TABLE OF CONTENTS

vii

SECTION 1

Introduction 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

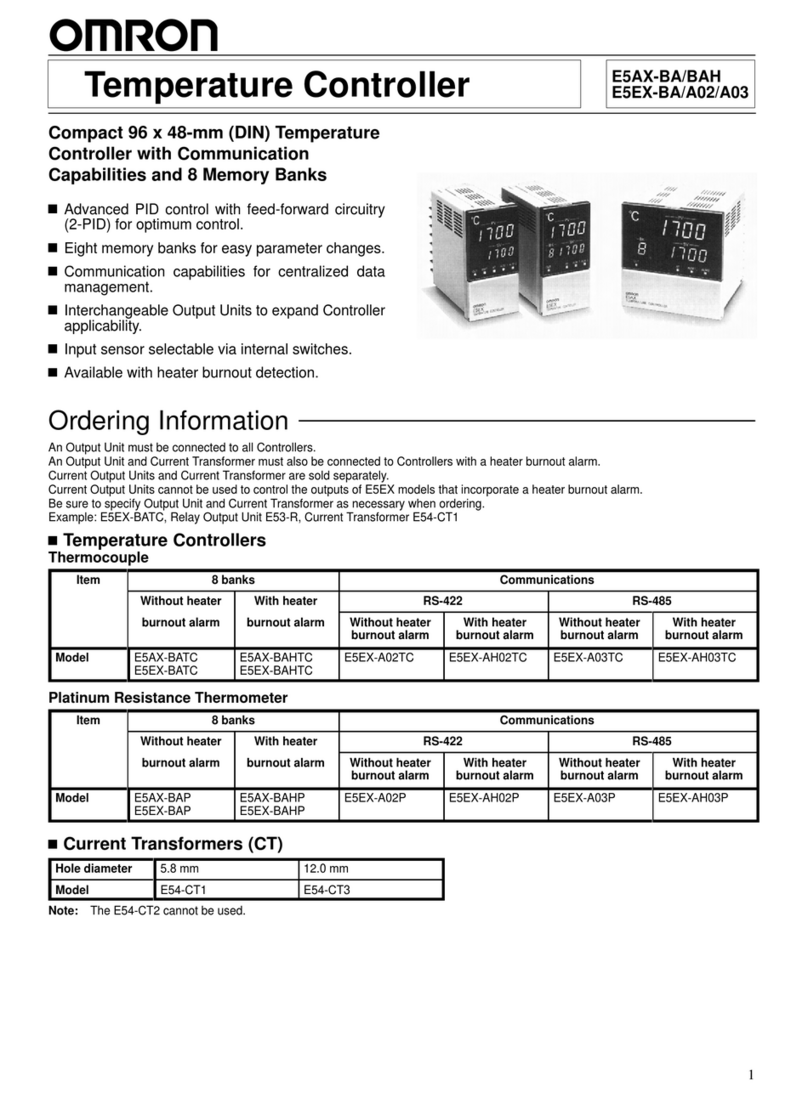

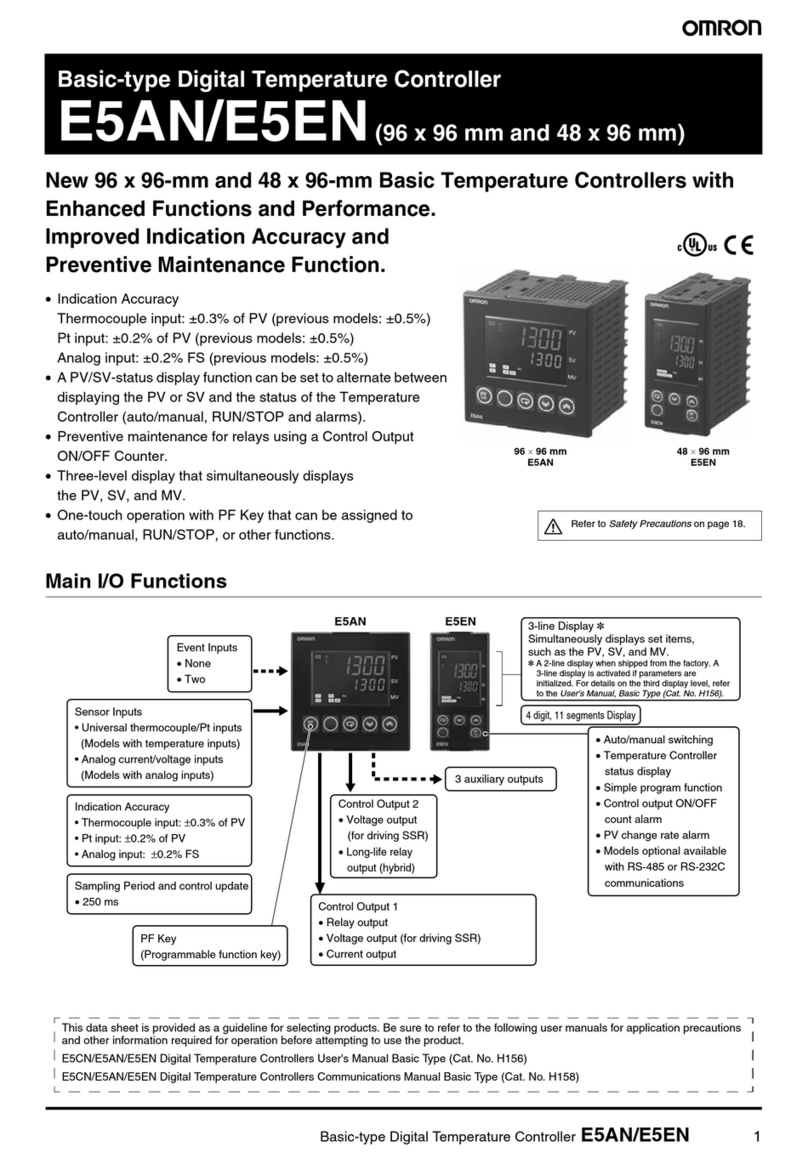

1-1 Product Information 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-2 Features 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-3 Models Available 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-4 Precautions 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 2

Preparations for Operation 9. . . . . . . . . . . . . . . . . . . . . . . .

2-1 E5ZD-4jjj-E/-6jjj-E Hardware 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-2 E5ZD-8jjj-E Hardware 24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-3 E5ZD-8HjjM-E Hardware 34. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 3

Basic Operation 51. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-1 Overview 52. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-2 Communications 52. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-3 Memory Banks 54. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-4 Parameter Backup 56. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-5 HB and HS Alarms 58. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-6 Fuzzy Control 60. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-7 Features 62. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-8 Adjusting Fuzzy Parameters 64. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 4

Commands and Responses 67. . . . . . . . . . . . . . . . . . . . . . . .

4-1 Overview 68. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-2 Temperature Control Commands (All Controllers) 71. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-3 Fuzzy Constant Commands (Fuzzy-logic Controllers Only) 109. . . . . . . . . . . . . . . . . . . . . .

4-4 Global Read and Control Operations 111. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-5 Global Write Operations 114. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 5

Transmission Times 119. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-1 Writing Times 120. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-2 Reading Times 120. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 6

Troubleshooting 123. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-1 Troubleshooting Lists 124. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-2 Loop-Back Communications Test 128. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Appendices

A Specifications 129. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B Parameter Defaults, Setting Ranges, and Commands 133. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

C End Codes 135. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

D Error Codes 137. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

E ASCII Codes 139. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Index 141. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Revision History 143. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .