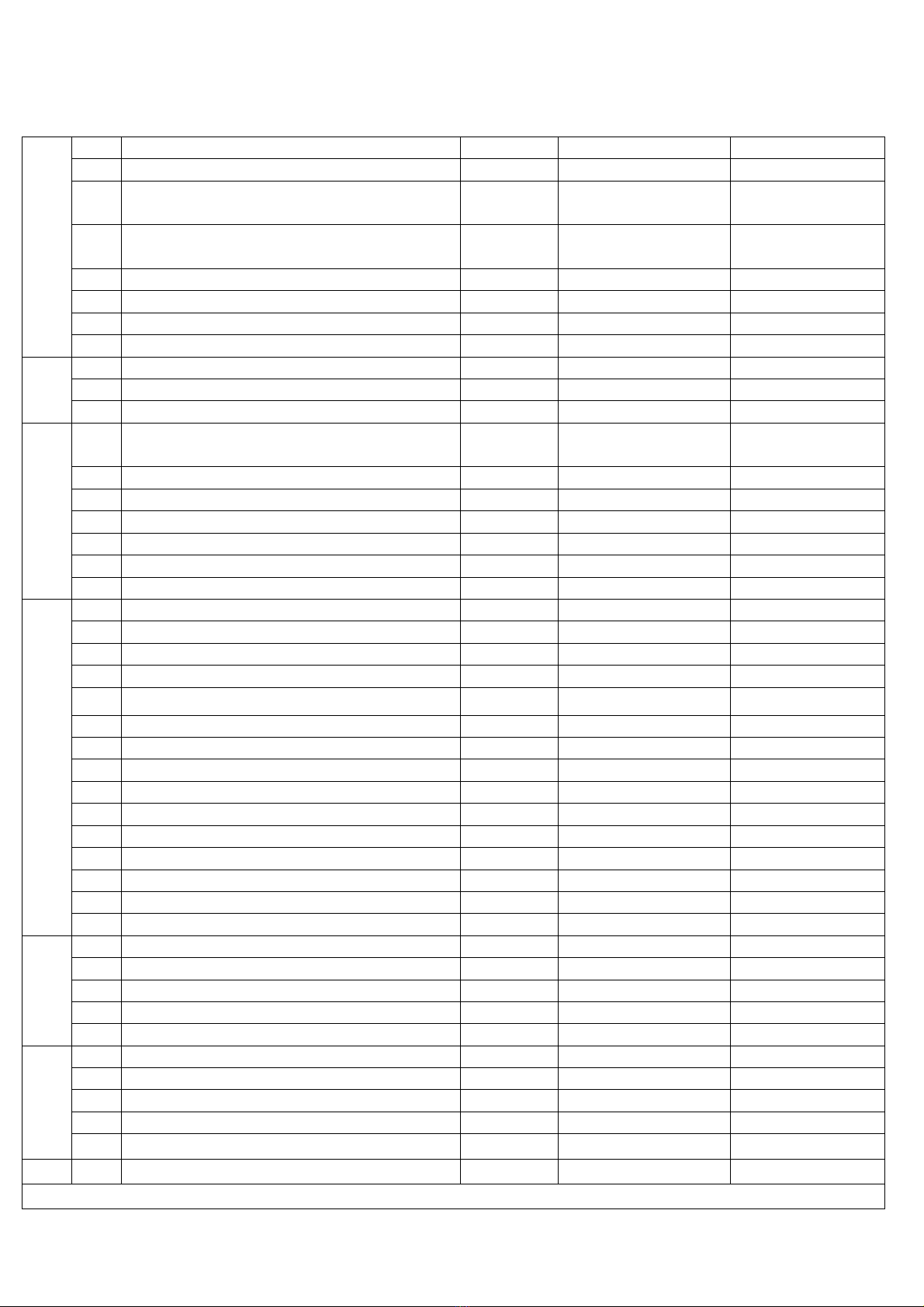

4

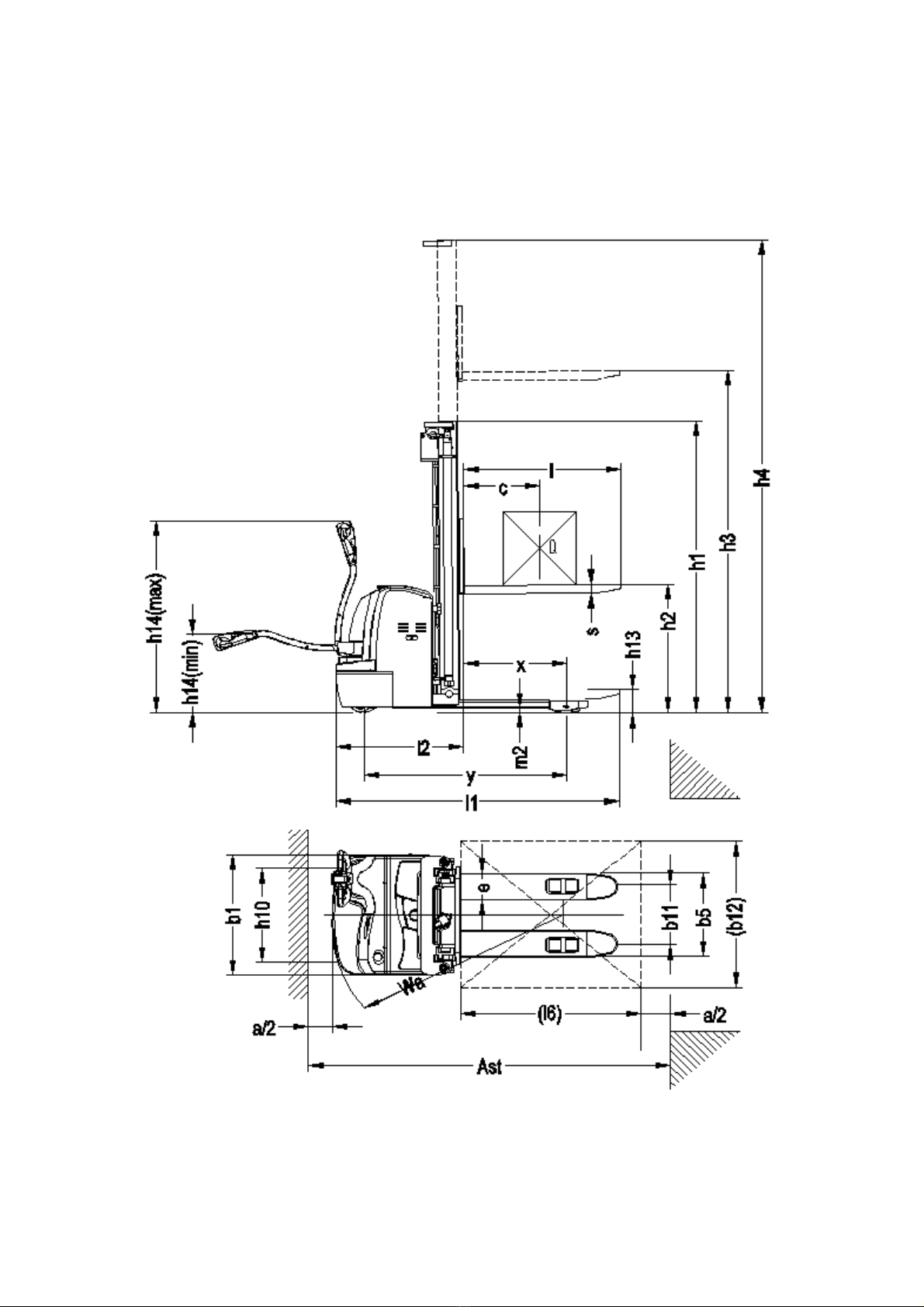

1.2 Main technical parameters(

((

(CDDR Electric Pallet Stacker)

))

)

Characteristics

1.1 Manufacturer(abbreviated) Ningbo Ru i Ningbo Ru i

1.2 Model CDDR10-I(high standard) CDDR10-II(standard)

1.3 Driving model:Electric(Storage batter ),

Electric(storage batter ) Electric(storage batter )

1.4 Driving model(Manual, Walking, Stand driving, Seat

)

walking walking

1.5 Rated load Q(kg) 1000 1000

1.6 Load center distance

c

(mm)

600 600

1.8 Front overhang

x

(mm)

697 697

1.9 Tread

Y

(mm)

1383 1383

Weight

2.1 Service weight(with batter ) kg 1220/1245/1260/1270 1160/1185/1200/1210

2.2 Axle load, front/rear, laden kg 1470/1310 1440/1280

2.3 Axle load, front/rear, unladen kg 900/380 870/350

Wheel chassis

3.1 Wheels (rubber, high elasticit , pneumatic t re,

pol urethane pol urethane

3.2 Wheel dimension, front φ250×70 φ250×70

3.3 Wheel dimension, rear φ80×84 φ80×84

3.4 Additional wheel(dimension) φ150×60 φ150×60

3.5 Wheel number, front/rear (x = driving wheel) 1x+1/4 1x+1/4

3.6 Tread, front

b

10

(mm)

520 520

3.7 Tread, rear

b

11

(mm)

404/525 404/525

Dimension

4.2 Height of mast, lowered

h

1

(mm)

1735/1985/2135/2235 1735/1985/2135/2235

4.3 Free lift height( optional)

h

2

(mm)

1300/1550/1700/1800 1300/1550/1700/1800

4.4 Lift height

h

3

(mm)

2500/3000/3300/3500 2500/3000/3300/3500

4.5 Max. height of mast, extended

h

4

(mm)

2955/3455/3755/3955 2955/3455/3755/3955

4.9

Min. /Max. height of operation handle, in driving position

h

14

(mm)

670/1300 670/1300

4.15 Height, lowered

h

13

(mm)

90 90

4.19 Overall length

l

1

(mm)

1950 1950

4.20 Length to fork face

l

2

(mm)

878 878

4.21 Overall width of truck bod

b

1

(mm)

820 820

4.22 Fork dimension s/e/l(mm) 60/180/1070(1150) 60/180/1070(1150)

4.25 Overall width of fork

b

5

(mm)

570/695 570/695

4.32 Wheelbase ground distance

m

2

(mm)

31 31

4.33 Aisle width, with pallet 1000x1200 crosswise

A

st

(mm)

2450 2450

4.34 Aisle width, with pallet 800x1200 lengthwise

A

st

(mm)

2420 2420

4.35 Turning radius

W

a

(mm)

1575 1575

Performance

Data

5.1 Traveling speed, laden/unladen Km/h 5.8/6 5.8/6

5.2 Lifting speed, laden/unladen m/s 0--0.12/0--0.19 0.11/0.20

5.3 Descending speed, laden/ unladen m/s 0--0.35/0--0.12 0.12/0.12

5.8 Max. gradeabilit , laden/unladen % 8/15 6/10

5.10 Traveling brake Electromagnetic brake Electromagnetic brake

Motor

6.1 Driving motor power kW 1.6(AC) 1.2(AC)

6.2 Lifting motor power kW 3 3

6.4 Batter voltage/rated capacit V/Ah 24/240 24/200

6.5 Batter weight kg 240 200

Batter dimension(LXWXH) mm 675×254×500 675×254×500

8.4 Noise level at operator’s ear, according to DIN12053 dB(A) 65 65

1.Parameters relating to h1、l、Q shall be calculated according to h1=3000mm and l=1070mm.