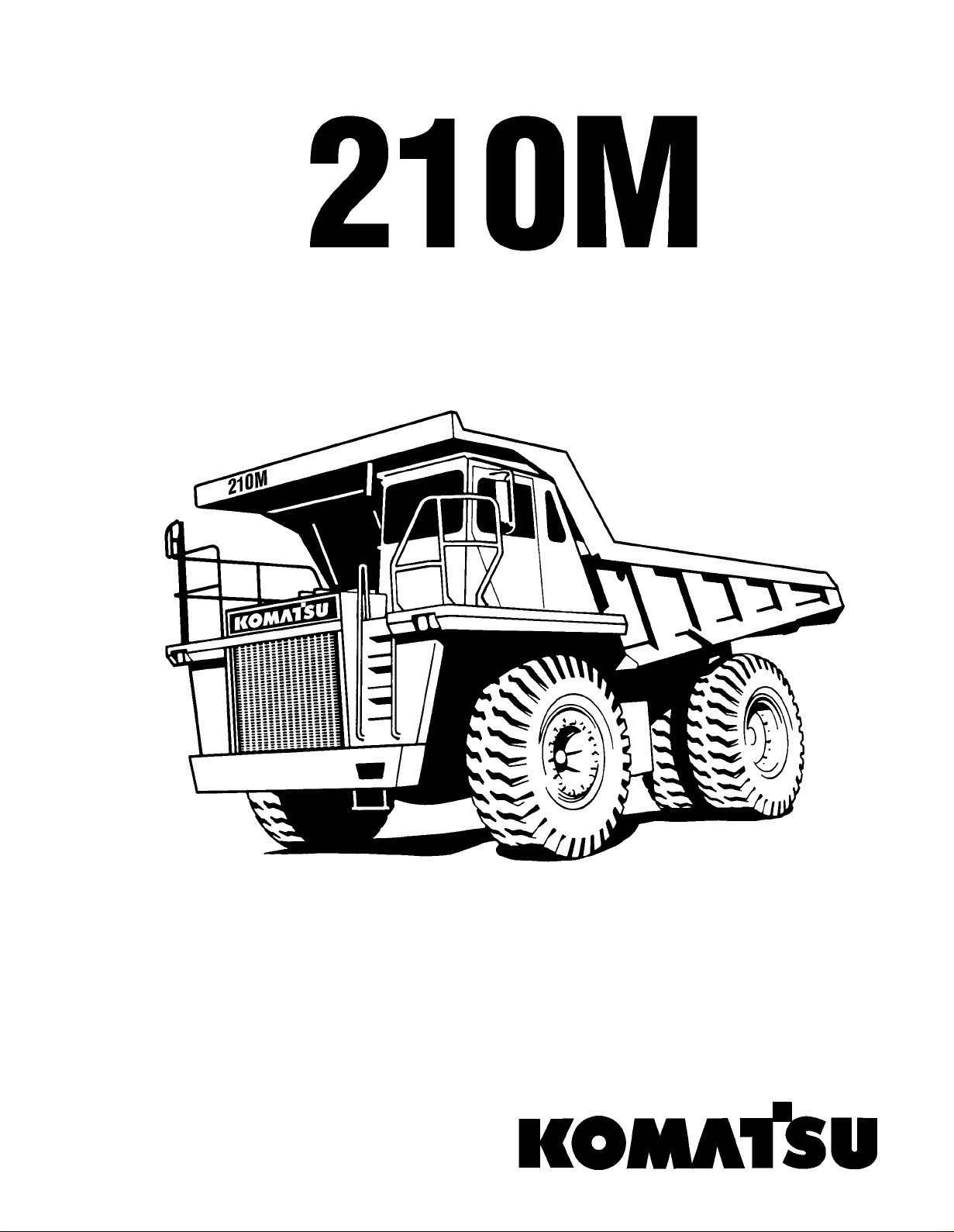

COMPONENT DESCRIPTION AND SPECIFICATIONS

ENGINE

The 210M HAULPAK®Truck is powered by

a Cummins KTTA--19C diesel engine. It is

capableofspeedsup to 35MPH(56.7km/h).

TRANSMISSION

The diesel engine drives a remote-mounted

Allison CLT-6063 transmission incorporating

a TC683 torque converter. The transmission

has six "Forward" speeds and two "Reverse"

speeds and uses Allison Transmission Elec-

tronicControl(ATEC)forcompleteautomatic

shift sequencing.

The operator may select "R1" or "R2" for

Reverse, "N" for Neutral, or any one of the six

Forward driving ranges by using the Trans-

mission Range Selector. Each position (R2,

R1, N, D, 5, 4, 3, 2, 1) is selected by releasing

a range locking mechanism on the lever and

choosing the desired range. "D" will permit

completely automatic up and down shifts

through all six ranges. "5" will limit upshifts to

5th range only. "4" will limit upshifts to 4th

range only. "3" will limit upshifts to 3rd range

only. "2" will limit upshifts to 2nd range only.

"1" is a first range hold position and no up-

shifts are permitted.

"R1"or "R2"REVERSE position is used to

back the truck. "R1"position should be used

for normal reverse operation. This range se-

lection utilizes the standard 5.12:1 gear re-

duction ratio. "R2"position may be used for

job operations that would benefit from a

higher speed reverse operation. This range

selection utilizes a 3.43:1 gear reduction ra-

tio.

FINAL DRIVE

The Planetary Final Drive has full floating axle

shaftsandaplug-indifferentialcarrierassem-

bly.

SERVICE BRAKE SYSTEM

The service brakes are controlled by an all

hydraulic actuation system. Depressing the

service brake pedal actuates front dry disc

brakes and rear wet disc brakes.

Automatic Emergency Braking is provided if

system pressure falls below a preset value.

All functioning wheel brakes will be automat-

ically applied by accumulators.

DYNAMIC RETARDING

Dynamic retarding is actuated by depressing

the operator’s retarder pedal which applies

oil-cooled, rear mounted, wet disc brakes

only; the front brakes are not applied.

Application of the retarder pedal may be fully

modulated and should be used to slow the

truck during normal truck operation, to con-

trol speed coming down a grade or to make

non-emergency stops. Use of the retarder

pedal saves wear on the front brakes and

provides better steering control.

POWER STEERING

The HAULPAK®Truck is equipped with an

orbital power steering system mounted un-

der the cab floor with noise and vibration

isolators. An accumulator automatically pro-

vides emergency power to safely steer the

truck while stopping.

INSTRUMENTS

The cab instrument panel displays for the

operator all switches and gauges which are

necessary to safely control the truck and

monitor the truck’s operating systems.

SUSPENSION

HYDRAIR®IIsuspensioncylinderslocatedat

each wheel provide a smooth and comfort-

able ride for the operator and dampens

shock loads to the chassis during loading.

HB1042 Component Description and Specifications HB1-1