Product range information

Product guide – BT Levio W-series 9

Product range information

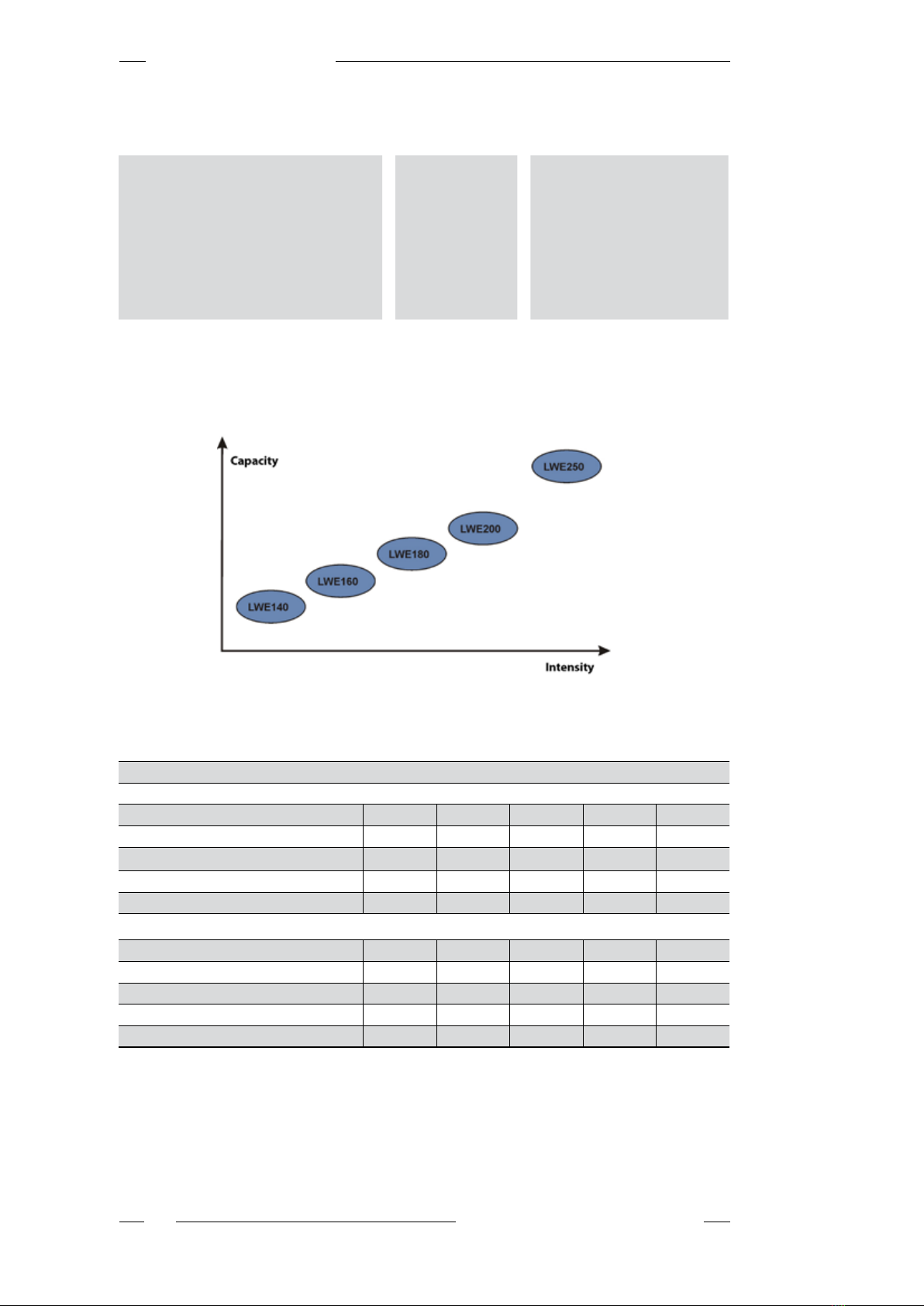

BT Levio W-series (Low-lifter Walkie Electric)

BT Levio W-series without platform is a complete low-lifter series for walkie

applications. These machines are mainly used where space is limited and travel

distances are relatively short. All models have a maximum speed of 6 km/h.

LWE200 can, as an option, be equipped with operator platform. This truck is pref-

erably used were travel distances are a bit longer and the operator wants to have the

comfort of a stand on platform. For more heavy duty applications were the truck is

used continuously in a multi shift operation the recommendation is to use a truck

from our LPE range.

The LWE series is built on a modular concept where a large number of compo-

nents are common for all models. This simplies production and increases truck

performance reliability.

The LWE machines are compact, easy-to-use trucks with AC drive motors. The

trucks' drive characteristics can be programmed and adapted to individual operator

preferences. The design with rounded body contours together with a 5-point wheel

conguration ensures operator comfort and safety. The placement of the tiller arm

and controls on the handle provide excellent ergonomics for the operator.

The LWE series has two fork carriages. The 156 mm fork width on the narrow

fork carriage is provided on the LWE140 and LWE160. The other LWE versions

feature a standard fork carriage with a fork width of 180 mm. The fork carriage

on the LWE250 is reinforced to accommodate increased rated load capacity. The

LWE200 and LWE250 have larger drive and lift motors. All models are supplied

with a standard battery compartment. Moreover, the LWE200 and LWE250 can be

optionally tted with a large battery combined with a side roller bed solution.

Open-end and bottom-boarded pallets account for a large portion of the load car-

riers handled by low-lifters. Additionally, this truck series offers a variety of fork

and wheel congurations to accommodate various load carriers (e.g. pallets, roll

containers, half pallets, etc.).

The BT model codes can be used as a guide for choosing the right model for the