Eoslift H10 User manual

H10/15/20

Operating Instructions

Manual

Pallet

Stacker

Hotline: 400-626-9090

Tel: +86 573 8622 9999

Fax: +86 573 8622 2900

For proper and safe operation of the products, before

using the products, be sure to read the operating

instructions carefully and retain them properly for

future reference.

The operator needs to have proficient operation skills.

The operator has responsibility to carefully understand

the performance and safety rules of the pallet stacker.

If you have any doubts during the application, please

don't hesitate to contact Eoslift.

Esteemed users:

H10/15/20 Series Manual Pallet Stackers

Ⅰ.Technical parameters 01

Ⅱ. Safe operating rules 02

Ⅲ.Maintenance 03

Ⅳ.Adjusting the finger grip handle 05

Table of contents

Ⅵ.Troubleshooting 07

Ⅶ.Parts list 09

Ⅴ.Transport, loading, test run and storage

06

H10/15/20 Series Manual Pallet Stackers

01 02

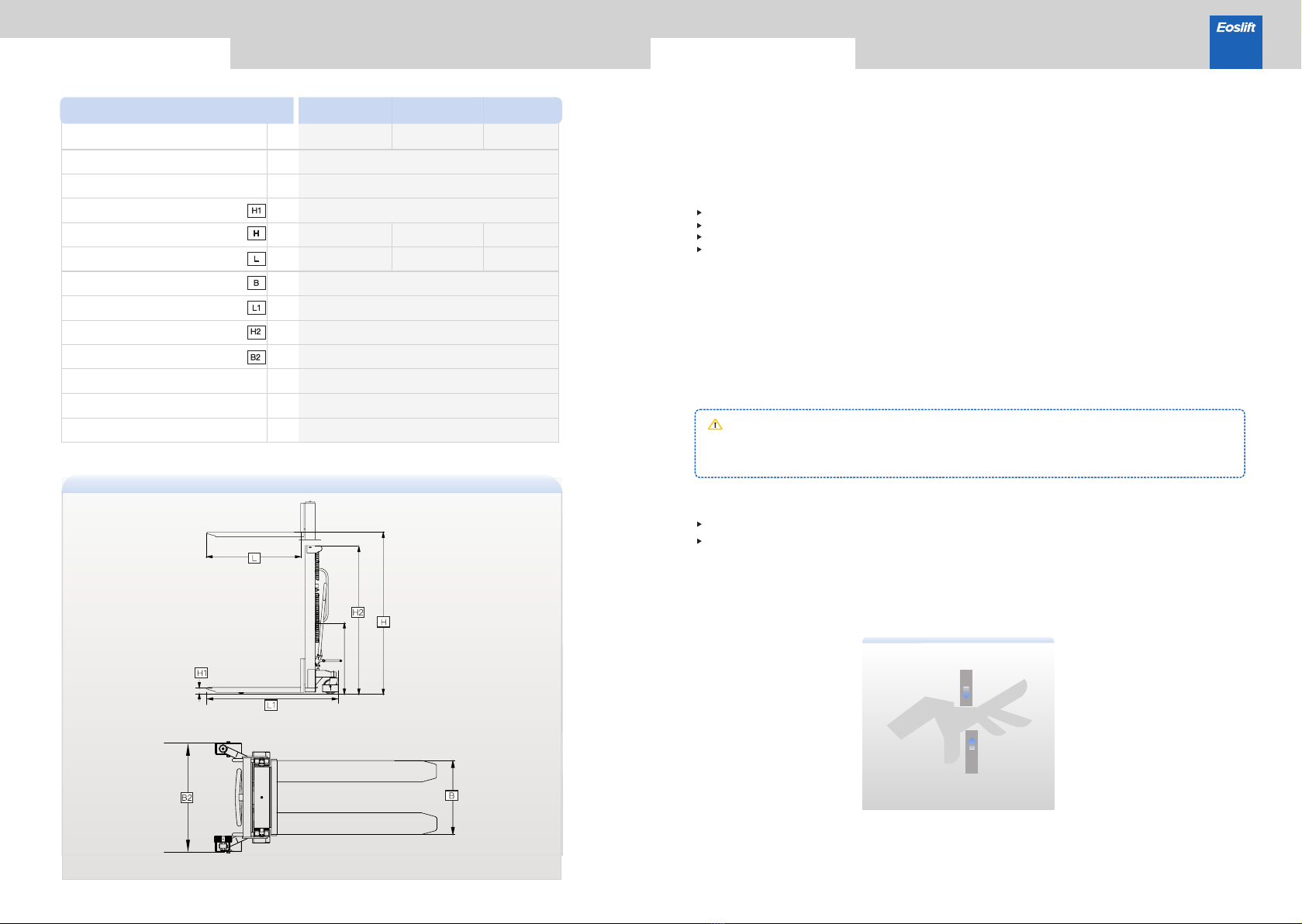

Figure1

Rated capacity

Load center

Dead-weight

Minimum fork height

Maximum fork height

Lowered Mast Height

Fork length

Overall fork width

Length of the stacker

Width of the stacker

Load-bearing wheel

Steering wheel

Minimum turning radius

1000

H10 H15

kg

mm

kg

mm

mm

mm

mm

mm

mm

mm

mm

kg

H20

1500 2000

600

270-320

85

1600/2500/3000

2030/1780/2030

1600

2030

1600

2030

1150

540/330-740

1670

764/834

Φ70×70

Φ180×50

1295

6. Operation protection

Hands and feet shall be kept far away from moving parts, such as frame, chains, forks and wheels to prevent

pinching hands.

5. Safety device and warning signs

Safety device, warning signs and the above safety precautions must be given enough attention to.

When handling the goods, the fork height must not exceed 300mm.

4. Hazardous area

The hazardous area usually refers to the area where the stacker or its lifting device (e.g. forks, attachments)

will pose threat to persons during their operation or lifting process. Typically, this range extends to the area

where goods or stacker accessories are lowered.

Unauthorized persons must leave the hazardous area. Whenever a situation causes possible harm to

persons, the operator must give a warning. If the unauthorized persons still stays in the hazardous

area after the waring is given, the operator must immediately stop the operation of the stacker.

Warning

3. Faults and defects

If stacker failure or defects occur, immediately notify the management personnel. If the stacker is not safe

for operation (such as wheel worn or brake failed, etc.), please stop using it before it is fully repaired.

2.

Free from rainwater or corrosion of harmful gases;

Room temperature of -20°C~+40°C;

Relative ambient humidity <90%;

Requirements for ground: hard, anti-skid and level without barriers.

The stacker is only applicable to indoor use and the application environment must meet the

following conditions:

1. Requirements for operator

The stacker must be operated by persons trained in operation. The operator shall be able to carry out

operation demonstration of moving and controlling goods for users, and he or she is responsible for the

stacker.Unauthorized persons are not allowed to operate the stacker. Do not carry or lift passengers.

Technical parameters

Model

Safe operating rules H10/15/20 Series Manual Pallet Stackers

03 04

Maintenance

7. Stable operation

Travel of stacker shall be stable, avoiding sharp turns and sudden start.

8. Loose or unstable stacking of goods or overloaded cargoes are prohibited.

Loose or unstable stacking of goods will cause falling of goods, or even turnover.

9. Other safety requirements

Do not use this stacker on the muddy ground.

Do not operate the stacker unless you have carefully checked its condition. Pay special attention

to the wheels, the handle assemblies, the frame, the chains, etc.

The operator shall wear safety shoes and gloves for protection.

Do not use the stacker in a potentially flammable and explosive atmosphere.

Do not use the stacker during strong wind forces.

Do not use the stacker on places insufficiently illuminated.

Do not use the stacker on a slopping ground.

The weight of goods should be distributed evenly on the two forks, do not use only one fork. The

center of gravity of goods beyond the two forks is forbidden.

Stackers should be parked on a smooth place, braked, with the forks lowered to the min. height.

Do not use the stacker with guarding removed.

Under special conditions or in special locations, the operator should be careful while operating

the stacker.

No modifications or alterations to the parts of the stacker, especially the safety device shall be made

without permission. All original spare parts have been checked by the quality inspection departments. To

ensure the safety and reliability of the stacker operation, only the manufacturer's spare parts can be used.

Replaced parts, such as batteries and waste oil must be disposed in accordance with the appropriate

environmental protection rules.

Only customer service persons specially trained by our company can carry out maintenance of the

stacker. Thoroughly standardized maintenance is the most important preconditions to ensure stable

and reliable operation performance of the stacker. Neglect of regular maintenance could result in failure

and malfunction of the stacker and poses a potential threat to the safety of the staff and operation.

Warning

1. Hydraulic oil

Please check the oil level every six months and change the oil every twelve months. 32 # hydraulic oil

is recommended, with total volume of about 2.0 liters.

2. Routine maintenance

It is necessary to check and maintain the stacker daily for sound application. Special attention should

be paid to:

(1)The wheels, the axles, as thread, rags, etc. may block the wheels and axles;

(2)The fork and the frame which may be deformed. The forks should be unloaded and lowered in the

lowest position.

3. Lubrication

Use motor oil or grease to lubricate all movable parts.

4. Remove the air

The air may enter the hydraulic pump during the transportation. It will cause the forks fails to be lifted

when switched to the lifting position. The air can be removed in the following way: pull the finger grip

control handle (3-1) to the lowering position and move handle up and down for several times.

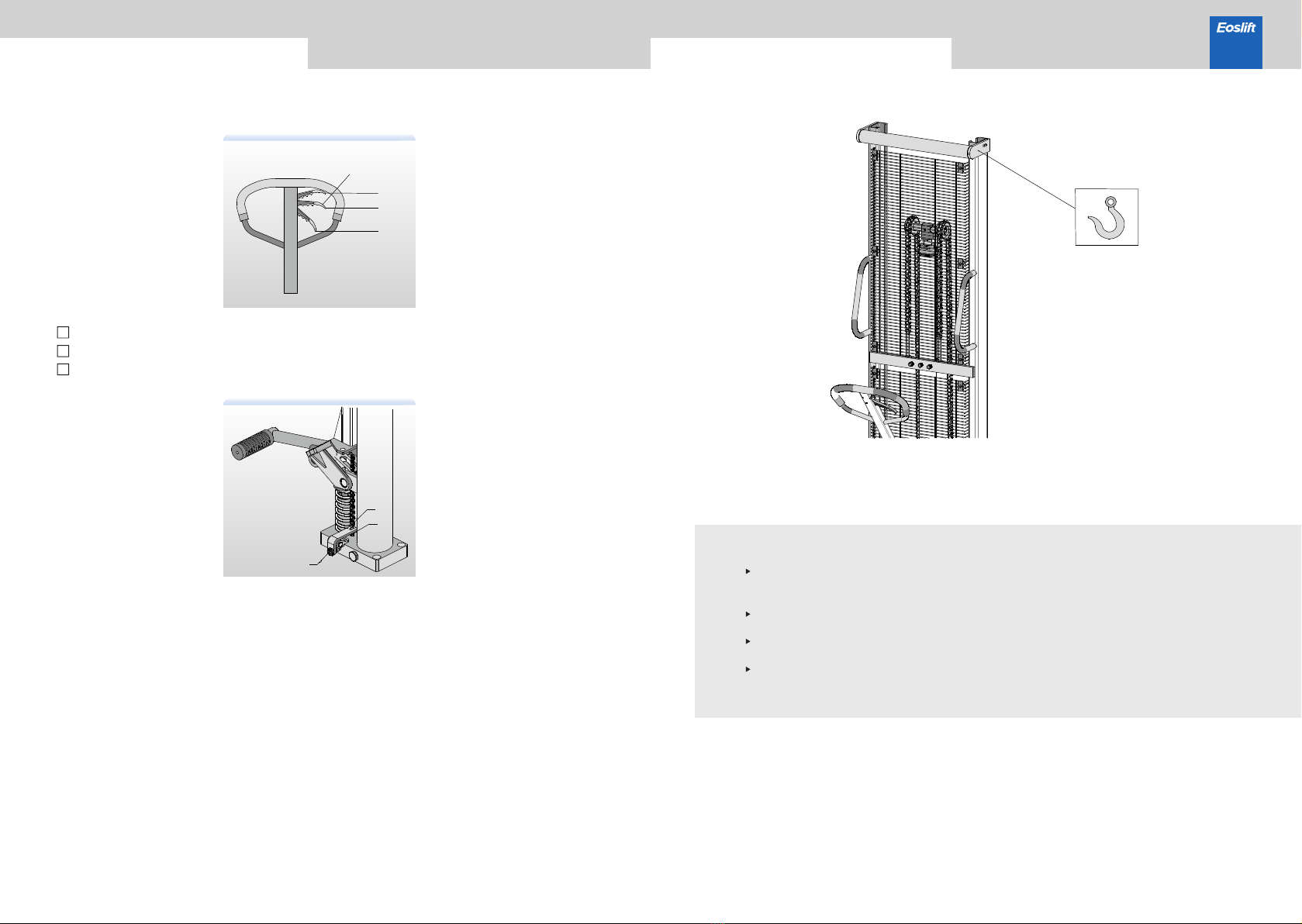

Figure 2

Safe operating rules H10/15/20 Series Manual Pallet Stackers

Adjusting finger grip control handle

05 06

On the handle of this stacker, you can find finger grip control handle (3-1) which can be

regulated in three positions :

However if they have been changed, you can adjust them according to the following steps:

①If the forks elevate while pumping in the Middle position, turn the adjusting nut (4-2) on the

adjusting bolt (4-1) or screw (4-3) clockwise until pumping action does not raise or lower the forks

and the finger grip control handle (3-1) works properly Middle position.

②If the forks descend while pumping in the Middle position, turn the adjusting nut (4-2) on the

adjusting bolt (4-1) or screw (4-3) counterclockwise until pumping action does not raise or lower

the forks and the finger grip control handle(3-1) works properly Middle position .

③If the forks do not descend when the finger grip control handle (3-1) is in the Lowering position,

turn adjusting nut (4-2) on the adjusting bolt (4-1) or screw (4-3) clockwise until raising the control

handle lowers the forks. Then check the Middle position according to items ①and ② to make sure

the nut (4-2) and screw(4-3) are in the proper position.

④ If the forks do not elevate when the finger grip control handle (3-1) is in the Lifting position, turn

adjusting nut (4-2) on the adjusting bolt (4-1) or screw (4-3) counterclockwise until turning the

control handle to that position lifts the forks. Then check the function of the Lowering position and

Middle position according to items ①, ②and ③ is normal.

Transport, loading, test run and storage

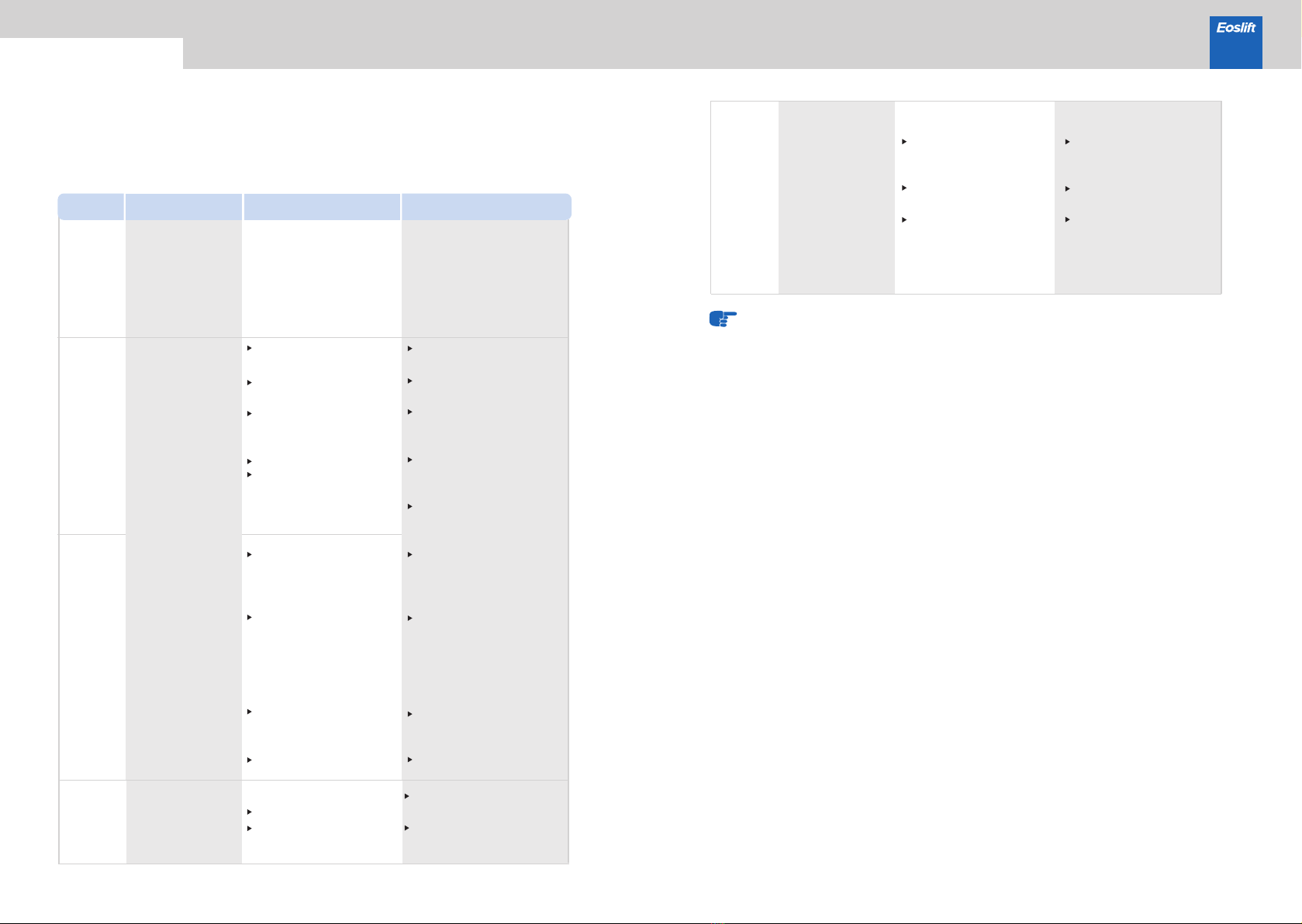

Figure 3

Figure 5

Before loading, the operator shall check the stacker weight to choose the suitable

hoisting equipment. When the stacker is unloaded, the operator shall look out for

safety around to ensure safe landing of the stacker.

The truck shall be commissioned according to the following function tests: steering,

traveling, braking and combined functions with rated capacity.

When a stacker is inoperative, the loads (if applicable) shall be removed with proper

tools, the stacker shall be transported out of the working zone with a proper way.

Shut down and in storage for a long time, the storage environment shall be kept dry

and clean, with forks lowered to their lowest position.

As shown in Figure 5, lifting points are on both sides of the stacker.

Figure 4

3-1

Lowering

Middle position

Lifting

4-1

4-2

4-3

Lift - lifting

Middle position - travel

Lower - lowering

1

2

3

H10/15/20 Series Manual Pallet Stackers

Troubleshooting

07 08

This chapter enables the user to identify and rectifies basic faults and the effects of incorrect

operation. When trying to locate a fault, proceed in the order shown in the table below. If, after

carrying out the following remedial action listed in“actions”, the stacker cannot be restored to

operation, contact the manufacturer’s after-sale service department. Additional troubleshooting

must only be performed by the manufacturer’s specialist service engineers. The manufacturer's

customer service department is specially trained to carry out these operations.

1

2

3

4

5

The forks

descended without

operation

Note: Do not attempt to repair the stacker unless you are trained in the professions.

Impurities in the oil cause

the valve to be unable to

close tightly

Seals damaged

Adjusting nut(4-2) or

adjusting screw(4-3) in

wrong positions

Change hydraulic oil

Replace the damaged

seals with new seals

Adjust nut(4-2) or adjusting

screw(4-3)

Fault Possible cause Action

No.

The forks cannot

be lifted to max.

height

The forks cannot

be lifted

The forks cannot

be lowered

Oil leakage

The hydraulic oil is

insufficient

The hydraulic oil is

insufficient

The hydraulic oil has

impurities

Adjusting nut(4-2) or

adjusting screw(4-3) in

wrong positions

Air enters into the cylinder

Seals damaged

The piston rod or the frame

is deformed resulting from

overloading or cargo

slanting to one side

The forks was kept in raised

position for extended period

of time, then the piston rod

is exposed to the air and gets

rusted , which blocks the

motion of the piston

Adjusting nut(4-2) or

adjusting screw(4-3) in wrong

positions

Rollers rusted and blocked

Seals damaged

Parts damaged

Replace the damaged seals

with new seals

Replace the damaged parts

with new parts

Add the hydraulic oil

Add the hydraulic oil

Change hydraulic oil

Adjust nut(4-2) or adjusting

screw(4-3)

Put the finger grip handle in

the upper position and press

the handle dozens of times

Replace the damaged seals

with new seals

Replace the related parts of

the cylinder or the frame with

new ones

Keep the forks at the lowest

position while not in use, and

keep piston rods lubricated in

time

Adjust nut(4-2) or adjusting

screw(4-3)

Lubricate rollers

H10/15/20 Series Manual Pallet Stackers

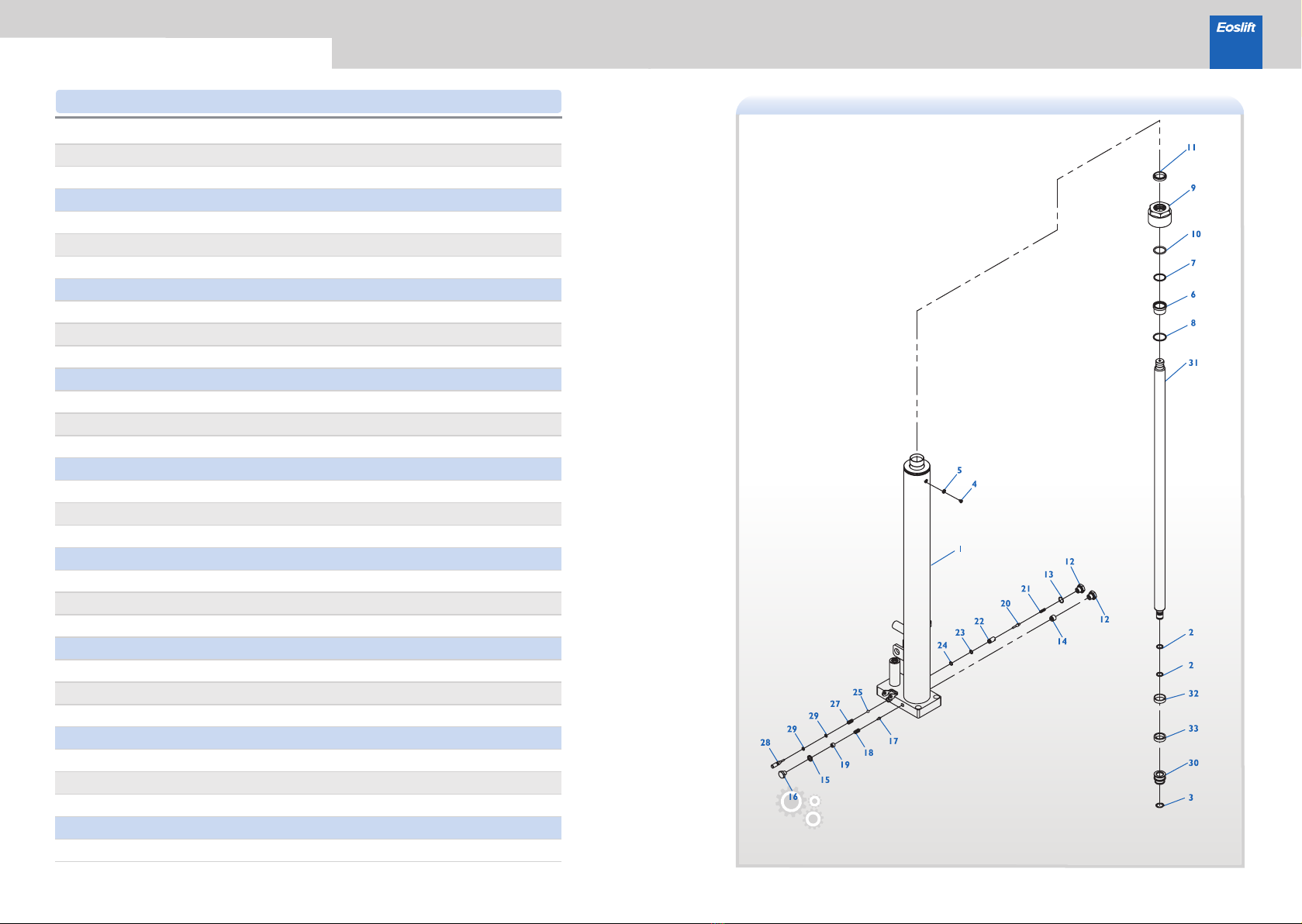

09 10

H10/15/20 Series Manual Pallet Stackers

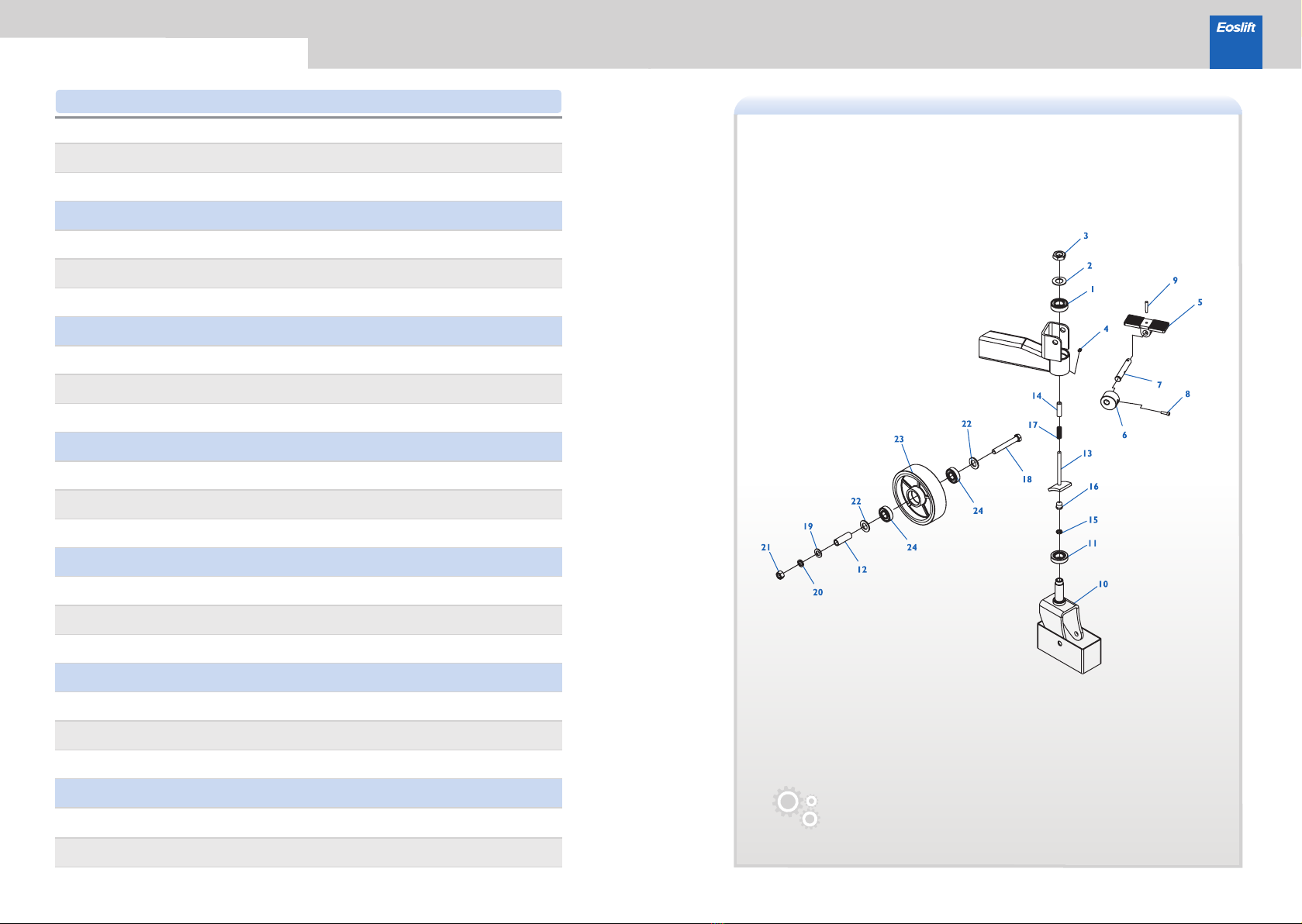

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

WC02000224

WC02000343

WE04000019

WC02000019

WC02000345

WC02000346

WC02000347

WE03000021

WE06000012

WC02000350

WC02000225

WC02000348

WC02000351

WC02000342

WE04000020

WC02000344

WC02000349

WE01000004

WE05000012

WE05000013

WE04000012

WE05000014

WC02000226

WC02000285

WC02000435

WC02000022

Washer

Pedal, galvanized

Clamping roller, galvanized

Shaft, galvanized

GB117, Taper pin 6 × 42, galvanized

Ribbon brake guide wheel bracket,black

GB297,Tapered Roller Bearings 30205

Big wheel shaft sleeve

Brake rod, black

Sleeve

Connecting sleeve, galvanized

Reset spring

GB95,Plain washer 14,galvanized

GB6170, Hexagon nut M14, galvanized

GB95,Plain washer 20,galvanized

Nylon wheelφ180×50(plane wheel)

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

2

1

2

GB276,Deep groove ball bearing 6205,

two-side shielded

GB6173,Hexagon thin nut M22×1.5,

galvanized

GB70.1, Hexagon socket head cap screw

M6 × 20, galvanized

JB7940.4, Push-fit type grease nipple 6

GB6172.1,Hexagon thin nut M10,galvanized

GB5780,Hexagon head bolt M14×100,

galvanized

GB93,Normal type spring lock washer 14,

galvanized

Iron-core PU wheel φ180×50, bright red PU,

black iron core

Nylon wheelφ180×50(flower-shape wheel)

GB276,Deep groove ball bearing 6204,

two-side shielded

Qty.

NO. Parts number Description

Parts list· Guide wheel,with brake

11 12

H10/15/20 Series Manual Pallet Stackers

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

WC02000224

WC02000352

WE05000002

WE03000004

WC02000019

WC02000353

WC02000348

WE01000004

WE05000012

WE05000013

WE04000012

WC02000225

WE05000014

WC02000226

WC02000285

WC02000435

WC02000022

Wheel shaft cover, galvanized

JB7940.4, Push-fit type grease nipple 6

Rear wheel carrier, black

Big wheel shaft sleeve

GB95,Plain washer 14,galvanized

GB6170, Hexagon nut M14, galvanized

GB297,Tapered Roller Bearings 30205

GB95,Plain washer 20,galvanized

Nylon wheelφ180×50(plane wheel)

1

1

1

1

1

1

1

1

1

1

1

1

2

1

2

GB276,Deep groove ball bearing 6205,

two-side shielded

GB93,Normal type spring lock washer 10,

galvanized

GB70.1,Hexagon socket head cap screw

M10×25,galvanized

GB5780,Hexagon head bolt M14×100,

galvanized

GB93,Normal type spring lock washer 14,

galvanized

Iron-core PU wheel φ180×50, bright red PU,

black iron core

GB276,Deep groove ball bearing 6204,

two-side shielded

Nylon wheelφ180×50(flower-shape wheel)

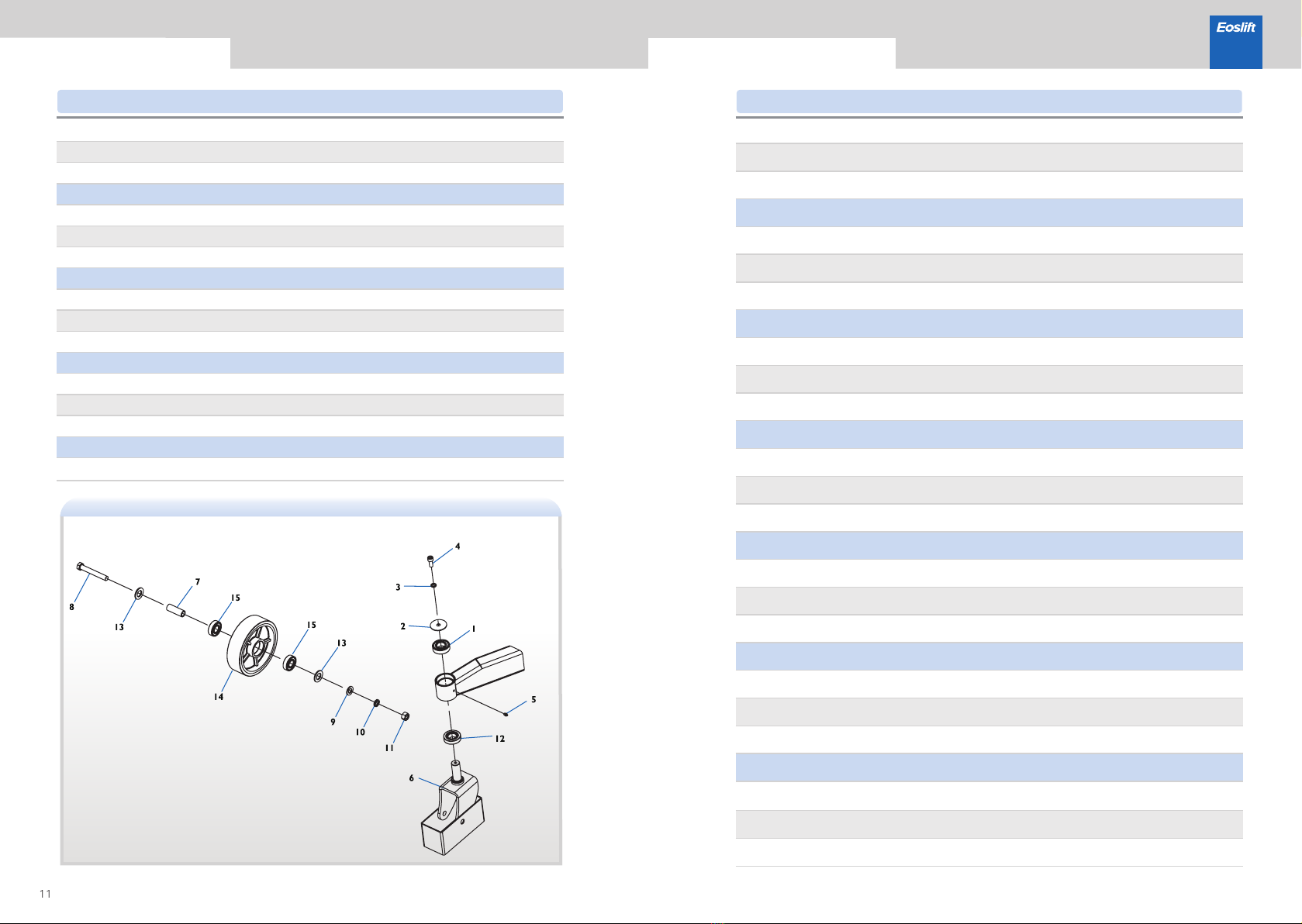

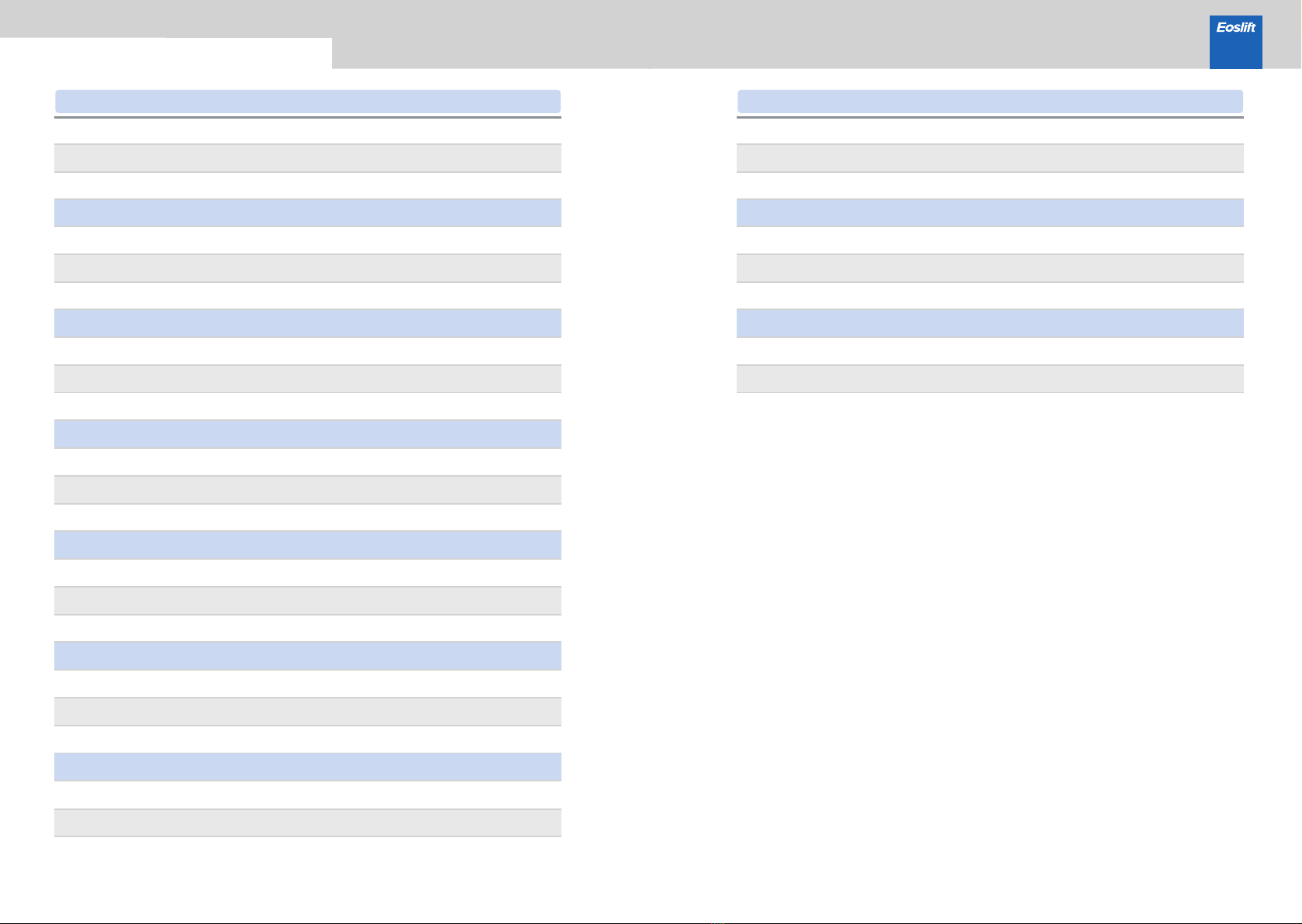

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

WC02000337

WC02000402

WC02000421

WC02000424

WC02000433

WC02000357

WE04000005

WE03000016

WE05000004

WC02000330

WE04000013

WE01000002

WC02000355

WE04000009

WE03000014

WE04000015

WC02000227

WC02000286

WC02000259

WE07000004

WC02000022

WC01000020

WC01000025

WE03000004

WC02000338

WE05000009

WE05000002

External frame (1.0t, fixed), 5012

External frame (1.0t, movable), 5012

External frame (1.5t, fixed), 5012

External frame (1.5t, movable), 5012

External frame (2.0t, movable), 5012

Guarding screen, black

GB6170,Hexagon nut M5,galvanized

GB95,Plain washer 5,galvanized

Guarding screen, black

Locking ring, galvanized

GB6170,Hexagon nut M10,galvanized

Nylon wheel φ70×70

Front wheel shaft

GB894.1,Circlip for shaft 20,blackening

Cylinder assembly(1.0t/1.5t,1.6), black

Cylinder assembly(2.0t,1.6), black

EOS-HS handle

GB95,Plain washer 10,galvanized

1

1

10

10

10

1

2

1

1

3

4

4

2

2

4

4

1

5

1

3

3

Gb5781, Hexagon head bolts-Full thread

M10 × 50, galvanized

GB802,Acorn nut--sssembling typeM10,

galvanized

GB70.1,Hexagon socket head cap screw

M5×16,galvanized

GB889.1, Hexagon locking nut M8, galvanized

GB276,Deep groove ball bearing 6204,

two-side shielded

GB70.1,Hexagon socket head cap screw

M10×25,galvanized

GB93,Normal type spring lock washer 10,

galvanized

GB70.1,Hexagon socket head cap screw

M8×20,galvanized

Iron-core PU wheel φ70×70, bright red PU

Qty.

NO. Parts number Description Qty.

NO. Parts number Description

Parts list· Guide wheel Parts list· Single frame

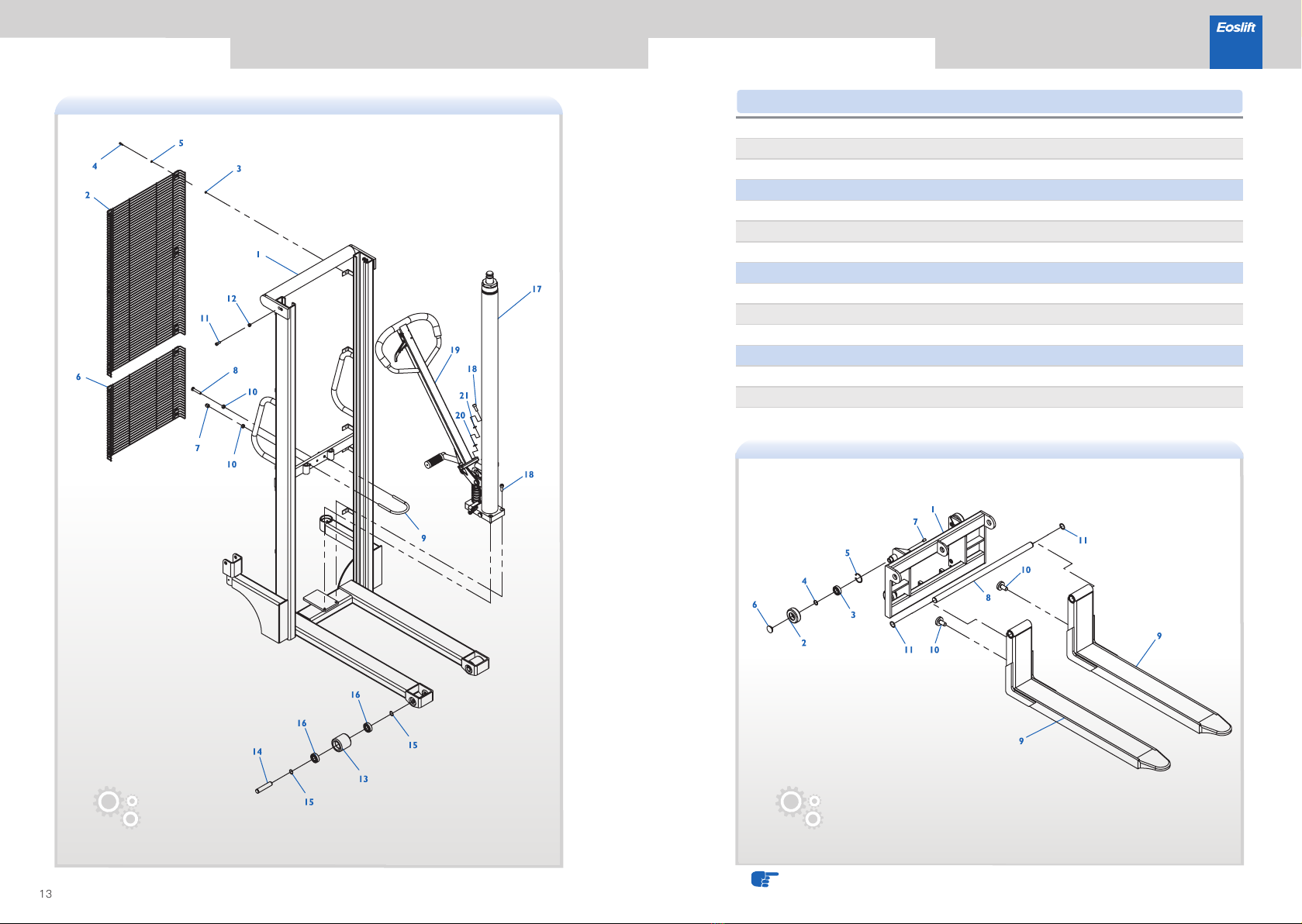

13 14

H10/15/20 Series Manual Pallet Stackers

1

2

3

4

5

6

7

8

9

10

11

WC02000403

WC02000425

WC02000434

WC02000341

WC02000231

WC02000224

WE07000010

WE07000007

WC02000232

WE03000019

WC02000404

WC02000282

WC02000284

WE07000011

Fork guide plate bracket(1.0t), black

Fork guide plate bracket(1.5t), black

Fork guide plate bracket(2.0t), black

Iron wheel (1.0t/1.5t)

Iron wheel (2.0t)

GB894.1,Circlip for shaft 25,blackening

GB893.1,Circlip for hole 52,blackening

Iron wheel cap

Shaft (740) galvanized

Fork assembly (1150), black

Adjusting screw,galvanized

GB894.1,Circlip for shaft 32,blackening

1

4

4

4

4

4

8

1

2

2

2

GB276,Deep groove ball bearing 6205,

two-side shielded

Gb77, Hexagon socket set screw with flat point

M12×20,galvanized

Qty.

NO. Parts number Description

Parts list· Single frame Parts list· Movable fork assy

NOTE:For single mast models

15 16

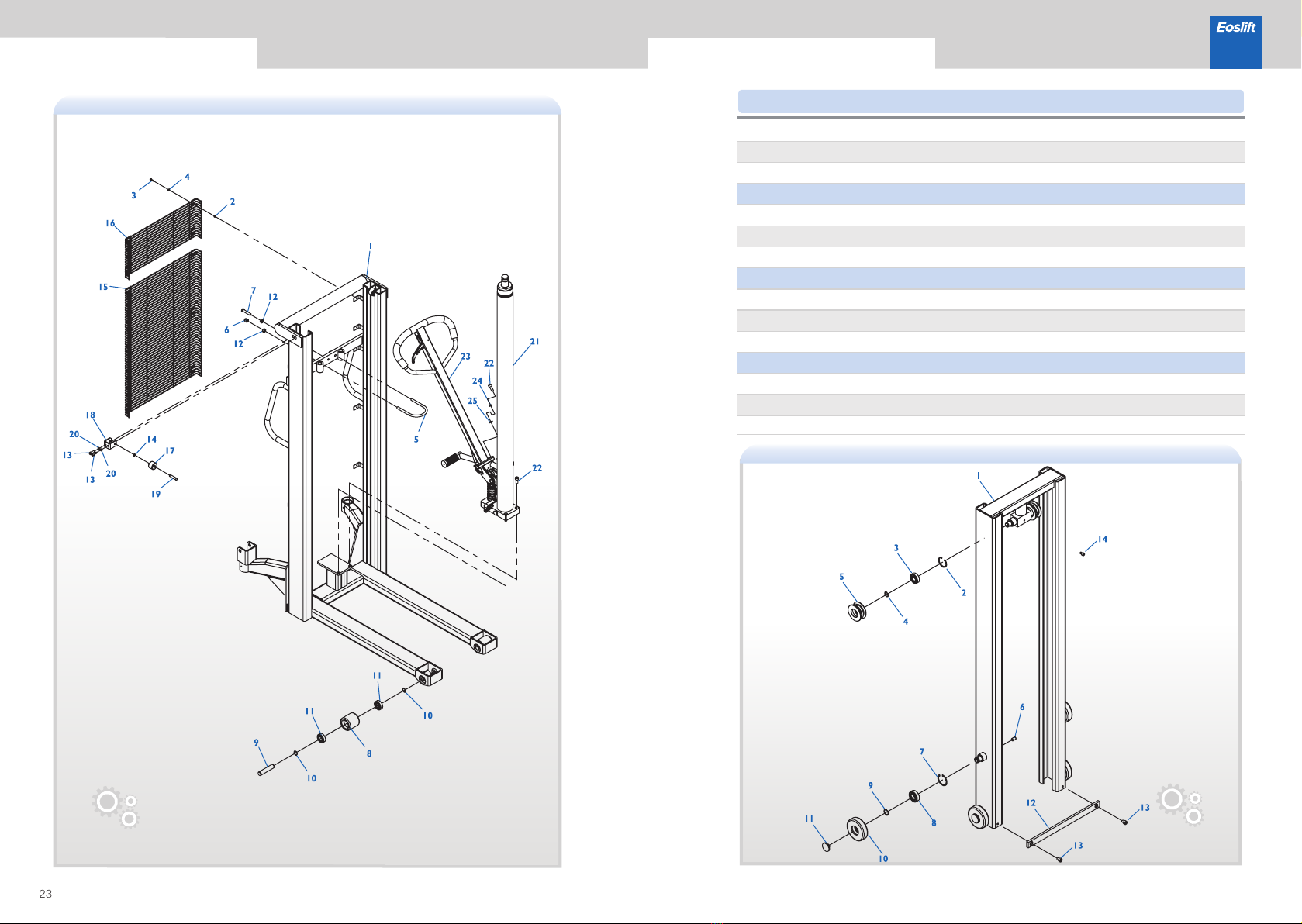

H10/15/20 Series Manual Pallet Stackers

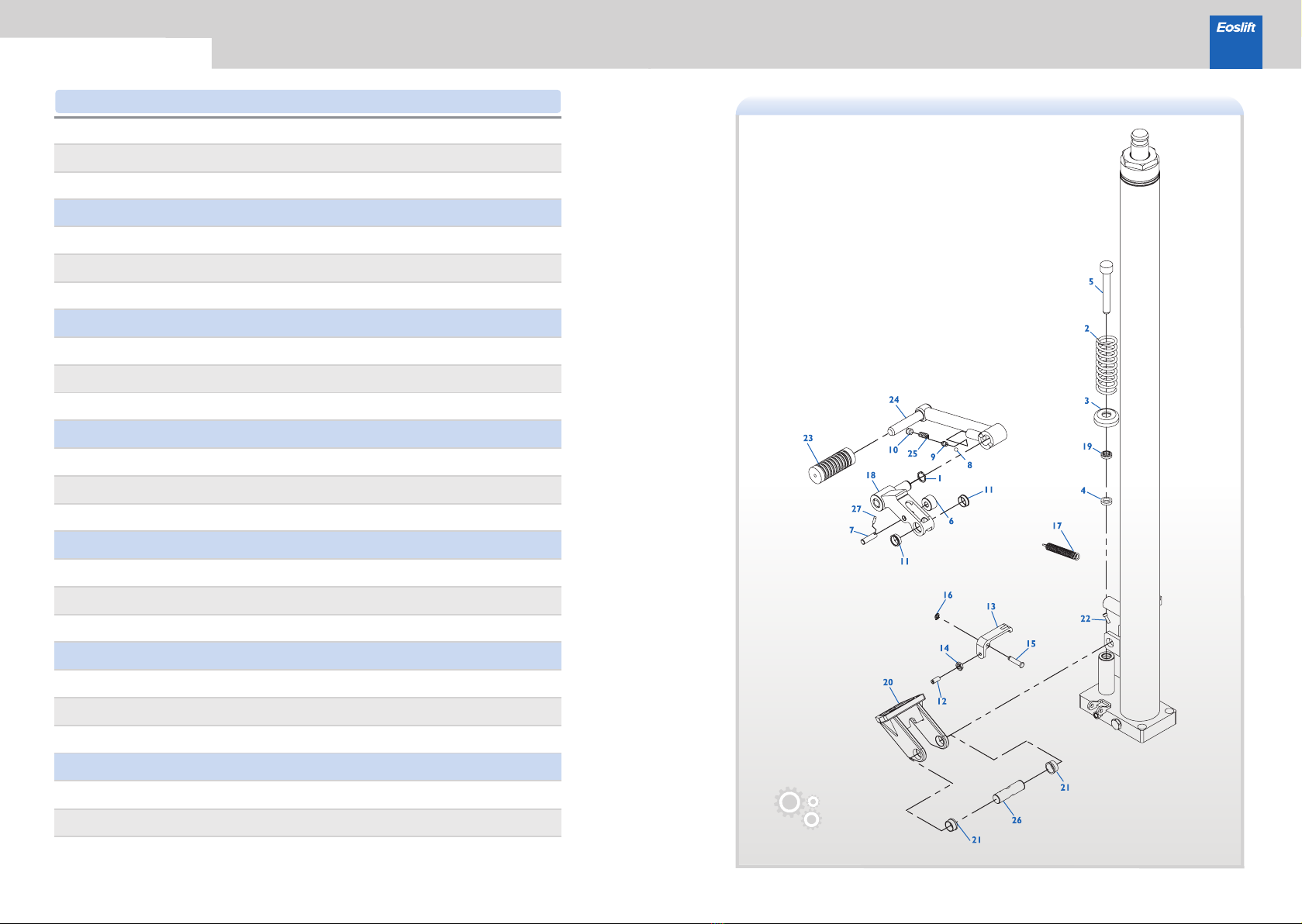

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

WE07000004

WC02000365

WC02000108

WC02000387

WC02000363

WC02000390

WC02000391

WC02000069

WC02000393

WC02000375

WC02000401

WE03000003

WC02000377

WE04000003

WC02000378

WE07000012

WC02000397

WC02000395

WC02000388

WC02000399

WC02000400

WE03000016

WC02000394

WC02000396

WC02000392

WC02000398

WE06000016

GB894.1,Circlip for shaft 20,blackening

Pressure spring

Spring cover,galvanized

Seal ring UHS14

Pump core

Small roller, galvanized

Roller shaft, galvanized

GB308,Steel ball S7

Spring seat

Screw

Flanged sliding bearing 30/23×20×8

Unloading plate, black

GB6172.1, Hexagon thin nut M8, galvanized

Pin, galvanized

GB894.1,Circlip for shaft 8,blackening

Extension spring

Pedal stand, black

Dustproof ring DH14

Handle holder, black

Flanged sliding bearing 30/23×20×11.5

Rubber sleeve

Pedal, black

Spring

Pivot, galvanized

GB117, Taper pin 4 × 18, blackening

1

1

1

1

1

1

1

1

1

1

2

1

1

1

1

1

1

1

1

1

2

1

1

1

1

1

1

Gb73, Slotted set screws with flat point

M8 × 20, galvanized

GB70.1,Hexagon socket head cap screw

M5×16,galvanized

Qty.

NO. Parts number Description

Parts list· Pedal

17 18

H10/15/20 Series Manual Pallet Stackers

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

WC02000358

WC02000382

WE07000004

WE03000023

WC02000383

WC02000364

WC02000385

WC02000384

WC02000362

WC02000386

WC02000110

WC02000369

WC02000115

WC02000381

WC02000389

WC02000376

WC02000045

WC02000374

WC02000375

WC02000372

WC02000370

WC02000371

WC02000132

WC02000373

WC02000069

WC02000366

WC02000368

WC02000367

WC02000117

WC02000361

WC02000360

WC02000380

WC02000379

Cylinder body(1.0t/1.5t,1.6m),black

GB3452.1,O-ring φ15×2.65

GB894.1,Circlip for shaft 20,blackening

GB982, Combination sealing gasket 6

Guide sleeve

GB3452.1,O-ring φ31.5×2.65

GB3452.1,O-ringφ34.5×2.65

Cap, galvanized

GB3452.1,O-ring φ31.5×3.55

Dustproof ring DHS31.5

Left screw plug

GB3452.1,O-ring φ16×1.8

Flow-limiting valve assembly

GB982, Combination sealing gasket 12

Screw plug, galvanized

Safety valve spool

Adjusting spring

Screw

Spool

Spool spring

Valve sleeve

GB3452.1,O-ring φ9.0×1.8

Sealing gasket

GB308,Steel ball S7

Dust cover

Unloading spring

Unloading rod

GB3452.1,O-ring φ6.9×1.8

Piston

Piston rod (1.0t / 1.5t, 1.6m)

Piston guide ring ZS35

Sealing ring YXD35

1

2

1

1

1

1

1

1

1

1

1

2

2

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

2

1

1

1

1

GB818,Pan head screw with cross recess

M6×10,galvanized

Qty.

NO. Parts number Description

Parts list· Cylinder assembly(φ31.5)

19 20

H10/15/20 Series Manual Pallet Stackers

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

WC02000437

WC02000414

WC02000418

WC02000369

WC02000389

WC02000376

WC02000045

WC02000374

WC02000375

WC02000372

WC02000370

WC02000371

WC02000373

WC02000069

WC02000366

WC02000368

WC02000367

WC02000438

WC02000410

WC02000419

WC02000382

WC02000411

WC02000407

WE05000014

WC02000413

WC02000409

WC02000384

Cylinder (2.0t,1.6m),black

Cylinder (2.5m), black

Cylinder (3.0m), black

Left screw plug

GB982, Combination sealing gasket 12

Screw plug, galvanized

Safety valve spool

Adjusting spring

Screw

Spool

Spool spring

Valve sleeve

Sealing gasket

GB308,Steel ball S7

Dust cover

Unloading spring

Unloading rod

Piston rod (2.0t, 1.6m)

Piston rod(2.5m)

Piston rod(3.0m)

GB3452.1,O-ring φ15×2.65

Piston

QYD seal ring 40 × 32 × 8

GB95,Plain washer 20,galvanized

Guide sleeve

GB3452.1,O-ring φ39.5×2.65

GB3452.1,O-ringφ34.5×2.65

1

2

1

1

1

1

1

1

1

1

1

1

1

1

1

1

2

1

1

1

1

1

1

24

25

26

27

28

29

30

31

32

33

WC02000412

WC02000058

WC02000408

WC02000383

WE03000023

WC02000117

WC02000132

WC02000115

WE07000004

WC02000381

Cap, galvanized

Dustproof ring DH35

Piston guide ring ZS40

GB982, Combination sealing gasket 6

GB3452.1,O-ring φ6.9×1.8

GB3452.1,O-ring φ9.0×1.8

GB3452.1,O-ring φ16×1.8

GB894.1,Circlip for shaft 20,blackening

Flow-limiting valve assembly

1

1

1

1

1

2

1

2

1

1

GB818,Pan head screw with cross recess

M6×10,galvanized

Qty.

NO. Parts number Description Qty.

NO. Parts number Description

Parts list· Cylinder assembly(φ35)

21 22

H10/15/20 Series Manual Pallet Stackers

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

WC02000405

WC02000420

WE04000005

WE03000016

WE05000004

WC02000355

WE04000013

WE01000002

WC02000227

WC02000286

WC02000259

WE07000004

WC02000022

WE04000009

WE03000014

WE07000008

WC02000406

WC02000357

WC02000292

WC02000293

WC02000294

WC02000295

WE05000005

WC01000022

WC01000023

WE03000004

WC02000338

WE05000002

WE05000009

External frame (1.0t, 2.5m, fixed), 5012

External frame(1.0t,3.0m,movable),5012

GB6170,Hexagon nut M5,galvanized

GB95,Plain washer 5,galvanized

Locking ring, galvanized

Iron-core PU wheel φ70×70, bright red PU

Nylon wheel φ70×70

Front wheel shaft

GB894.1,Circlip for shaft 20,blackening

GB6170,Hexagon nut M10,galvanized

GB894.1,Circlip for shaft 10,blackening

Guarding screen (2.5m), black

Guarding screen (3.0m), black

Guarding screen, black

Upper guide wheel

Upper guide bracket, galvanized

Pivot

Cylinder assembly (2.5m), black

Cylinder assembly (3.0m), black

EOS-HS handle

GB95,Plain washer 10,galvanized

1

10

10

10

1

2

1

2

2

4

4

3

4

2

1

1

2

2

2

2

1

5

1

3

3

GB70.1,Hexagon socket head cap screw

M5×16,galvanized

GB802,Acorn nut--sssembling type

M10,galvanized

Gb5781, Hexagon head bolts-Full thread

M10 × 50, galvanized

GB276,Deep groove ball bearing 6204,

two-side shielded

GB70.1,Hexagon socket head cap screw

M8×20,galvanized

GB93,Normal type spring lock washer 8,

galvanized

GB70.1,Hexagon socket head cap screw

M10×25,galvanized

GB93,Normal type spring lock washer 10,

galvanized

Qty.

NO. Parts number Description

Parts list· Cylinder assembly(φ35)Parts list· External frame

23 24

H10/15/20 Series Manual Pallet Stackers

1

2

3

4

5

6

7

8

9

10

11

12

13

14

WC02000290

WC02000299

WE07000006

WC02000022

WE07000004

WC02000261

WE03000019

WE07000007

WC02000224

WE07000010

WC02000231

WC02000232

WD01000211

WE03000020

WE03000017

Internal frame, 5012 (2.5m)

Internal frame, 5012 (3.0m)

GB893.1,Circlip for hole 47,blackening

GB894.1,Circlip for shaft 20,blackening

Sprocket (roller chain)

GB893.1,Circlip for hole 52,blackening

GB894.1,Circlip for shaft 25,blackening

Iron wheel

Iron wheel cap

Lower stay bar

1

2

2

2

2

8

4

4

4

4

4

1

2

1

GB276,Deep groove ball bearing 6204,

two-side shielded

Gb77, Hexagon socket set screw with flat point

M12×20,galvanized

GB276,Deep groove ball bearing 6205,

two-side shielded

GB70.1,Hexagon socket head cap screw

M10×12,galvanized

GB70.1,Hexagon socket head cap screw

M8×12,galvanized

Qty.

NO. Parts number Description

Parts list· Internal frameParts list· External frame

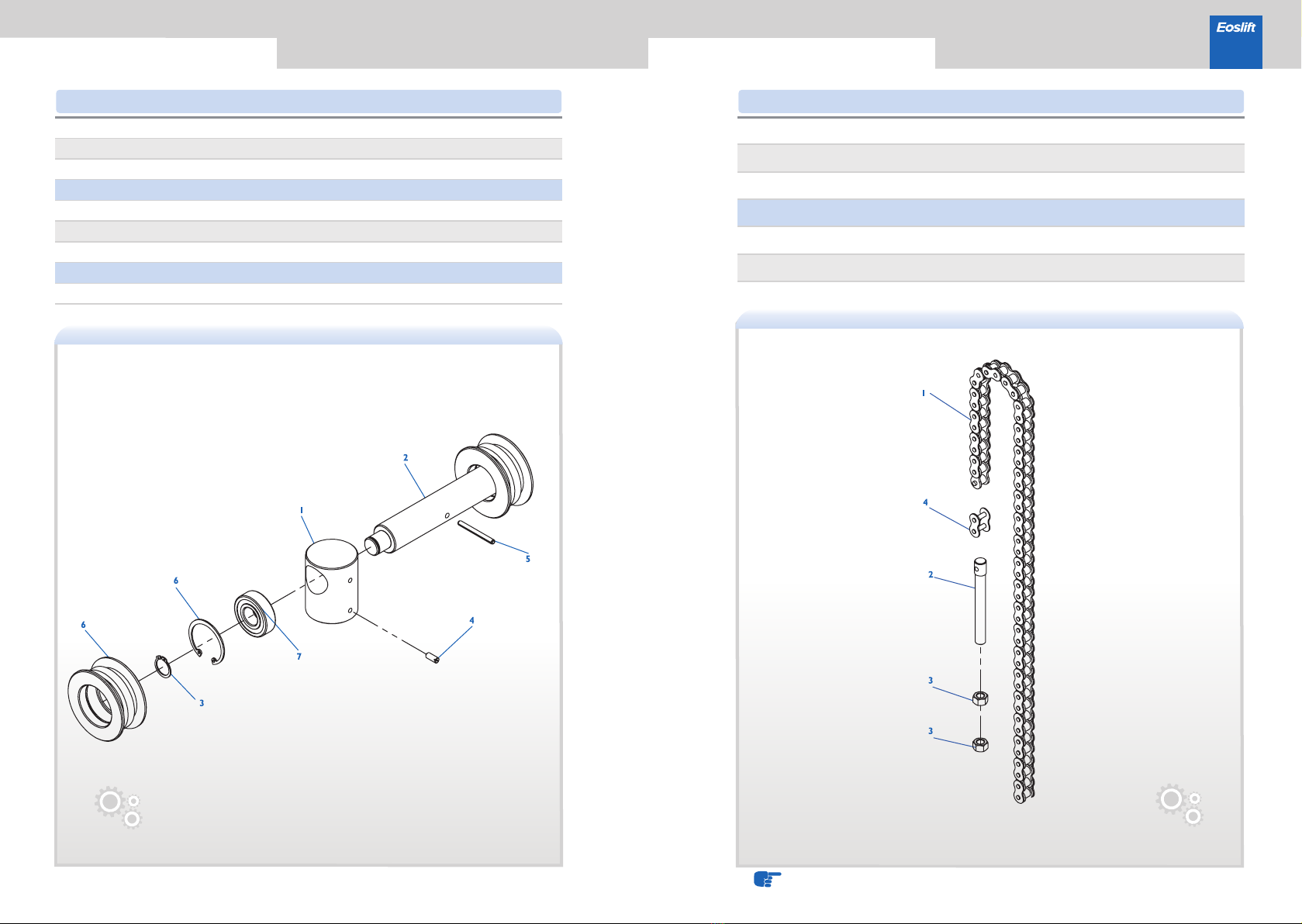

H10/15/20 Series Manual Pallet Stackers

26

1

2

3

4

5

6

7

8

WC02000354

WC02000356

WE07000004

WE03000022

WE06000013

WC02000261

WC02000317

WC02000022

WE07000006

Top beam seat,galvanized

Top beam shaft, galvanized

GB894.1,Circlip for shaft 20,blackening

Sprocket (roller chain)

Sprocket (leaf chain)

GB893.1,Circlip for hole 47,blackening

1

1

2

1

1

2

2

2

1

2

3

4

WC02000340

WC02000287

WC02000300

WC02000260

WE04000012

WC02000222

Roller chain(1.6m)

Roller chain(2.5m)

Roller chain(3.0m)

Bolt

GB6170, Hexagon nut M14, galvanized

Single-row roller chain CL connector 12A-1

2

2

4

4

GB71,Slotted set screws with flat point

M6×16,galvanized

GB879.1,Spring type straight pin

5×50,blackening

GB276,Deep groove ball bearing 6204,

two-side shielded

25

Qty.

NO. Parts number Description Qty.

NO. Parts number Description

Parts list· Roller ChainParts list· Top beam assembly

NOTE:For the 1.0t models.

H10/15/20 Series Manual Pallet Stackers

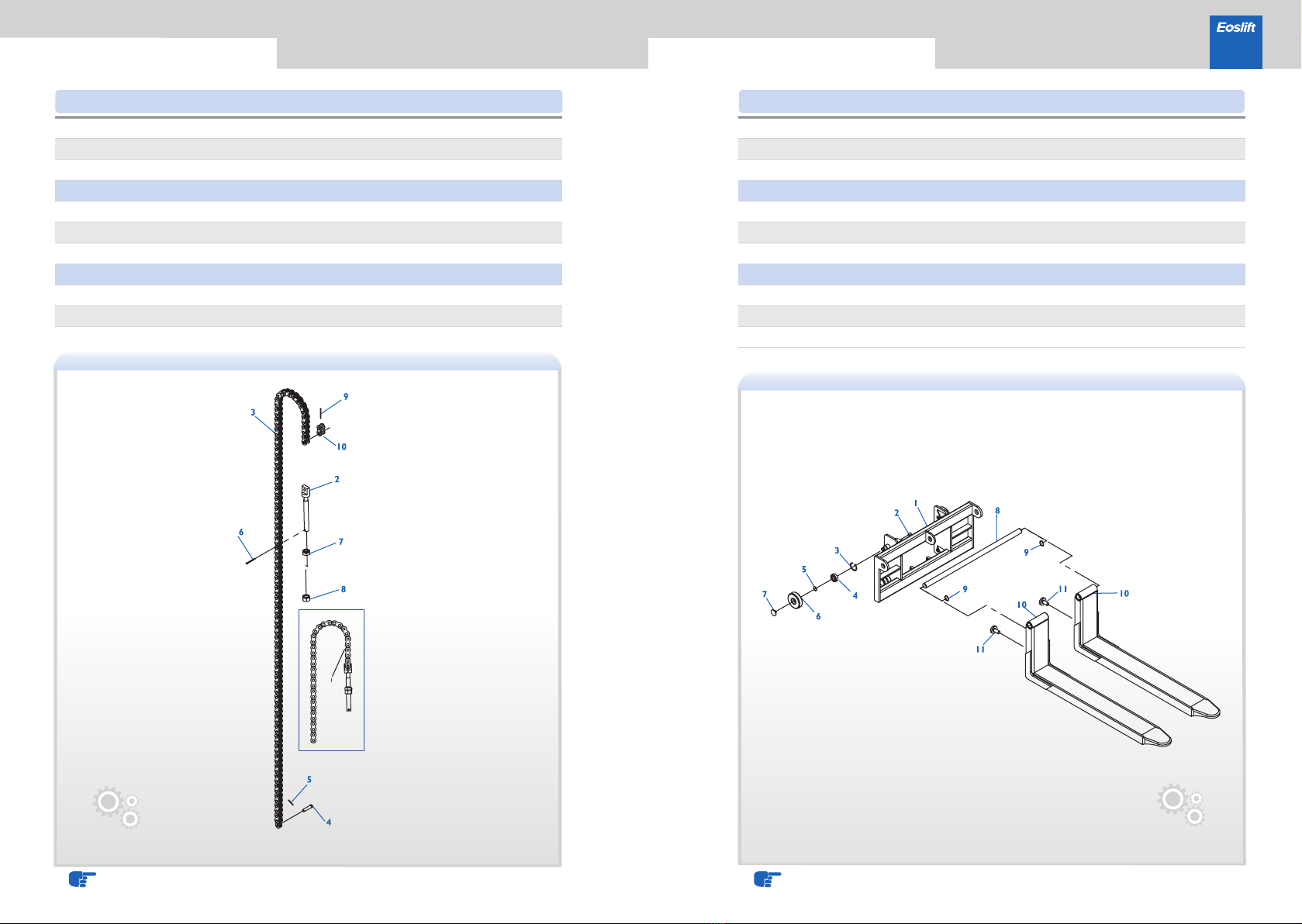

1

2

3

4

5

6

7

8

9

10

WC02000423

WJ11900006

WJ11900007

WJ11900015

WJ11900003

WJ11900001

WJ11900005

WJ11900004

WJ11900002

WJ11900016

Leaf chain, 58 links (1.6m)

LH1223 long end connector

Leaf chain

Chain pivot

GB91, Cotter pin 2 × 16

GB91, Cotter pin 3.2 × 32

Spherical nut

GB6171, nut M14 × 1.5 × 12.8

GB91, Cotter pin 2 × 32

Chain shackle

2

2

2

2

2

2

2

2

2

2

27 28

WC02000416

WE03000019

WE07000007

WC02000224

WE07000010

WC02000231

WC02000232

WC02000404

WE07000011

WC02000282

WC02000284

Fork guide plate bracket(1.0t), black

GB893.1,Circlip for hole 52,blackening

GB894.1,Circlip for shaft 25,blackening

Iron wheel

Iron wheel cap

Shaft (740) galvanized

GB894.1,Circlip for shaft 32,blackening

Fork assembly (1150), black

Adjusting screw,galvanized

1

8

4

4

4

4

4

1

2

2

2

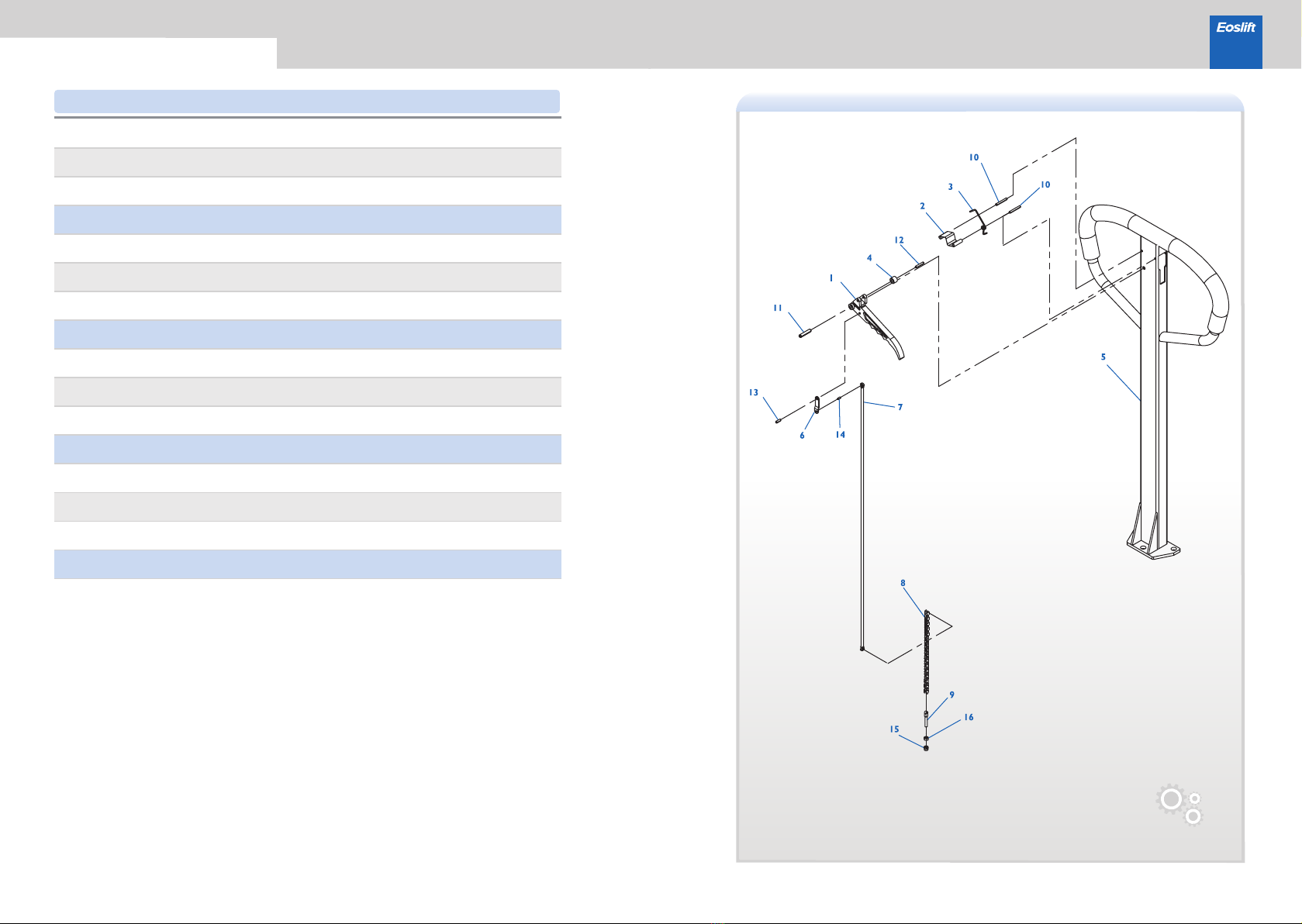

1

2

3

4

5

6

7

8

9

10

11

GB276,Deep groove ball bearing 6205,

two-side shielded

Gb77, Hexagon socket set screw with flat point

M12×20,galvanized

Qty.

NO. Parts number Description Qty.

NO. Parts number Description

Parts list· Movable fork assyParts list· Leaf chain

NOTE:For double mast modelsNOTE:For the 1.5t and 2.0t models

H10/15/20 Series Manual Pallet Stackers

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

WJ10800036

WJ10800037

WJ10800038

WJ10800039

WJ10800040

WJ10800041

WJ10800042

WJ10800043

WJ10800044

WJ10800045

WJ10800046

WJ10800047

WJ10800048

WJ10800049

WJ10800050

WJ10800051

Finger grip handle

positioning plate

torsion spring

plastic roller

handle welded

Connecting sheet of pull rod

pull rod

chain

adjusting bolt

Spring type pin(10)

Spring type pin(11)

Spring type pin(12)

Spring type pin(13)

Spring type pin(14)

nut(16)

locking nut(15)

1

1

1

1

1

1

1

1

1

2

1

1

1

1

1

1

29 30

Qty.

NO. Parts number Description

Parts list· Handle assemblies

H10/15/20 Series Manual Pallet Stackers

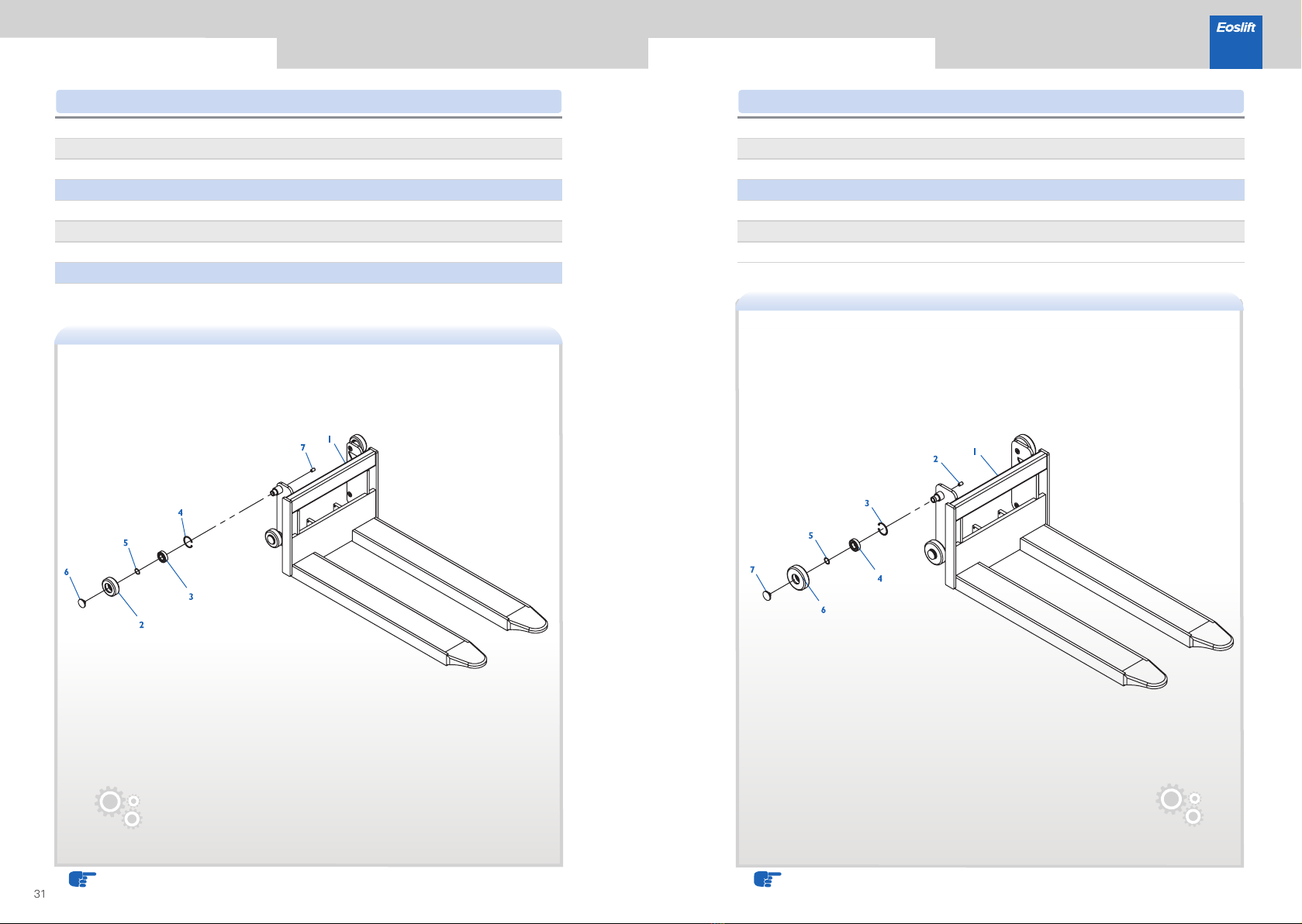

31 32

1

2

3

4

5

6

7

WC02000339

WC02000422

WC02000341

WC02000224

WE07000007

WE07000010

WC02000232

WE03000019

Fixed fork (1.0t), black

Fixed fork (1.5t), black

Iron wheel

GB893.1,Circlip for hole 52,blackening

GB894.1,Circlip for shaft 25,blackening

Iron wheel cap

1

4

4

4

4

4

8

GB276,Deep groove ball bearing 6205,

two-side shielded

GB77, Hexagon socket set screw with flat point

M12×20,galvanized

1

2

3

4

5

6

7

WC02000289

WE03000019

WE07000007

WC02000224

WE07000010

WC02000231

WC02000232

Fixed fork, black (1.0t)

GB893.1,Circlip for hole 52,blackening

GB894.1,Circlip for shaft 25,blackening

Iron wheel

Iron wheel cap

1

8

4

4

4

4

4

GB276,Deep groove ball bearing 6205,

two-side shielded

Gb77, Hexagon socket set screw with flat point

M12×20,galvanized

Qty.

NO. Parts number Description Qty.

NO. Parts number Description

Parts list· Fixed fork assyParts list· Fixed fork assy

NOTE:For double mast modelsNOTE:For single mast models

This manual suits for next models

2

Table of contents

Other Eoslift Truck manuals