PRO 32 & 48 X-AXIS ASSEMBLY

10

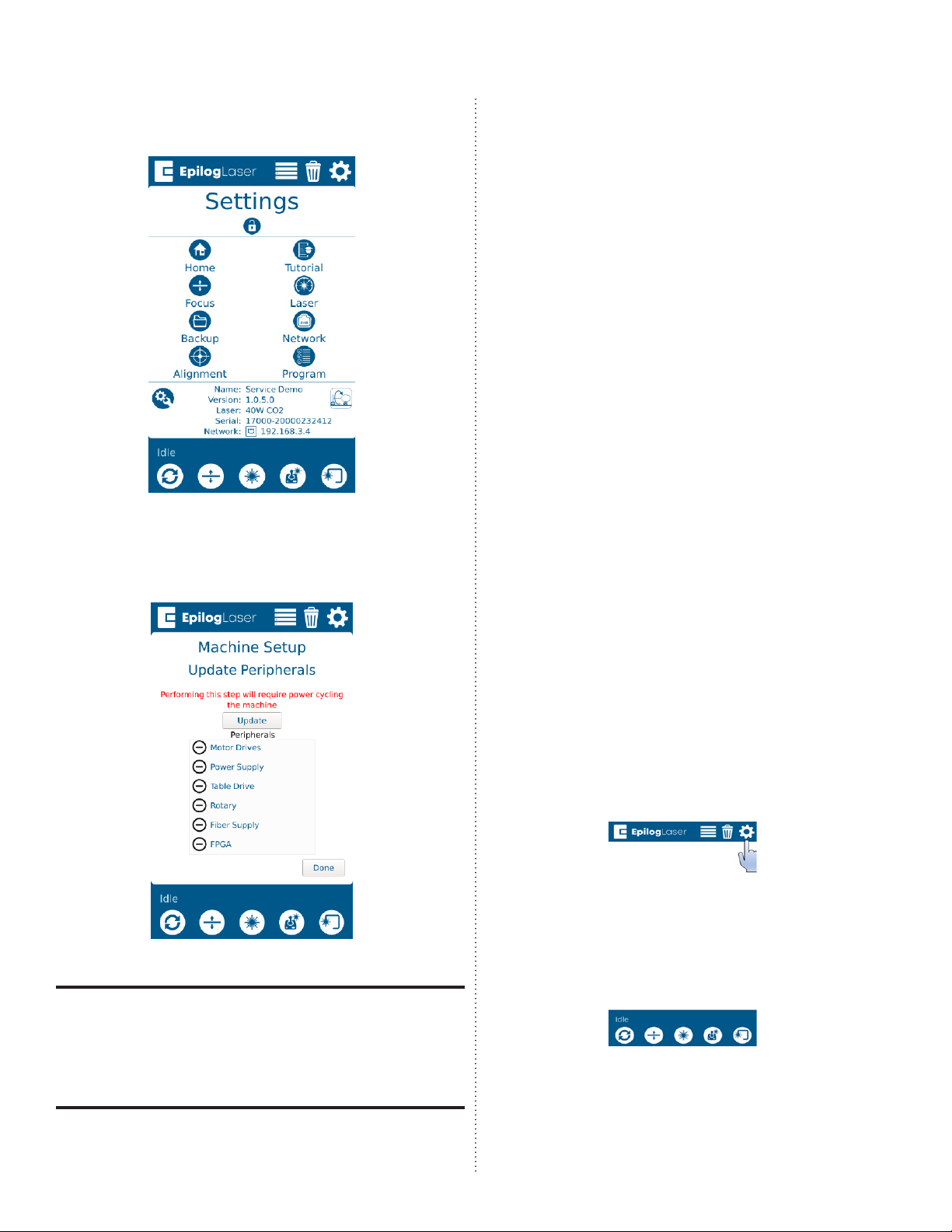

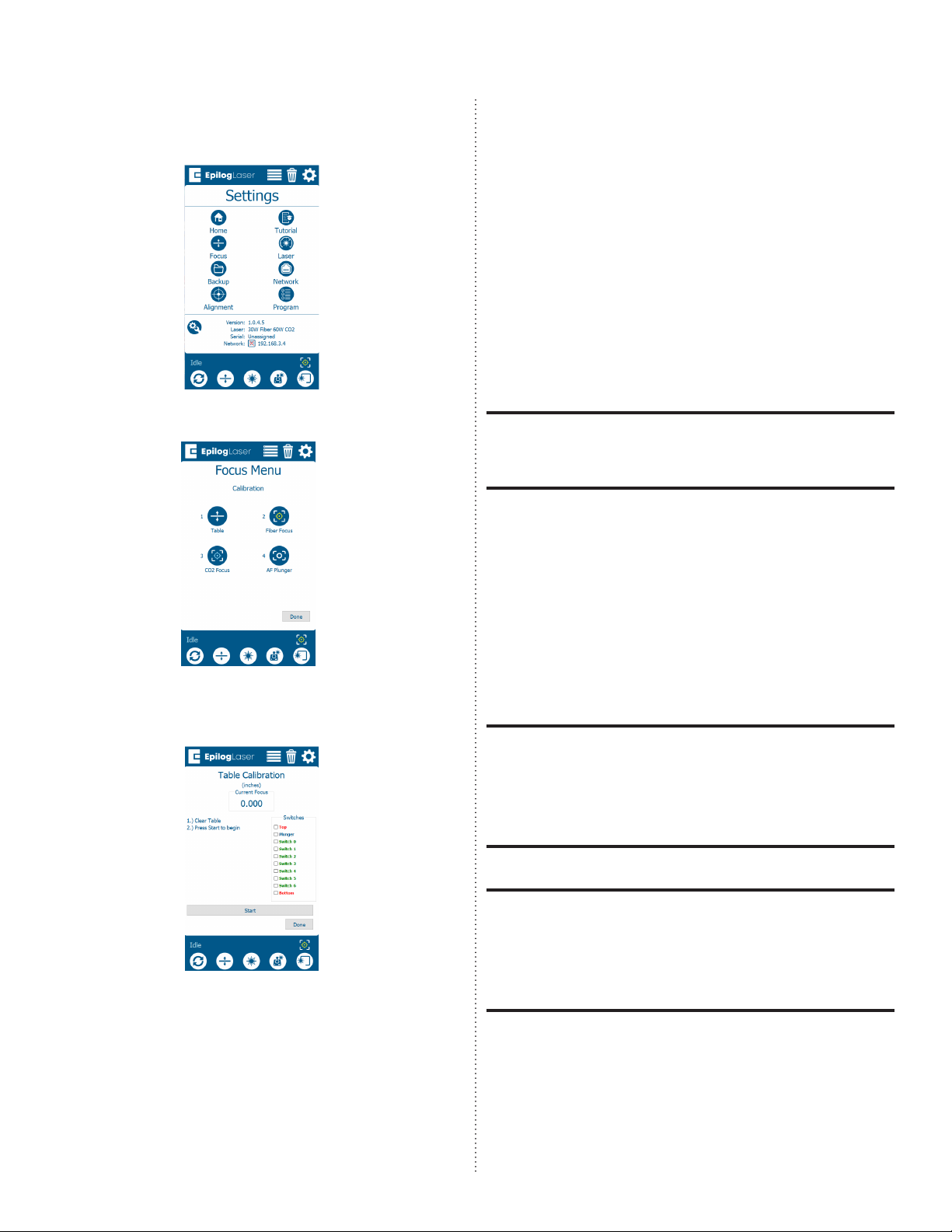

2. Once in the Settings menu, press

the Focus button to enter the Focus

Commands/Calibrations menu:

3. Press the Table button:

4. Press the Start button to start the table

calibration:

4. Allow the engraver to complete the

calibration. Once complete, a success

message should appear.

Move to the CO2 Focus Procedure.

CO2 Focus Calibration

The CO2 focus calibration establishes

the focal height of the laser and manual

focus gauge. You will run a small job while

adjusting the table height to find the

correct focal height.

A small piece of anodized aluminum (at

least 3” x 3” or 75mm x 75mm) is required to

complete this procedure.

1. Open your preferred illustrating

program and create a black, raster box

measuring ~2” x 2” or 50mm x 50mm.

2. Send the job to the Soware Suite.

3. Ensure that the process shows as an

engraving job and set the both power

and speed at 5-10%.

If completing the procedure on the Fusion

Pro 32, place the artwork and material

in the upper le corner of the engraving

table, ensuring that the artwork appears

over the anodized aluminum.

If completing the procedure on the Fusion

Pro 48, place the artwork and material in

the center of the engraving table, ensuring

that the artwork appears over the anod-

ized aluminum.

4. Send the job to the engraver.