E+E Elektronik EE23 series User manual

BA_EE23_B2_e // v1.0 // technical data are subject to change // 194768

Operation Manual

EE23

Humidity/Temperature Sensor

E+E Elektronik Ges.m.b.H. doesn’t accept warranty and liability claims neither upon this publication nor in case of

improper treatment of the described products.

The document may contain technical inaccuracies and typographical errors. The content will be revised on a

regular basis. These changes will be implemented in later versions. The described products can be improved and

changed at any time without prior notice.

© Copyright E+E Elektronik Ges.m.b.H.

All rights reserved.

EMC note USA (FCC):

This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant to part 15

of the FCC Rules. These limits are designed to provide reasonable protection against harmful interference when

the equipment is operated in a commercial environment. This equipment generates, uses, and can radiate radio

frequency energy and, if not installed and used in accordance with the instruction manual, may cause harmful

interference to radio communications. Operation of this equipment in a residential area is likely to cause harmful

interference in which case the user will be required to correct the interference at his own expense.

EMC note Canada (ICES-003):

CAN ICES-3 (A) / NMB-3 (A)

CONTENT

1 General .................................................................................................................................................4

1.1 Explanation of Symbols.................................................................................................................................4

1.2 Safety Instructions.........................................................................................................................................4

1.2.1 General Safety Instructions..................................................................................................................................4

1.2.2 Safety Instructions for the Alarm Output Module with Voltage >50V....................................................................4

1.2.3 Safety Instructions for the Integrated Power Supply (Option AM3)......................................................................4

1.3 Environmental Aspects..................................................................................................................................5

2 Scope of Supply ..................................................................................................................................5

3 Operating Components ......................................................................................................................6

3.1 Electronics Board for Model T1, T2, T4 and T6.............................................................................................6

3.2 Display for Model T1, T2, T4 and T6 .............................................................................................................7

3.3 Electronic Board for Model T5.......................................................................................................................8

3.4 Display for Model T5 .....................................................................................................................................9

4 Intallation ...........................................................................................................................................10

4.1 Mounting the Enclosure...............................................................................................................................10

4.2 Mounting the Sensing Probe .......................................................................................................................11

4.3 Electrical Connection...................................................................................................................................12

4.4 Connection Versions ...................................................................................................................................12

5 Calibration / Adjustment ...................................................................................................................14

5.1 Denitions....................................................................................................................................................14

5.2 Adjustment of EE23 Model T1, T2, T4 and T6 via Push Buttons on the Electronics Board........................14

5.2.1 2-Point RH Adjustment Procedure / T Adjustment Procedure............................................................................ 14

5.2.2 1-Point RH Adjustment Procedure / T Adjustment Procedure ........................................................................... 15

5.2.3 Return to Factory Calibration .............................................................................................................................15

5.3 Adjustment of the EE23 Model T5 via the USB Service Interface...............................................................16

6 Maintenance.......................................................................................................................................16

7 Troubleshooting ................................................................................................................................16

7.1 Fuse Replacement for Option AM3 .............................................................................................................16

8 Accessories and Spare Parts ..........................................................................................................17

9 Technical Data ...................................................................................................................................18

9.1 Operating Range Humidity Sensor..............................................................................................................19

4

Operating manual EE23 humidity / temperature sensor

1 General

This operation manual is part of the scope of supply and serves for ensuring proper handling and opti-

mal functioning of the device.

The operation manual shall be read before commissioning the equipment and it shall be provided to all

staff involved in transport, installation, operation, maintenance and repair.

The operation manual may not be used for the purposes of competition without the written consent of

E+E Elektronik® and may not be forwarded to third parties. Copies may be made for internal purposes.

All information, technical data and diagrams included in these instructions are based on the information

available at the time of writing.

1.1 Explanation of Symbols

This symbol indicates safety information.

It is essential that all safety information is strictly observed. Failure to comply with this information can

lead to personal injuries or damage to property. E+E Elektronik® assumes no liability if this happens.

This symbol indicates instructions.

The instructions shall be observed in order to reach optimal performance of the device.

1.2 Safety Instructions

1.2.1 General Safety Instructions

• Avoid any unnecessary mechanical stress and inappropriate use.

• Replacetheltercapwithutmostcare,sothattheltercapdoesnottouchthesensingelementsof

the sensing head at any time.

• Do never touch the sensing elements.

• Forsensorcleaningandltercapreplacementpleasesee“Cleaninginstructions”atwww.epluse.com.

• Installation,electricalconnection,maintenanceandcommissioningshallbeperformedbyqualied

personnel only.

1.2.2 Safety Instructions for the Alarm Output Module with Voltage >50V

(not available for model T5 with remote probe up to 180 °C (356 °F))

• The alarm output module must be separated from the screw terminals

by the partition plate (see picture).

• The enclosure must be properly closed before power on.

• Power off the device before opening the enclosure.

1.2.3 Safety Instructions for the Integrated Power Supply (Option AM3)

• The back cover and the middle (active) part of the EE23 with

metal enclosure must be grounded during operation.

• The E23 enclosure must be properly closed before power on.

• Power off the device before opening the enclosure.

5

Operating manual EE23 humidity / temperature sensor

1.3 Environmental Aspects

Products from E+E Elektronik® are developed and manufactured observing of all relevant requirements

with respect to environment protection. Please observe local regulations for the device disposal.

For disposal, the individual components of the device must be separated according to local recycling

regulations. The electronics shall be disposed of correctly as electronics waste.

2 Scope of Supply

Included in

all versions

According to ordering

guide

EE23 according to ordering guide x

Operation manual in English x

InspectioncerticateaccordingtoDINEN10204–3.1 x

Allen key 3.0 only for metal enclosure

Mating cable connector for integrated power supply AM3

Mating cable connector RSC 5/7 AM3 / E4

M16 cable gland except AM3, E4

6

Operating manual EE23 humidity / temperature sensor

3 Operating Components

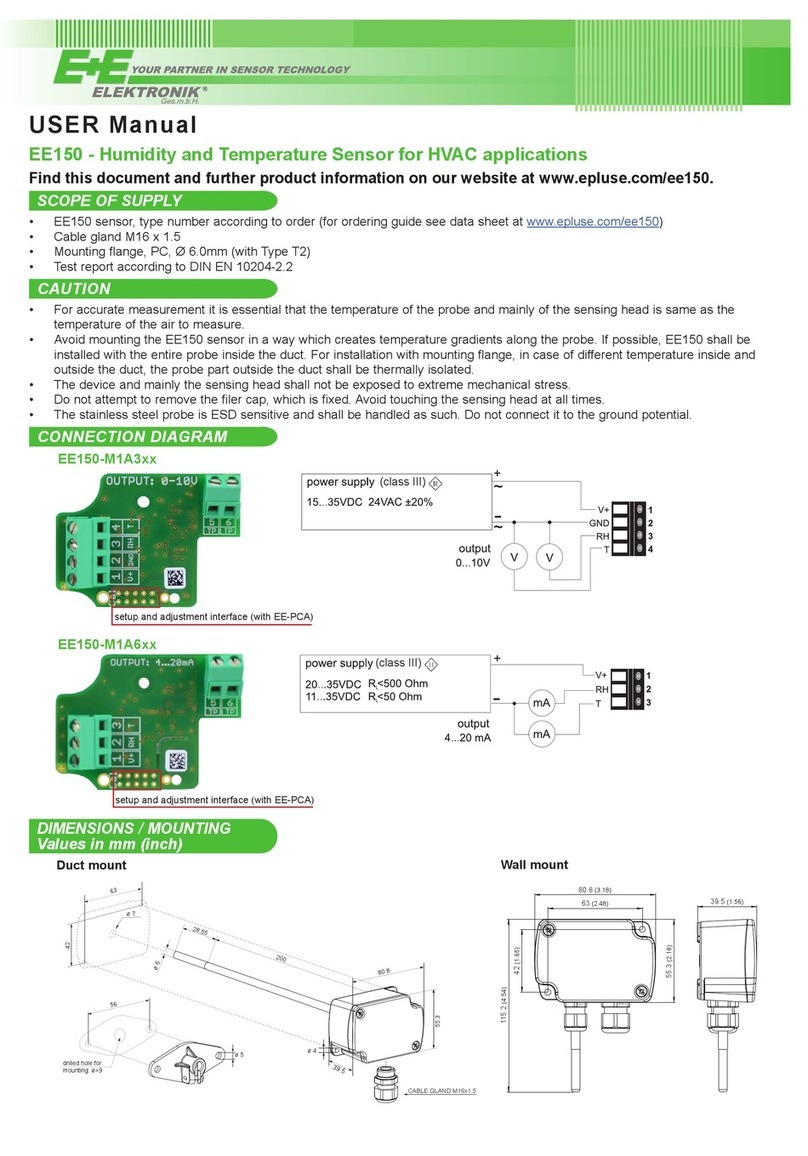

3.1 Electronics Board for Model T1, T2, T4 and T6

Fig. 1 Electronics board model T1, T2, T4 and T6

1. Jumpers:

Selection of the output signal and output range

voltage output current output

2. Display:

Connectors for the optional display

3. Status LEDs

D1 (red) - continuously on during the calibration routine

-oneshortashconrmsresettofactorycalibration

D2(green) -ashesduringnormaloperation

- continuously on indicates sensor damage

4. Push-Buttons

The S1 and S2 push buttons are used for the EE23 adjustment as well as for returning to the factory

calibration (see Calibration / Adjustment).

5. Level / Hysteresis

Potentiometers for setting the threshold / hysteresis (available with alarm module only)

7

Operating manual EE23 humidity / temperature sensor

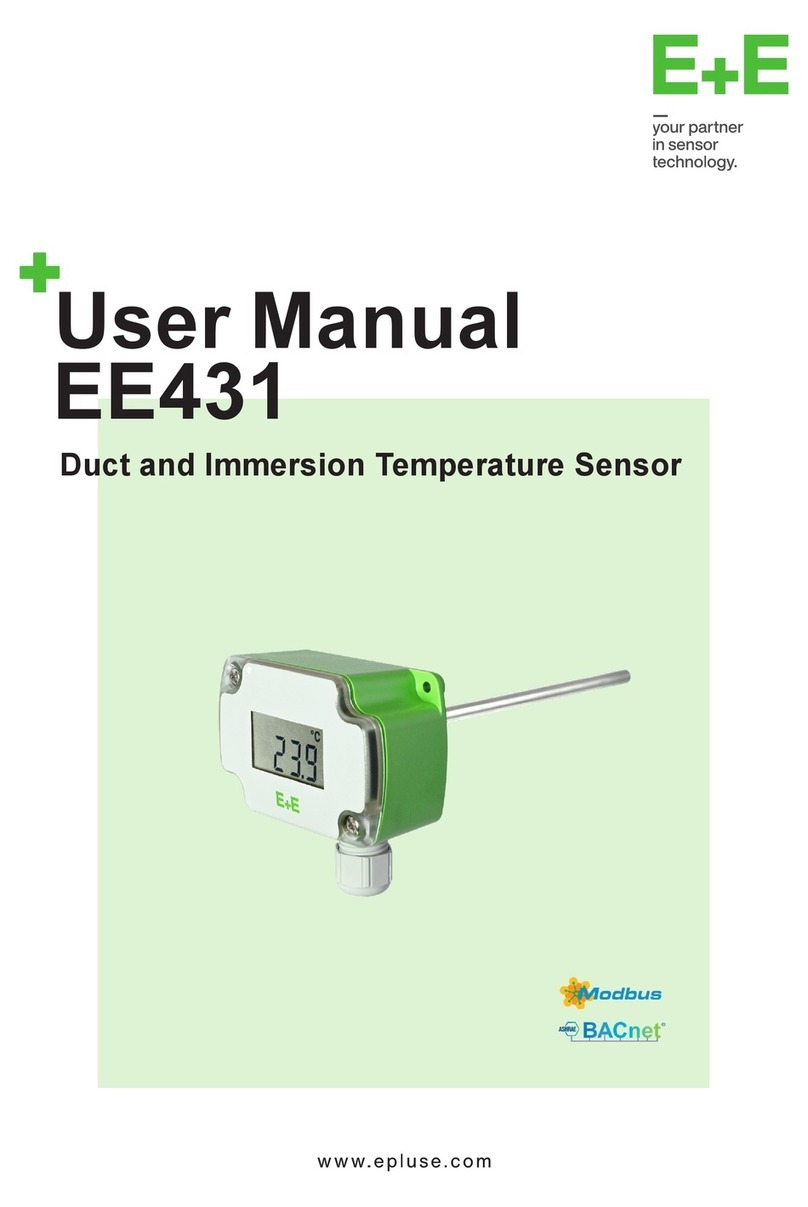

3.2 Display for Model T1, T2, T4 and T6

The display is plugged into the connectors on the electronics board and it can easily be replaced. For

upgradinganEE23originallywithoutdisplaypleasesee“Replacementparts/accessories”.

1 2 3 4

5

6

Fig. 2 Display description T1, T2, T4 and T6

1. CAL

Indicates that the device in calibration/adjustment mode

2. > <

>: indicates measured value above the alarm threshold (with alarm module only).

visual feedback when depressing the S1 push button (Fig. 1)

<: indicates measured value below the alarm threshold (with alarm module only).

visual feedback when depressing the S2 push button (Fig. 1)

3. SET

Indication for EE23 with optional alarm output

4. Td / Tf

Dew point temperature / frost point temperature

5. °C / °F

Unit for temperature (T) and dew point temperature (Td) and frost point temperature (Tf)

6. %RH

Unit for relative humidity (RH)

8

Operating manual EE23 humidity / temperature sensor

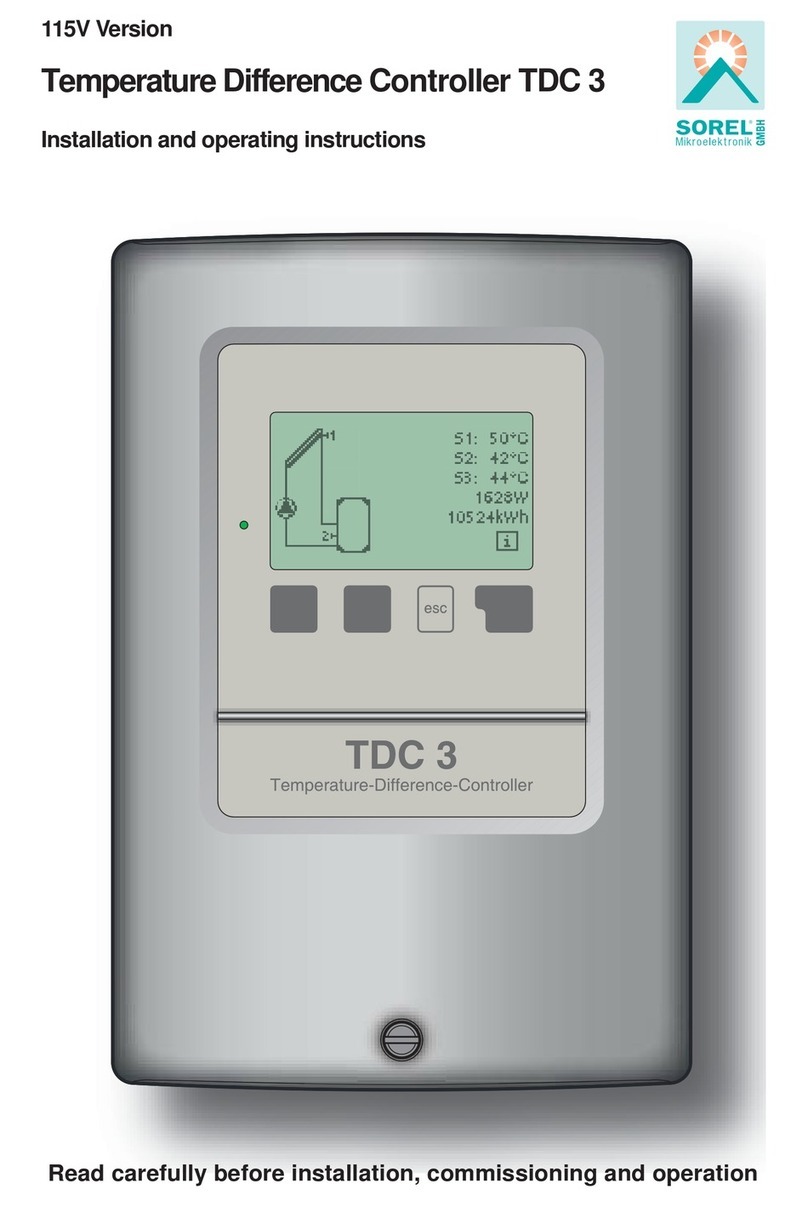

3.3 Electronic Board for Model T5

T5 = remote probe up to 180 °C (356 °F)

1. Display

2. Status LEDs

3. Interface

Fig. 3 Electronics board model T5

1. Display:

Connectors for the optional display

2. Status LEDs:

Green LED

ashing-->Supplyvoltageapplied/Microprocessorisactive

Red LED

constantly lit --> Error category 1 = non-critical error, can be solved by the user

ashing-->Errorcategory2=criticalerror,returnthedeviceforservice

Blue LED

constantly lit --> analogue output is set to voltage.

Orange LED

constantly lit --> analogue output is set to current.

3. Interface:

USB-Interface for service use

9

Operating manual EE23 humidity / temperature sensor

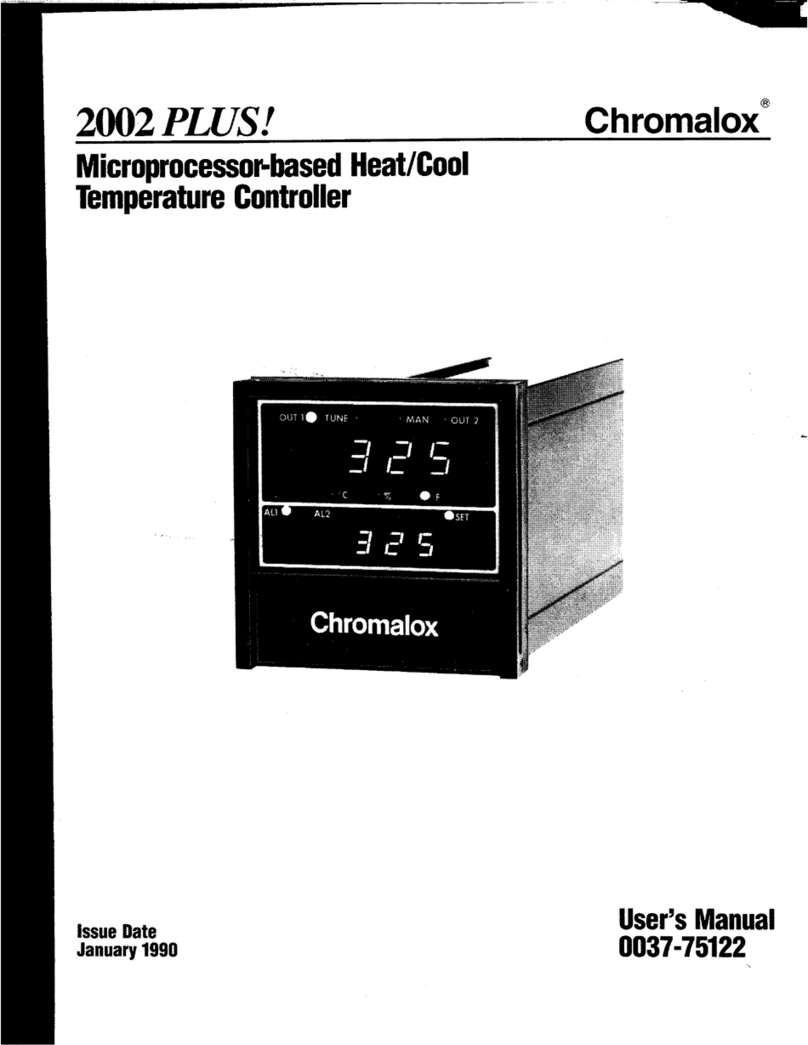

3.4 Display for Model T5

Fig. 4 Display description T5

1. Measurand 2. Units 3. Mesurand selection

SI US

RH Relative humidity % %

Press the ∆or ∇ button

to select the measurand

to be displayed.

T Temperature °C °F

h Enthalpy kJ/kg ftlbf/lb

r Mixture ratio g/kg gr/lb

dv Absolute humidity g/m³ gr/ft

Tw Wet-bulb temperature °C °F

Td Dew-point temperature °C °F

e Water vapour partial pressure mbar psi

Tab. 1 Mesurand selection

Error description Error code

(display)

Error

category Recommended action

Short circuit - on voltage output 11)

ERROR: 01

1

Check wiring of outputsShort circuit - on voltage output 21)

Short circuit - on both voltage outputs*

Current loop open - output 1

ERROR: 02 Check wiring of outputsCurrent loop open - output 2

Current loop open - both outputs

RH sensor dirty ERROR: 03 Clean the sensor2)

Hardware error

ERROR: 05

2Return the faulty unit for

service

ERROR: 06

ERROR: 08

Temperature measurement failure ERROR: 07

Humidity measurement failure ERROR: 09

ERROR: 10

1) not available with 0 - 1 V output

2)see“CleaningInstructions”atwww.epluse.com/ee23

Tab. 2 Description of error messages on the display

10

Operating manual EE23 humidity / temperature sensor

4 Intallation

4.1 Mounting the Enclosure

1. Only for model T2 (duct mounting). Drill the hole for inserting the probe into the duct wall,Fig. 7 on

page 11. The relevant position of top left mounting screw of the back cover with respect to the probe

center:

2. FixthebackcoverofEE23ontothewall/panelusing4screws(diametermax.4.2mm(0.2”);not

included in the scope of supply).

The device shall be mounted with the cable glands pointing downwards or horizontal.

3. Wiretheterminalsinsidethebackcoveraccordingto„Fig.10Connectiondiagram“onPage12.

4. Insert the middle (active) part into the back cover. By this the connection pins of the middle part will

plug into the terminals of the back cover and thus realize the electrical connection.

5. Place the front cover onto the middle part and close tight the enclosure using the four screws included

in the scope of supply.

Drilling for round holes:

Drilling for long holes:

Fig. 5 Mounting of metal enclosure

116 (4.5“)

50.8 (2“)

Fig. 6 Mounting of polycarbonat enclosure

Metal enclosure: x=28.5mm(1.1”) y=37.5mm(1.5”)

Polycarbonate enclosure: x=20.5mm(0.8”) y=25.4mm(1”)

11

Operating manual EE23 humidity / temperature sensor

For the wall mount model the probe must point downwards.

For the duct mount model the probe must point either horizontally or downwards.

Ø12 (0.5“)

Ø12

(0.5“)

Ø14 (0.6“)

X

Y

Fig. 7 T1 Wall mount T2 Duct mount

Mounting onto DIN rails

EE23 with polycarbonate enclosure can be mounted also on DIN rails with the bracket HA010203 (not

includedinthescopeofsupply,see“spareparts/accessories”).

4.2 Mounting the Sensing Probe

Whenever possible place the entire probe inside the space to be monitored.

In case of mounting the probe into a partition wall, it is of paramount importance for accurate mea-

surement to avoid T gradients along the probe. In case of large T difference between the two sides of

the wall, it is highly recommended to insert the probe completely (up to the cable outlet) into the wall.

Should this not be possible, place a thermal isolation layer on the part of the probe outside the wall (on

the cable side).

ForprobemountingintoapartitionwallusethemountingangesHA010201forprobediameter12mm

andHA010208forprobediameter5mm.NeitherthemountingangesnortheEE23probesarepres-

sure rated and as such they are not appropriate for pressure tight mounting. For pressure tight require-

ments please see www.epluse.com for appropriate products such as EE310.

Ø46 (1.8“)

Ø

12 (0.5“)

Ø

13

(0.51“)

37 (1.5“)

Fig. 8 Mounting ange HA010201 Mounting ange HA010208

12

Operating manual EE23 humidity / temperature sensor

For applications where condensation is likely to happen, certain ways of mounting are required.

• For probe hanging onto its cable from the ceiling, use the drip water protection HA010503 (not inclu-

dedinthescopeofsupply,see“spareparts/accessories”).Thisprotectstheprobeandthesensing

head against water dripping along the cable.

• For horizontal mounted probe, a drip water point should be made just before the probe.

13 (0.51“)

85 (3.3“)

34

(1.3“)

horizontal hanging onto the probe cable

stainless steel

mounting flange

drip water loop

drip water

protection

Fig. 9 Mounting the sensing probe

4.3 Electrical Connection

Power supply and outputs Alarm output

output and supply alarm output

Relais status for

RH < threshold

Power supply

Fig. 10 Connection diagram

4.4 Connection Versions

standard option E4 option AM3

1) Two M16x1.5 cable glands (one of them mounted onto the enclosure)

2) Power supply + analogue outputs: cable connector, 5-poles, straight M12 (Lumberg RKC 5/7)

3) Analogue output: cable connector, 5-poles, straight M12 (Lumberg RKC 5/7)

4)ACpowersupply:cableconnector,3-poles,straight(7/8ʺ-16UN)

13

Operating manual EE23 humidity / temperature sensor

Pin assignment for option E4 (with supply 8...35V DC / 12...30V AC)

plug for supply and

analogue output

(front view) 12

3

4

5

Description: Pins:

V+ 5

GND 4

GND 3

OUT1 2

OUT2 1

Pin assignment for option AM3 (integrated supply unit for 100...240V AC)

plug for

analogue outputs

(front view) 12

3

4

5

Description: Pins:

GND 3

OUT1 2

OUT1 1

plug for 100-240 V

metal enclosure

(front view)

Description: Pins:

grounding (PE) 1

phase (L1) 2

neutral wire (N) 3

plug for 100-240 V

polycarbonate enclosure

(front view)

Description: Pins:

phase (L1) 1

neutral wire (N) 3

Externaldiameterofsupplycable:10-12mm(0.39-0.47”)

Maximum wire cross section for connecting cable: 1.5mm² (AWG 16)

The protection of the supply cable against excess current and short-circuit must be designated

to a wire cross section of 0.8mm² (AWG 18) (6A fuse).

The back cover and the middle part of the metal enclosure must be grounded during operation!

14

Operating manual EE23 humidity / temperature sensor

5 Calibration / Adjustment

5.1 Denitions

Calibration

The calibration documents the accuracy of a measurement device. The device under test

(specimen)iscomparedwiththereferenceandthedeviationsaredocumentedinacalibrationcerti-

cate. During the calibration, the specimen is not changed or improved in any way.

Adjustment

The adjustment improves the measurement accuracy of a device. The specimen is compared with the

reference and brought in line with it. An adjustment can be followed by a calibration which documents

the accuracy of the adjusted specimen.

For general calibration / adjustment guidelines and for the choice of humidity reference devices please

see“CalibrationInstructions”at www.epluse.com/ee23

The 2-point adjustment is recommended for best accuracy over a wide RH and / or T range.

Always start the 2-point adjustment with the lower adjustment point RH_low / T_low, followed by the

higher adjustment point RH_high / T_high.

The span between the two adjustment points must be:

|RH_high–RH_low| >30%RH

|T_high–T_low| >30°C(54°F)

The 1-point adjustment should be used only when the RH and/or T range of interest is rather narrow.

The RH resp. T adjustment point should be ideally in the middle of the range of interest.

Example:

In a climate controlled environment with 40% < RH < 60% and 15 °C < T < 25 °C (59 °F < T < 77 °F),

1-point adjustment shall be performed at 50 % RH and 20 °C (68 °F).

1-point adjustment leads to very good accuracy within the range of main interest at the cost of the

accuracy beyond this range.

5.2 Adjustment of EE23 Model T1, T2, T4 and T6

via Push Buttons on the Electronics Board

5.2.1 2-Point RH Adjustment Procedure / T Adjustment Procedure

1. For a RH humidity adjustment set the jumper to CAL RH / for a temperature adjustment set the

jumper to CAL T.

First point adjustment

2. Allow for the probe to stabilize at RH_low / T_low for min. 30 minutes.

3. Press BUTTON S2formin.3secondstostarttheadjustmentprocedurefortherstpoint.TheLED

„D1“illuminatesand„CAL<“appearsontheLCdisplay.

4. Press BUTTON S1 (up) and S2 (down) to adjust the measured value in steps of 0.1% / 0.1 °C up

or down to match the reference value. The change is indicated on the display (if available) or can be

measured at the analogue output.

5. Press BUTTON S1formin.3secondstostoreadjustedvalueandendtherstpointadjustment.

or

15

Operating manual EE23 humidity / temperature sensor

Press BUTTON S2 for min. 3 seconds to exit adjustment procedure without storing the adjusted

value.

InbothcasestheLED„D1“andthesymbol„CAL<“ontheLCdisplayaredeactivated.

Second point adjustment

6. Allow for the probe to stabilize at the desired RH_high / T_high for min. 30 minutes.

7. Press BUTTON S1 for min. 3 seconds to start the adjustment procedure for the second point. The

LED„D1“illuminatesand„CAL>“appearsontheLCdisplay.

8. Press BUTTON S1 (up) and S2 (down) to adjust the measured value in steps of 0.1% / 0.1 degC up

or down to match the reference value. The change is indicated on the display (if available) or can be

measured at the analogue output.

9. Press BUTTON S1formin.3secondstostoreadjustedvalueandendtherstpointadjustment.

or

Press BUTTON S2 for min. 3 seconds to exit adjustment procedure without storing the adjusted

value.

In both cases the LED„D1“andthesymbol„CAL>“ontheLCdisplayaredeactivated.

5.2.2 1-Point RH Adjustment Procedure / T Adjustment Procedure

1. For a RH humidity adjustment set the jumper to CAL RH / for a temperature adjustment set the

jumper to CAL T.

2. Allow for the probe to stabilize at the desired RH / T for min. 30 minutes.

3. For adjustment point > 50% RH / in the upper half of the T output scale): press BUTTON S1 for min.

3secondstostarttheprocedure.TheLED„D1“illuminatesand„CAL<“appearsontheLCdisplay.

or

For adjustment point < 50% RH / in the lower half of the T output scale): press BUTTON S2 for min.

3secondstostarttheprocedure.TheLED„D1“illuminatesand„CAL>“appearsontheLCdisplay.

4. Press BUTTON S1 (up) and S2 (down) to adjust the measured value in steps of 0.1% / 0.1 °C up or

down to match the reference value. The change is indicated on the display (if available) or can be

measured at the analogue output.

5. Press BUTTON S1formin.3secondstostoreadjustedvalueandendtherstpointadjustment.

or

Press BUTTON S2 for min. 3 seconds to exit adjustment procedure without storing the adjusted

value.

InbothcasestheLED„D1“andthesymbol„CAL“ontheLCdisplayaredeactivated.

5.2.3 Return to Factory Calibration

ToreturntoRHorTfactorycalibrationsetrstthejumpertoRHortoTrespectively.

During normal measuring mode (i.e. not during the adjustment procedure. LED D1 shall be off, the

displayshallnotshow“CAL”)pressingBUTTON S1andS2togetherformin5seconds.Thereturnto

factorycalibrationisconrmedbyashortashoftheLED„D1“.

16

Operating manual EE23 humidity / temperature sensor

5.3 Adjustment of the EE23 Model T5 via the USB Service Interface

1. DownloadandinstalltheEE-PCSProductCongurationSoftwarefromwww.epluse.com/congurator

2. Connect the USB service interface of EE23-T5 to the PC.

3. Start the EE-PCS software.

4. Select the desired adjustment mode and follow the instructions of the EE-PCS.

6 Maintenance

When employed in dusty, polluted environment:

• TheltercapshallbereplacedasneededwithanE+Eoriginalone.Apollutedltercapcauses

longer response time of the device.

• Forcleaningofthesensingheadpleasesee“CleaningInstructions”atwww.epluse.com/ee23.

7 Troubleshooting

SeestatusLEDsat„3OperatingComponents“onPage6 and error messages on the display at „3.4

DisplayforModelT5“onPage9.

7.1 Fuse Replacement for Option AM3

IfthegreenLEDonthePCBisnotashingwiththesupplyvoltageswitchedoncheckthefuseand

replace if required.

Fuse secondary: 250mA / T UL248-14

Recommended replacement types:

Series: MSTU 250 Manufacturer: Schurter Order No.: 0034.7109

Series: 374 Manufacturer: Littelfuse Order No.: 374 0250

Fig. 11 Fuse replacement

17

Operating manual EE23 humidity / temperature sensor

8 Accessories and Spare Parts

Description Order Code

- Filter caps HA0101xx

- External power supply unit V03

- Display + housing cover in metal

for T1, T2, T4 and T6 D03M-EE23

for T5 D05M-EE23T5

- Display + housing cover in polycarbonate

for T1, T2, T4 and T6 D03P-EE23

for T5 D05P-EE23T5

-Mountingangeforprobediameter12mm HA010201

-Mountingange5mm(formodelT6only) HA010208

- Bracket for plastic enclosure - for installation onto mounting rails HA010203

- Drip water protection HA010503

- Calibration set (seedatasheet„CalibrationKit“) HA0104xx

- Radiation shield HA010502

18

Operating manual EE23 humidity / temperature sensor

9 Technical Data

Measurands

Relative Humidity

Working range 0...100% RH

Accuracy1(including hysteresis, non-linearity and repeatability, traceable to intern. standards, administrated by NIST, PTB, BEV...)

EE23-T1/T2/T4/T5 EE23-T6

-15...40°C (5...104°F) ≤90% RH ± (1.3 + 0.3%*mv) % RH ± (1.8 + 0,3%*mv) % RH

-15...40°C (5...104°F) >90% RH ± 2.3% RH ± 2.8% RH

-25...70°C (-13...158°F) ± (1.4 + 1%*mv) % RH ± (1.9 + 1%*mv) % RH

-40...180°C (-40...356°F) ± (1.5 + 1.5%*mv) % RH -

Temperature dependence electronics typ. ± 0.015% RH/°C

Response time t90 with metal grid filter at 20 °C (68 °F) < 15 sec.

Temperature

Probe working range EE23-T1 -40...60°C (-40...140°F)

EE23-T2/T6 -40...80°C (-40...176°F)

EE23-T4 -40...120°C (-40...248°F)

EE23-T5 -40...180°C (-40...356°F)

Accuracy

Temperature dependence of electronics typ. 0.002°C/°C

Output Scale Span

from up to units

EE23-T1 EE23-T2/T6 EE23-T4 EE23-T5

Humidity RH 0100 100 100 100 % RH

Temperature T -40 (-40) 60 (140) 80 (176) 120 (248) 180 (356) °C (°F)

Dew point temperature Td -40 (-40) 60 (140) 80 (176) 100 (212) 100 (212) °C (°F)

Frost point temperature Tf -40 (-40) 0(32) 0(32) 0(32) 0(32) °C (°F)

Outputs 0 - 1 V -0.5 mA < IL < 0.5 mA

0 - 5 / 0 - 10 V -1 mA < IL < 1 mA

0 - 20mA / 4 - 20 mA RL< 470 Ohm

General

Supply voltage

for 0 -1 V / 0 - 5 V outputs 10.5 - 35V DC or 12 - 28V AC

for 0 - 10 V / 0 - 20 mA / 4-20 mA outputs 15.0 - 35V DC or 15 - 28V AC

100...240V AC, 50/60Hz supply module (optional)

Current consumption for voltage output

for DC supply ≤25 mA (with alarm module ≤35 mA)

for AC supply ≤45 mAeff (with alarm module ≤70 mAeff)

Current consumption for current output

for DC supply ≤55 mA (with alarm module ≤65 mA)

for AC supply ≤100 mAeff (with alarm module ≤120 mAeff)

Enclosure/protectionclass PCorAlSi9Cu3/IP65;NEMA4

Cablegland M16x1.5 cableØ4.5-10mm(0.18-0.39”)

Electrical connection screw terminals max. 1.5 mm² (AWG 16)

Working temperature range of electronics -40...60°C (-40...140°F)

Working temperature range with display -30...60°C (-22...140°F)

Storage temperature range -40...60°C (-40...140°F)

CE compatibility according EN61326-1 EN61326-2-3 ICES-003 ClassB

Industrial Environment FCC Part15 ClassB

Alarm Module2)

Output SPDT-Switch max. 250V AC/8A or 28V DC/8A

threshold hysteresis

Setting range 10...95% RH 3...15% RH

Setting accuracy ± 3% RH

1) The accuracy statement includes the uncertainty of the factory calibration with an enhancement factor k=2 (2-times standard deviation). The accuracy was calculated in

accordance with EA-4/02 and with regard to GUM (Guide to the Expression of Uncertainty in Measurement).

2) only for models T1, T2, T4 and T6.

EE23-T1/T2/T4/T5 EE23-T6

°C°C

∆°C∆°C

19

Operating manual EE23 humidity / temperature sensor

9.1 Operating Range Humidity Sensor

Relative humidity [%RH]

Temperature [degC]

The gray area shows the allowed measurement range for the humidity sensor.

Operationbeyondthisrangedoesnotdestroythesensingelement,butthespeciedmeasurement

accuracy cannot be guaranteed.

HEADQUARTERS

E+E Elektronik Ges.m.b.H.

Langwiesen 7

A-4209 Engerwitzdorf

Austria

Tel: +43 7235 605 0

Fax: +43 7235 605 8

www.epluse.com

SUBSIDIARIES

E+E Elektronik Germany

Office Bad Homburg

Tel: +49 6172 13881-0

Office Hamburg

Tel: +49 160 9050 6460

Office Stuttgart

Tel: +49 151 538 37 500

E+E Elektronik Italy

Tel: +39 02 2707 86 36

E+E Elektronik France

Tel: +33 4 74 72 35 82

E+E Elektronik USA

Office Boston

Tel: +1 508 530 3068

Office Chicago

Tel: +1 847 490 7813

E+E Elektronik Korea

Tel: +82 31 732 6050

E+E Elektronik China

Office Beijing

Tel: +86 10 8499 2361

Office Shanghai

Tel: +86 21 6117 6129

Office Guangzhou

Tel: +86 20 3898 7052

Other manuals for EE23 series

2

Table of contents

Other E+E Elektronik Temperature Controllers manuals