Eoslift S15J User manual

BEFORE YOU BEGIN

Welcome to use our electric stacker. Your stacker is made of high quality steel and SPED mast and was

designed to give a durable, reliable and easy to use product. For your safety and correct operation, please

carefully read this instruction book and warnings on the stacker before using it.This Operation Instruction of

the stacker is edited for you to completely acquire and master the safety operation of the stacker.

All of the information reported herein is based on data available at the moment of printing. We reserve the

right to modify our own products at any moment without notice and incurring in any sanction. So, it is

suggested to always verify possible updates.

Operating Instructions

S15J

Semi-Electric Stacker

S15J

Eoslift Automation Technology Corp.

No.99, Yanjia Road, Yuantong Town, Haiyan, Zhejiang

6

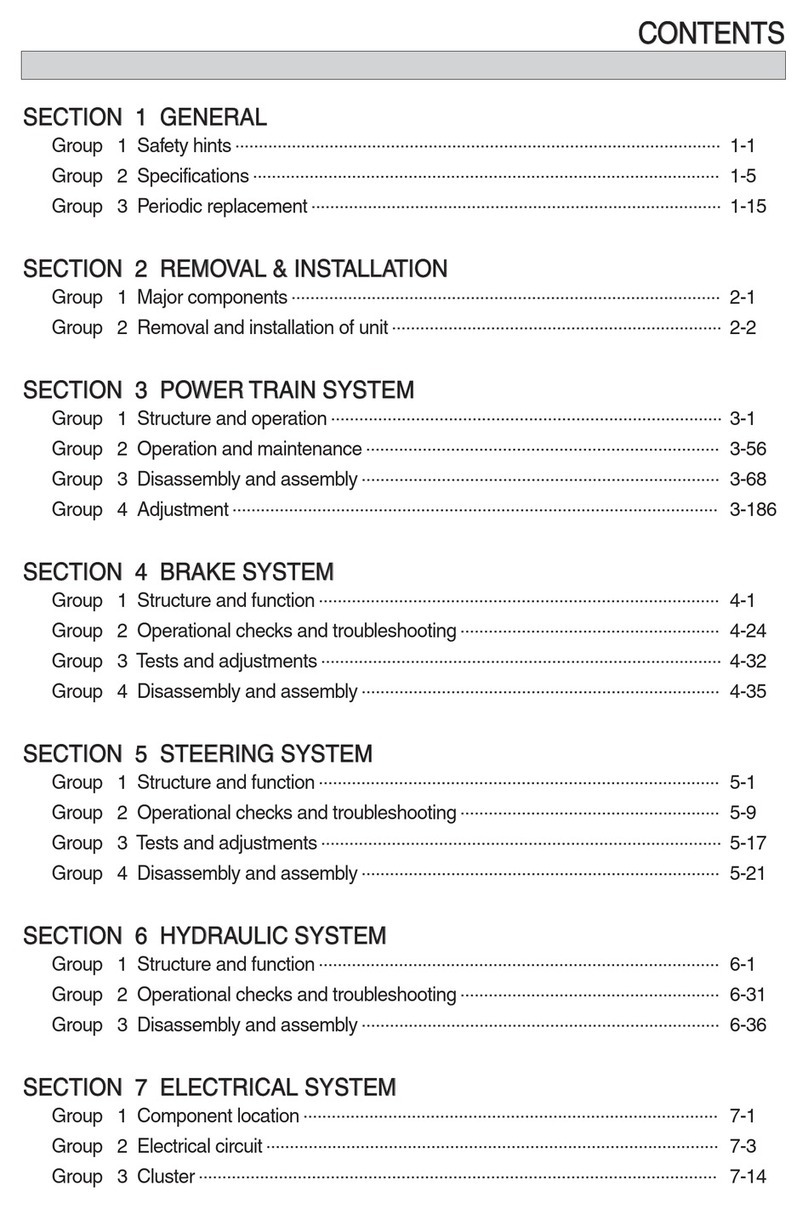

1 Technical Specifications

2 Installation & Adjustment

3 Safety Guidance

4 Maintenance

5 Battery Power System

6 Battery Charging

7 Control Panel

8 Transportation, Loading, Commission & Storage

9 Trouble Shooting

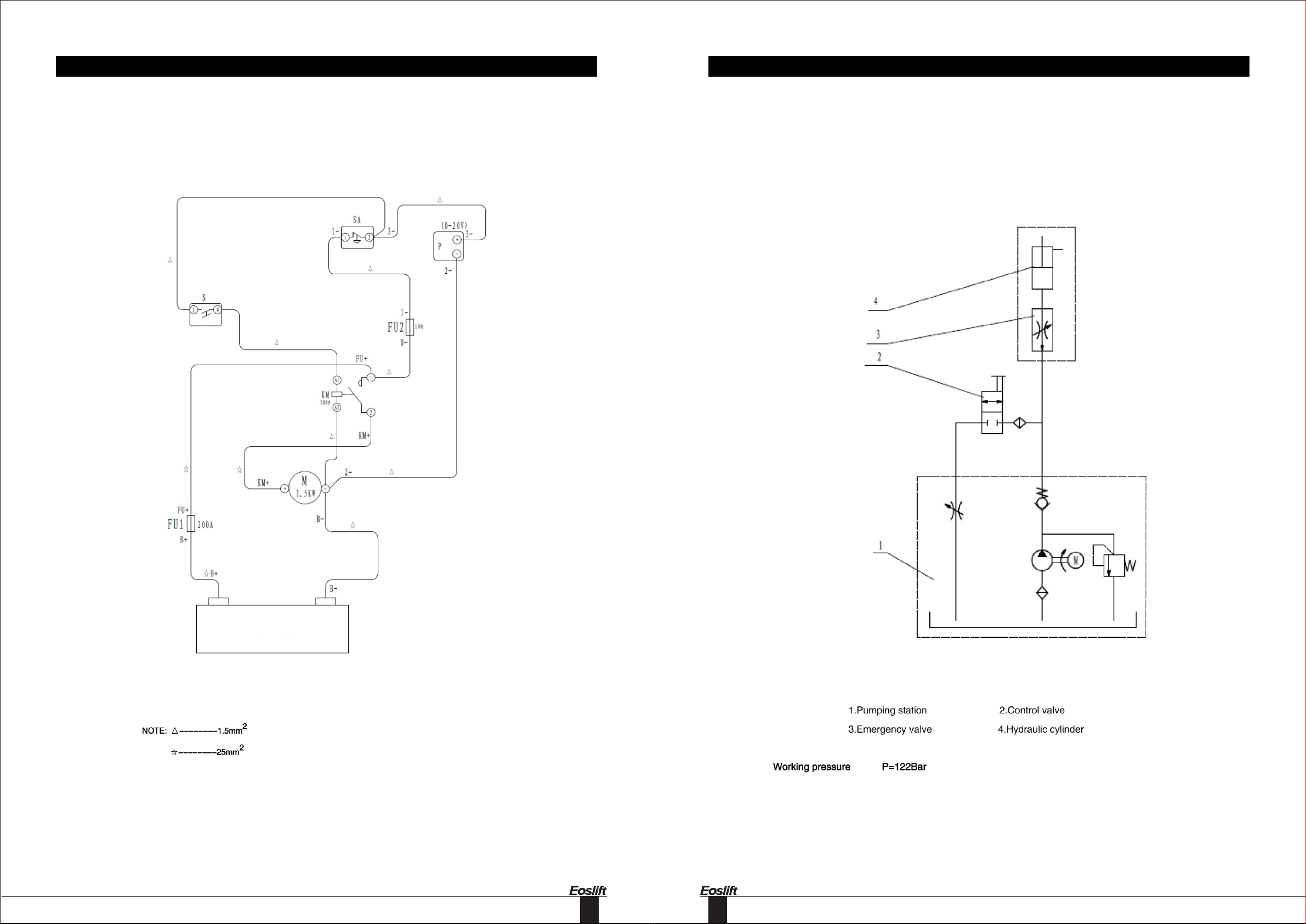

10 Electric Wires Diagram

11 Hydraulic Flow Diagram

12 Parts List

1.1 Technical Specifications

KJ(Door frame)

1

Page 1

Page 3

Page 4

Page 4

Page 5

Page 5

Page 5

Page 6

Page 7

Page 8

Page 9

Page 10

CONTENTS

Model

Manufacture

Load Capacity

Inner Width of Legs

Outer Width of Legs

Min.Fork Height

Lift Height

Min.Mast Height

Fork Length

Fork Width

Fork Thickness

Fork Ajustable

Load wheels

Steer wheels

Overall Length

Turning Radius

Battery

Lifting Motor

Charger Output

lb

B1(in)

B2(in)

H1(in)

H(in)

H2(in)

L(in)

W(in)

T(in)

B3(in)

in

in

L1(in)

R(in)

V/AH

V/Kw

V/A

S15J

EOSLIFT

3300

33-49

41-57

1.4

118

80

42

3.9

1.4

8.3-33

φ

φ7.1x2

70

57

12V/160AH

12V/1.6Kw

12V/20A

2.8×2.8

23

1.2 Residual Capacity at different load centre with Lift height 118in.

2. Installation & Adjustment

2.1 Adjust the screws on the mast guard to removing and re-attaching it. The screws are always remaining

on the guard.

2.2 Use of the removable load backrest extension: during operation of the truck, if lift height exceeds 1.8 m,

it is suggested that an extension backrest should be added for the lifting part. The manufacturing and

installation of backrest should be completed by professional personnel specialized in industrial vehicle.

With regard to detailed requirements, you should contact the manufacturer.

KJ(Door frame)

3000

2500

2000

1500

1000

500

18

Load Centre(in.)

24 30 36 42 48

Capacity

(LB)

4000

3500

Raisde to 118 in.

C

Capacity Chart

45

3. Safety Guidance

3.1 Operator should read all warning signs and instructions here and on the stacker before using it.

3.2 Do not operate a stacker unless you are familiar with it and have been trained or authorized to do so.

3.3 Do not operate a stacker unless you have checked its condition. Give special attention to the chain, the

wheels, the handle, the guide frame, the pilot wheel, the mast, battery, etc.

3.4 Do not use on a slopping ground or on a barbaric or explosive danger environment.

3.5 Do not take up any people on the forks.

3.6 When forks lifting, forbid anyone to stand under the forks or pass through the forks.

3.7 The operator had better take on safety shoes and gloves for labor protecting against crushing and

shearing hazards. Keep feet out from underneath load.

3.8 Do not move the stacker when the goods are lifted to the height more than 300mm.

3.9 When the goods have been transported or lifted, all people should be away from the forks for 600mm.

3.10 The weight of goods should be distributed on the two forks, do not use only one fork. The center of

gravity of goods should be in the center of two forks.

3.11 Do not load over maximum capacity according to the capacity diagram. Heavy load should not be

allowed to remain on the forks for a long time after operation is over.

3.12 Before using or charging it, check cell liquid, if not enough, full it with distilled water.

3.13 Charging should be in dry and ventilated location, and far away from the fire.

3.14 Keeping the forks in the lowest position if not using.

3.15 Do not use the truck when traveling on lorries.

3.16 Do not use the truck in a potentially explosive atmosphere.

3.17 Do not use the truck as a vehicle jack.

3.18 Do not use under wind forces.

3.19 Do not use the truck on places insufficiently illuminated.

3.20 Do not use the truck with guarding removed.

3.21 Stackers should be parked on a smooth place, keep power off, lower the forks to the min. height, and

press on the brake. Stackers should not be parked in the unsafe area such as busy streets, intersections,

narrow roads, blind curves, slopes, soft ground, place around the

inflammable, fire fighting access.

3.22 At other special condition or place, the operator should be carefully to operate the stacker.

3.23 Unauthorized truck modification is not permitted. No modifications or alterations to a powered

industrial truck, which may affect, for example, capacity, stability or safety requirements of the truck,

shall be made without the prior written approval of the original truck manufacturer, its authorized

representative, or a successor thereof. This includes changes affecting, for example braking, steering,

visibility and the addition of removable attachments. When the manufacturer or its successor approve a

modification or alteration, they shall also make and approve appropriate changes to capacity plate,

decals, tags and operation and maintenance handbooks. Only in the event that the truck manufacturer is

no longer in business and there is no successor in the interest to the business, the user may arrange for

a modification or alteration to a powered industrial truck, provided, however, that the user shall:

a) Arrange for the modification or alteration to be designed, tested and implemented by an engineer(s)

expert in industrial trucks and their safety.

b) Maintain a permanent record of the design, test(s) and implementation of the modification or alteration.

c) Approve and make appropriate changes to the capacity plate(s), decals, tags and instruction handbook.

d) Affix a permanent and readily visible label to the truck stating the manner in which the truck has been

modified or altered together with the date of the modification or alteration, and the name and address of

the organization that accomplished the tasks.

4.1 Hydraulic oil

Please check the oil level every six months. The oil can be hydraulic oil: ISO VG32, its viscosity should

be 32cSt at 40℃, total volume is about 4.0lt. use temperature -20oC~50 oC

Replace the hydraulic oil (every 12 months).

4.2 Daily check and maintenance

It is necessary to check the stacker daily. Special attention should be paid to the wheels, the axles, as

thread, rags, etc., it may block the wheels, the fork and the mast, the chain, the battery should be

checked, too. The forks should be unloaded and lowered in the lowest position when the job is over.

4.3 Lubrication

Use motor oil or grease to lubricate all movable parts.

4.4 Maintenance of battery: Keep all the screw caps on each cell battery dry and clean. Each connecting

terminal and cable terminal should be tightened and painted with clean grease. The exposed connecting

terminal and connecting rod of battery should be covered with anti-slip insulated cover.

4.5 Recharge the battery fully and carry out usual battery maintenance. Charge the battery every third

month and check the fluid level.

4.6 Change the wheels

Put the unladen stacker on a smooth place, keep power off, lower the forks to the min. height. Keep the

wheels off the ground, take off the elastic retaining ring on one side of the wheel axle, take out the

wheel, put in the new wheel, and put back the elastic retaining ring.

4. Maintenance

5. Battery Power System

5.1 12V/120AH lead-acid storage battery is used in this series stacker.

5.2 The storage battery should be put in the special anti-spilling case which should be fixed with bolts.

5.3 The storage battery cannot be overturned during the process of installing and moving in case the acid

liquor spills out.

5.4 Keep power off when the stacker is not in use.

5.5 Please use the assorted charger or charger with same specifications, and follow Article 6 to charge the

battery.

6. Battery Charging

6.1 Charge storage battery when its voltage is less than 10 Volt.

6.2 Please check the battery liquid before charging, if it is not enough, add some distilled water.

6.3 The charging environment should be ventilated and far away from the fire.

6.4 If the stacker not use for long time, charge it for not less than two hours every week.

6.5 The voltage on the indicator should not be over 15 Volt when charging.

6.6 Do not use the stacker when charging.

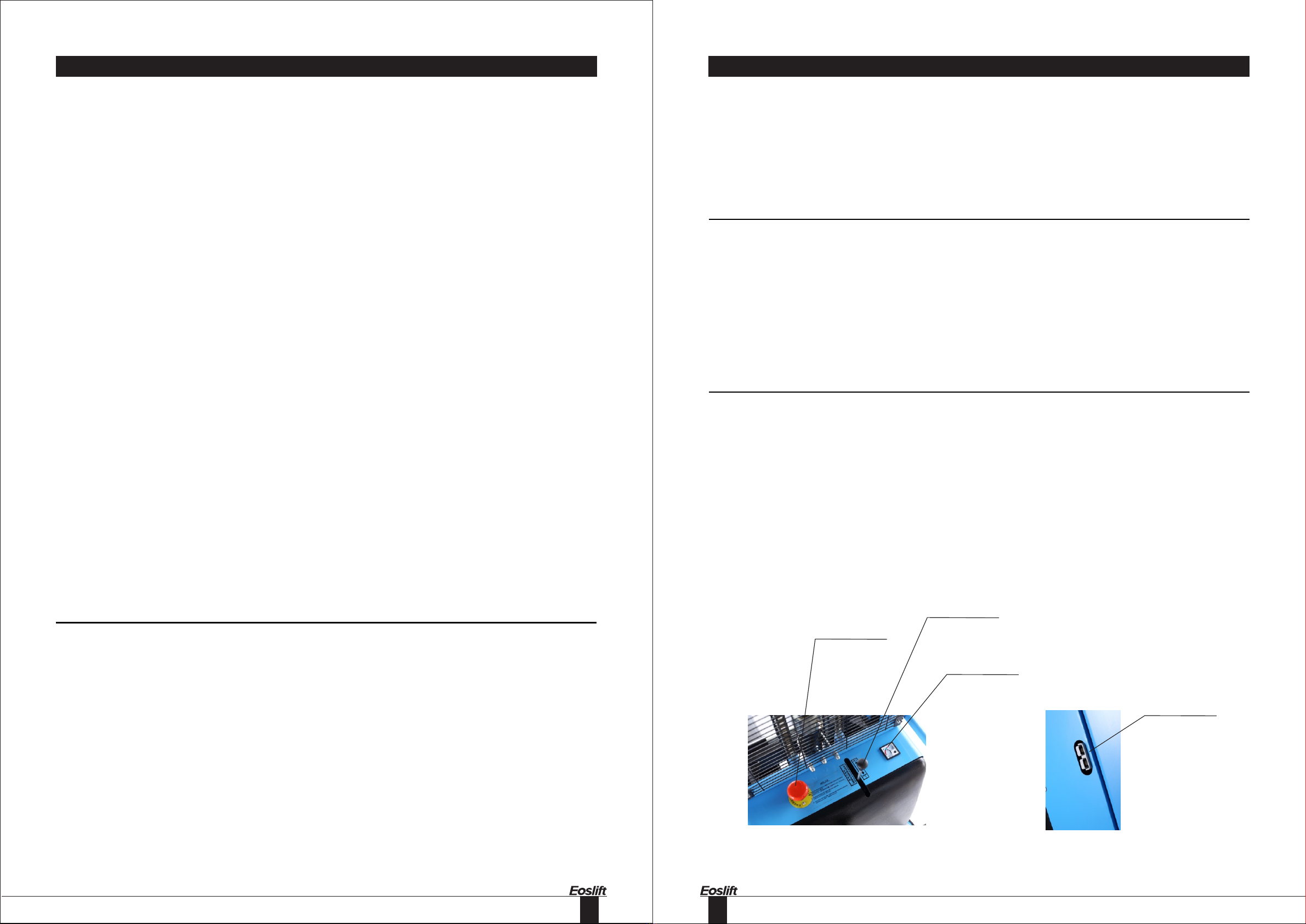

7. Control Panel

7.1 Emergency Stop

When you press down this switch, it will switch off the power, and then you turn it clockwise, it will switch on

the power.

7.2 Battery indicator

It indicates the voltage of battery. When its voltage is less than 10 Volt, you should not use this stacker, you

must charge it.

7.3 Control stick

This stick controls the forks to lower or lift. Push forward to make the motor start. Push backward and down

to make the pressure released and the oil return to tank.

7.4 Charger socket

Charger socket

battery charge

indicator

emergency stop

&on/off switch

raise /lower lever

67

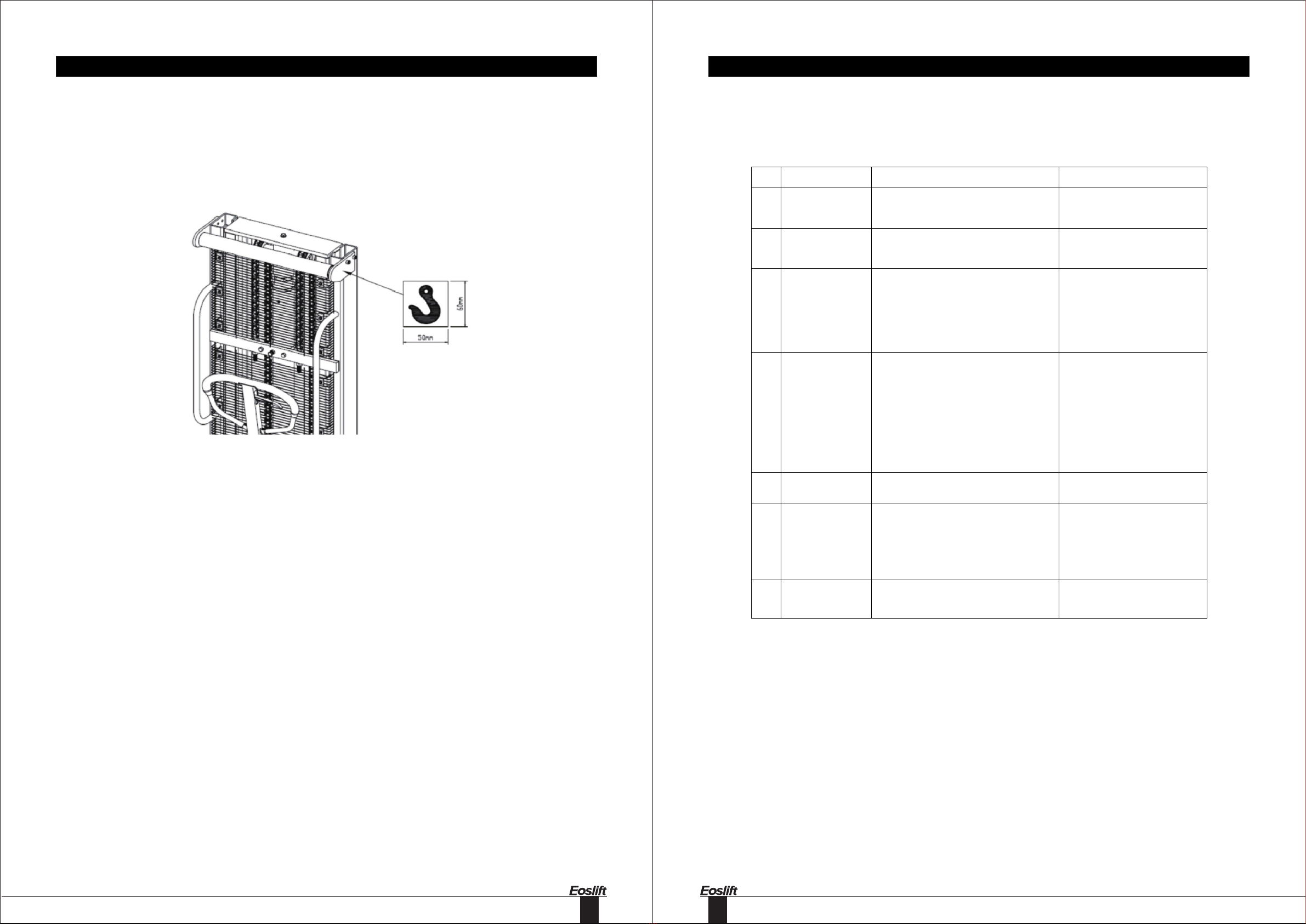

8. Transportation, Loading, Commissioning And Storage

If the truck has to be transported for a long distance, it should be packed in the container in order to avoid

collision during transportation.

8.1 The truck is packed properly in a container and transported by hoisting apparatus. Lifting points are on

both sides of the stacker, which are identified as the below picture.

8.2 Before loading, the operator shall make sure the truck weight on the nameplate to choose the suitable

hoisting equipment. When the truck is unloaded, the operator shall look out for safety around to ensure

slow landing of the truck.

8.3 On completion of commissioning, the truck shall be submitted to and verified according to the following

function test: steering, traveling, braking, load handling controls and combined functions with rated

capacity.

8.4 When a truck is inoperative, the load (if applicable) shall be removed with a proper tool and measure, the

truck shall be transported out of the working zone with a proper way.

8.5 When the truck will be shutdown and in storage for a long time, the storage environment shall be kept dry

and clean, fork shall be lowered to its lowest position.

9. Troubles Shooting

NO. Trouble Clause Fixing Methods

1

The forks can not

be up the max.

height.

-The hydraulic oil is not enough. -Pour in the oil.

2

The forks can not

be lifted up.(Motor is

rotary)

-Without hydraulic oil.

-The oil has impurities.

-Fill in the oil.

-Change the oil.

3 The motor cannot

run.

-The urgent switch is pressed down, cut

off the power.

-The voltage is too lower.

-The connectors of electrical wire is

loose.

-The contactor of DC motor is bad.

-Turn it clockwise, switch on the

power

-Charge it.

-Turn it firm.

-Replace with new one.

4 The forks cannot

be descended.

-The piston rod or mast is deformed

resulting from partial loading slanting to

one side or over-loading.

-The fork was kept in the high position for

long time with piston rod bared to arise in

rusting and jamming of the rod.

-The release valve of pump is not

opened.

- Replace with new one.

-Keeping the fork in the lowest

position if not using, and pay

more attention to lubricate the

rod.

-Check it, if damaged, replace

with new one.

5 Leaks -Sealing parts worn or damaged.

-Some part cracked or worn into small.

-Replace with the new one.

-Replace with the new one.

6

The fork descends

without the release

valve worked.

-The impurities in the oi l cause

the release valve to be unable to close

tight.

-Sealing parts worn or damaged.

-The release valve is damaged.

-Replace with new oil.

-Replace with the new one.

-Replace with the new one.

7 Battery cannot be

Charged

-Battery is bad.

-The charging plug is loose.

- Replace with the new one.

- Turn it firm.

89

11. Hydraulic Flow Diagram10. Electric Wires Diagram

Circuit Diagram

GB 12V 160AH

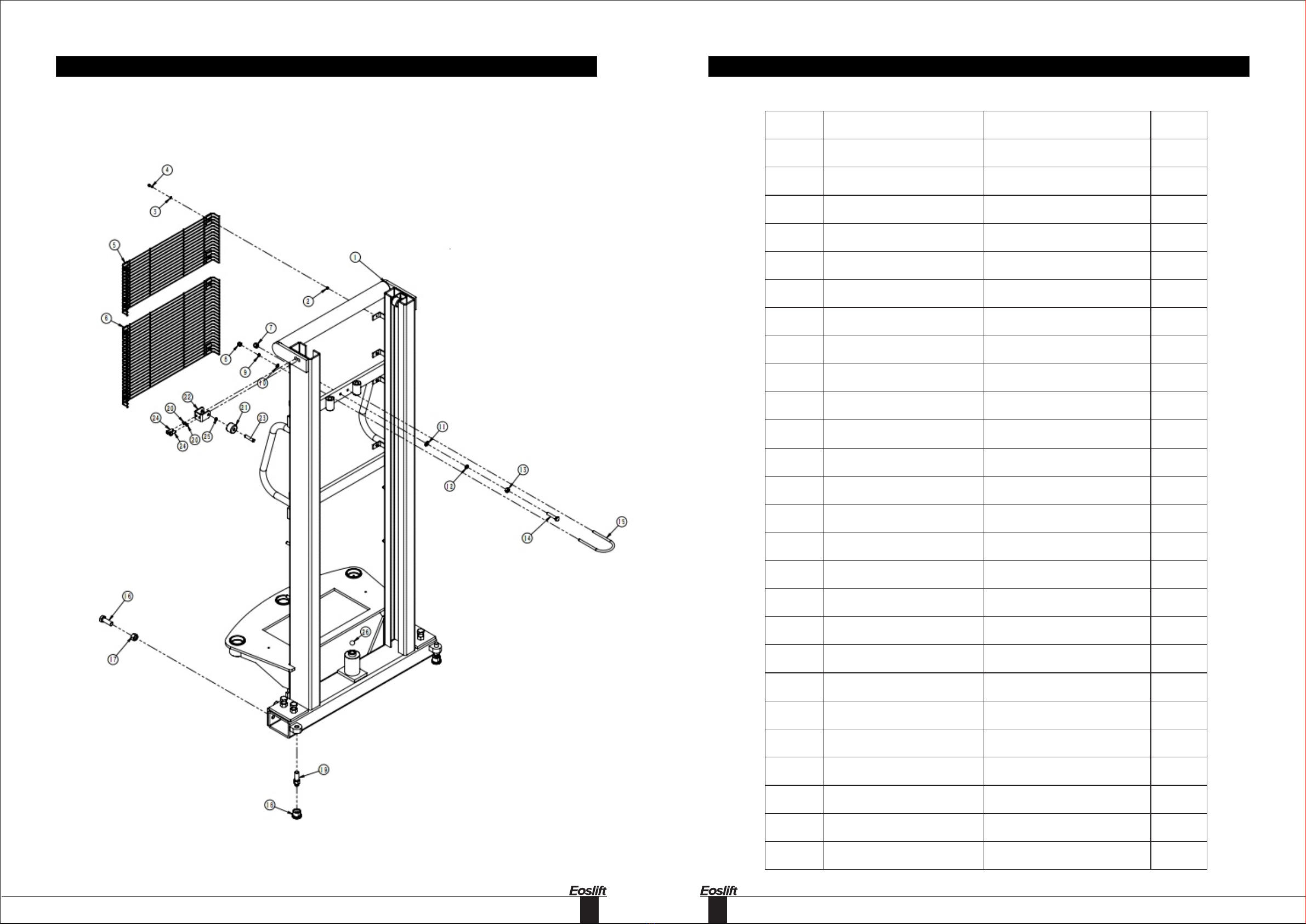

12 Parts List

Universal wheel with brake

1011

No. Stock Number Description Qty.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

WC 02000237

WC02000234

WC02000243

WC02000244

WC02000245

WC02000240

WC02000238

WC02000241

WC02000242

WC02000239

WC02000235

WC02000236

WC02000226

WC02000285

WE05000010

WC02000225

WC02000224

WE03000013

WC02000022

WE03000018

WE05000006

WE04000011

WE 07000009

steering wheel frame with brake,black

steering axle sleeve 1

chain wheel

backing ring

wheel cap

pressure spring

brake plate,galvanized

brake pedal

brak pedal axis

axial view bolts

steering axle sleeve2

key

iron core PU wheelφ180×50,PU red,

iron coreblack

nylon wheelφ180×50(flower shape wheel)

GB95 Plain washer 24,galvanized

GB297,circular cone running pulley

bearing 30205

GB276,deep groove ball bearing6205,

two-side dusty cover

GB2673,Inner hex screw M10×16,

galvanized

GB276,deep groove ball bearing6204,

two-side dusty cover

GB70.1 Hex socket screw M10×100,

galvanized

GB93 Spring washer 12,galvanized

GB6170 Hex nut M12,galvanized

GB894.1 Circlip for Shaft 12,black

1

2

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

2

1

1

1

2

Universal wheel with brake

1213

No. Stock Number Description Qty.

1

2

3

4

5

6

7

8

9

10

11

12

13

WC 02000246

WC02000022

WC02000234

WC02000226

WC02000285

WC02000235

WE03000018

WE05000006

WE04000011

WC02000245

WE05000010

WC02000225

WC02000224

WE 03000013

guide pulley seat,black

GB276,deep groove ball bearing6204,

two-side dusty cover

steering axle sleeve 1

iron core PU wheelφ180×50,PU red,

iron coreblack

nylon wheelφ180×50(flower shape wheel)

steering axle sleeve2

GB70.1 Hex socket screw M10×100,

galvanized

GB93 Spring washer 12,galvanized

GB6170 Hex nut M12,galvanized

wheel cap

GB95 Plain washer 24,galvanized

GB297,circular cone running pulley

bearing 30205

GB276,deep groove ball bearing6205,

two-side dusty cover

GB2673,Inner hex screw M10×16,

galvanized

1

2

1

1

1

1

1

1

1

1

1

1

2

Universal wheel without brake Universal wheel without brake

14 15

No. Stock Number Description Qty.

1

2

3

4

5

6

7

8

9

10

11

12

13

WC 02000252

WC02000248

WE07000008

WC02000249

WC02000247

WC02000242

WC02000251

WC02000250

WE07000009

WC02000224

WC02000244

WC02000243

WC02000236

WE05000010

WE 04000016

handle assembly

gas spring

GB894.1 Circlip for Shaft 10,black

axle 2,galvanized

handle seat,black

brak pedal axis

axle 3,galvanized

axle sleeve,galvanized

GB894.1 Circlip for Shaft 12,black

GB276,deep groove ball bearing6205,

two-side dusty cover

backing ring

chain wheel

key

GB95 Plain washer 24,galvanized

GB889.1 Hex lock nut M18,galvanized

1

1

1

2

2

2

1

1

1

1

14

1

15

1

4

1

1

Handle assembly

Handle assembly

16 17

No. Stock Number Description Qty.

1

2

3

4

5

6

7

8

9

10

11

12

13

WC 02000253

WC02000269

WC04000022

WC04000020

WC04000013

WE03000006

WC01000014

WE03000015

WE03000004

WE05000002

WE05000009

WE03000001

WC04000011

WC02000254

WE01000003

WE05000003

WE05000007

WE04000017

WC02000255

WC02000268

WC 01000044

Electrical Cabinet,5012

hydraulic pumpDC12160 12V 160KW

fuse connect seat RQD-1 220V 800A

The abrupt stop switch ZJK250A

nstrument JY-99 20V

GB818 Screw M5×12,galvanized

charger socket line

GB70.1 Hex socket screw M6×25,

galvanized

GB70.1 Hex socket screw M10×25,

galvanized

GB93 Spring washer 10,galvanized

GB95 Plain washer 10,galvanized

GB70.1 Hex socket screw M6×16,

galvanized

CNL300 chip fuse

cover,black

GB5781 Hex bolt M6×35,galvanized

GB95 Plain washer 6,galvanized

GB96.1 Washer 6,galvanized

GB889.1 Hex lock nut M6,galvanized

battery box(120),black

Uniform dosing batteryN120Ah

Charger CZC7-20A/12V

(American standard)

1

1

1

1

1

8

1

2

2

2

2

2

1

1

2

4

6

4

1

1

1

14

15

16

17

18

19

20

21

Motor Box Motor Box

18 19

Parts List for SPN1016G

No. Stock Number Description Qty.

1

2

3

4

5

6

7

8

9

10

11

12

13

WC 01000017

WC02000303

WC02000275

WC02000272

WC02000304

WC02000274

WC02000273

WC02000279

WE05000011

WE04000018

WC02000278

WC02000276

WC02000280

WC 02000277

Black cylinder assembly

oil cylinderseaming part,black

guide sleeve

hood,galvanized

piston rod

gasket,galvanized

piston

GB3452.1,O-ringφ26.2×2.4

GB93 Spring washer 24,galvanized

GB6171 Hex nut M24×1.5,galvanized

ZS50 guild ring 50×55×14.8

DH45 dusty ring 45×53×6.5

UHS45 seal ring45×56×7

GB3452.1,O-ringφ50.8×3.1

1

1

1

1

1

1

1

2

1

1

1

1

1

1

14

Cylinder assembly

Cylinder assembly

20 21

No. Stock Number Description Qty.

1

2

3

4

5

WC 02000219

WC02000263

WC02000262

WC02000265

WC 02000220

chain

screw(right)

screw sleeve

screw(left)

single row running pulley chain CL

contact 08A-1

2

2

2

2

4

No. Stock Number Description Qty.

1

2

3

4

5

WC 02000325

WJ11900012

WJ11900006

WJ11900005

WJ11900004

WJ11900003

WJ11900002

WJ11900001

WJ 11900015

Leaf chain

Leaf chain

LH1223 Long end joint

Spherical nut

GB6171,nut M14×1.5×12.8

GB91,Cotter pin 2×16

GB91,Cotter pin 2×32

GB91,Cotter pin 3.2×32

The chain pin shaft

2

2

2

2

6

7

2

8

9

2

4

2

2

Chain Plate link chain

22 23

No. Stock Number Description Qty.

1

2

3

4

5

WC 02000299

WE07000006

WC02000022

WE07000004

WC02000317

WE03000019

WE07000007

WC02000224

WE07000010

WC02000231

WC02000232

WD01000211

WE03000020

WE 03000017

inner mast,5012

GB893.1 Cieclip for hole 47,black

GB276,deep groove ball bearing6204,

two-side dusty cover

GB894.1 Circlip for Shaft 20,black

chain wheel(Leaf chain)

Gb77 Hexagon flat set screw M12×20,

galvanized

GB893.1 Cieclip for hole 52,black

GB276,deep groove ball bearing6205,

two-side dusty cover

GB894.1 Circlip for Shaft 25,black

steel wheel

steel wheel cap

down support pole

GB70.1 Hex socket screw M10×12,

galvanized

GB70.1 Hex socket screw M8×12,

galvanized

1

2

2

2

2

8

4

4

4

4

4

1

2

1

6

7

8

9

10

11

12

13

14

Mast assy - outer

Mast assy - outer

24 25

No. Stock Number Description Qty.

1

2

3

4

WC 02000266

WC02000301

WC02000267

WC02000223

WC 02000228

fuel injection pipe

oil return pipe

bolt

rectangular connector

GB982,sseal washer 18

5

1

1

2

2

4

No. Stock Number Description Qty.

1

2

3

WC 02000713

WC02000712

WC02000022

WE07000004

WC02000227

WC02000286

WC 02000259

The right fork leg welded,5012

The left fork leg welded,5012

deep groove ball bearing6204

Circlip for Shaft 20,black

iron corePU wheel φ70×70,PU red

nylon wheelφ70×70

steering wheel axle

4

1

4

4

2

2

5

Oil tube Front wheel assembly

26 27

No. Stock Number Description Qty.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

WC 02000832

WE04000005

WE05000004

WE03000016

WC02000292

WC02000302

WE04000013

WE04000014

WE05000005

WE05000008

WE05000009

WE05000002

WE04000009

WE01000002

WC02000264

WE01000006

WE04000022

WC02000710

WC02000709

WE05000005

WC02000293

WC02000294

WC02000295

WE03000014

WE07000008

WC 02000020

outer mast,5012

GB6170 Hex nut M5,galvanized

GB95 Plain washer 5,galvanized

GB70.1 Hex socket screw M5×16,

galvanized

gauze pad,black

gauze pad,black

GB802 Cap Nut M10,galvanized

GB802 Cap Nut M8,galvanized

GB93 Spring washer 8,galvanized

GB95 Plain washer 8,galvanized

GB95 Plain washer 10,galvanized

GB93 Spring washer 10,galvanized

GB6170 Hex nut M10,galvanized

GB5781 Hex bolt M10×50,galvanized

locking ring

GB5783 Hex bolt M16×40,galvanized

GB6170 Hex nut M16,galvanized

Support shaft Ⅱ,galvanized

Support shaft I,galvanized

GB93 Spring washer 8,galvanized

top guild wheel

top guild plate,galvanized

pin roll

GB70.1 Hex socket screw M8×20,

galvanized

GB894.1 Circlip for Shaft 10,black

GB308,steel ball S18

1

8

8

8

1

1

1

2

2

2

1

1

1

1

1

8

8

2

2

2

2

2

2

4

2

1

Mast assy - inner

Mast assy - inner

28

No. Stock Number Description Qty.

1

2

3

4

5

6

7

8

9

10

11

WC 02000323

WC02000283

WC02000284

WC02000711

WE07000011

WE03000019

WC02000232

WC02000231

WC02000224

WE07000007

WE 07000010

fork guide plate,black

axle (830),galvanized

adjustable bolt,galvanized

telescope-feed fork,black

GB894.1 Circlip for Shaft 32,black

Gb77 Hexagon flat set screw M12×20,

galvanized

steel wheel cap

steel wheel

GB276,deep groove ball bearing6205,

two-side dusty cover

GB893.1 Cieclip for hole 52,black

GB894.1 Circlip for Shaft 25,black

1

1

2

2

2

4

4

4

4

4

4

Forks

Table of contents

Other Eoslift Forklift manuals