Catalog

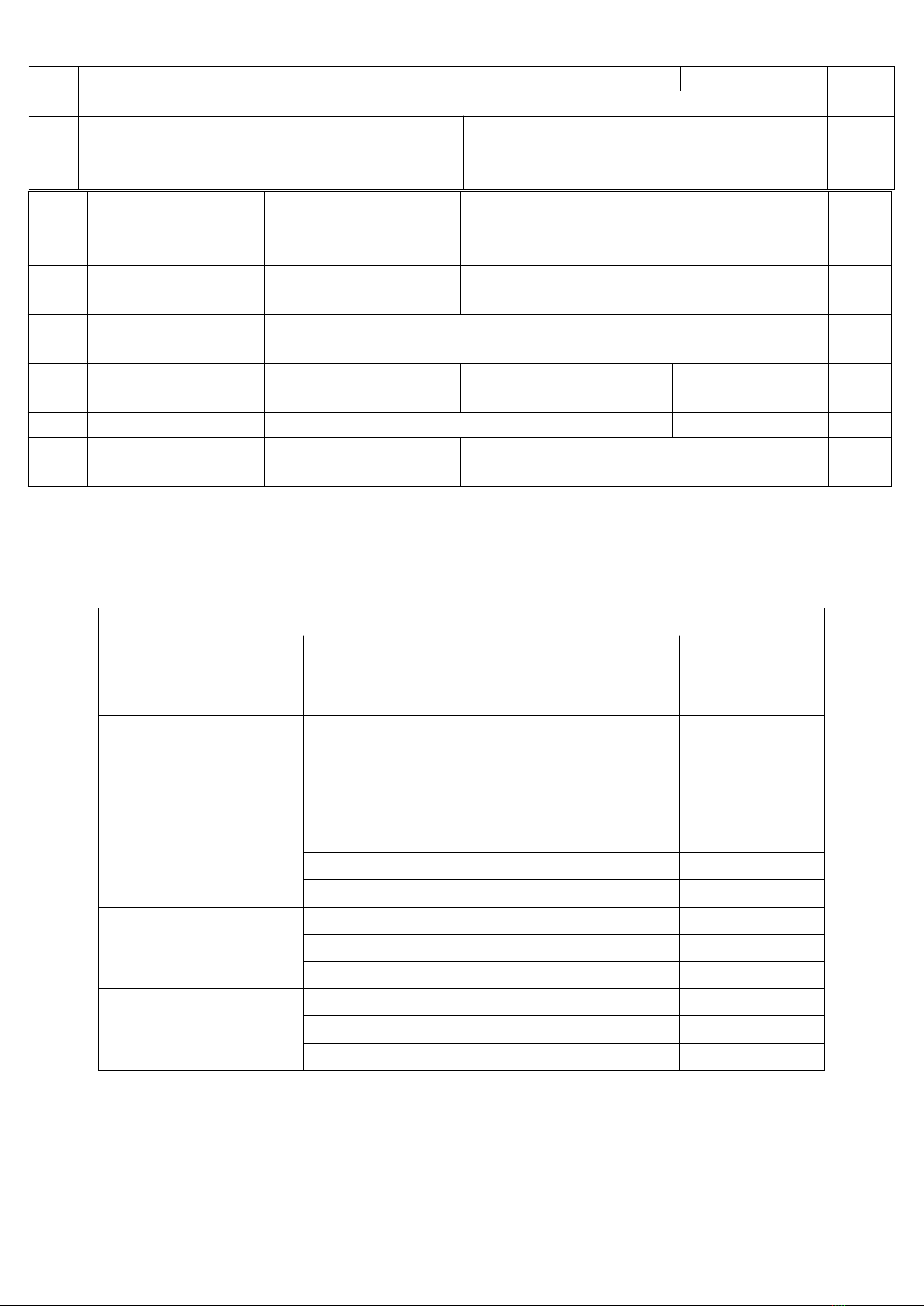

Correct use and application..............................................................................................................1

Chapter 1 stacker Description.......................................................................................................2

1 Application....................................................................................................................................2

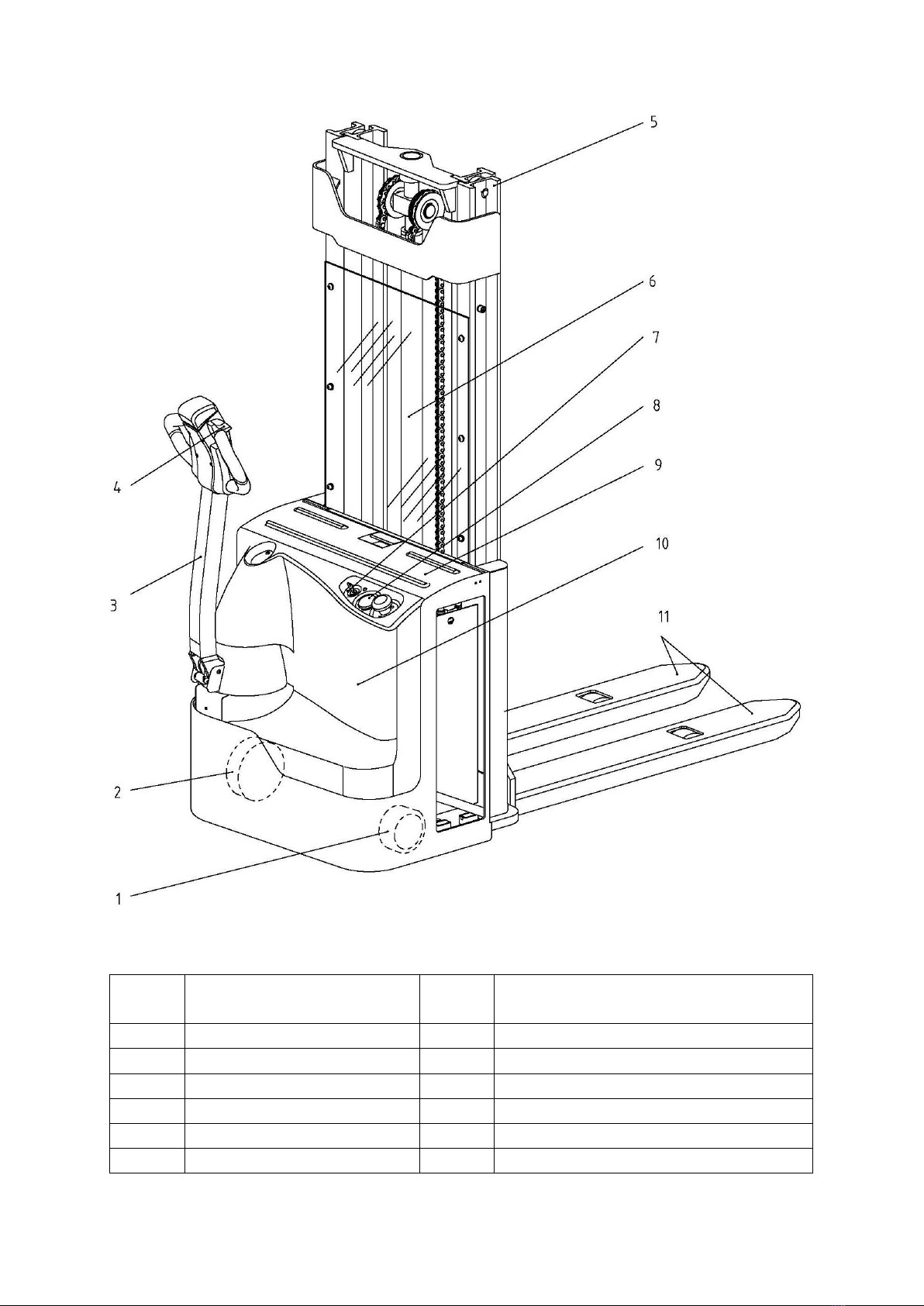

2 Assemblies...................................................................................................................................3

3 Standard Version Specifications...............................................................................................4

3.1 Performance data for standard stackers........................................................................4

3.2 Dimensions......................................................................................................................... 4

3.3 Conditions of use............................................................................................................... 8

4. Identification points and data plates....................................................................................... 8

4.1 stacker data plate............................................................................................................ 10

4.2 Capacity chart.................................................................................................................. 10

Chapter 2 Operation.......................................................................................................................11

1 Safety Regulations for the Operation of stacker..................................................................11

2 Controls and Displays.............................................................................................................. 12

3 Starting up the stacker............................................................................................................. 14

4 Industrial stacker operation..................................................................................................... 14

4.1 Safety regulations for stacker operation...................................................................... 14

4.2 Travelling, Steering, Braking......................................................................................... 15

4.3 Collecting and depositing loads.................................................................................... 17

5 Parking the stacker securely...................................................................................................18

6 Display instrument.................................................................................................................... 18

6.1 Battery Discharge Indicator........................................................................................... 18

6.2 Operating hours display................................................................................................. 18

6.3 Power up test................................................................................................................... 19

7 Troubleshooting........................................................................................................................ 19

Chapter 3 Battery Maintenance, Charging & Replacement.................................................20

1 Safety regulations for handling acid batteries...................................................................... 20

2 Battery specifications............................................................................................................... 20

3 Exposing the battery.................................................................................................................21

4 Charging the battery.................................................................................................................21

5 Battery removal and installation............................................................................................. 22

Chapter 4 stacker Maintenance.................................................................................................. 24

1 Operational safety and environmental protection................................................................24

2 Maintenance Safety Regulations........................................................................................... 24

3 Servicing and inspection..........................................................................................................25

4 Maintenance Checklist.............................................................................................................26

5 Lubrication Schedule................................................................................................................28

5.1 Fuels, coolants and lubricants.......................................................................................29

6 Maintenance Instructions.........................................................................................................30

6.1 Prepare the stacker for maintenance and repairs......................................................30