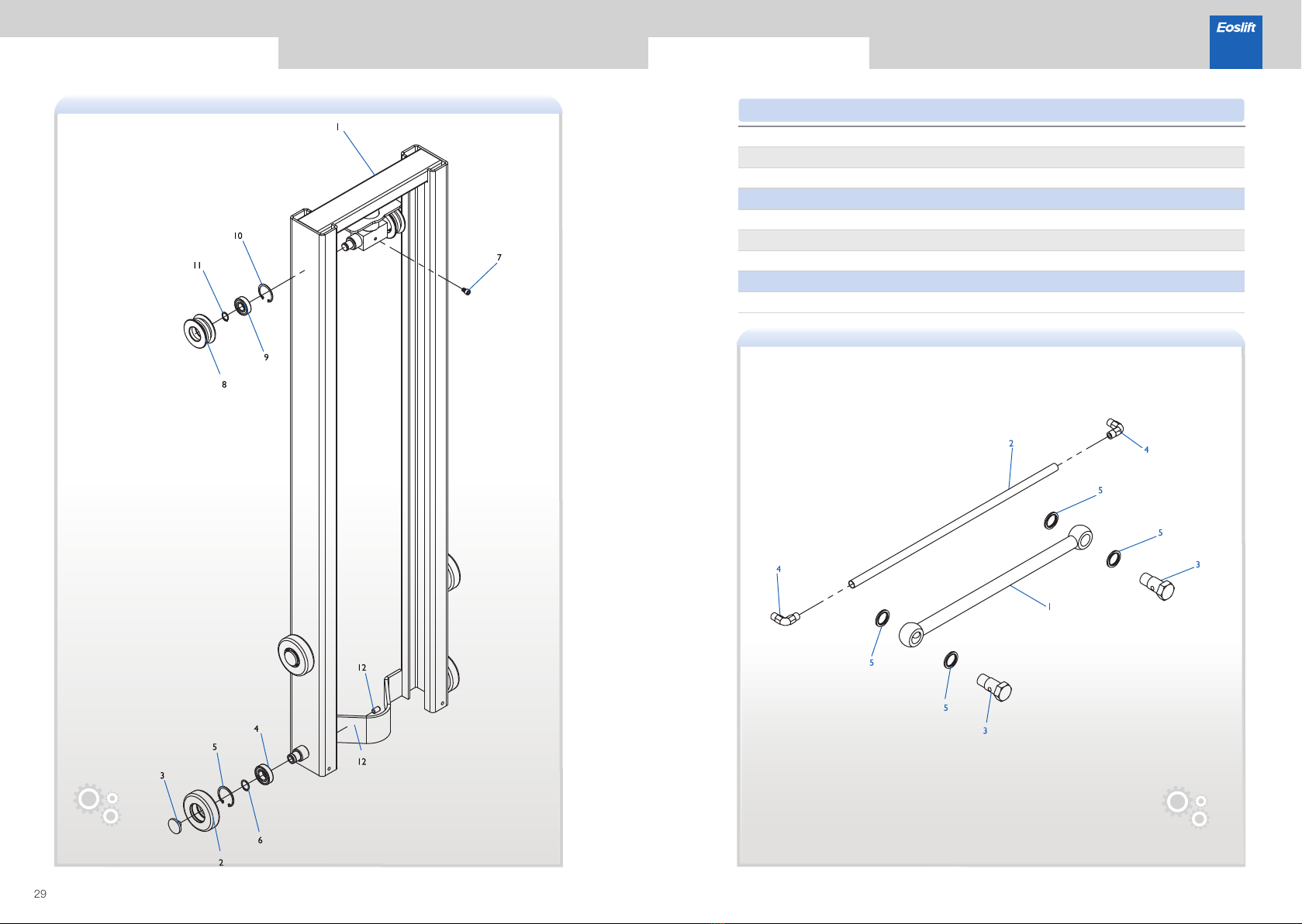

2

3

4

5

6

7

8

9

10

11

12

WC02000812

WC02000874

WC02000902

WC02000231

WC02000232

WC02000224

WE07000007

WE07000010

WE03000017

WC02000261

WC02000022

WE07000006

WE07000004

WE03000019

Internal frame,5012(2.5m)

Internal frame,5012(3.0m)

Internal frame,5012(3.5m)

Iron wheel

Iron wheel cap

Deep groove ball bearing

Circlip for hole

Circlip for shaft

Hexagon socket head cap screw

Sprocket

Deep groove ball bearing

Circlip for hole

Circlip for shaft

Hexagon socket set screw with flat point

1

1

1

4

4

4

4

4

1

2

2

2

2

8

Parts list· Internal frame

Gb77, Hexagon socket set screw with flat point

M12×20,galvanized

GB276,Deep groove ball bearing 6205,

two-side shielded

NO. Parts number Description Qty.

NO. Parts number Description Qty.

NOTE:For double mast models

S10/15 Series Semi-electric Pallet Stackers

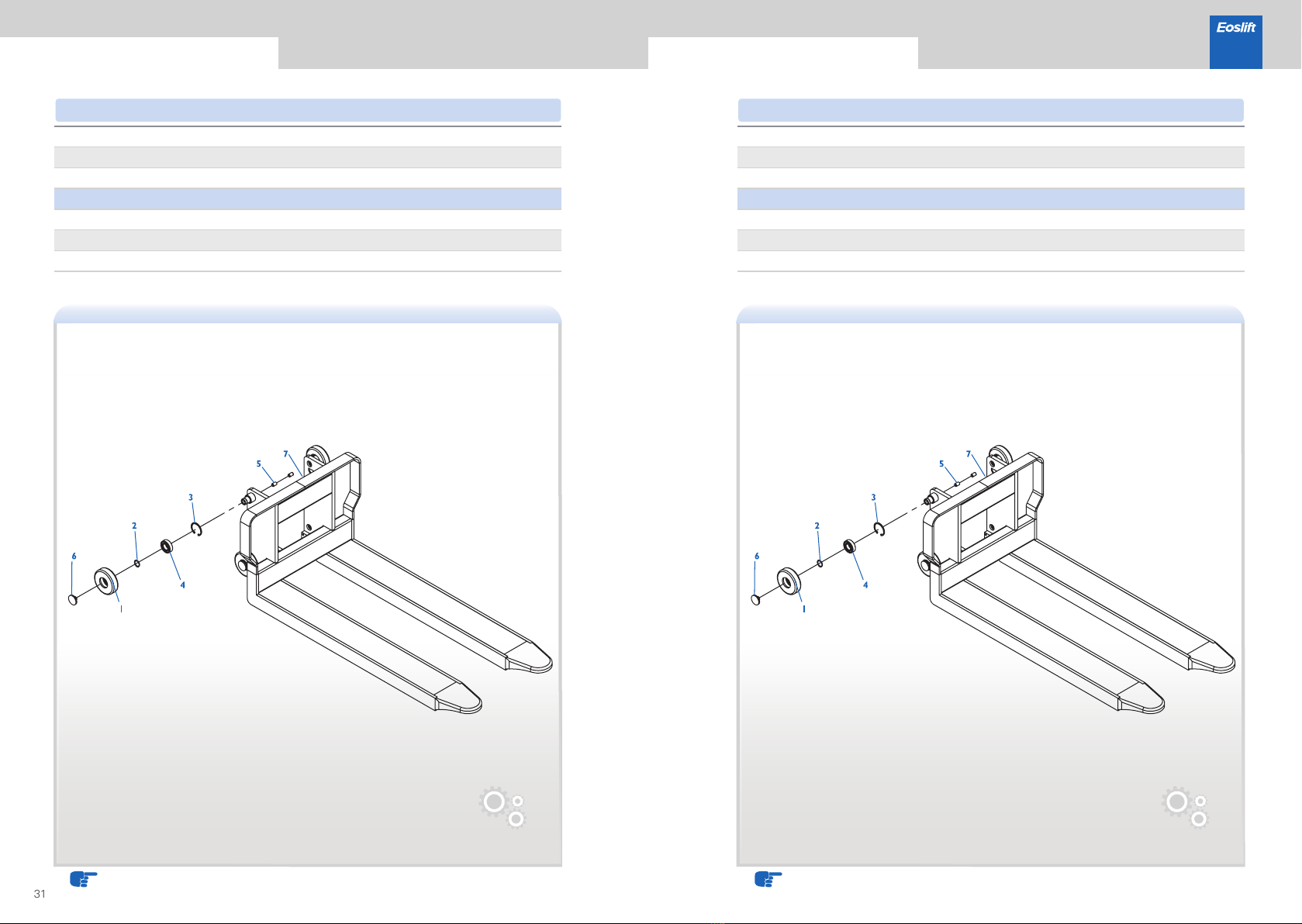

Parts list· Oil pipe

29 30

1

2

3

4

5

WC02000266

WC02000270

WC02000331

WC02000296

WC02000301

WC02000311

WC02000267

WC02000223

WC02000228

High-pressure pipe

Oil return pipe (1.6m)

Oil return pipe (2.0m)

Oil return pipe (2.5m)

Oil return pipe (3.0m)

Oil return pipe (3.5m)

Bolt

Union elbow

GB982, Combination sealing gasket 18

1

1

2

2

4

NO. Parts number Description Qty.

Parts list· Internal frame

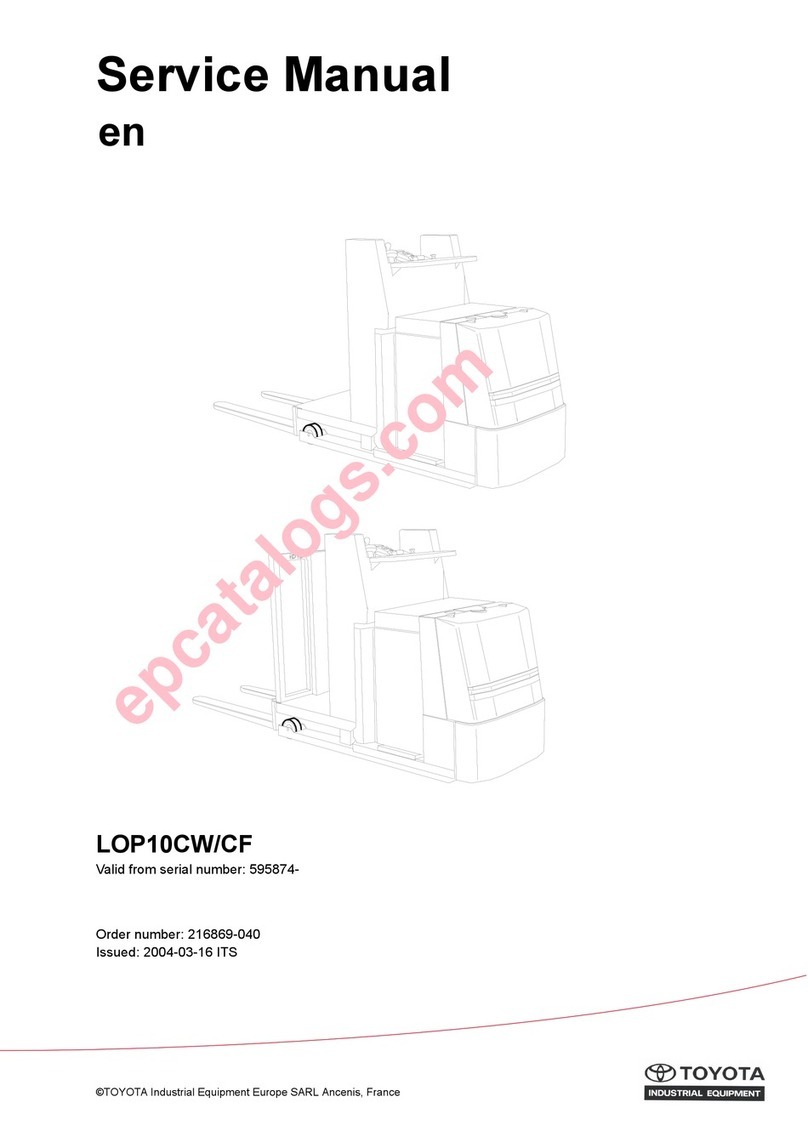

Parts list· Fixed fork assy S10/15 Series Semi-electric Pallet Stackers

Parts list· Fixed fork assy

31 32

1

2

3

4

5

6

7

WC02000231

WE07000010

WE07000007

WC02000224

WE03000019

WC02000232

WC02000900

Iron wheel

Circlip for shaft

Circlip for hole

Deep groove ball bearing

Hexagon socket set screw with flat point

Iron wheel cap

Fork frame welded

4

4

4

4

8

4

1

1

2

3

4

5

6

7

WC02000231

WE07000010

WE07000007

WC02000224

WE03000019

WC02000232

WC02000831

Iron wheel

Circlip for shaft

Circlip for hole

Deep groove ball bearing

Hexagon socket set screw with flat point

Iron wheel cap

Fork frame welded

4

4

4

4

8

4

1

NO. Parts number Description Qty.

NO. Parts number Description Qty.

NOTE:For single mast models NOTE:For double mast models

This manual suits for next models

1

Table of contents

Other Eoslift Forklift manuals

Popular Forklift manuals by other brands

Toyota

Toyota LOP10CW Service manual

Hyster

Hyster A244 Service & repair manual

Simon, Evers & Co

Simon, Evers & Co EZ2515 manual

Jungheinrich

Jungheinrich DFG 425s operating instructions

Clarke

Clarke strong-arm CFT5B Operation & maintenance instructions

cascade corporation

cascade corporation 782008-R3 Operator's guide