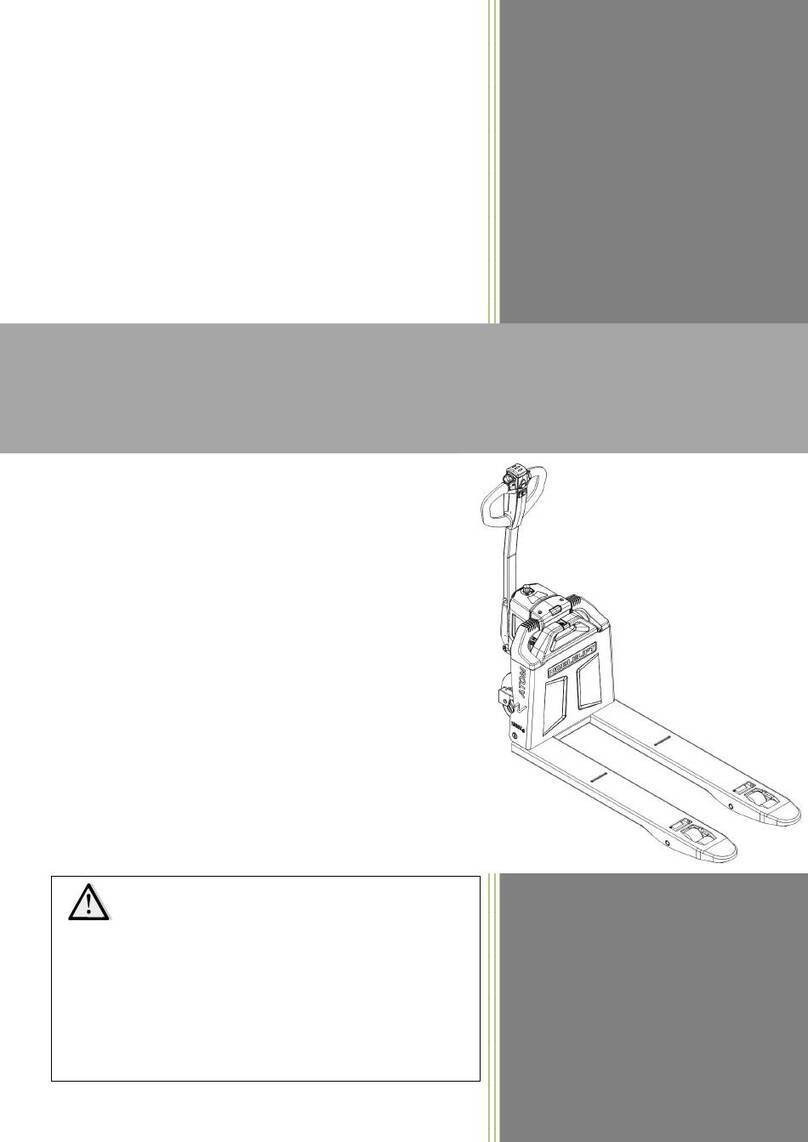

2.2. Assemble the tiller and pump unit

2.2.1. Insert the draw-bar onto the pump piston (303),

then use a hammer to insert the axle with hole (G105)

into the hydraulic pump and draw bar from the right to the

left (see figure 1).

2.2.2. Put the control handle (G117) to the lower position,

then pass the adjusting nut (G104), adjusting bolt (G103)

and chain (G102) through the hole of the axle (G105)

with your hand.

2.2.3. Press the draw-bar (G110) down, take away the spring which fixes the Spring Cap

(301).

2.2.4. Put the control handle (G117) to then raise position, the raise the lever plate (319)

with the pin and insert the adjusting bolt (G103) into the front slot of the lever plate (319).

Note: keep the adjusting nut (G104) underneath the lever plate.

2.2.5. Use a hammer to tap another elastic pin (G106) into the axle with hole (G105).

The draw-bar is now assembled to the pump.

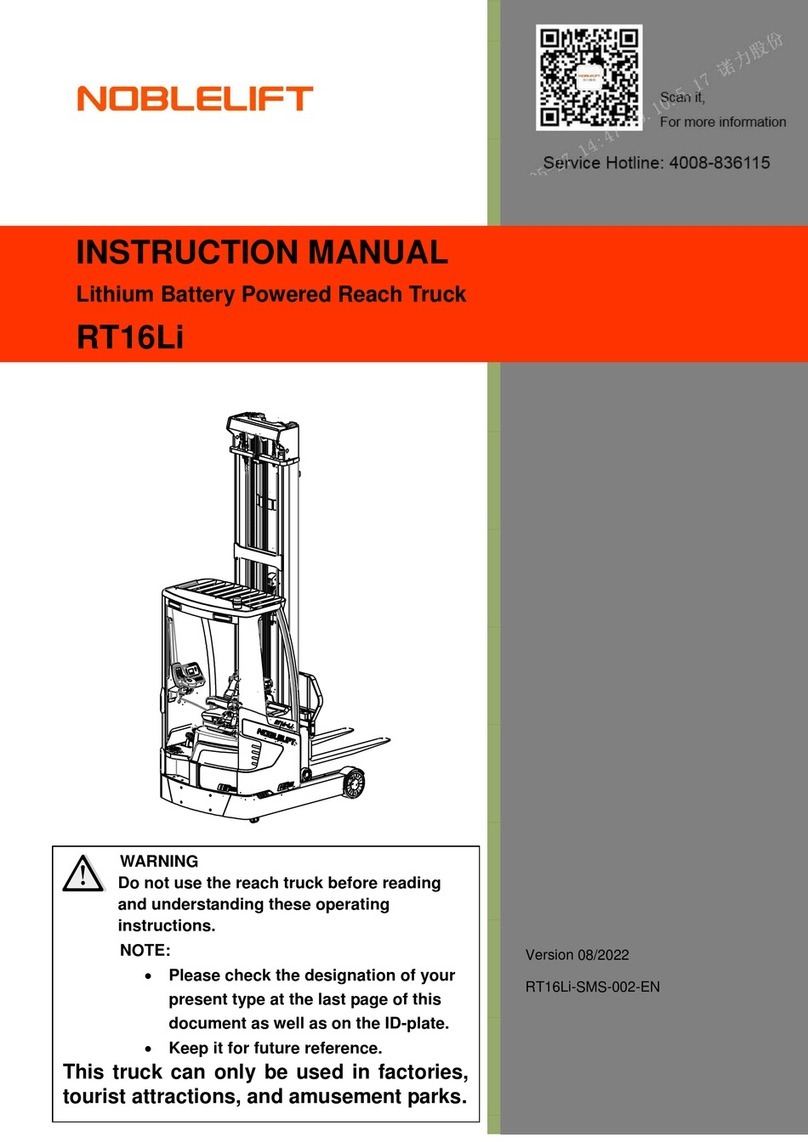

3. Adjust the release device

On the tiller grip of the truck, you can find the finger tip control handle lever (G117) with

three positions:

Lift Position - pull up the finger tip control

Neutral Position - place the finger tip control at center position

Lower Position- push down the finger tip control

The three positions of the finger tip control have been adjusted before delivery. If there

are some changes due to unexpected reasons, make adjustment according to the

following instructions:

3.1. Place the finger tip control (G117) in the Neutral Position and swing the tiller up

and down. At this time, the forks should neither go up nor go down. If:

A) the forks go up, turn the nut (G104) clockwise until the forks stop lifting.

B)the forks go down, turn the nut (G104) counterclockwise until the forks stop lowering.

3.2 Pull up the finger tip control (G117) in the Lift Position, and swing the tiller up and

down. At this time, the forks should lift steadily. If not, turn the nut (G104)

counterclockwise until it starts lifting, then repeat step 3.1.

3.3 Push down the finger tip control (G117) in the Lower Position. If the forks can not go

down. Turn the nut (G104) or screw (318) clockwise until the lifting control (G117)

can lower the forks. Then follow step 3.1 to check the neutral position to make sure

the nut (G104) and screw (318) are in place.