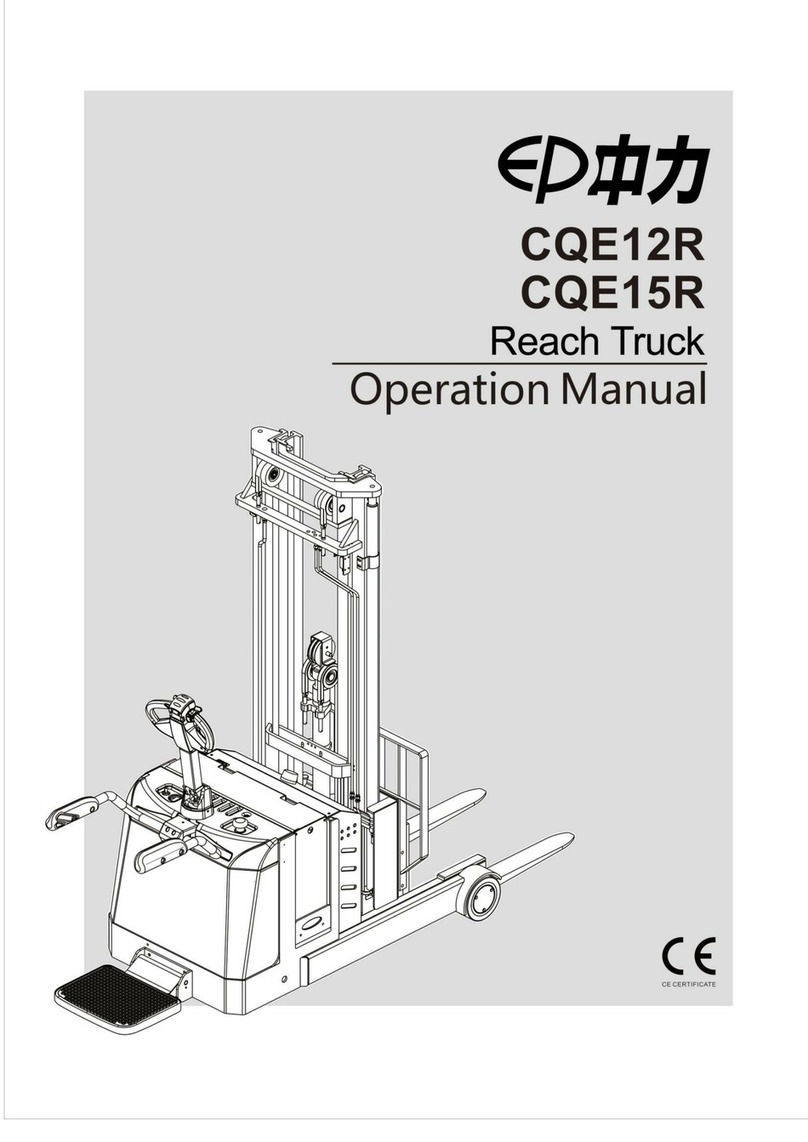

EP Equipment ES16-RS User manual

I

Foreword

This manual is about how to use, operation and maintenance . Please operator

and whom in charge of the truck must read the manual carefully before operate the

truck.

We have the right to improve the truck, maybe there are some difference between

your product and the description in this manual.

If you have any questions please keep in touch with the sales department or let

the dealer know.

Notes:

1. This manual is used for operation and maintenance , the detail parameters, size a

nd specifications in context is only for reference , the real parameters will depend on

sale files.

2. Manual pictures for reference only, the real car shall prevail, and shall not affect the

manual use.

EP EQUIPMENT CO.,LTD.

Address: XIAQUAN,DIPU,ANJI,ZHEJIANG,CHINA

Tel:86-571-28031990

Fax:86-571-28035616

Net:www.ep-ep.com

Email:Service@ep-ep.com

ALL RIGHT RESERVED COPYRIGHT

2016.11 FRIST EDITION

II

WARNING!

TO PREVENT SETIOUS RISK OF INJURY TO

YOURSELF AND OTHERS OBSERVE THE

FOLLOWING SAFETY INSTRUCTIONS.

These truck may become hazardous if adequate maintenance is neglected. Therefore,

adequate maintenance facilities, trained personnel and procedures should be

provided.

Maintenance and inspection shall be performed in conformance with the following

practices:

1. A scheduled planned maintenance,lubrication and inspection system should be

followed.

2. Only qualified and authorized personnel shall be permitted to maintain, repair,

adjust, and inspect truck.

3. Before leaving the truck:

–Do not park the truck on an incline.

–Fully lower the load forks.

–Set the key switch to the "OFF" position and remove the key.

–Drawing back the emergency brake switch .

–Fold in the folding side arm

4. Before starting to operate truck:

–Be in operating position

–Place directional control in neutral

–Before operating truck, check functions of lift systems, directional control,speed

control,steering, warning devices and brakes.

5. Avoid fire hazards and have fire protection equipment present. Do not use open

flame to check lever, or for leakage of electrolyte and fluids or oil. Do not use open

pans of fuel or flammable cleaning fluids for cleaning parts.

6. Brakes,steering mechanisms, control mechanisms,guards and safety devices shall

be inspected regularly and maintained in legible condition.

7. Capacity, operation and maintenance instruction plates or decals shall be

maintained in legible condition.

8. All parts of lift mechanisms shall be inspected to maintain them in safe operating

condition.

III

9. All hydraulic systems shall be regularly inspected and maintained in conformance

with good practice. Cylinders, valves and other similar parts shall be checked to

assure that "drift" has not developed to the extent that it would create a hazard.

10. Truck shall be kept in a clean condition to minimize fire hazards facilitate detection

of loose or detective parts.

11. Modifications and additions which affect capacity and safe truck operation shall

not be performed by the customer or user without manufacturers prior written

approval. Capacity, operation and maintenance plates or decals shall be changed

accordingly.

IV

Catalog

Correct use and application........................................................................................1

1. Truck Description ...................................................................................................2

1.1 Application.....................................................................................................2

1.2 Assemblies....................................................................................................3

1.2.1 Folding operator pedal.........................................................................4

1.2.2 Safety Gate..........................................................................................4

1.2.3 Control Handle.....................................................................................4

1.2.4 Key switch............................................................................................5

1.2.5 Battery discharge indicator...................................................................5

1.2.6 Emergency brake switch......................................................................5

1.3 Identification points and data plates...............................................................6

1.3.1 Truck data plate ...................................................................................7

1.3.2 Capacity chart......................................................................................7

1.4 Specifications ................................................................................................8

1.4.1 Performance data for standard trucks ..................................................8

1.4.2 Dimensions..........................................................................................9

2.Transport and Commissioning...............................................................................12

2.1Transport......................................................................................................12

2.1.1 Lifting the truck by crane....................................................................12

2.1.2 Securing the truck during transport ....................................................12

2.2 Using the Truck for the First Time................................................................12

2.3 During brake-in............................................................................................13

3.Operation..............................................................................................................14

3.1 Safety Regulations for the Operation of stackers.........................................14

3.2 Starting up the truck.....................................................................................15

3.2.1 Preparing...........................................................................................15

3.2.2 Travelling, Steering, Braking ..............................................................16

3.2.3 Lifting, transporting and depositing loads...........................................17

3.2.4 Parking the truck securely..................................................................18

4.Battery Maintenance & Charging...........................................................................19

4.1 Safety regulations for handling acid batteries ..............................................19

4.2 Charging the battery....................................................................................20

4.2.1 Exposing the battery..........................................................................20

4.2.2 Charging the battery ..........................................................................20

4.3 Battery removal and installation...................................................................21

4.3.1 Changing the battery..........................................................................21

5.Stacker Maintenance.............................................................................................23

5.1 Operational safety and environmental protection.........................................23

5.2 Maintenance Safety Regulations .................................................................23

5.3 Servicing and inspection..............................................................................24

5.3.1 Maintenance Checklist.......................................................................25

5.3.2 Lubrication Schedule .........................................................................27

V

5.3.3 Maintenance Instructions...................................................................28

5.4 Decommissioning the industrial truck...........................................................30

5.4.1 Prior to decommissioning...................................................................30

5.4.2 During decommissioning....................................................................30

5.4.3 Restoring the truck to operation after decommissioning.....................30

5.5 Safety checks to be performed at regular intervals

and following any unusual incidents......................................................31

5.6 Final de-commissioning, disposal................................................................31

6. Troubleshooting....................................................................................................32

1

Correct use and application

The “Guidelines for the Correct Use and Application of Industrial Trucks” (VDMA) are

supplied with the truck. The guidelines form part of these operating instructions and

must be observed. National regulations apply in full.

The truck described in the present operator manual is an industrial truck designed for

lifting and transporting load units.

It must be used, operated and serviced in accordance with the present instructions.

Any other type of use is beyond the scope of application and can result in damage to

personnel, the truck or property. In particular, avoid overloading the truck with loads

which are too heavy or placed on one side. The data plate attached to the truck or the

load diagram are binding for the maximum load capacity. The industrial truck must not

be used in fire or explosion endangered areas, or areas threatened by corrosion or

excessive dust.

Proprietor responsibilities

For the purposes of the present operator manual the “proprietor” is defined as any

natural or legal person who either uses the industrial truck himself, or on whose behalf

it is used. In special cases (e.g. leasing or renting) the proprietor is considered the

person who, in accordance with existing contractual agreements between the owner

and user of the industrial truck, is charged with operational duties.

The proprietor must ensure that the truck is used only for the purpose it is intended for

and that danger to life and limb of the user and third parties are excluded.

Furthermore, accident prevention regulations, safety regulations and operating,

servicing and repair guidelines must be followed. The proprietor must ensure that all

truck users have read and understood this operator manual.

Failure to comply with the operator manual shall invalidate the warranty. The same

applies if improper work is carried out on the truck by the customer or third parties

without the permission of the manufacturer’s customer service department.

Attaching accessories

The mounting or installation of additional equipment which affects or supplements the

performance of the industrial truck requires the written permission of the manufacturer.

In some cases, local authority approval shall be required.

Approval of the local authorities however does not constitute the manufacturer’s

Approval.

2

1. Truck Description

1.1Application

The truck is a tiller operated electric stacker with a folding operator platform and side

arms.The truck is designed for lifting and transporting goods on a level surface. The

truck can pick up, outside the load wheel area, open bottom or diagonal board

pallets as well as roll cages . The capacity of the truck is shown on the data plate or

the data capacity plate Qmax.

3

1.2 Assemblies

Item

Component

Item

Component

1

Folding operator pedal

6

Mast

2

Safety Gate

7

Emergency stop swich

3

Drive wheel

8

Fork

4

Battery discharge indicator

9

Chassis

5

Control Handle

10

Caster wheel

4

1.2.1Folding operator pedal

Folding operator pedal have two state: fold and

unfold. While the state of Folding operator pedal

changed the Travel speed (Max) changed too.

Because of gas spring the folding operator pedal

can fold self-motion.

1.2.2Safety Gate

Travel speed (Max) will change when the state of

side arm is changed. Travel speed (Max) is much

higher when the side arm is unfolded. The side

arm can protect operator when truck running in

high speed.

1.2.3 Control Handle

Item

Control / Display

Function

1

Key switch

Switches control current on and off.

2

“Lower” button

Lowers load forks.

3

“Lift” button

Raises load forks.

4

Travel switch

Controls the driving speed and direction

5

Warning signal button

Triggers a warning signal.

6

Collision safety switch

Safety function which, when activated, forces the

truck to reverse until the switch restored to neutral.

5

1.2.4 Key switch

Switches control current on and off.

Truck power supply is break off when the key turn "OFF".

Truck power supply is turn on when the key turn "ON".

Removing the key prevents the truck from being switched

on by unauthorised personnel.

1.2.5 Battery discharge indicator

The LEDs (1) represent battery residual capacity, The

LCD (2) displays the operating hours

Battery Discharge Indicator(1)

When the truck has been released via the key switch,

the battery charge status is displayed.

The colours of the LEDs (1) represent the following

conditions:

LED colour

value

Green

Standard battery residual capacity

70-100%

Orange

Standard battery residual capacity

30-60%

Flashing Red

Standard battery residual capacity

0-20%

Battery Discharge for 70%, A flashing red show on storage battery charge warning.

Battery Discharge for 80%, Two flashing reds show on battery charge used up

warning, Lifting is now inhibited. The battery must be charged.

Operating hours display

Display range between 0.0 and 99,999.0 hours. Travel and lifting are logged. This is a

backlit display.

Power up test

On power up the display shows:

–the operating hours

–the charge status

1.2.6Emergency brake switch

The supply current is interrupted, all electrical functions are deactivated and the truck

is automatically braked.

Low Voltage Protection

This vehicle has a low-voltage protection function.

When the battery voltage is less than, the vehicle will appear that the driving speed

is slow ,but the fork can be lifted.And now the battery needs to be charged.

6

1.3 Identification points and data plates

Item

Description

1

Operator Warning Decal

2

Stacker data plate

3

Direction Decal On Control Handle

4

“Never stand ” warning

5

“Never put your hands in inner“warning

6

Capacity chart

7

1.3.1Truck data plate

Item

Description

Item

Description

1

Manufacturer

6

Fork length

2

Type

7

Lift height

3

Load capacity(kg)

8

Battery nominate capacity

4

Load center

9

Service weight with battery

5

Fork width

10

Serial no.

For queries regarding the truck or ordering spare parts please quote the truck serial

number(10).

MODEL NUMBER EXAMPLE

Electric Stacker Series label

Load capacity:16=1600Kg

1.3.2 Capacity chart

The chart given above shows the relation

between the load center and the weight of

loads.

ES

16-

RS

8

1.4 Specifications

Technical specification details in accordance with VDI2198. Technical modifications

and additions reserved.

1.4.1Performance data for standard trucks

Description

ES16-RS

Unit

Q

Load capacity

1600

kg

C

Load center

600

mm

Travel speed

laden

5.5

km/h

unladen

6.0

km/h

Lifting speed

laden

0.13

m/s

unladen

0.16

m/s

Lowering speed

laden

0.25

m/s

unladen

0.24

m/s

Maximum grade ability S2

5 min.

laden

8

%

unladen

16

%

Service brake

electromagnetic

Service weight

Incl. battery

1350

kg

Motor rating power

Driving

1.5

Kw

Lifting

3.0

Kw

Tyre type

PU/PU

Tyre size, operator side

1-Ф230×75

mm

Tyre size, load side

4-Ф85×70

mm

Balance wheels (dimensions)

2-Ф130×55

mm

Battery

Type

Battery

voltage/rated capacity

24/210

V/Ah

Sound level at operator's ear

AC

dB(A)

74

9

1.4.2Dimensions

Description

ES16-RS

Unit

x

Load distance

693

mm

Y

Wheelbase

1375

mm

b3

Fork carriage width

800

mm

b5

Distance between fork-arms

570/600/685

mm

h1

Height, mast lowered

2020

mm

h2

Free lift

100

mm

h3

Lift height

3000

mm

h4

Height, mast extended

3465

mm

h14

Height of tiller arm in operating position, min/ max

1150/1480

mm

h13

Fork height, lowered

88

mm

l1

Overall length

2495

mm

l2

Length to face of forks

879

mm

b1

Overall width

850

mm

s

Fork dimensions

thickness

60

mm

e

width

190

mm

l

length

1150

mm

m2

Ground clearance

28

mm

Wa

Turning radius

1730/2090

mm

Ast

Aisle width1), 1000×1200 pallet crossways

2605/2965

mm

Ast

Aisle width1), 800×1200 pallet lengthways

2575/2935

mm

1)Including safety distance a = 200 mm

10

Standard Mast Types (mm)

Mast types

Close Mast

height

Free height

lift height

Extended Mast

Height

h1

h2

h3

h4

Two Stage Mast

(Wide view)

1870

100

2650(2700)

3165

2020

100

2950(3000)

3465

2170

100

3250(3300)

3765

2320

100

3550(3600)

4065

2470

100

3850(3900)

4365

2600

100

4110(4200)

4625

Two Stage Mast

(Free Lifting)

1819

1320

2620(2700)

3135

1969

1470

2920(3000)

3435

2119

1620

3220(3300)

3735

Three Stage Mast

(Free Lifting)

1822

1390

3990(4000)

4460

2022

1590

4490(4500)

4960

2122

1690

4790(4800)

5260

2187

1760

4990(5000)

5460

2278

1840

5250(5300)

5760

2352

1910

5440(5500)

5910

11

ES16-RS

12

2.Transport and Commissioning

2.1Transport

2.1.1Lifting the truck by crane

1.Only use crane lifting gear with sufficient

capacity.

2.Loading weight = net weight of truck (+ battery

weight for electric trucks).

3.crane lifting gear get across fixed hole(1) to

Lifting the truck.

–Park the truck securely.(see 3.2.4 Parking the

truck securely).

–Secure the crane slings to the attachment

points (1).

Raise the truck with the forks at the side between

the axles. Raise the truck slightly and make sure

it is securely positioned on the forks. Necessary

adjust or secure the forks with stops. Lower the

truck slowly onto the ground and prevent it from

rolling away.

2.1.2Securing the truck during transport

The truck must be securely fastened when

transported on a lorry or a trailer.

Keep pedal and side arm folded,avoid them out

of bodywork.

- The rope is used to fix the truck must be firm

enough.

- Check .

Both sides need to fix.

Loading must be carried out by staff specially

trained. In each case correct measurements

shall be determined and appropriate safety

measures adopted.

2.2Using the Truck for the First Time

Only operate the truck with battery current. Rectified AC current will damage the

electronic components. Cable connections to the battery (tow leads) must be less

than 6 m .

Preparing the truck for operation after delivery or transport

Procedure

–Check the equipment is complete.

13

–Check the hydraulic oil level.

–Install the battery if necessary, (see "4.4 Battery removal and installation" ).

–Charge the battery, (see "4.3 Charging the battery").

2.3During brake-in

We recommended operating the machine under light load conditions for the first stage

of operation to get the most from it. Especially the requirements given below should

be observed while the machine is in a stage of 100 hours of operation.

1. Must prevent the new battery from over discharging when early used.

2. Perform specified preventive maintenance services carefully and completely.

3. Avoid sudden stop, starts or turns.

4. Oil changes and lubrication are recommended to do earlier than specified.

5. Limited load is 70~80% of the rated load.

14

3.Operation

3.1Safety Regulations for the Operation of stackers

Driver authorisation: The stacker may only be used by suitably trained personnel,

who have demonstrated to the proprietor or his representative that they can drive

and handle loads and have been authorised to operate the truck by the proprietor or

his representative.

Driver’s rights, obligations and responsibilities: The driver must be informed of

his duties and responsibilities and be instructed in the operation o f the truck and

shall be familiar with the operator manual . The driver shall be afforded all due rights .

Safety shoes must be worn with pedestrian operated trucks.

Unauthorised Use of Truck: The driver is responsible for the truck during the time it

is in use. He shall prevent unauthorised persons from driving or operating the truck.

It is forbidden to carry passengers or lift personnel.

Damage and Faults: The supervisor must be immediately informed of any damage

or faults to the stacker. Trucks not safe for operation (e.g. wheel or brake problems)

must not be used until they have been rectified.

Repairs: The driver must not carry out any repairs or alterations to the stacker without

the necessary training and authorisation to do so. The driver must never disable or

adjust safety mechanisms or switches.

Hazardous area: A hazardous area is defined as the area in which a person is at

risk due to truck movement, lifting operations, the load handler (e.g. forks or

attachments) or the load itself. This also includes areas which can be reached by

falling loads or lowering operating equipment.

Unauthorised persons must be kept away from the hazardous area. Where there is

anger to personnel, a warning must be sounded with sufficient notice. If unauthorised

personnel are still within the hazardous area the truck shall be brought to a halt

immediately.

Safety Devices and Warning Signs: Safety devices, warning signs and warning

instructions shall be strictly observed.

Table of contents

Other EP Equipment Truck manuals

EP Equipment

EP Equipment EPL152 User manual

EP Equipment

EP Equipment CQE12R User manual

EP Equipment

EP Equipment CQD16 User manual

EP Equipment

EP Equipment HPL152 User manual

EP Equipment

EP Equipment EPT20-15ET User manual

EP Equipment

EP Equipment CQD15S-E User manual

EP Equipment

EP Equipment J1HD User manual

EP Equipment

EP Equipment LIST JX0 User manual

EP Equipment

EP Equipment EPT16-ET User manual

EP Equipment

EP Equipment LIST JX0 User manual