Epilog Fusion Pro 48 User manual

www.epiloglaser.com

tech@epiloglaser.com

303-215-9171

Leveling the Table

Fusion Pro 48

Parts Required Tools Required

• None • 5/32” Allen wrench

.

02/2023

Leveling the Fusion Pro 48 Table

2

Leveling the Fusion Pro

Table

Table level should be checked

periodically to ensure that the all areas of

the table are the same distance from the

focusing lens. If all areas of the table are

not the same distance from the focusing

lens, loss of laser power and inconsistent

engraving and cutting marks can occur.

Complete this procedure if any of the

following behaviors are observed.

• Laser power appears weak in certain

areas of the table.

• The engraver is unable to cut

through materials at or around the

recommended settings in certain

areas of the table.

• If the engraver has been moved to a

new location.

Leveling the Table Tub

1. Turn on the engraver, and let it

complete the startup process.

2. Ensure that the engraving tables

are installed in the engraver. This

procedure will not yield good results if

completed while the vector tables are

installed in the engraver.

3. Lower the manual focus gauge.

4. Use the Focus menu to raise the table

up enough to make contact with the

manual focus gauge.

5. Use the Jog menu and move the lens

carriage to each corner of the table to

determine which corner or corners are

lower than another. On a level table,

the manual focus gauge will touch the

table at each table corner.

6. If a front corner appears to be lower

than the others, remove the front

access panel of the engraver:

7. If a rear corner appears to be lower

than the others, remove the exhaust

plenum:

At each corner of the table are the table

lead screws table levelers:

Leveling the Fusion Pro 48 Table

3

8. To adjust the table levelers, loosen

the two (2) Allen screws on either side

of the lead screw and twist the lead

screw nut:

9. Turn the lead screw nut until the table

corner is in contact with the manual

focus gauge.

10. Once the table has been adjusted the

appropriate amount, tighten the two

(2) Allen screws on either side of the

lead screw to lock in the table leveler.

11. Use the Jog menu to move the lens

carriage to each corner of the table

to ensure that each corner is level. The

manual focus gauge should touch the

table at each table corner.

Leveling the Engraving Table

Inserts - Overview

Before beginning this procedure,

remove the engraving table and ensure

that there is no damage to the table,

especially to the edges of the table. A

damaged or warped engraving table

can prevent you from completing this

procedure. Aer inspection, place the

engraving table back into the engraver.

While this procedure can be used to level

the engraving tables in both the Fusion

Pro 32 and Fusion Pro 48 engravers, there

are slight dierences.

The Fusion Pro 32 allows for adjustments

in four (4) locations.

The Fusion Pro 48 allows for adjustments

in eight (8) locations. This is due to the

modular table assembly design in the

Fusion Pro 48 engraver.

Adjustment screws are located under

the front access panel and the exhaust

plenum.

The procedure shown here contains

images and certain instructions specific

to the Fusion Pro 48; however, the

concepts are directly applicable to the

Fusion Pro 32 engraver.

There are eight (8) leveling points at both

the front and rear of the Fusion Pro 48

engraver.

Front Table Adjustment Screws

While facing the leveling adjustment

points at the front of the engraver:

• The le screws adjust the le side of

the le table.

• The center screws adjust the right side

of the le table and the le side of the

right table.

• The right screws adjust the right side

of the right table.

Leveling the Fusion Pro 48 Table

4

Rear Table Adjustment Screws

While facing the leveling adjustment

points at the rear of the engraver:

• The le screws adjust the right side of

the right table.

• The center screws adjust the right side

of the le table and the le side of the

right table.

• The right screws adjust the le side of

the le table.

6. Remove the exhaust plenum:

7. While standing at the rear of the

machine and with the focus gauge in

contact with the table, move the lens

carriage between positions 1 and 2.

Observe the focus gauge to confirm

that it remains in contact with the

engraving table.

8. If adjustments are needed to this area

of the table, loosen the table clamp

locking screws for positions 1 and 2:

Table Clamp Locking Screws Position 1

Leveling the Fusion Pro 48 Table

5

6. Remove the exhaust plenum:

7. While standing at the rear of the

machine and with the focus gauge in

contact with the table, move the lens

carriage between positions 1 and 2.

Observe the focus gauge to confirm

that it remains in contact with the

engraving table.

8. If adjustments are needed to this area

of the table, loosen the table clamp

locking screws for positions 1 and 2:

Table Clamp Locking Screws Position 1

Table Clamp Locking Screws Position 2

9. Once the table clamp locking screws

are loosened, the table can be

raised or lowered using the Allen

head leveling screws shown below.

Tightening the screws will lower the

table and loosening the screws will

raise the table:

Table Leveling Screw Position 1

Leveling the Fusion Pro 48 Table

6

Table Leveling Screw Position 2

10. Adjust the table height until the tip of

the manual focus gauge is in contact

with the suace of the engraving

table when moving between positions.

11. Once the appropriate adjustments

have been made, tighten the table

clamp locking screws.

12. Move the lens carriage between

positions 3 and 4. Observe the focus

gauge to confirm that it remains in

contact with the engraving table.

14. If adjustments are needed to this area

of the table, repeat the table height

adjustment process outlined above to

level positions 3 and 4 using the table

clamp and leveling screws shown

below:

Table Clamp Locking Screws Position 3

Table Level Adjustment Screw Position 3

Leveling the Fusion Pro 48 Table

7

Table Clamp Locking Screws Position 4

Table Level Adjustment Screw Position 4

15. Once the rear of the table is level

between positions 1,2,3, and 4, move to

the front of the engraver.

16. While standing at the front of the

machine move the lens carriage

between positions 5 and 6. Observe

the focus gauge to confirm that it

remains in contact with the engraving

table.

17. If adjustments are needed to this area

of the table, repeat the table height

adjustment process outlined above to

level positions 5 and 6 using the table

clamp and leveling screws shown

below:

The table adjustment screws in the front

of the engraver work the opposite of the

table adjustment screws in the rear of

the engraver. Tightening the screws will

raise the table and loosening the screws

will lower the table.

Table Clamp Locking Screws Position 5

Table Adjustment Screws Position 5

Leveling the Fusion Pro 48 Table

8

Table Clamp Locking Screws Position 6

Table Level Adjustment Screw Position 6

18. Once the appropriate adjustments

have been made, tighten the table

clamp locking screws.

19. Move the lens carriage between

positions 7 and 8. Observe the focus

gauge to confirm that it remains in

contact with the engraving table.

20. If adjustments are needed to this area

of the table, repeat the table height

adjustment process outlined above to

level positions 5 and 6 using the table

clamp and leveling screws shown

below:

The table adjustment screws in the front

of the engraver work the opposite of the

table adjustment screws in the rear of

the engraver. Tightening the screws will

raise the table and loosening the screws

will lower the table.

Table Clamp Locking Screws Position 7

Table Level Adjustment Screw Position 7

Leveling the Fusion Pro 48 Table

9

Table Clamp Locking Screw Position 8

Table Level Adjustment Screw Position 8

21. Once the appropriate adjustments

have been made, tighten the table

clamp locking screws.

22. Test both engraving tables by pressing

down on each corner of the inserts

to ensure that theydo not rock up

and down. If rocking is observed, the

leveling procedure may need to be

repeated.

Fine Tuning the Table Level

1. The autofocus can be used to confirm

the quality of the table level.

2. Using the same table locations

described above, jog the lens carriage

to the desired location on the table

and initiate an autofocus command

via the Focus menu.

3. Compare the value returned from

each location. If all locations are

within +/-0.010, the table level is within

specifications.

If further assistance is required, please

contact Epilog Laser Tech Support by

phone at 303-215-9171, or by email at

tech@epiloglaser.com.

Other manuals for Fusion Pro 48

1

Other Epilog Engraver manuals

Popular Engraver manuals by other brands

GRAVOGRAPH

GRAVOGRAPH M40 Vice Technical manual

GRAVOGRAPH

GRAVOGRAPH LS100 IQ Operating and maintenance manual

Proxxon

Proxxon GG 12 operating manual

MasterCraft

MasterCraft 054-4605-0 instruction manual

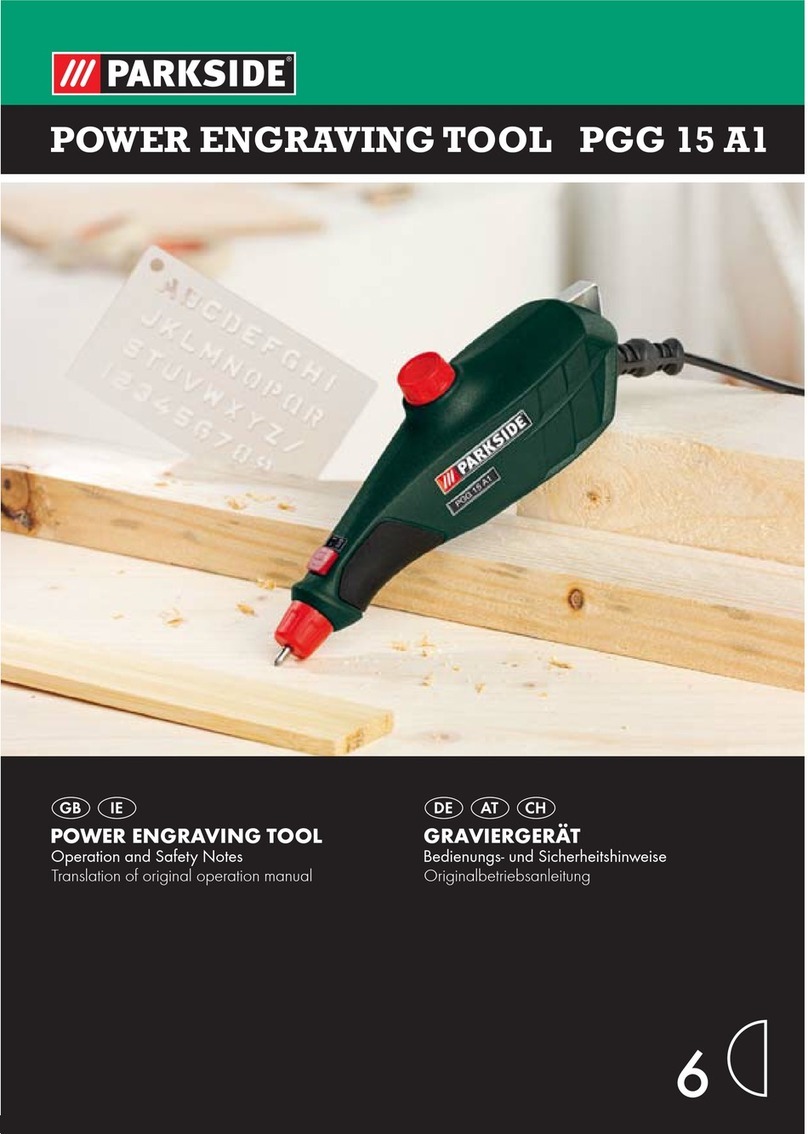

Parkside

Parkside PGG 15 A1 Operation and safety notes

Parkside

Parkside PGG 15 A1 Operation and safety notes translation of original operation manual