4EXPERT 64EU rev.03

TABLE OF CONTENTS

1. INTRODUCTION ........................................................................................... 6

1.1 Precautions ...................................................................................................................... 6

1.2 Symbols of the Manual ..................................................................................................... 7

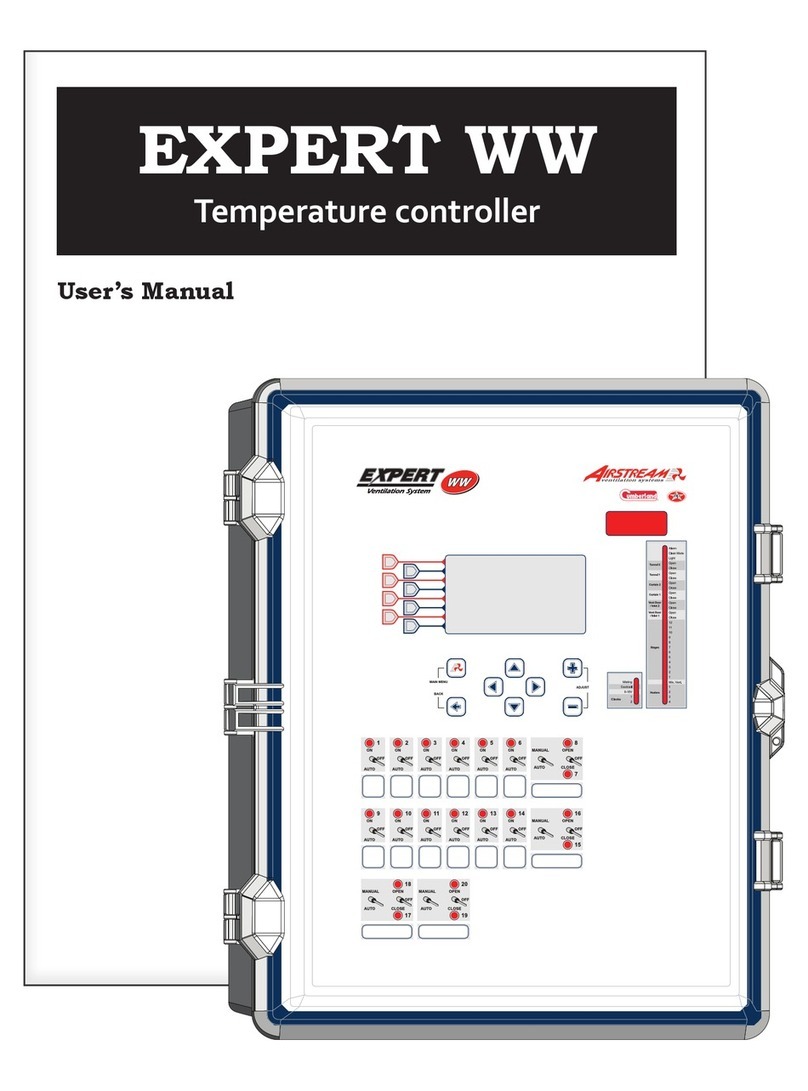

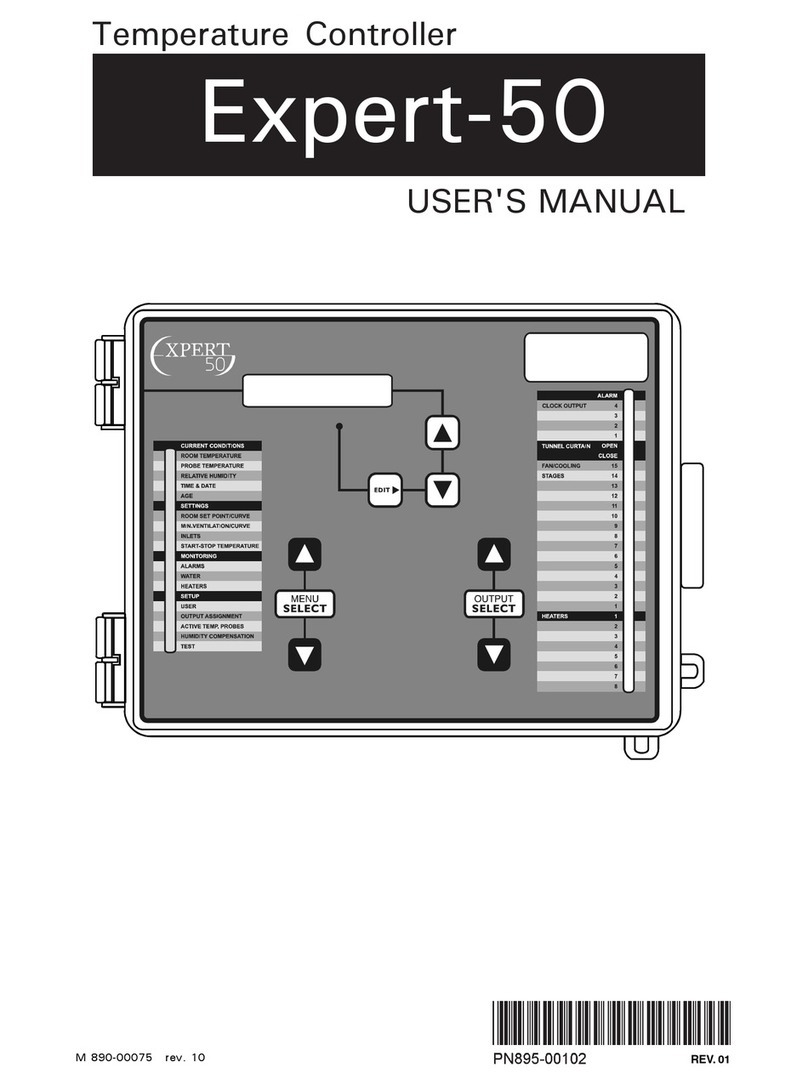

1.3 Controller’s Overview ........................................................................................................7

2. MOUNTING INSTRUCTIONS ........................................................................ 10

2.1 Installing the Controller on the Wall ................................................................................... 10

2.2 Connections ..................................................................................................................10

2.2.1 Controller’s Main Wiring ...................................................................................................... 10

2.2.2 Probe Inputs ....................................................................................................................... 10

2.2.3 Alarm Connection ............................................................................................................... 11

2.2.4 0-10V Output Connection .................................................................................................... 11

3. USER INTERFACE....................................................................................... 12

3.1 Location of the Controls .................................................................................................. 12

3.2 How to Select & Modify the Parameters ............................................................................. 14

3.3 Status Leds ................................................................................................................... 15

4. CONTROLLER SETUP .................................................................................. 16

4.1 Setting the Time & Date .................................................................................................. 16

4.1.1 Day / Night Times ............................................................................................................... 16

4.2 Password ...................................................................................................................... 17

4.3 Controller Programs ........................................................................................................ 18

4.3.1 Selecting a Program ............................................................................................................ 18

4.3.2 Copying / Pasting a Program Configuration .............................................................................. 19

4.4 Installation Setup ............................................................................................................ 20

4.5 Output Setup .................................................................................................................23

4.6 Relay Assignment ........................................................................................................... 26

4.6.1 Principle of Operation .......................................................................................................... 26

4.6.2 Making the Assignment ....................................................................................................... 27

4.7 Assignment of Variable Outputs ....................................................................................... 28

4.7.1 Principle of Operation .......................................................................................................... 28

4.7.2 Making the Assignment ........................................................................................................ 28

4.8 Temperature Probe Assignment ........................................................................................ 29

4.9 Clean Mode & Empty Zones ............................................................................................. 31

4.9.1 Principle of Operation .......................................................................................................... 31

4.9.2 Settings ............................................................................................................................. 32

4.10 Test Mode ..................................................................................................................... 33

4.11 Version .........................................................................................................................33

5. TEMPERATURE SETTINGS ............................................................................ 34

5.1 Set Points ..................................................................................................................... 34

5.1.1 Adjusting the Set Points ....................................................................................................... 35

5.1.2 Set Point Curve .................................................................................................................. 36

6 VENTILATION SETTINGS............................................................................. 38

6.1 Minimum Ventilation ....................................................................................................... 38

6.1.1 Minimum Ventilation Timer ..................................................................................................38

6.1.2 Minimum Ventilation Curves ................................................................................................... 38

6.1.3 Minimum Ventilation Using Variable Fans ............................................................................... 39

6.1.4 Minimum Ventilation Using On/Off Fans ................................................................................. 39

6.1.5 Minimum Ventilation Settings ...............................................................................................40

6.1.5.1 Main Options ............................................................................................................................................. 40

6.1.5.2 Minimum Ventilation Timer Settings ............................................................................................................... 41

6.1.5.3 Minimum Ventilation Relay Selection .............................................................................................................. 42

6.1.5.4 Curve Settings ........................................................................................................................................... 44

6.2 Fan Stages .................................................................................................................... 46

6.2.1 Principle of Operation .......................................................................................................... 46

6.2.1.1 Main Operation of the Fan Stages ................................................................................................................. 46

6.2.1.2 Operation of Variable Outputs ....................................................................................................................... 47

6.2.1.3 Outside Temperature Compensation .............................................................................................................. 48

6.2.1.4 Operation of 0-10V Outputs used for Ventilation .............................................................................................. 49