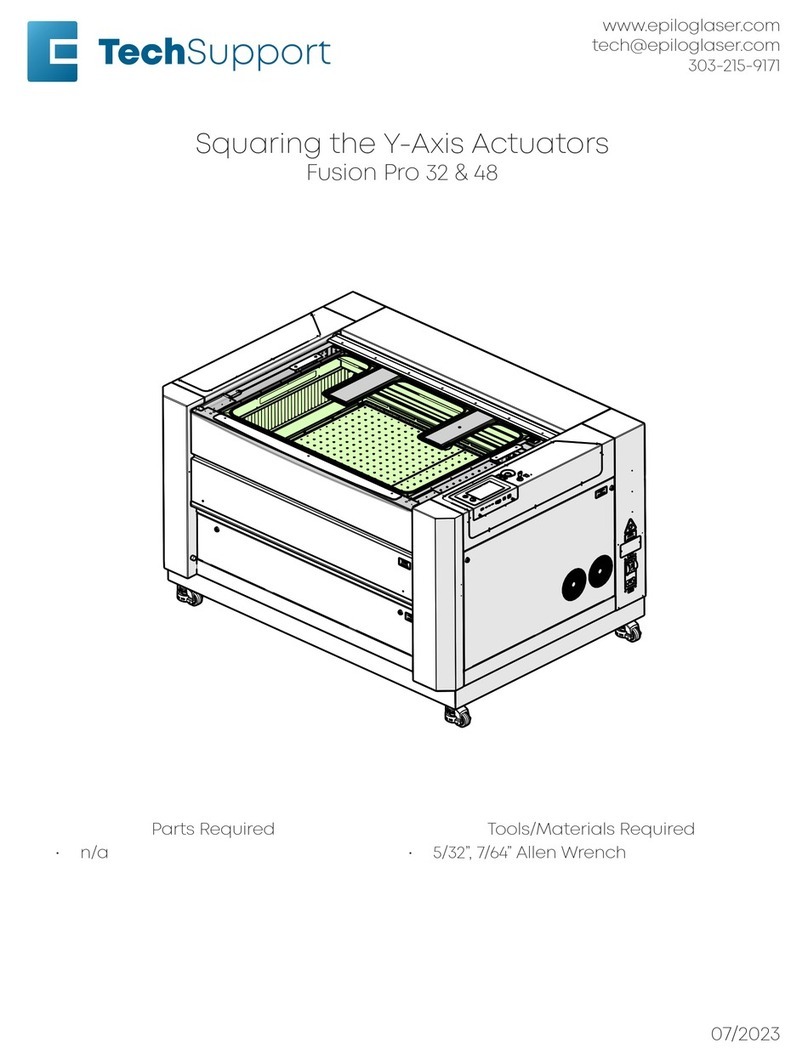

Epilog Fusion M2 User manual

• 1 •

Laser Safety Module Fusion M2 Laser Systems

Phone: 303-215-9171

Email: Tech@Epiloglaser.com

Laser Safety Module

For the Epilog Fusion M2 Laser Engraver

Revision 8/2/2017

Overview

This Document is designed to guide you

through replacing the Laser Safety Module

Assembly on an Epilog M2 with any laser source.

Requirements:

Tools:

Allen wrench - 5/32”

¼ Inch Nut Driver or Socket with

Extension.

Precision (Small) Flat Head

Screwdriver

Parts:

Laser Safety Module Assembly

HT1210

Before We Begin

In order to have the best experience possible,

collect the tools listed above and be sure that

you have all of the parts that you need before

starting this procedure. If you run into any

problems or have questions, please contact

Epilog Tech Support at 303-215-9171 or

[email protected]. For the fastest service,

please have your serial number available.

Safety

When working on or maintaining a Laser

engraver, it is likely that the sides of the machine

will be removed. Be sure that when doing

maintenance in this way, that everyone in the

room has eye protection on. Standard

Polycarbonate Safety glasses or even glass

spectacles will protect your eyes from the C02

laser.

Energized electronics can spark, shock or

force motors to suddenly move. When working

on electronics or near mechanical parts, be sure

that the machine is powered off.

Verify Correct Parts

Locate the sticker on the new module’s

packaging and take note of the part number.

1 Example Part Number

To verify that the correct part has been

received use the following table.

Laser Safety Module

Fusion M2 HT1210

If the part number is not correct, Please

contact Tech Support at 303-215-9171.

• 2 •

Laser Safety Module Fusion M2 Laser Systems

Phone: 303-215-9171

Email: Tech@Epiloglaser.com

Remove Old Part:

Remove Right

Panel

Locate the Cam

Locks on the upper

right hand panel.

Using a 5/32” Allen

wrench, turn the

lock counter

clockwise to release

the door panel.

Allow top of the

panel to swing

forward where it can

be lifted out of the

machine and

removed.

Locate the

Module

Next we will

locate the laser safety module inside of the

engraver. The top of the module can be located

on the top of the right hand side of the engraver.

You should see the module case and connections

from below, looking up.

2 Laser Safety Module from Below

Remove Mounting Nuts

Locate the Laser Safety Module on the right

side of the engraver.

From beneath locate the four mounting nuts

which fasten the module to the chassis of the

engraver. The mounting nuts can be

distinguished from the Case nuts by their

positioning, one behind each case nut.

3 Mounting Nuts

Loosen Case Nuts

If the module does not come away from the

chassis of the engraver after removing the

mounting nuts, the case nuts may also need to

be loosened to allow the module to slide freely

from the mounting studs.

4 Case Nuts

Disconnect Laser Connections

Depending on the configuration of your

engraver you may have a connection for a Fiber

Laser, a Co2 Laser, or both.

Co2 Laser

If your engraver has a C02 Laser installed,

locate and disconnect the 8-Pin Modular “RJ45”

Connecter and disconnect it. This port looks

similar to an Ethernet or Telephone jack.

Removing the Right Side

Panel

• 3 •

Laser Safety Module Fusion M2 Laser Systems

Phone: 303-215-9171

Email: Tech@Epiloglaser.com

Fiber Laser

If your engraver has a Fiber laser installed,

you will need to disconnect the DB15 connector.

This connecter has two screws which secure it to

the housing for the Laser Safety Module. Loosen

these screws and gently pull to disconnect the

cable.

5 Laser Connection Ports

Disconnect DB25 and DB15

There are two more connecters on the left

side of the Laser Safety Module which need to be

disconnected. They each have two screws

securing them to the housing of the Laser Safety

Module. Loosen the screws and gently pull to

disconnect the harness.

6 DB15 and DB9 Connections

Remove Part form Machine

You can now remove the Laser Safety Module

from the engraver.

Install New Part

Prep Case for Install

Orient the new Laser Safety Module so that

the led panel is lying flat on the table. Locate and

loosen the four case nuts.

Once the case nuts have been loosened,

squeeze the case together from either side

(where the ports are located) and continue to

apply pressure while you retighten the nuts.

Attach DB9 and DB15

Reattach the DB9 and DB15 computer cables

to the module, match the orientation of the D

shaped connecters and be sure to secure

connecter screws tightly with a precision flat

head screw driver.

Attach Laser Connection

CO2

If your engraver is equipped with a C02 laser

source, Locate the data cable and connect the 8-

• 4 •

Laser Safety Module Fusion M2 Laser Systems

Phone: 303-215-9171

Email: Tech@Epiloglaser.com

Pin Modular (RJ45) plug into the Modular Jack on

the Laser Safety Module.

Fiber

If your engraver is equipped with a Fiber

Laser source, locate the data cable and connect

it to the DB25 Port on the Laser Safety Module.

Secure Part

Place the new Laser Safety Module onto the

mounting studs so that the LED Panel can be

seen from the exterior of the engraver and

replace the Mounting Nuts.

Power on and Update

Power on the engraver and follow the

instructions on the display. Sometimes the

firmware in other parts of the engraver will need

to synchronize and update to the new part. Do

not power off the engraver until the instructed

or the display reads “Job”.

Complete

Other Epilog Engraver manuals