Eoslift M Series User manual

M Series

Operating Instructions

Hand

Pallet

Truck

Eoslift Automation Technology Corp.

No.99 Yanjia Road, Yuantong Town, Haiyan,

Zhejiang Province China 314317

Tel:+86 573 8622 9999

Fax: +86 573 8622 2900

info@eoslift.com

www.eoslift.com

Esteemed users:

For proper and safe operation of the products, before

using the products, be sure to read the operating

instructions carefully and retain them properly for

future reference.

The operator need to have proficient operation skills.

The operator has responsibility to carefully understand

the performance and safety rules of the pallet truck.

If you have any problemes during the application, please

contact Eoslift.

M Series Hand Pallet Trucks

Ⅰ.Technical parameters

01

Ⅱ. Safety rules 03

Ⅲ.Installation of handles 04

Ⅳ.Adjusting the finger grip handle

05

Table of contents

Ⅵ.Transportion, loading, test and storage

07

Ⅶ.Troubles shooting 08

Ⅷ.Parts list

Ⅴ.Maintenance

06

10

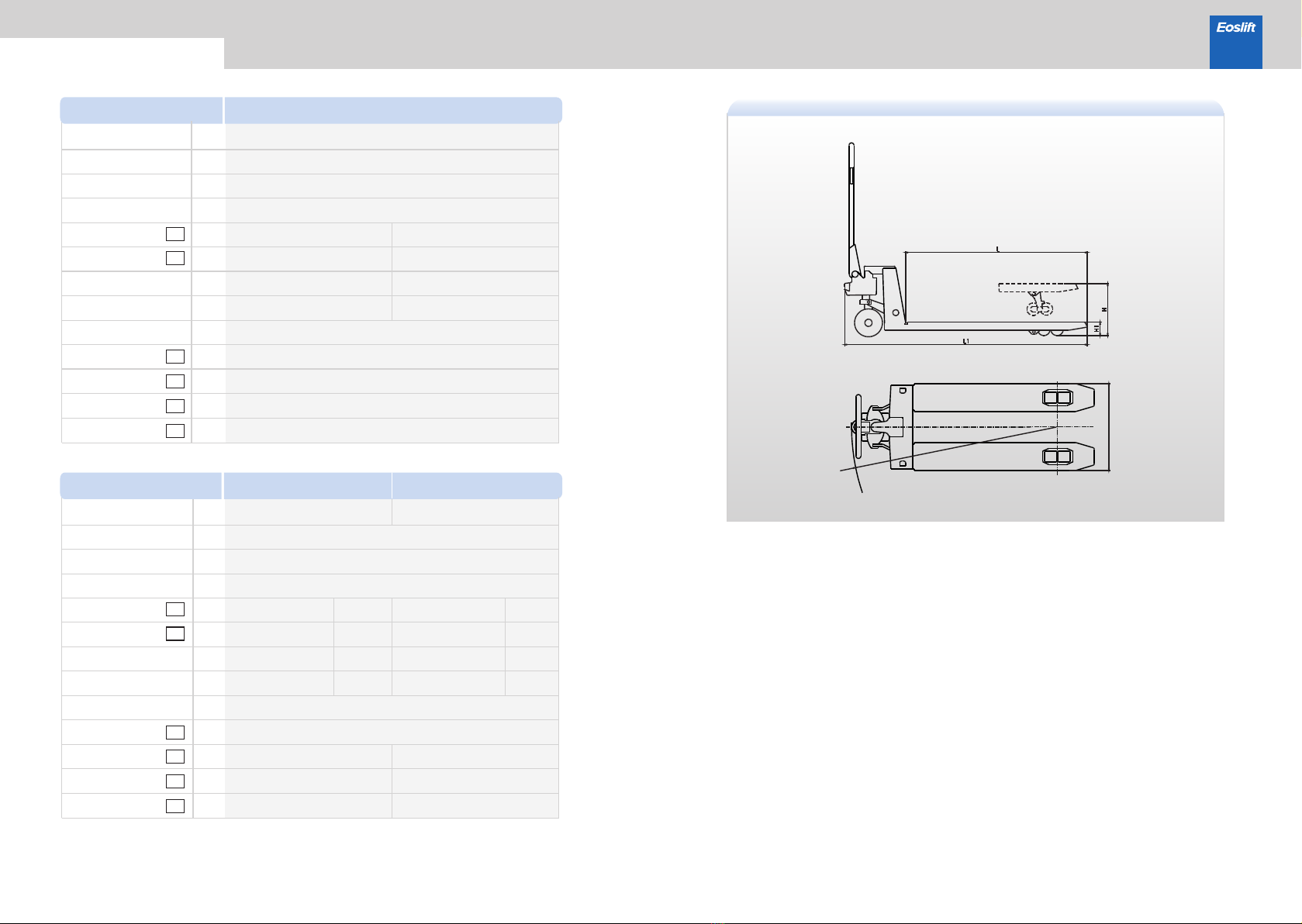

M Series Hand Pallet Trucks

01 02

M20/M25/M30/M20Q/M25Q/M30Q/M20Z/M25Z/M30Z

Rated capacity

Load center

Service weight

Wheel

Max. lift height

Min. fork height

Steer wheel

Load wheel

Single Load wheel

Fork width

Fork length

Overall length

Turning radius

M20L/M25L

Rated capacity

Load center

Service weight

Wheel

Max. lift height

Min. fork height

Steer wheel

Load wheel

Single Load wheel

Fork width

Fork length

Overall length

Turning radius

kg

mm

kg

mm

mm

mm

mm

mm

mm

mm

mm

mm

H

H1

B

L

L1

R

M30L

kg

mm

kg

mm

mm

mm

mm

mm

mm

mm

mm

mm

H

H1

B

L

L1

R

Technical parameters

Model

2000/2500/3000

600

72-79

PU/NYLON/RUBBER

200 190

85 75

Φ200x50/Φ180x50

Φ80x70

Φ74x93

540/685

1150/1220

1580/1650

1325/1395

Φ180x50

Φ74x70

Model

2000/2500

600

72-85

PU/NYLON/RUBBER

200 190

85 75

Φ200x50/Φ180x50

Φ80x70

Φ74x93

540/685

1500/1800/2000/2500

1930/2230/2430/2930

1675/1975/2175/2675

Φ180x50

Φ74x70

3000

200 190

85 75

Φ200x50/Φ180x50

Φ80x70

Φ180x50

Φ74x70

1500/1800/2000

1930/2230/2430

1675/1975/2175

B

R

M Series Hand Pallet Trucks

03 04

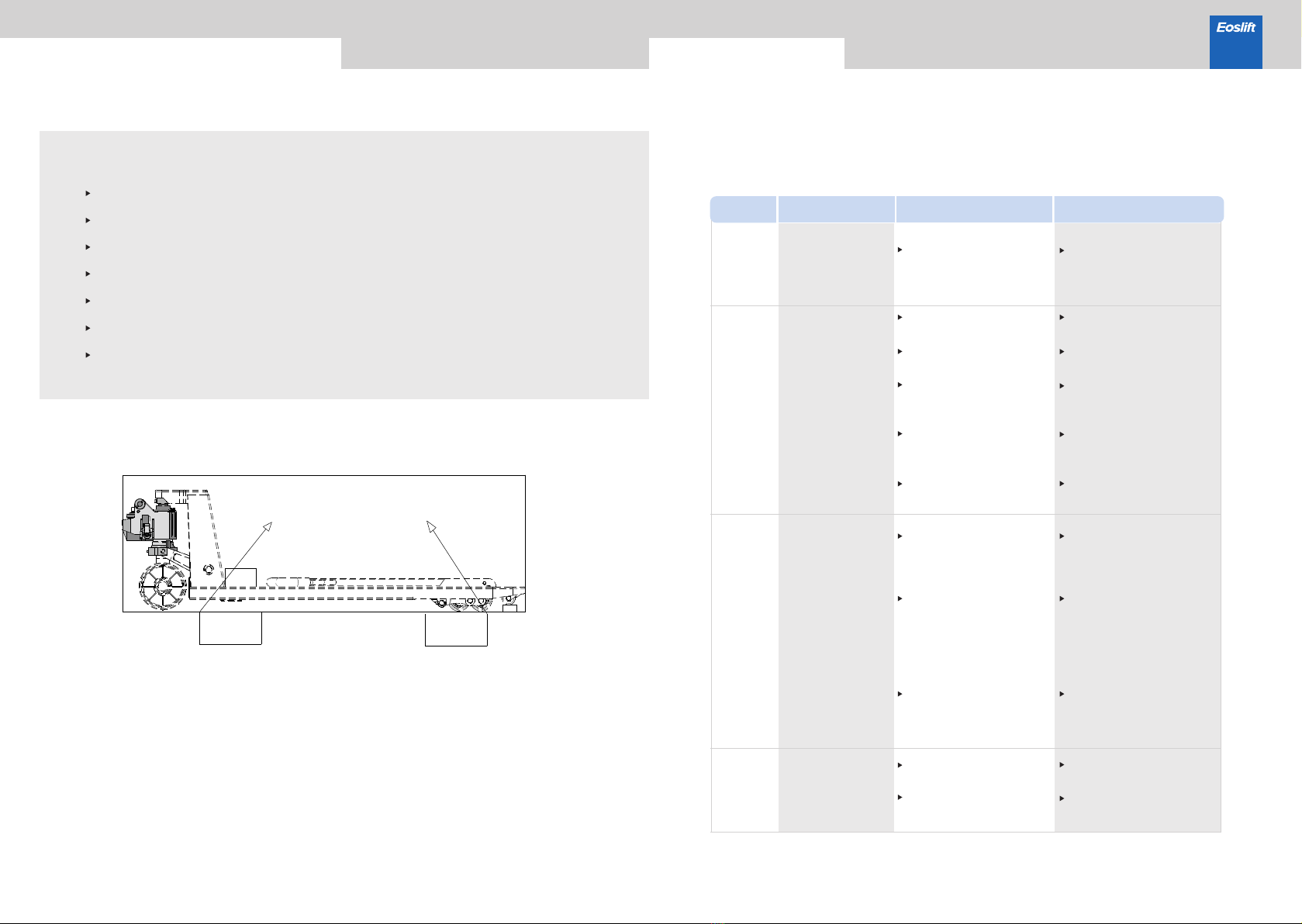

1.Make sure the chain on the handle

is in this position shown in the picture.

2.Push the handle shaft through the

holes, fix it with the spring pin.

3.Put the chain through the hole on the shaft. With the handle at 45º tilt.

4.Fix the chain in the slot of the

unloading plate.

5.Pull the shaft from the hole. Then

the assembly is complete.

Installation of handles

Safety rules

The truck is only applicable to indoor use and the application environment must meet the following conditions:

Free from rainwater or corrosion of harmful gases;

Room temperature of -20°C~+40°C;

Relative ambient humidity <90%;

and Requirements for ground: hard, anti-skid and level without barriers.

Before using the pallet truck, the operator must read the operating instructions and the warning labels on the

truck body carefully.

Do not use this truck on the muddy ground.

Do not operate the pallet truck unless you are fully familiar with it and have been authorized to do so.

Do not operate the pallet truck unless you have carefully checked its condition. Pay special attention to the

wheels, the handle assemblies, the truck frame, the unloading plate, etc.

To pull the truck, always move the finger grip control handle into the middle position. This makes the handle

easier to move and reduces the rebounce of the handle by the small piston. This also preserves the hydraulic

seals and the piston components. A long service life can be expected.

Do not carry or lift passengers.

The operator shall wear safety shoes and gloves for protection.

While the goods are being transported, all people should stay 600mm away from the truck frame.

Do not lift goods in the way as shown in Figure B. Goods should be stacked stably.

Overload is prohibited.

Do not use the truck in a potentially flammable and explosive atmosphere.

Do not use the truck as a vehicle jack.

Do not use the truck during strong wind forces.

Do not use the truck on places insufficiently illuminated.

A B

M Series Hand Pallet Trucks

05 06

1.Hydraulic oil

Please check the oil level every six months and change the oil every twelve months. 32 #

hydraulic oil is recommended, with total volume of about 0.5 liters.

2.Remove the air

The air may enter into the pump because of transportation or pump in upset position. It will cause

the forks fail to be lifted when the finger grip control handle switched to the lifting position. The

air can be removed in the following way: pull the finger grip control handle (1-1) to the lowering

position and move handle up and down for several times.

3.Daily check and maintenance

Daily check and maintenance of the pallet truck can limit wear as much as possible. Special

attention should be paid to the wheels, the axles, as thread, rags, etc.To avoid block the wheels

and axles. The forks should be unloaded and lowered in the lowest position when the job is over.

4.Lubrication

All bearings and pivots are provided with long-life lubricants at the factory. You just need to fill the

lubrication points with long-life lubricants monthly intervals or after each time the truck is cleaned

thoroughly.

1The truck should be parked with the forks lowered to min. height.

2Check if the signs and warning labels on the truck are in place before using the truck each time.

3Use original parts.

4 The waste liquid shall be place in special collection places for disposal.

5 Modifications or alterations to the truck, especially the safety device are prohibited.

6Only customer service persons specially trained by our company can carry out maintenance

of the truck.

7Thoroughly standardized maintenance is the most important preconditions to ensure stable

and reliable operation performance of the truck. Neglect of regular maintenance could result

in failure and malfunction of the truck and poses a potential threat to the safety of the staff and

operation.

Maintenance

1

2

3

1-1

Upper

Middle

Lower

2-3

2-4

2-6

On the handle of this pallet truck, you can find finger grip control handle(1-1) which can be regulated in

three positions :

Lifting-set the control handle at lower position. When lift up the hand pallet truck.

Middle position: set the control handle at middle position. When the operator need to move it.

Lowering: set the control handle at upper position. When lift down the hand pallet truck.

The handle moves back to the middle position when released

However if the truck cannot operate normally as above the three positions, you can adjust them according to the

following steps:

① If the forks elevate while pumping in the Middle position, adjust the adjusting nut (2-4) on the adjusting bolt

(2-3) or screw (2-6) clockwise until pumping action does not raise the forks and the finger grip control handle

works properly Middle position .

② If the forks descend while pumping in the Middle position, the screw(2-6) or nut(2-6) counteradjust

clockwise until the forks stop descending.

③ If the forks do not descend when the finger grip control handle (1-1) is in the Lower position, adjust

the nut (2-4) or screw (2-6) clockwise until the forks. Then check the

Middle position according to steps and ② to make sure the nut (2-4) and screw(2-6) are in the proper①

position.

④ If the forks can’t lift up when the finger grip control handle is in the lower position, adjust the nut

(2-4) or screw (2-6) counterclockwise until the forks lift up. Then check the function of the Lower

position and Middle position according to steps ,②and③ are normal.①

Adjusting the finger grip handle M Series Hand Pallet Trucks

07 08

This chapter enables the user to identify and rectifies basic faults and the effects of incorrect operation.

When trying to locate a fault, proceed in the order shown in the table below. If, after carrying out the

following remedial action listed in “actions”, the truck cannot be restored to operation, contact the

manufacturer’s after-sale service department. Additional troubleshooting must only be performed by the

manufacturer’s specialist service engineers. The manufacturer's customer service department is specially

trained to carry out these operations.

1

Fault Possible cause Action

2

No.

3

4

Troubles shooting

The forks cannot

be lifted to max.

height

The forks cannot

be lifted up

The forks cannot

be lifted down

Oil leakage

The hydraulic oil is

insufficient

Change hydraulic oil

Put the finger grip handle in

the upper position and press

the handle dozens of times

Add the hydraulic oil

Replace the seals

The hydraulic oil has

impurities

Adjusting nut(2-4) or

adjusting screw(2-6) is in

wrong positions

The hydraulic oil is

insufficient

Air enters into the cylinder

Seals damaged

Piston rod or the frame is

deformed resulting from

overloading or cargo

slanting to one side

The forks was kept in raised

position for extended period

of time, then the piston rod

is exposed to the air and gets

rusted , which blocks the

motion of the piston

The adjusting nut(2-4) or

the adjusting screw(2-6) in

wrong positions

Replace the related parts of

the cylinder or the frame with

new ones

Keep the forks at the lowest

position while not in use, and

keep piston rods lubricated in

time

Parts damaged

Seals damaged Replace the seals

Replace the parts

Adjust the adjusting nut(2-4)

or adjusting screw(2-6) to

correct the position

If the truck have to transporte for a long distance, it should be packed in the wooden pallet in order

to avoid collision during transportation.

Transportion, loading, test and storage

The handle should be fixed stably in case sliding and damages and transported by fork truck

or crane.

Before loading, the operator should first check the truck weight, in order to choose the right

crane.

When unloading the truck, the operator should be aware of safety of the surroundings to ensure

the truck slowly unloaded.

If the truck is transported with the forklift, the forklift shall lift and lower slowly to keep the balance

of the truck.

The truck shall be commissioned according to the following function tests: steering, traveling,

loading control and combined functions with rated capacity.

If the truck doesn’t work, please remove the cargo from the frame and move out the truck from

the working area reasonably.

When the truck won’t be use for a long time, the storage environment shall be kept dry and clean,

with forks lift down to their lowest position.

Add the hydraulic oil

M Series Hand Pallet Trucks

Adjust the adjusting nut(2-4)

or adjusting screw(2-6) to

correct the position

09 10

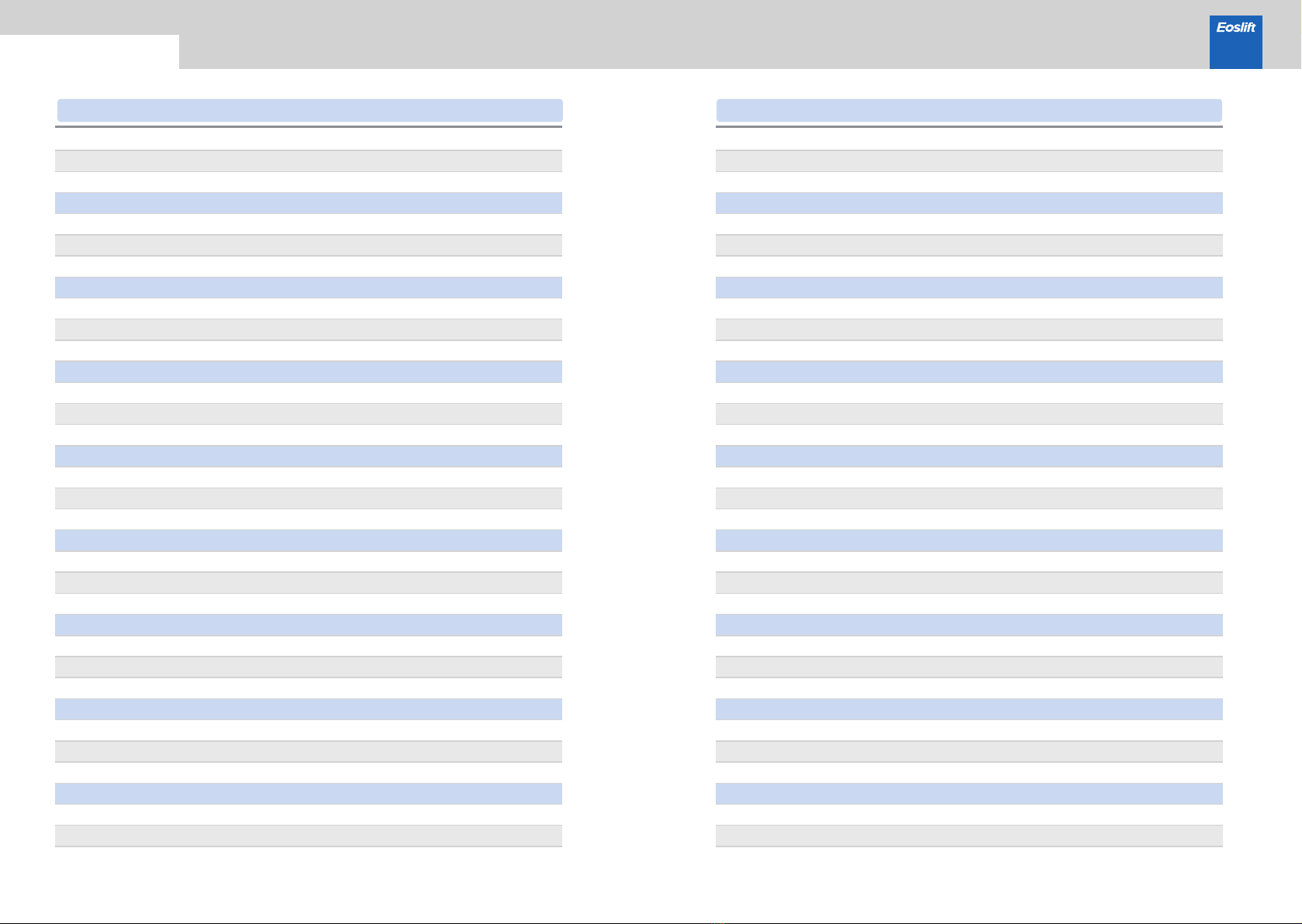

Parts list · Frame

Frame(2.5t, 540×1150-85), 5012

Frame(3.0t, 540×1150-85), 5012

Frame(2.5t, 685×1220-85), 5012

Frame(3.0t, 685×1220-85), 5012

Double -wheel frame(2.5t, 685×1220-75), 5012

Single -wheel frame(2.5t, 685×1220-75), 5012

Double -wheel frame(3.0t, 685×1220-75), 5012

Single -wheel frame(3.0t, 685×1220-75), 5012

Frame(2.0t, 540×1150-85), hot galvanized

Frame(2.5t, 540×1150-85), galvanized

Frame(3.0t, 540×1150-85), hot galvanized

Frame(2.5t, 685×1150-85), galvanized

Frame(2.5t, 685×1220-85), hot galvanized

Frame(2.5t, 685×1220-85), galvanized

Frame for single wheel(2.5t, 685×1220-75), galvanized

Long shaft(540)

Long shaft(685)

Long shaft(540), galvanized

Long shaft(685), galvanized

Connecting rod assembly(2.0t, 540), black

Connecting rod assembly(3.0t, 540), black

Connecting rod assembly(2.0t, 685), black

Connecting rod assembly(3.0t, 685), black

Connecting rod assembly(2.0t, 540), galvanized

Connecting rod assembly(3.0t, 540), hot galvanized

Connecting rod assembly(2.0t, 685), galvanized

Connecting rod assembly(2.0t, 540), hot galvanized

Connecting rod assembly(2.5t, 685), hot galvanized

Cylinder assembly (AC-85), galvanized

Cylinder assembly (AC-75), galvanized

Cylinder assembly (AC-85), with quick lift, galvanized

Cylinder assembly (AC-75), with quick lift, galvanized

Push rod welded (1150), black

Push rod welded (1220), black

1

1

1

1

2

WC02000001

WC02000083

WC02000079

WC02000086

WC02000119

WC02000162

WC02000788

WC02000490

WC02000942

WC02000852

WC02000761

WC02000857

WC02001025

WC02000895

WC02000893

WC02000013

WC02000082

WC02000532

WC02000186

WC02000005

WC02000084

WC02000081

WC02000087

WC02000604

WC02000762

WC02000184

WC02000531

WC02001026

WC01000001

WC01000006

WC01000005

WC01000007

WC02000002

WC02000080

1

2

3

4

5

Qty.

NO. Parts number Description

5

Seals damaged

Impurities in the oil cause

the valve to be unable to

close tightly

The adjusting nut(2-4) or

the adjusting screw(2-6) in

wrong positions

Note: Do not attempt to repair the pallet truck unless you are specially trained.

The forks

lift down without

operation

Change hydraulic oil

Replace the seals

Troubles shooting M Series Hand Pallet Trucks

Adjust the adjusting nut(2-4)

or adjusting screw(2-6) to

correct the position

11 12

WC02000605

WC02000182

WC02001027

WC02000134

WC02000136

WC02000138

WC02000154

WC02000009

WC02000032

WC02000006

WC02000688

WC02000185

WC02000894

WC02000008

WC02000011

WC02000031

WC02000021

WC02000029

WC02000030

WC02000078

WC02000085

WC02000199

WC02000156

WC02000177

WC02000485

WC02000003

WC02000183

WC02000530

WC02000020

WC02000010

WC02000007

WC02000022

WC02000023

WC02000077

5

6

7

8

9

10*

11

12

13

14

15

16

17*

18

19*

Push rod welded (1150), galvanized

Push rod welded (1220), galvanized

Push rod welded (1220), hot galvanized

Push rod welded (1500), black

Push rod welded (1800), black

Push rod welded (2000), black

Push rod welded (2500), black

Connecting shaft for small wheel carrier, galvanized

Connecting base, galvanized

Small wheel carrier (85), black

Small wheel carrier (75), black

Small wheel carrier (85), galvanized

Small wheel carrier (75), galvanized

Plastic washer

Wheel shaft, galvanized

Plastic roller

Guide wheel (into roller 40 × 50 × 10.5)

Iron-core PU wheel φ180×50, bright red PU, black iron core

Aluminium-core rubber wheel φ180 × 50 × 140, black

Nylon wheel φ180×50(flower-shape wheel)

Nylon wheel φ180×50, white(plane wheel)

Aluminium-core PU wheelφ180×50, bright red PU

Aluminium-core rubber wheelφ200×50×160, black

Iron-core PU wheel φ200×50, bright red PU, black iron core

Nylon wheel φ200 × 50, white (flower-shape wheel)

Handle EOS-AC, black

EOS-AC Galvanized steel handle(BZ)

Handel assembly AC-B, hot galvanized

GB308, Steel ball S18

Push rod connecting shaft, galvanized

Rocker, galvanized

GB276, Deep groove ball bearing 6204, two-side shielded

Iron-core PU wheel φ80×70, bright red PU, black iron core

Nylon wheel φ80 × 70, white

2

2

2

2

4

4

2

2

2

1

1

2

4

8

4

Qty.

NO. Parts number Description

Iron-core PU wheel φ74 × 70, bright red PU, black iron core

Nylon wheel φ74 × 70, white

Bolt pin 2, galvanized

Bolt pin, galvanized

Dust cover, galvanized

Big wheel cover, black

Big wheel cover, white

Big wheel shaft, galvanized

Connecting bracket, galvanized

Sliding bearing 29×25×25

Sliding bearing 18×16×15

GB301, thrust ball bearing 51111

GB3452.1, O-ring φ5×1.8

JB7940.2, Angle hydraulic grease nipple M6

GB894.1, Circlip for shaft 16, blackening

GB894.1, Circlip for shaft 20, blackening

GB879.1, Spring type straight pin 8×45, blackening

GB70.1, Hexagon socket head cap screw M6 × 16, galvanized

GB93, Normal type spring lock washer 6, galvanized

GB893.1, Circlip for hole 25, blackening

Connecting shaft, galvanized

JB7940.4, Push-fit type grease nipple 6

GB879.1, Spring type straight pin 5×26, blackening

GB879.1, Spring type straight pin 5×28, blackening

GB879.1, Spring type straight pin 5×32, blackening

GB5780, Hexagon head bolt M10×65, galvanized

GB889.1, Hexagon locking nut M10, galvanized

GB6173, Hexagon thin nut M20×1.5, galvanized

Washer

Iron-core PU wheel φ74 × 93, bright red PU, black iron core

Nylon wheelφ74×93

Single wheel shaft, galvanized

GB894.1, Circlip for shaft 52, blackening

Small wheel carrier (85), black

4

2

2

1

2

1

1

2

4

1

1

1

2

2

1

1

1

2

1

3

2

2

8

2

2

2

4

2

2

1

2

WC02000160

WC02000120

WC02000012

WC02000014

WC02000015

WC02000016

WC02000076

WC02000017

WC02000018

WC02000024

WC02000025

WC02000028

WC02000027

WC02000026

WE07000002

WE07000004

WE06000004

WE03000001

WE05000001

WE07000001

WC02000004

WC02000019

WE06000002

WE06000003

WE06000001

WE01000001

WE04000002

WE04000001

WC02000075

WC02000074

WC02000118

WC02000073

WE07000003

WC02000006

19*

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49*

Qty.

NO. Parts number Description

Parts list · Frame M Series Hand Pallet Trucks

Parts list · Frame

Small wheel carrier (75), black

Small wheel carrier (85), galvanized

Small wheel carrier (75), galvanized

GB879.1, Spring type straight pin 5×32, blackening

GB276, Deep groove ball bearing 6204, two-side shielded

2

8

8

WC02000688

WC02000185

WC02000894

WE06000001

WC02000022

49*

50*

51*

Qty.

NO. Parts number Description

Note:Marked with * are doube wheel parts

24

16

13

18

32

23

21

38

25

40

48

28

22

33

4

37

41

15

14

3

3029

27

31

20

26

2

36

34 35

1

744 5

16

9

8

41

6

11

41

47

45

18

46

18

45

38

9

39

42

12

43

49

10

51

19

51

17

50

13 14

M Series Hand Pallet Trucks

16

15

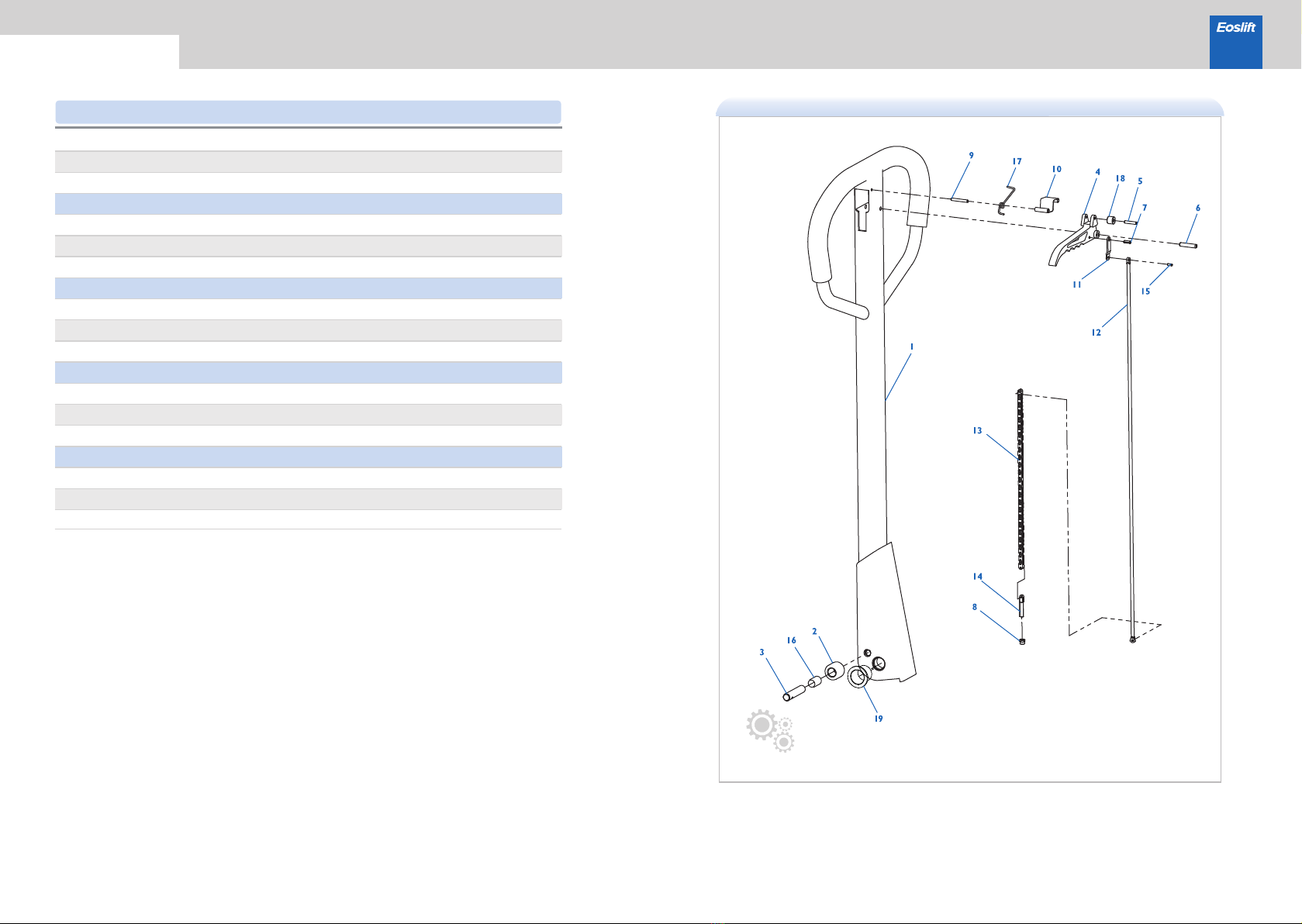

Parts list · Handle M Series Hand Pallet Trucks

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

WJ10800014

WJ10800015

WJ10800016

WJ10800011

WJ10800006

WJ10800003

WJ10800004

WJ10800020

WJ10800002

WJ10800008

WJ10800012

WJ10800013

WJ10800018

WJ10800019

WJ10800005

WJ10800017

WJ10800009

WJ10800010

WJ10800058

Handle welded

Clamping roller

Roller pin

Finger grip handle

Spring type pin (5)

Spring type pin (6)

Spring type pin (7)

Locking nut

Spring type pin (9)

Positioning plate

Connecting sheet of pull rod

Pull rod

Chain

Adjusting bolt

Spring type pin (15)

Bushing

Torsion spring

Plastic roller

Bush (19)

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

Qty.

NO. Parts number Description

18

17

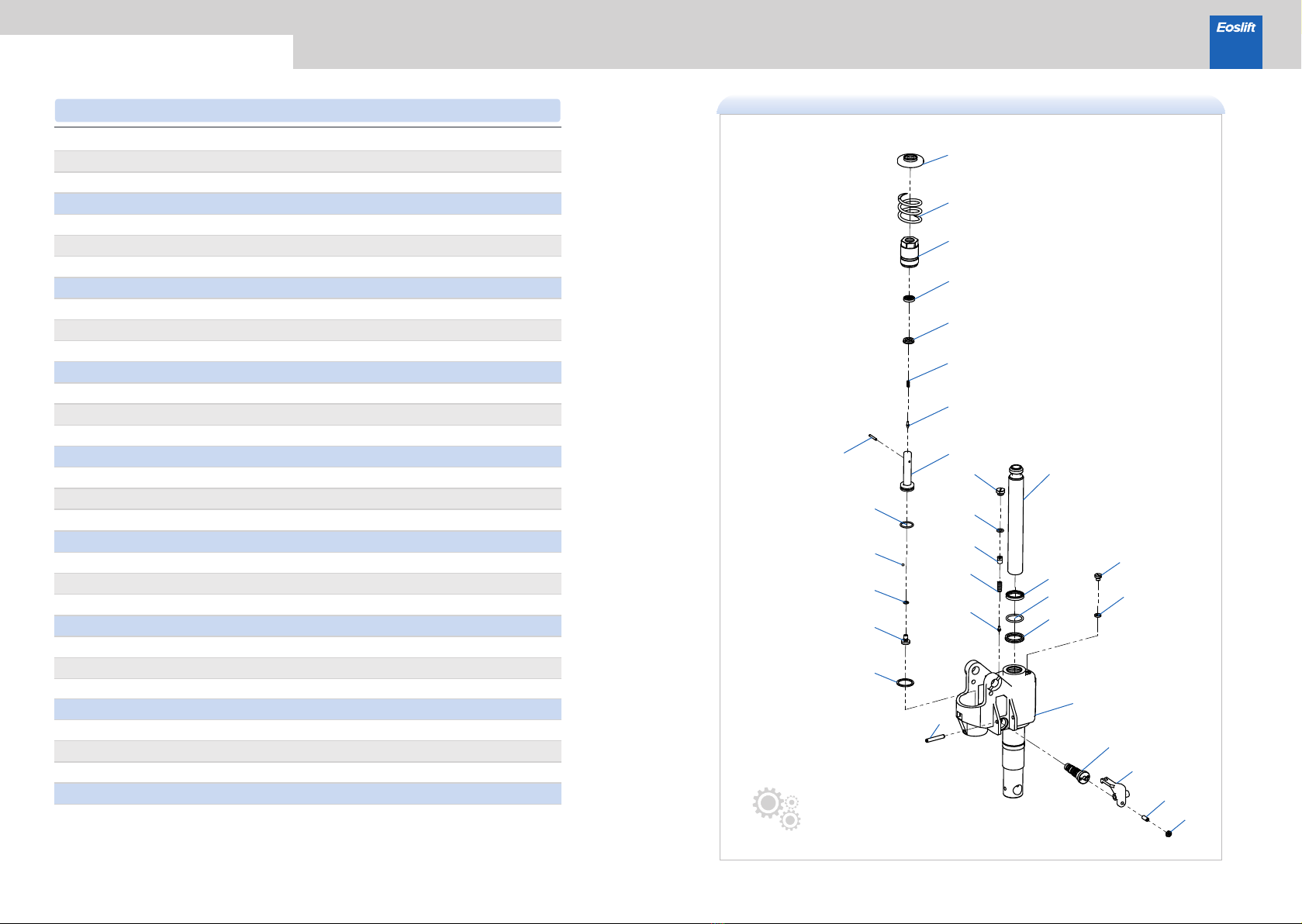

Parts list · Cylinder

*26

M Series Hand Pallet Trucks

Qty.

NO. Parts number Description

Note: Marked with * are optional parts

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

*26

WC02000157

WC02000033

WC02000060

WC02000036

WC02000061

WC02000059

WC02000058

WC02000035

WC02000045

WC02000046

WC02000038

WC02000071

WC02000037

WC02000044

WC02000039

WC02000064

WC02000063

WC02000042

WC02000041

WC02000043

WC02000040

WC02000049

WE06000005

WE03000003

WE04000003

WC01000046

WC02000620

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

Valve body welded(75), galvanized

Valve body welded(85), galvanized

GB982, Combination sealing gasket 10

Screw

Seal ring UHS35

GB3452.1, O-ringφ34.5×3.55

Dustproof ring DH35

Piston rod

Safety valve spool

Pressure adjusting spring

Pressure adjusting screw

GB3452.1, O-ring φ11.2×2.65

Screw plug

Copper gasket

Pump body

Seal ring UHS18

Dustproof ring DH18

Spring cover

Pump core

Pressure spring

Pin

Unloading plate, galvanized

GB879.1, Spring type straight pin 8×50, blackening

GB73, Slotted set screws with flat point M8 × 20, galvanized

GB6172.1, Hexagon thin nut M8, galvanized

Integrated valve assembly

Unloading plate, galvanized

19 20

Parts list · Integrated valve M Series Hand Pallet Trucks

Qty.

NO. Parts number Description

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

WC02000051

WC02000065

WC02000067

WC02000053

WC02000066

WC02000050

WC02000052

WC02000054

WC02000069

WC02000070

WE06000006

WC02000055

WC02000062

WC02000048

WE03000002

WC02000056

WC02000057

WC02000047

WC02000068

Push pin sleeve

GB3452.1, O-ringφ15.2×2.4

GB3452.1, O-ringφ8×1.8

Return valve sleeve

GB3452.1, O-ringφ9.5×1.8

Stem

Unloading spring

O-ring retainer Ⅱ

GB308, Steel ball S7

Liquid inlet valve sleeve

GB117, Copper taper pin 2 × 5

O-ring retainerI

GB3452.1, O-ringφ13.2×2.4

Spring leaf

GB818, Pan head screw with cross recess M2×2, galvanized

Boost valve spool

Spool spring

Blind nut

GB3452.1, O-ring φ21.2×2.65

1

1

2

1

1

1

1

1

1

1

2

1

1

1

1

1

1

1

1

31

26

25

24

23

22

19

21

20

18

17

1

2

3

4

5

6

8

9

10

11

12 7

16

27

28

14

15

13

30

29

21

M Series Hand Pallet Trucks

Parts list · Quick lift cylinder

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

WC02000121

WC02000723

WC02000060

WC02000036

WC02000061

WC02000059

WC02000058

WC02000035

WC02000045

WC02000046

WC02000038

WC02000071

WC02000037

WC02000122

WC02000064

WC02000063

WC02000123

WC01000046

WC02000049

WE06000005

WE03000003

WE04000003

WC02000126

WC02000127

WC02000132

WC02000129

WC02000131

WC02000128

WC02000130

WC02000124

WC02000125

WE06000011

Valve bodyseaming part(AC-85), quick lift pump, galvanized

Valve bodyseaming part(AC-75), with quick lift, galvanized

GB982, Seal washer 10

Bolt

Seal ring UHS35

GB3452.1, O-ringφ34.5×3.55

Dusty seal ringDH35

Piston rod

Safety valve

Pressure spring

Pressure adjusting screw

GB3452.1, O-ringφ11.2×2.65

Screw

Quick lift pump body

Seal ring UHS18

Dusty seal ringDH18

Quick lift pump pistion

One valve assembly

Unloading plate, galvanized

GB879.1 Pin 8×50, black

GB73 Screw M8×20, galvanized

GB6172.1 Hex nut M8, galvanized

Copper gasket

Quick lift blind nut

GB3452.1, O-ringφ9.0×1.8

GB308, Steel ball S5

GB3452.1, O-ringφ27×3

Centre

Spring

Spring cover

Pressure spring

GB119.1 Pin 4×28, galvanized

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

Qty.

NO. Parts number Description

22

This manual suits for next models

12

Other Eoslift Truck manuals

Popular Truck manuals by other brands

Hamron

Hamron 325-001 operating instructions

Komatsu

Komatsu Galeo HD325-6 brochure

Jungheinrich

Jungheinrich ETX ac 125 operating instructions

Mitsubishi

Mitsubishi Fuso FK/FM 2006 owner's manual

chevrolet truck

chevrolet truck Light Duty Truck 1994 Series Repair manual

HERKULES

HERKULES AHW 2500/1 Original operating instructions