Big Joe PDM-20-154 User manual

Document 367 1

06/12/06

PDM

SUPPLEMENT

CIRCUIT CITY

PDM-20-154

Table 1. Serial Number Effectivity

1. GENERAL

This document supplements the basic PDM Manual

No. 901356 and provides additional operating, safety

and maintenance information.

Additional standard equipment of the platform, strobe

light, a lowering buzzer, an emergency lowering valve,

a keyswitch, an emergency power disconnect (EPD),

a safety belt, and a self-retracting lifeline.

TRUCK MODEL SERIAL NUMBERS

PDM Equipped With Special Features 375784 AND HIGHER

IMPORTANT

Ultra-deep discharging of brand new batteries should be avoided for at least 15 cycles.

These batteries have a superior deep cycle life. However, to dramatically extend battery life, ultra-deep

discharge should be avoided. The shallower the average discharge, the longer the life.

If the batteries are continually undercharged, performance is reduced and life is shortened.

THESE BATTERIES ARE MAINTENANCE-FREE. ANY ATTEMPT TO OPEN THE BAT-

TERY WILL VOID WARRANTY.

1Miller® is a registered trademark of Miller Equipment, Franklin PA.

2DBI/SALA® is a registered trademark of DBI/SALA, Red Wing, MN.

2Document 367

2. SAFETY PRECAUTIONS

The following safety precautions must be adhered to

at all times.

• All warnings and instructions must be read and

understood before using the equipment.

• Equipment must not be altered in any way.

• Equipment must be inspected by a qualified person

on a regular basis.

• Be certain that required restraining means such as

safety belts, lifelines, and chains are properly used.

• Safety belt buckles must be visually inspected to

assure proper and secure connection before use.

• The self retracting lifeline should be attached to the

back Dee ring only on the safety belt.

• Replace any safety belt or life line that sustains per-

manent deformation or is otherwise damaged.

• Be certain that the lifting mechanism is operating

smoothly throughout its entire lift height, both empty

and loaded.

• Be sure that mast is vertical--do not operate on a

side slope.

• Be sure the platform is not tilted forward or rearward

when elevated.

• Be sure the truck has a firm and level footing.

• Before personnel are elevated, mark area with

cones or other devices to warn of work by elevated

personnel.

• Avoid overhead wires and obstructions.

• Personnel are to remain on the platform floor. Use of

railings, planks, ladders, etc., on the platform for pur-

pose of achieving additional reach or height is pro-

hibited.

• Personnel and equipment on the platform must not

exceed the available space.

• Lower platform to floor level for personnel to enter

and exit. Do not climb on any part of the truck in

attempting to enter and exit.

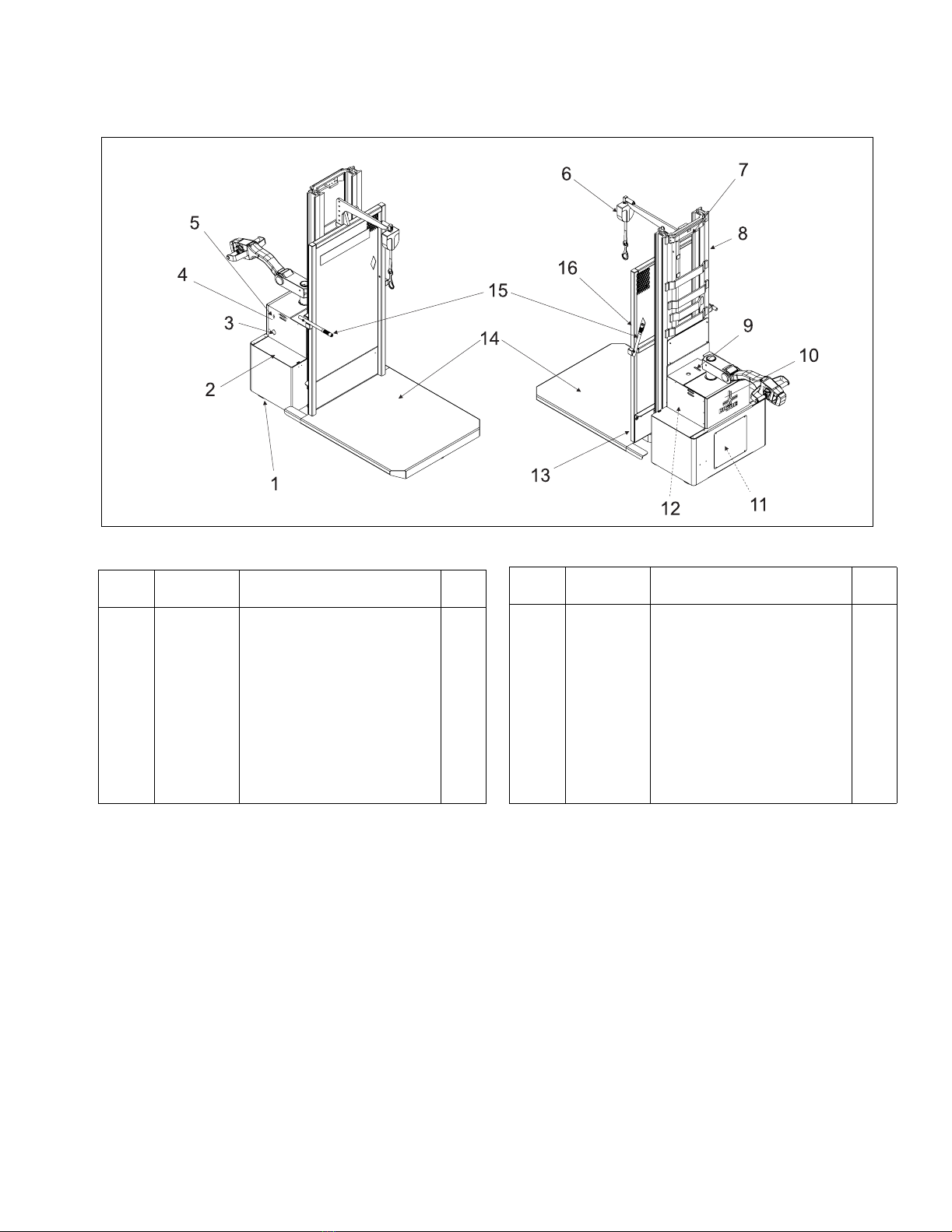

3. CONTROLS AND INDICATORS

Steering Control Head of the truck is covered in

Supplement 220.

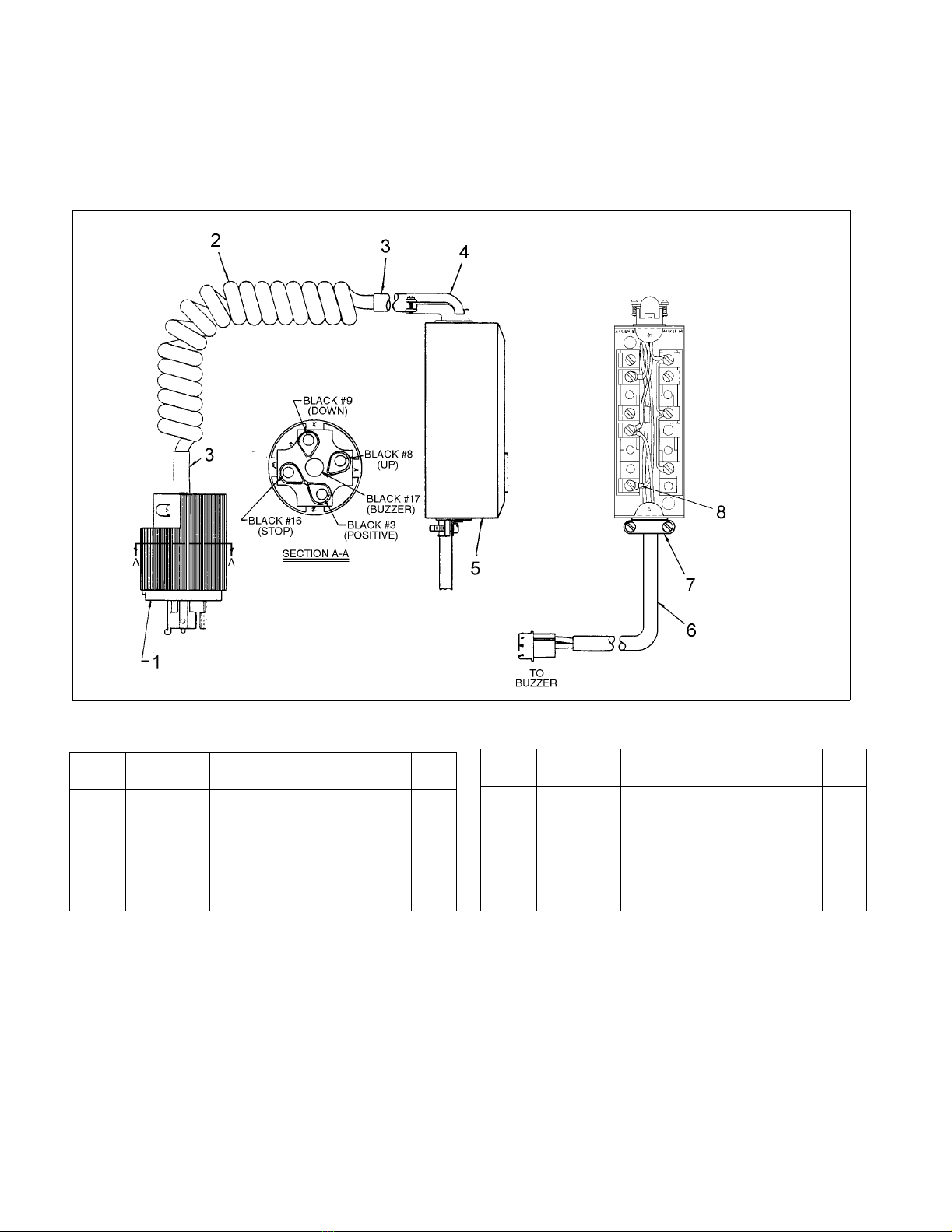

A remote lift, lower and stop switch is located on the

platform as shown in Figure 1. An emergency power

disconnect (EPD), keyswitch and an emergency low-

ering valve are located on the rear of the truck as

shown in Figure 1.

4. OPERATING PROCEDURES

WARNING: Understand truck limitations and oper-

ate the truck in a safe manner so as not

to cause injury to personnel. Safeguard

pedestrians at all times. Be sure you

have read and understand the Safety

Precautions listed in paragraph 2.

Users shall comply with all requirements indicated in

applicable OSHA Standards and current edition of

A.N.S.I. B56.1 Part II. By following these requirements

and the requirements in this supplement you will get

many years of safe, dependable service from your Big

Joe lift truck.

The basic operation of the truck is covered in the PDM

Manual No. 901356. Steering Control Head operation

of the truck is covered in Supplement 220. Refer to the

Miller®1Equipment manual supplied with this truck for

information on the proper use, safety precautions and

maintenance procedures applicable to the Safety Belt.

Refer to the DBI/SALA®2Operation and Maintenance

manual supplied with this truck for information on the

proper use, safety precautions and maintenance pro-

cedures applicable to the Self Retracting Lifeline. Prior

to operating the truck a check of safety items should

be performed to insure the operating integrity of these

items.

Document 367 3

Figure 1. Location of Special Items

R6287

INDEX

NO.

PART

NO.

PART NAME NO.

REQ.

1 054412 CASTER 2

2 003216 BATTERY 2

3 — BATTERY CHARGER (FIGURE 3)REF

4 20574 DECAL 1

5 020698 SWITCH, EPD ENGAGE 1

6 — BOOM (FIGURE 18)REF

7 — STROBE LIGHT (FIGURE 9)REF

8 — ELEVATION SYSTEM (FIGURE 17)REF

9 23742 DECAL 1

INDEX

NO.

PART

NO.

PART NAME NO.

REQ.

10 — HYDRAULIC SYSTEM

(FIGURE 14)

REF

11 — EPD CONTACTOR BOX

(FIGURE 13)

REF

12 — ELECTRICAL PANEL ASSEMBLY

(FIGURE 7)

REF

13 — LOWERING BUZZER (FIGURE 11)REF

14 506268 CARRAGE AND PLATFORM 1

15 — GRAB HANDLE (FIGURE 18)REF

16 — REMOTE CONTROL (FIGURE 10)

4Document 367

4.1. Safety Check

The following safety checks should be made at least

once each day to verify operation of safety devices.

Also perform the daily checks in the basic PDM Man-

ual No. 901356, paragraph 2-3. If any malfunctions are

found, do not use the truck until repairs are made.

1. Verify that platform chains are present and func-

tional.

2. Verify that the flashing red light operates when the

keyswitch is engaged.

3. Verify that buzzer sounds when the DOWN button

on the platform is pressed.

4. Verify that the safety belt and self-retracting lifeline

are present, installed with locking carabiner (when

applicable), and functioning properly.

5. Verify that the travel defeat switch disables the

steering arm when the platform is raised.

6. Verify that the emergency lowering valve is func-

tioning properly.

WARNING: Do not operate with platform railing

chains missing or not functioning.

4.2. Load Rating

Trucks are designed to handle loads up to 650 pounds

at a 19" load center. Loads include personnel. Always

carry loads as far back as possible on the platform.

Refer to basic PDM Manual No. 901356, paragraph

2-2 and Figure 2-1.

WARNING: Exceeding the load rating specified

above can cause the truck to tip resulting

in possible injury.

4.3. Special Operating Information (Figure 1)

1. When the truck power is disconnected by the bat-

tery disconnect, the Emergency Power Disconnect

(EPD) will automatically disengage. To reset, con-

nect the battery and momentarily press the EPD

Engagement switch. If the EPD does not operate

refer to paragraph 6.9.

NOTE: If the EPD will not reset, there may be

another electrical open or loose connection.

2. The keyswitch should be turned to the off position

and the key removed when the truck is left unat-

tended. Turning off the keyswitch reduces battery

discharge.

3. A travel defeat switch completely disables the

steering arm when the platform is raised.

4. The platform can be raised and lowered using the

remote switch box located on the platform.

5. When the platform is lowered, a buzzer will sound.

6. The emergency lowering valve can be used to

lower the platform when conditions require it's

use.

7. If the platform hangs up on a shelf or obstruction

during lowering, a hang-up valve will stop the cyl-

inder from lowering further. Raise the platform to

eliminate the hang-up contact before moving truck

to clear obstruction.

Document 367 5

5. PLANNED MAINTENANCE

Refer to the basic PDM Manual No. 901356 Chapter 3

for basic planned maintenance procedures. Ta b l e 2

indicates additional planned maintenance tasks which

should be performed on a quarterly basis. These

maintenance procedures should be performed only by

qualified service personnel.

Table 2. VISUAL CHECKS

ITEM PROCEDURE

Check all fluids and lubrication points. Refer to PDM manual paragraph 3-4

Check lift chains Check for damage and adjustment. If adjustment is necessary refer

to PDM manual Chapter 8

Check sheaves and bearings. Check for damage or binding.

Check cable in pivot tube. Check for excessive wear around spring tube assembly and where

cable exits pivot tube.

Check brake linkage and pads for wear. Refer to PDM manual Chapter 6 to replace worn linkage or pads.

Check lift cylinder for leakage. Raise cylinder to fully elevated position. Disconnect drain line and

observe amount of oil coming from cylinder fitting. If more than a

couple of drops of oil is forced out of gland, change packing. Refer

to Figure 16.

Check hydraulic system filter and breather. Replace if dirty.

6Document 367

6. MAINTENANCE

Refer to the basic PDM Manual No. 901356 for all

general service information. Refer to Figure 1 for the

location and identification of items not listed in the

basic manual.

6.1. Battery Part Number 003216

These Gel Cell Batteries are maintenance-free. Any

attempt to open the battery will void the warranty.

Ultra-deep discharging of brand new batteries should

be avoided for at least 15 cycles. To dramatically

extend battery life, ultra-deep discharge should be

avoided. The shallower the average discharge, the

longer the battery life.

6.1.1. Charging Batteries

Charging requirements will vary depending on depth of

discharge and temperature. Follow safety rules when

placing a battery on charge.

Proceed as follows:

1. Park truck at charging station with platform low-

ered and key switch off.

2. Check the condition of the AC cord, the battery

connector and battery cables. If there are any cuts

in the cable, any exposed wires, loose plugs or

connectors, DO NOT attempt to charge the batter-

ies. Contact appropriate personnel for repairs to

be made.

3. Disconnect the batteries from the truck and con-

nect batteries to the charger. Make sure connec-

tors are mated properly.

4. Connect the AC cord to the truck and then plug

into the 120 Volt AC power supply.

5. The battery charger is fully automatic and will

cycle automatically (depending on amount of

charge needed). Charge status can be observed

as follows (Refer to Figure 2):

a. The top three LED’s indicate charger status.

At start of charge the RED (Charge) LED will

be ON indicating the batteries are connected

and charging. After the batteries charge to

approximately 80% the Yellow LED comes

ON. After a time (1 hour minimum) the Green

LED comes ON indicating battery ready.

NOTE: The battery charger includes an

override timer which terminates the

charge if the cycle does not complete

after 18 hours of charging. This time-

out condition is indicated by the

green LED flashing off and on, and it

indicates a fault condition which

should be investigated. This will

occur if the charger cannot raise the

battery voltage to the preset voltage

limit. Possible causes indicate a bat-

tery fault, a charger fault, low AC

power supply voltage, or excessive

discharge. The override timer can be

reset by switching the AC power to

the charger off.

b. The lower four red LED’s indicate current flow.

Normally at start of charge, if the batteries are

discharged, all four red LEDs will be on indi-

cating maximum 25A charge current. As the

batteries charge the current drops and the

LEDs go OFF as the current drops to 20A,

15A, 10A and 5A respectively.

Figure 2. Charge Indicator

R6114

Document 367 7

6.1.2. Removing Batteries from Charger

1. The Green “READY“ LED stays on until the

charger is unplugged from AC outlet.

2. Disconnect AC plug from the power supply and

then remove it from the truck.

3. Disconnect the batteries from the charger and

connect the batteries to the truck. Make sure con-

nectors are mated properly.

6.2. Electrical System

Refer to the basic PDM Manual No. 901356 for all

general service information. Refer to Supplements 220

for general information for the Steering Control Head.

Refer to Figure 6 in this document for the wiring dia-

gram of truck.

R6115

8Document 367

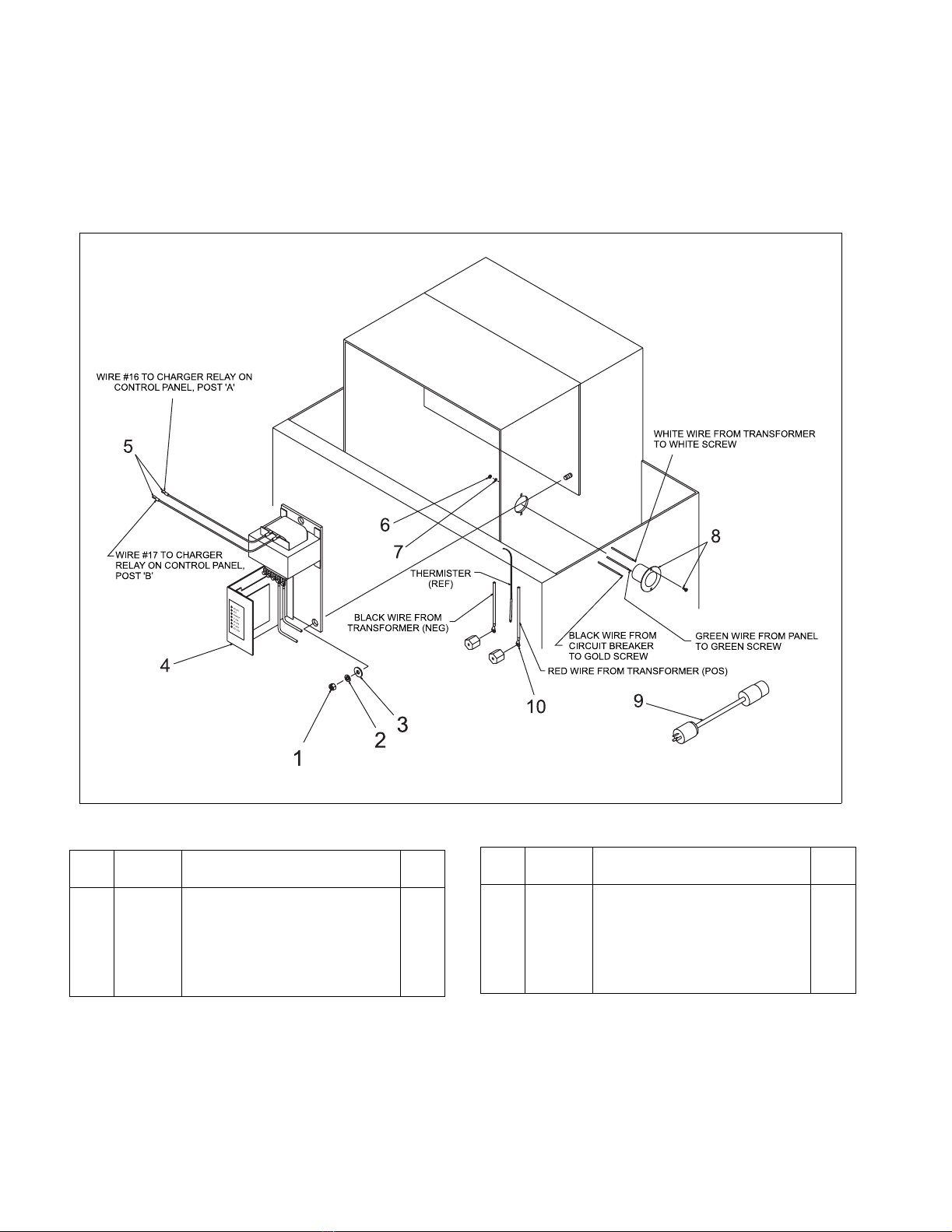

6.3. Battery Charger

The 23840 battery charger is located inside the cover

in front of the steering arm as shown in Figure 1. Refer

to Figure 3 for charger installation and Figure 4 for dis-

assembly and part number information.

Figure 3. Battery Charger Installation

R6286

INDEX

NO.

PART

NO.

PART NAME NO.

REQ.

1 059529 NUT, HEX, JAM, 3/8-16 2

2 077211 WASHER, LOCK, SPLIT, 7/16 2

3 077056 WASHER, FLAT 2

4 — CHARGER (FIGURE 4)REF

5 021249 TERMINAL 2

INDEX

NO.

PART

NO.

PART NAME NO.

REQ.

6 059412 NUT - HEX, 6-32 2

7 077204 WASHER - LOCK, SPLIT, #6 2

8 005454 CONNECTOR - INLET, FLANGED 1

9 005810 CORD ASSY - EXTENSION, 120V 1

10 021238 TERMINAL 2

Document 367 9

Figure 4. Battery Charger

R6288

INDEX

NO.

PART

NO.

PART NAME NO.

REQ.

— 23840 CHARGER, 24 VOLT 1

1 056681 . DECAL, CHARGER, LED 1

2 023018 . WIRE, 16 GA, BLACK 30”

3 23831 . PANEL 1

4 023000 . WIRE, 16 GA, WHITE 16”

5 023004 . WIRE, 16 GA 16”

6 023018 . WIRE, 16 GA, BLACK 16”

7 021237 . TERMINAL RING 2

8 021207 . TERMINAL RING 1

9 023010 . WIRE 30”

10 023011 . WIRE 30”

— 004987 . CHARGER KIT-24V, 25 AMP 1

INDEX

NO.

PART

NO.

PART NAME NO.

REQ.

11 904075 . . PCB ASSY WITH HEATSINK 1

12 904074 . . . THERMISTOR 1

13 003403 . . CIRCUIT BREAKER, AUTO RESET 1

14 904076 . . TRANSFORMER 1

15 071376 . SCREW, TRUSS, #10-32 X 1/2 2

16 077208 . WASHER, LOCK, SPLIT, #12 3

17 059416 . NUT, HEX, 10-32 3

18 021218 . TERMINAL, RING, #4 CABLE, 3/8” 4

19 070475 . SCREW, PH RD HD, 1/4-20 X 3/8 4

20 077209 . WASHER, LOCL, SPLIT, 1/4 4

21 077031 . WASHER, 5/16 X 3/4 X 16 GA 5

22 077032 . WASHER, 3/16 X 1/2 X 13 GA 1

10 Document 367

6.4. Battery Charger Troubleshooting

Refer to Figure 6 for part identification. Be sure the

batteries are connected to the charger and the AC

cord is connected to 120 VAC power supply.

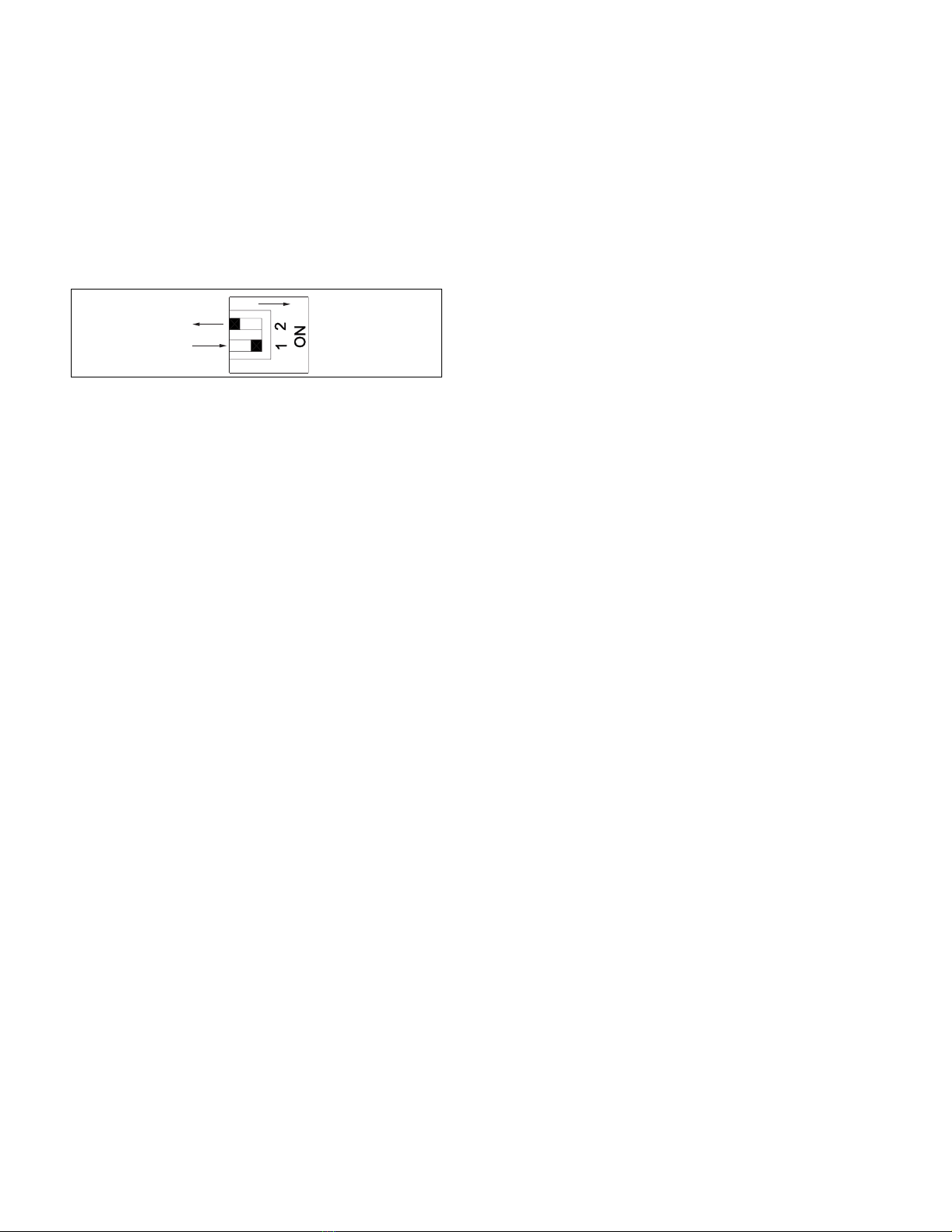

6.4.1. Dip Switch Setting (Figure 5)

The DIP switch on the Printed Circuit Board (PCB)

must be set for Gel Cell Batteries. Check that switch 1

is be ON and switch 2 is be OFF.

Figure 5. Dip Switch Settings

6.4.2. Thermistor

There is a temperature sensing thermistor plugged

into a 2-pin socket marked THERM on the PCB.

Check that this is firmly connected or the battery volt-

age control will not work properly.

6.4.3. Circuit Breaker Testing

Using a multimeter set to measure 120 VAC, check

each side of the circuit breaker to ground. If 120 VAC

was not indicated on both sides, replace the circuit

breaker.

6.4.4. Power Transformer Testing

The two 0.250” tabs on the primary side of the trans-

former and the five #10 screw lugs on the secondary

side. Test the transformer as follows:

1. Using a multimeter set to measure at least 120

VAC, verify that AC Power supply 120V 60Hz

input is present at the transformer primary termi-

nals. If 120 VAC was not indicated, check the cir-

cuit breaker and wiring.

2. Using a multimeter set to measure at least 50

VAC, verify the transformer secondary terminals

as follows:

a. Verify 25 VAC from blue wire to each white

wire.

b. Verify 50 VAC from the white wire to white

wire.

c. If these voltages were not indicated, replace

the transformer.

6.4.5. Circuit Board Testing

The circuit board has a built in diagnostic test at

power-up.

1. Switch the AC supply OFF and then ON, watching

the 3 upper LEDs on the PCB. The 3 LEDs should

light briefly in sequence Green-Yellow-Red when

power is applied. This indicates the transformer is

OK and that power is getting to the PCB.

2. If the battery DC is connected to the charger cor-

rectly, the Red LED should come ON immediately

after this test sequence.

3. If the Green-Yellow-Red LED test sequence does

not show at power-up, or if it cycles constantly

Green-Yellow-Red, the PCB assembly should be

replaced.

4. If the Red or Yellow charging LED does not stay

ON after the test sequence, check that the batter-

ies are connected to the charger.

5. Using a multimeter set to measure at least 30

VDC, verify DC Voltage from Black to Red wire is

as follows:

a. If the Red charging LED is on and the Yellow

charging LED is off, voltage from black to red

wire should be at least 24 VDC.

b. If the Red and Yellow charging LEDs are on,

voltage should be 29 ±1 VDC.

c. If there is no Voltage, check the wiring and

connections from the charger to the battery

terminals. Battery Voltage must be correct

polarity and more than 1 Volt to commence

charging.

R6120

Document 367 11

NOTES

12 Document 367

Figure 6. Wiring Diagram (Sheet 1)

R6289A

Document 367 13

Figure 6. Wiring Diagram (Sheet 2)

R6289B

Document 367 15

INDEX

NO.

PART

NO.

PART NAME NO.

REQ.

— 23836 PANEL ASSY-ELECT,

TRANSISTOR

1

1 506044 . PANEL WELDMENT 1

2 008904 . FUSEHOLDER 1

3 008910 . FUSE, 15 AMP 1

4 068177 . SCREW-RH HD, 5-40 X 3/8 5

5 077203 . WASHER-LOCK, SPLIT, #5 5

6 077007 . WASHER-FLAT 4

7 056504 . DECAL, FUSE, 15 A 1

8 023262 . HARNESS ASY - WIRE, PANEL 1

9 005422 . CONNECTOR, IN-LINE 6

10 23837 . CABLE ASSY - LIMIT SWITCH 1

11 018411 . RELAY-AC 1

12 305407 . BUS BAR 1

13 070491 . SCREW, RD HD, 8-32 X 7/8 4

14 077205 . WASHER - LOCK, SPLIT, #8 4

15 077032 . WASHER-FLAT, 3/16 ID 4

16 005657 . CONTACTOR, 24V 2

17 504150-15 . CABLE ASSY - BUSS 4

18 504150-21 . CABLE ASSY - MTR A2 1

19 504150-22 . CABLE ASSY - MTR S2 1

20 504150-23 . CABLE ASSY - MTR A1 1

21 504181-47 . CABLE ASSY - B+ 1

22 504181-10 . CABLE ASSY - MTR S1 1

INDEX

NO.

PART

NO.

PART NAME NO.

REQ.

23 504150-01 . CABLE ASSY - A2 1

24 505084-14 . CABLE ASSY - POS 1

25 505181-50 . CABLE ASSY - NEG 1

26 063552 . SCREW, HX HD, 5/16-18 X 5/8 3

27 077210 . WASHER - LOCK, SPLIT, 5/16 4

28 059426 . NUT-HEX, 5/16-18 4

29 063553 . SCREW, HX HD, 5/16-18 X 3/4 1

30 005468 . CONTROLLER - SPEED, 24V 1

31 069477 . SCREW, FL HD, 1/4-20 X 1/2 2

32 010614 . STANDOFF-INSULATOR 2

33 077105 . WASHER - BRONZE 4

34 077209 . WASHER - LOCK, SPLIT, 1/46 5

28 059426 . NUT-HEX, BRASS 1/4-20 2

36 075620 . STUD-THREADED, 1/4-20 2

37 070475 . SCREW-RH HD, 1/4-20 X 3/8 5

38 008906 . FUSE, 300 AMP 1

39 056507 . DECAL, FUSE, 300 AMP 1

40 005976 . DIODE 2

41 018409-02 . RELAY-DC 1

42 505321 . SUPPRESSOR ASSY 1

43 021204 . TERMINAL - SLIDE CLIP, 1/4 4

44 021249 . TERMINAL 1

45 023001 . WIRE - 16 GA RED A/R

46 21548 . RESISTOR ASSY - 2700 OHMS 1

16 Document 367

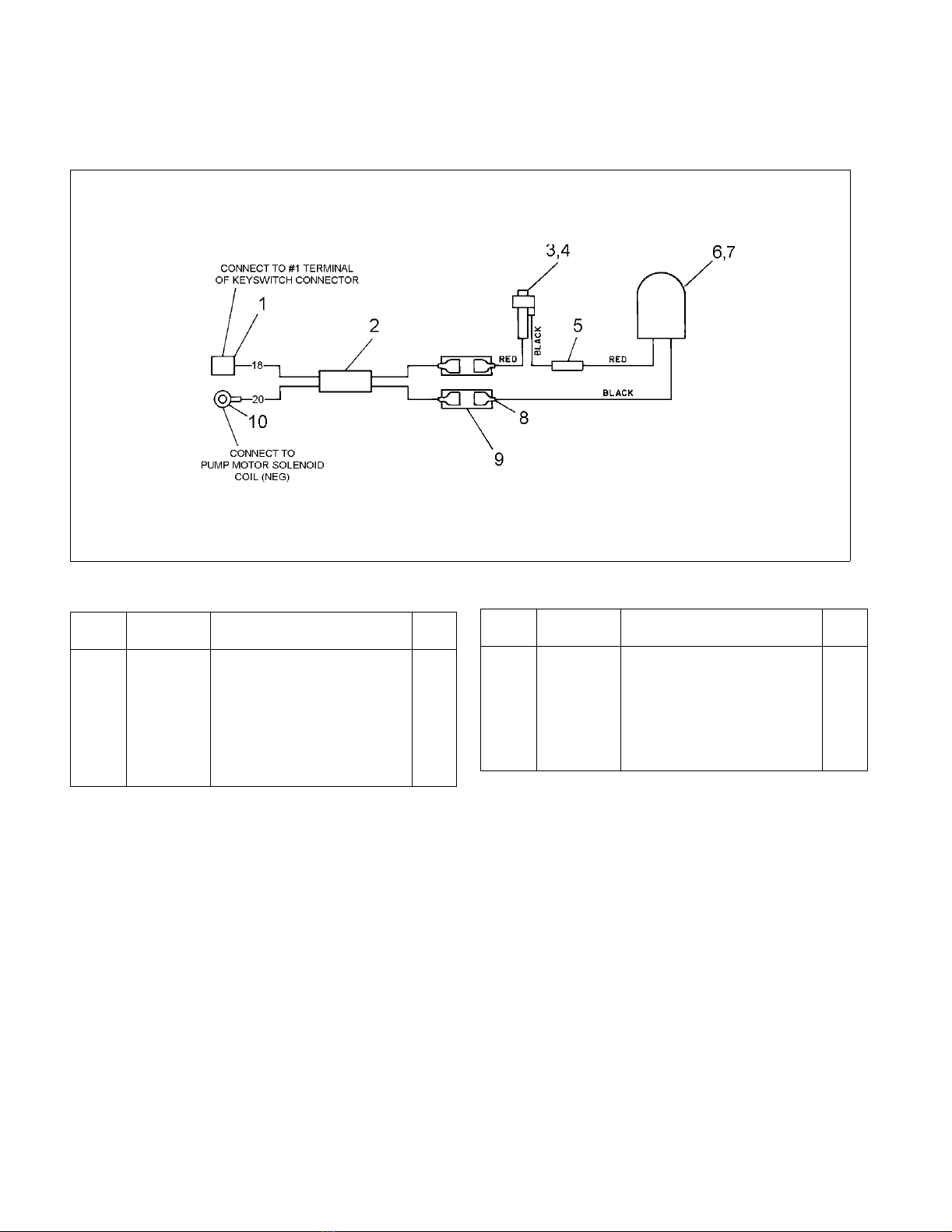

6.6. Flashing Red Light

The Flashing Red Light is located on the Mast as

shown in Figure 1.

Refer to Figure 8 and Figure 9 for part number and wir-

ing information.

Figure 8. Flashing Light Wiring Diagram

R6291

INDEX

NO.

PART

NO.

PART NAME NO.

REQ.

1 005649 CONNECTOR 1

2 20624 WIRE BUNDLE 1

3 901470 FUSE AND FUSE HOLDER 1

4 901469 . FUSE 2 AMP (IF EQUIPPED) 1

5 005433 CONNECTOR 1

INDEX

NO.

PART

NO.

PART NAME NO.

REQ.

6 013609-02 FLASHING RED LIGHT 1

7 904186 . BULB 1

8 021204 TERMINAL 4

9 005422 CONNECTOR 2

10 021203 TERMINAL 1

Document 367 17

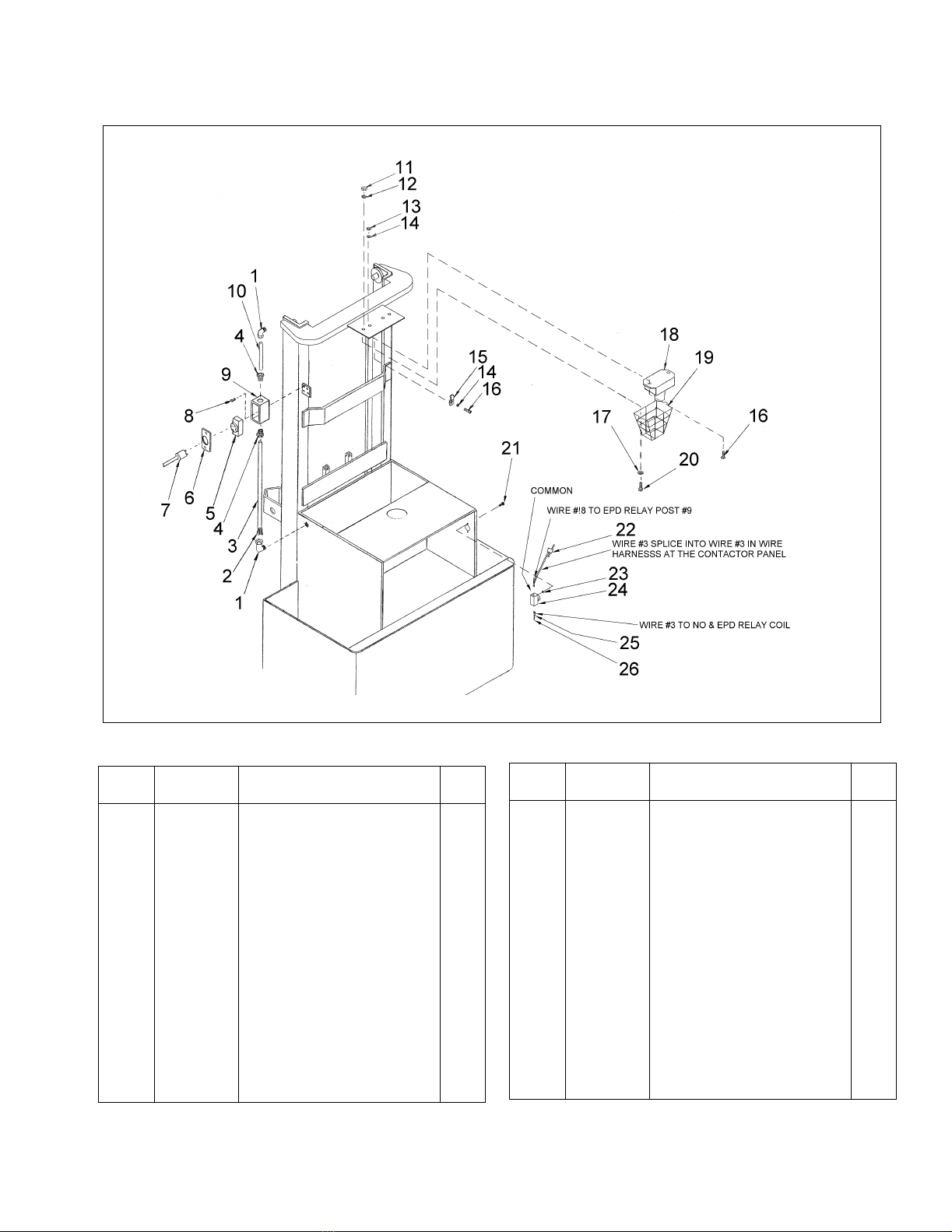

Figure 9. Flashing Red Light, Remote Control Conduit and EPD Reset Button

R6292

INDEX

NO.

PART

NO.

PART NAME NO.

REQ.

1 005318 ELBOW 2

2 023014 WIRE BUNDLE 1

3 005311 CONDUIT AR

4 005317 CONNECTOR 1

5 005321 OUTLET 1

6 005320 COVER 1

7 — PLUG (FIGURE 10)REF

8 071379 SCREW 4

9 005315 CONDUIT BOX 1

10 20414 CONDUIT, 1/2” 1

11 059421 NUT 2

12 077209 WASHER 2

13 059416 NUT 2

INDEX

NO.

PART

NO.

PART NAME NO.

REQ.

14 077207 WASHER 3

15 056122 CLIP 1

16 071376 SCREW 3

17 077031 WASHER 2

18 — FLASHING RED LIGHT

(FIGURE 8)

REF

19 013610 GUARD 1

20 063480 SCREW 2

21 069465 SCREW 2

22 005649 CONNECTOR 1

23 074712 WASHER 2

24 020698 EPD RESET BUTTON 1

25 021718 TERMINAL 2

26 023018 WIRE A/R

18 Document 367

6.7. Platform Remote Control Box

The Remote Control UP DOWN STOP push-button

switch box assy 11151 is located on the Platform as

shown in Figure 1.

Refer to Figure 9 and Figure 10 for part number and

wiring information.

Figure 10. Remote Control Box

R6294

INDEX

NO.

PART

NO.

PART NAME NO.

REQ.

— 11151 REMOTE CONTROL SWITCH BOX

ASSY

1

1 017815 . PLUG 1

2 907199 . CABLE KIT 1

3 278600 . . TUBING AR

INDEX

NO.

PART

NO.

PART NAME NO.

REQ.

4 005451 . CONNECTOR 1

5 020785 . CONTROL BOX 1

6 907175 . CABLE ASSY 1

7 005405 . STRAIN RELIEF 1

8 021210 . SPADE TERMINAL 6

Document 367 19

6.8. Platform Buzzer

The platform lowering buzzer housing is located near

the front lower edge of the platform as shown in Figure

1. Refer to Figure 10 and Figure 11 for part number

information.

Figure 11. Buzzer and Housing

R6293

INDEX

NO.

PART

NO.

PART NAME NO.

REQ.

1 063478 SCREW 1

2 077209 WASHER, LOCK 1

3 11874 GUARD 1

4 800257 CLAMP 1

5 059421 NUT 1

6 11590 BUZZER 1

INDEX

NO.

PART

NO.

PART NAME NO.

REQ.

7 077203 WASHER, LOCK 2

8 068180 SCREW 2

9 056113 TIE, WIRE 1

10 — CABLE (FIGURE 10)REF

11 056111 TIE, WIRE 1

20 Document 367

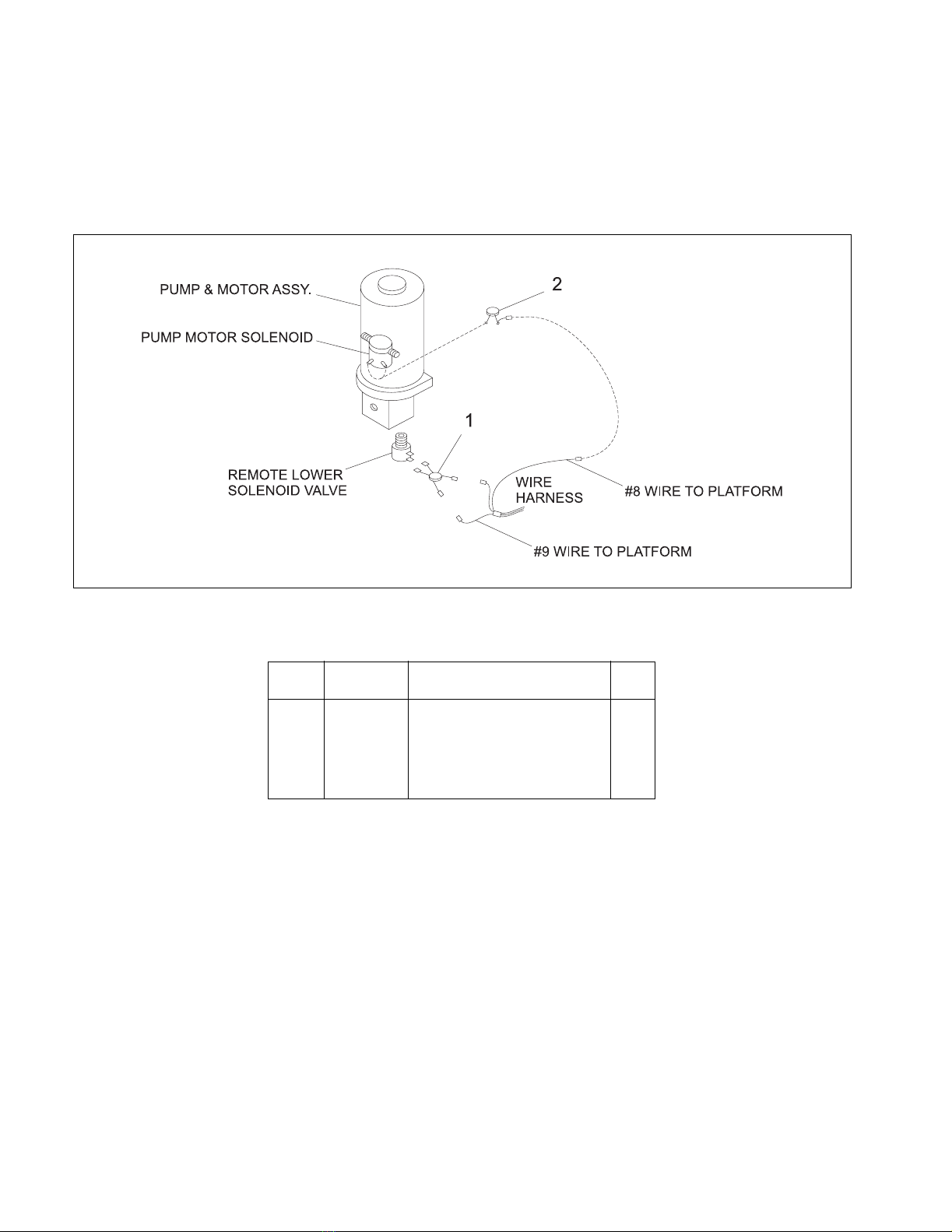

6.8.1. Spike Suppressor & Diode Assy

The 505837 suppressor and diode assembly is

located on remote lowering valve solenoid which is

mounted on the bottom of the hydraulic pump as

shown in Figure 12.

Figure 12. Spike Suppressor & Diode Assys.

INDEX

NO.

PART

NO.

PART NAME NO.

REQ.

1 505837 SPIKE SUPPRESSOR & DIODE

ASSY

1

2 505921 SPIKE SUPPRESSOR & DIODE

ASSY

1

R6295

Table of contents

Other Big Joe Truck manuals