E+E Elektronik HCT01 Instruction Manual

Rev. 0.2 / 09 /2015 2

AN1111-2

Developer’s Guide for

HCT01

Humidity and

Temperature

Sensors

Rev. 0.2 / 09 /2015 3

AN1111-2

Table of content:

1Driving circuitry for HCT01 .............................................................................................................. 4

2Pre-adjusted HCT01 with an initial accurate circuitry with frequency output .................................. 6

2.1 Schematic circuit diagram ....................................................................................................... 6

2.1.1 Bill of Material................................................................................................................................ 6

2.1.2 Correlation between sensor capacity and period........................................................................... 7

3RH measurement with pre-adjusted HCT01 and microcontroller based, initially accurate circuitry 8

3.1 Schematic circuit diagram ....................................................................................................... 8

3.1.1 Bill of Material................................................................................................................................ 9

4Hints for the development engineer .............................................................................................. 11

5Contact information ....................................................................................................................... 12

6Revision history ............................................................................................................................. 12

Rev. 0.2 / 09 /2015 4

AN1111-2

1 Driving circuitry for HCT01

HCT01 is a capacitive, thin-film sensor for relative humidity (RH) in a robust SMD enclosure. The

enclosure can accommodate an optional high precision temperature (T) sensor – a prerequisite for

precisely calculating dew point.

The enclosure provides optimal mechanical sensor protection and can be used with a standard reflow

process. The E+E proprietary coating protects the active surface of the RH sensor against dust, salt

and other corrosive or low impedance deposits.

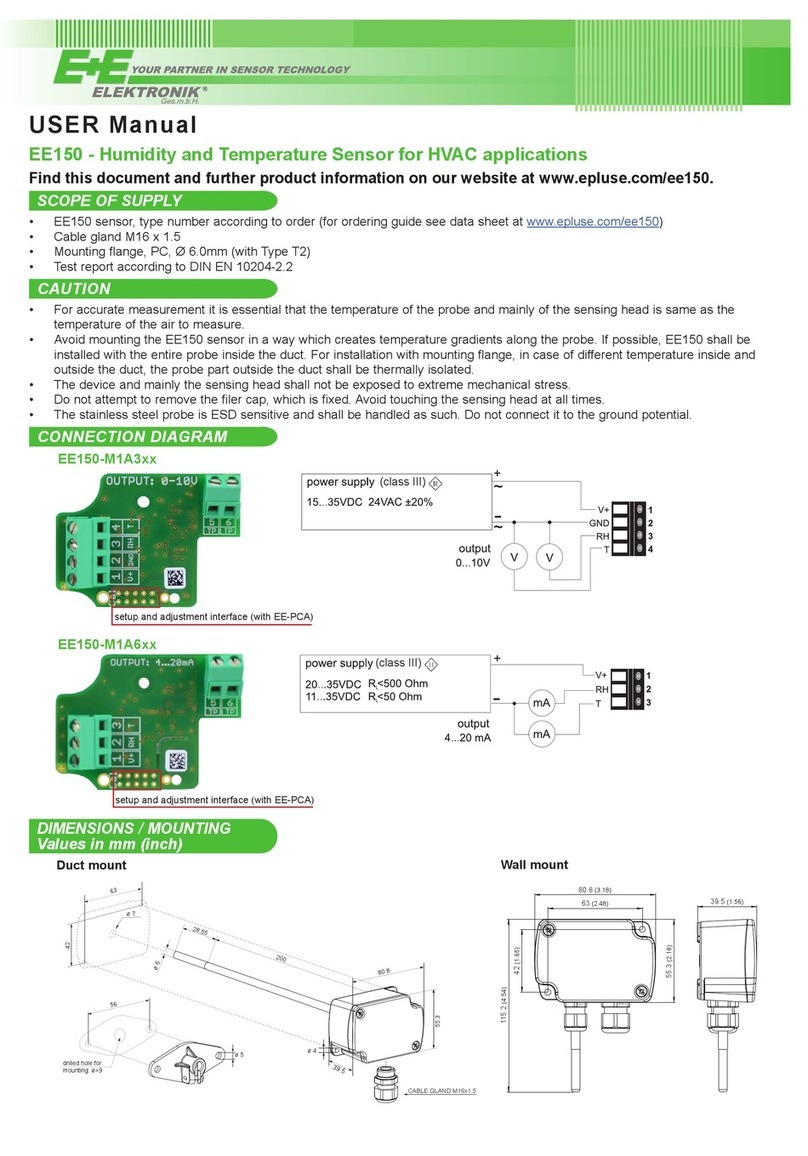

The choice of HCT01 sensor type

HCT01 is available as pre-adjusted ( HCT01-02 and HCT01-03) or unadjusted HCT01-00 RH sensor,

each of these with or without integrated T sensor. The choice is based on accuracy requirements, on

the availability of humidity calibration benches, on the available or intended driving electronics and on

cost/performance considerations and it is illustrated in Figure 1. Additionally, Figure 1gives an

overview on the accuracy which can be achieved by various combinations of HCT01 circuitry.

•Using an unadjusted RH sensor (HCT01-00) implies humidity calibration for the device built

with it. The accuracy achieved depends mainly on the overall uncertainty of the calibration

process.

•A pre-adjusted RH sensor (HCT01-02/03) eliminates the need for humidity calibration. The

accuracy of the final device rests solely on the spread of the initial accurate electronics

employed.

The choice of driving circuitry

The driving circuitry for HCT01 can be realized with an oscillator as “capacity to frequency converter”

or with a microcontroller.

Features of the capacity to frequency converter:

Cost efficient solution – material costs approx. 0,25 € (using an existing oscillator)

Accuracy ±0,8 % rH

Extremely short measuring time possible to save power and prevent self heating

Frequency (period) output

Features of the microcontroller based circuitry:

Cost efficient solution – material costs approx. 0,05 € (using an existing microcontroller)

Electronic accuracy of ±1 % rH with reference adjustment

Customer specific, digital output depending on the microcontroller

Rev. 0.2 / 09 /2015 5

AN1111-2

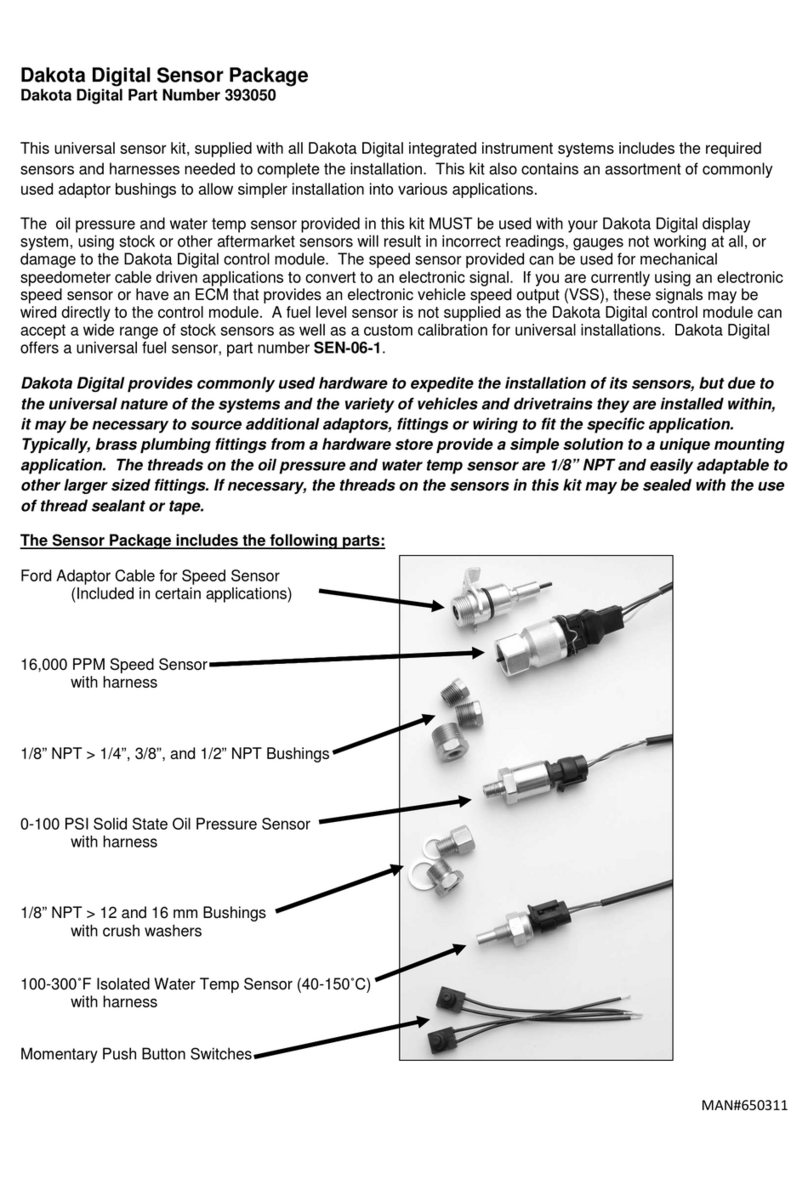

Choice of HCT01 version and driving circuitry

Figure 1: Circuitry options for HCT01

Rev. 0.2 / 09 /2015 6

AN1111-2

2 Pre-adjusted HCT01 with an initial accurate circuitry

with frequency output

The circuitry in Fig. 2 delivers a frequency output signal, where the period of the signal is proportional

to the capacity of the RH sensor and consequently with the relative humidity at the sensor. The

accurate measurement of the period requires a precise time base such as a quartz crystal.

2.1 Schematic circuit diagram

Figure 2: Circuitry with frequency output

2.1.1 Bill of Material

Quantity

Symbol

Device

Dimension

Supplier

1 pc

HCT01

Humidity sensor

HCT01-02 or HCT01-03

E+E Elektronik

1 pc

IC1

Existing

comparator

MCP6561T

Microchip

1 pc

C1

Capacitor

100 nF, ceramic

1 pc

R1

Resistor

82 kΩ

2 pcs

R2, R3

Resistor

100 kΩ

2 pcs

R4, R5

Resistor

1 kΩ

Rev. 0.2 / 09 /2015 7

AN1111-2

2.1.2 Correlation between sensor capacity and period

•Humidity Sensor HCT01 (approx.): 70 pF @ 0 % rH -95 pF @ 100 % rH

•Period at RH_OUT: 70 pF 19.0 µs cycle duration

95 pF 25.4 µs cycle duration

Figure 3: The sensitivity is approx. 0,064 µs/% rH (with a rise of 0.25 pF/% rH)

Figure 4: Nominal characteristic of the measuring device with frequency output

Figure 5: Example of RH & T measuring device with HCT01 and frequency output

19

20

21

22

23

24

25

26

0 10 20 30 40 50 60 70 80 90 100

cycle period [µs]

relative humidity [% rH]

Nominal characteristic @5,0 V

Rev. 0.2 / 09 /2015 8

AN1111-2

3 RH measurement with pre-adjusted HCT01 and

microcontroller based, initially accurate circuitry

A measuring device with pre-adjusted HCT01 and with a microcontroller based initially accurate

circuitry can achieve an accuracy of ±2,24 % rH.

A detailed description of the circuitry is available in the E+E patent EP 1 574 847 B1 // US 7,084,644

B2.

3.1 Schematic circuit diagram

Figure 6: Schematic circuit design1

There are three possible measurement paths:

1.) Sensor (capacitance) path with R1 + HCT01 + D1 + C2 (= CL)

2.) Reference (capacitance) path with R2 + C_REF + D1 + C2 (= CL)

3.) Calibration (capacitance) path with R3 + C_CAL + D1 + C2 (= CL)

U

L

= voltage at C

L

(=C2)

U

V

= Voltage at the voltage

divider (reference voltage)

1C_REF = ±1% @82 pF = ±0.82 pF ≈ ±3.4 % rH

C_Cal= Capacitance which is used for calibration end testing [no soldering necessary]

Rev. 0.2 / 09 /2015 9

AN1111-2

All three measurement paths (“sensor” or “reference” or “calibration”) use the same

algorithm.

Example: reference path:

1.) Discharge all capacitors (I/O pins RC1, RC5, RC6, RC7 and RA2 = output LOW)

2.) Charge reference capacitor and CL(RC6, RC5, RA2 = input, RC1 = switched to

comparator input, RC7 = output HIGH). The charge from the reference capacitor

is also transferred in the capacitor C2 (=CL) and the voltage in C2 (=CL) rises a

little bit. C2 is approx. 10.000 times higher than C_REF.

3.) Discharging reference capacitor (RC6, RC5 = input, RC1 = switched to

comparator input, RA2, RC7 = output LOW).

4.) Increment the number of charge/discharge events (in this case N_CRef).

5.) Check if the voltage at the pin RC1 (comparator) reaches the voltage at the

voltage divider:

no repeat point 2.) and recharge the reference.

yes end of loop and save the numbers of charge/discharge events.

6.) Each cycle measures the reference path and the sensor path and calculates the

sensor capacitance from these measurements.

3.1.1 Bill of Material

Quantity

Symbol

Device

Dimension

Supplier

1 pc

HCT01

Humidity sensor

HCT01-02 or HCT01-03

E+E Elektronik

1 pc

D1

Fast Si-Diode

1SS400TiG

1 pc

C2

Resistor

1 µF, ceramic / X7R

1 pc

Existing

microcontroller

PIC16F690

Microchip

1 pc

C_REF

Capacitor

82 pF, ceramic / NP0 / CG0

5 pcs

R1-R5

Resistor

470 Ω

Requirements for the microcontroller

1.) 3 to 4 digital I/O pins, switchable between output and (analog) input

2.) Integrated comparator (switchable to digital I/O output), external component also possible

3.) Integrated voltage divider (used as reference voltage at comparator), external component also

possible

Rev. 0.2 / 09 /2015 10

AN1111-2

The nominal characteristic of the device (HCT01 sensor together with electronics) can be determined

by measurement at various levels of relative humidity.

Figure 7: Example of nominal characteristic

The deviation from the reference RH after correcting for PCB influences and hysteresis is shown in

Figure 8.

Figure 8: Initial accurate electronics – w/o C_Cal: PCB corrected

0

10

20

30

40

50

60

70

80

90

100

0 10 20 30 40 50 60 70 80 90 100

digital capacitance values [pF]

relative humidity [% rH]

Example of nominal characteristic @3V3

-5,0

-4,0

-3,0

-2,0

-1,0

0,0

1,0

2,0

3,0

4,0

5,0

0 20 40 60 80 100

deviation relative humidity [% rH]

relative humidity [% rH]

Initial accurate electronics, 55 units @3V3

w/o C_CAL ; PCB corrected ; w/o hysteresis; nominal

characeristic

Rev. 0.2 / 09 /2015 11

AN1111-2

For even better overall uncertainty, measure each PCB with a very well defined C_CAL during the

electrical test of the PCB. Correct the C_REF based on this measurement, or determine the exact

value of C_REF during the PCB in circuit test.

The deviations from reference with C_CAL = 82.79 pF are shown in Figure 9.

Figure 9: Initial accurate electronics – 1 point C_Cal; PCB corrected

4 Hints for the development engineer

Choose HCT01 version and the driving circuitry according Figure 1 depending on the accuracy and

output requirements as well as on existing electronics.

For accurate measurement it is of utmost importance to reduce as far as possible any stray

capacitance (and by this also its variation with temperature and humidity) related to the printed circuit

board. This might require several test and layout optimizing loops. These imply tests for assessing the

impact of the stay capacitance and its variations on the output signal of the device, as follows:

1. Test a sample of relevant size at defined environmental conditions (various combinations of

humidity and temperature) for determining the spread of the characteristic of the device including

HCT01 sensor.

2. Test a batch of printed circuit boards with a known, accurate capacitor instead of the humidity

sensor at defined environmental conditions (various combinations of humidity and temperature) for

determining the impact of the board on the output signal.

The electronics design shall be optimized for narrow spread of the characteristic of the entire device

and for minimum impact of the electronics layout on the output signal.

-5,0

-4,0

-3,0

-2,0

-1,0

0,0

1,0

2,0

3,0

4,0

5,0

0 20 40 60 80 100

deviation relative humidity [% rh]

relative humidity [% rH]

Initial accurate electronics, 55 units @3V3

1 point C_CAL ; PCB corrected ; w/o hysteresis; nominal

characeristics

Rev. 0.2 / 09 /2015 12

AN1111-2

5 Contact information

E+E Elektronik Ges.m.b.H.

Langwiesen 7

A-4209 Engerwitzdorf

Austria

Tel.: +43 7235 605 0

Fax.: +43 7235 605 8

E-Mail: info@epluse.com

Homepage: www.epluse.com

Please visit our website to find your local contact.

6 Revision history

Date

Revision number

Changes

November 2011

V_0.1

Initial release

September 2015

V_0.2

Revised version

Copyright© 2014, E+E Elektronik.

Subject to technical changes and misprints

All rights reserved

This manual suits for next models

3

Table of contents

Other E+E Elektronik Temperature Controllers manuals