9

ADJUSTING BLADE HEIGHT

CAUTION: Make sure the machine is unplugged before proceeding with checking blades.

The blades have been adjusted at the factory to assure proper operation and should require no adjustment.

However, shipping and handling may have caused misalignment. For accurate cutting, the blades must be

as high as the out feed table when positioned at the highest point.

To check blade height:

Loosen the bridge cover locking knob, pull out the bridge cover.

Turn the cutter head so that one of the blades is at the highest position.

CAUTION: The cutter head blades are extremely sharp. Do not let your fingers contact the cutting edge at

any time.

Place a straightedge over the out feed table and the blade

The straight edge must touch evenly on the out feed table at both ends of the blade.

Rotate the cutter head by hand. The blades should just touch the straightedge. Ifa blade is too low or too

high at either end, adjust blade height using the jack screws.

AVOID DAMAGE TO BLADES

This Planer is a precision woodworking machine and should only be used on quality lumber. Using bad lumber

could result in a poor quality cut on subsequent pieces.

For proper operation, it is preferable to use the Planer with adust collecting system attached to the chip port in

the rear of the jointer. Attaching a dust collecting system isespecially required when taking deeper cuts to

prevent clogging of wood chips

Do not use dirty boards. Dirt and stones are abrasive and will wear the blade quickly.

Remove nails and staples from the wood before planing.

Avoid knots. Heavy cross-grain makes knots hardand they can come loose and jam the planer.

Assess value of badly warped boards. Operator can be tempted to use too deep of cut to square boards

quickly.Use several passes to maintain a level surface so you do not wear or jam the blades.

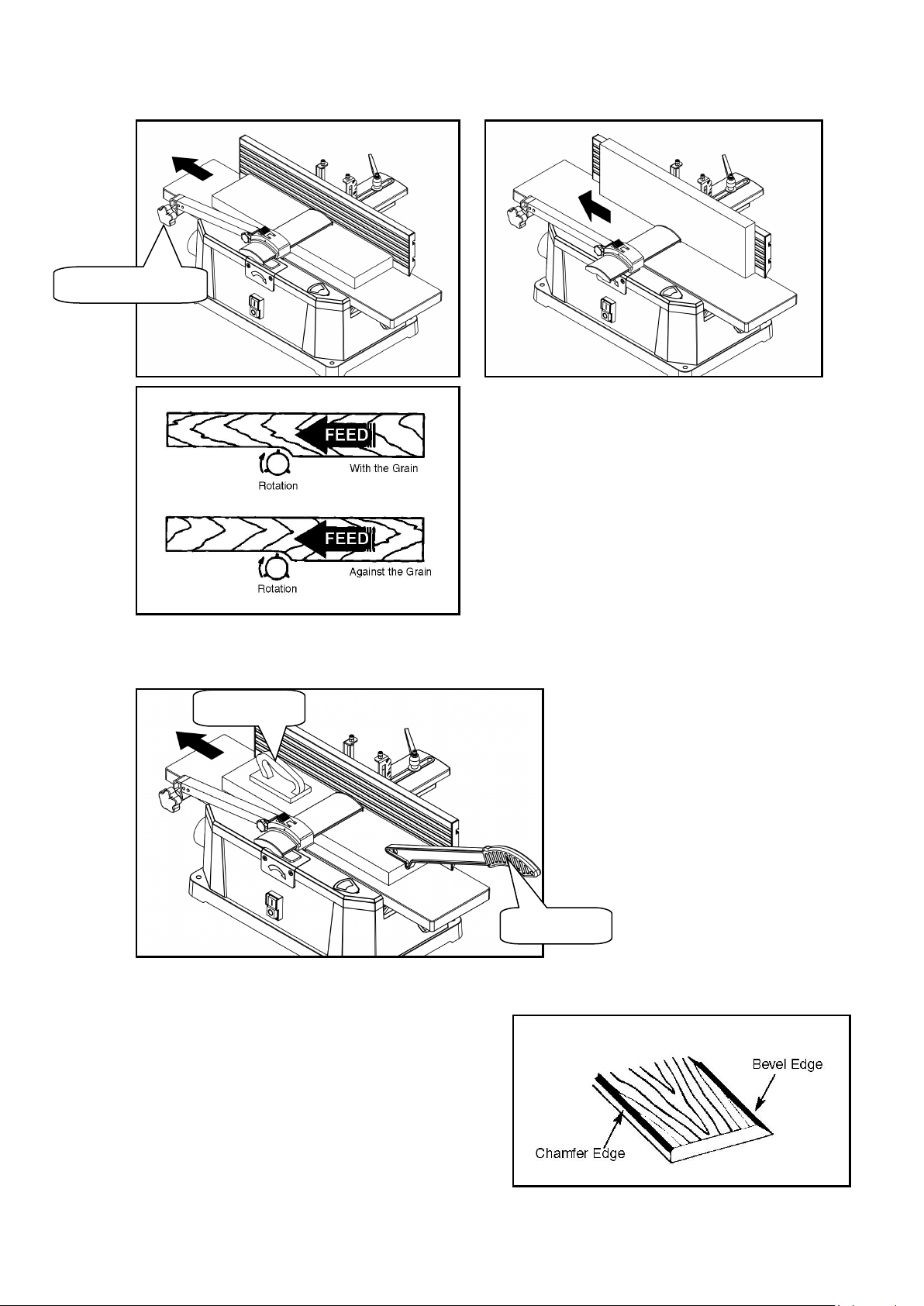

FEEDING WORKPIECE

Feed rate refers to the rate at which wood is passed over the blades, an even feed will produce a uniformed job.

To feed work piece:

Adjust the bridge cover to desired position, and tighten the knob.

Hold the work piece firmly down on the feed table and against the fence.

Feed the work piece at an even rate over the cutterhead, any hesitation or stopping will cause a “step” to be

cut in the work piece.

Asyour trailing hand passes over the cutter head remove your leading hand and place behind your trailing hand

and repeat until the entire length of work piece has been cut.

Lock knob

Bridge cover