HEVAC ENDEAVOUR V2 User manual

ENDEAVOUR V2 USER MANUAL

HEVAC CONTROL AGENCIES PTY LTD. 7/54 HOWLEYS RD. NOTTINGHILL, VIC. 95627888 www.hevac.com.au 28/11/19

V2 NEW FEATURES

1.) ADDED INDEPENDENT AUXILIARY TIME SWITCH

2.) EVENT DATA LOGGER

3.) FAN RELAY (R5) SETTABLE AS CONTINUOUS OR CYCLE

4.) ADJUSTABLE MIN. / MAX SETTINGS FOR Y1 & Y2 0-10v O/P's

5.) SUPPLY AIR TEMPERATURE SENSOR MONITORING INPUT

6.) EXTERNAL A/C FAULT (D3) & AUX I/P (D4) BMS MONITORING INPUTS

7.) ACTIVE 0-10vdc SENSORS NOW SCALABLE

8.) ADDED CO2 ON/OFF RELAY CAPABILITY CONTROL.

9.) CAN BE SET TO TIME SWITCH ONLY MODE (-NO TEMP. CONTROL)

10.) LOCKABLE 3 LEVEL MENU & SETPOINT ACCESS

11.) RECLAIM LOCAL SETPOINT CONTROL FROM REMOTE FOR SERVICE

12.) FURTHER ENHANCEMENTS TO HMI CONTROL OF ENDEAVOUR

v2

INDEX

BASIC OVERVIEW, OVERRIDES & I/O USAGE………………………………………………….. 3

USER INTERFACE & KEYBOARD LOCK LEVELS………….……...……………………………… 6

MENU DESCRIPTION …..………………............................................................……… 7

SET (A/C SYSTEM) "START BY" METHOD…………….…………………..………………..….. 9

RUN / AHR TIMER ..………..………………………..…............................................…….. 12

MAIN TIME SWITCH (1) ……….……………………………………………………………….……… 10

EVENT HISTORY DATA LOGGER ………….........………….....…..............................…..

12

RELAY 1-4 ASSIGNMENT & PARAMETER PROGRAMMING……………………………..

Y1 & Y2 ANALOGUE OUTPUT PROGRAMMING……………........…....….……………….

13,14

X3 OUTSIDE AIR TEMP. SENSOR CONFIGURATION………………………….….………….

15,16

X7 CO2 SENSOR ENABLE & Y1 ECON.CYCLE OVERRIDE SETTINGS.……..…………..

18

CLOCK SETUP - TIME, DATE & DAYLIGHT SAVING ENABLE…….………………………..

20

X1 MAIN TEMP. SENSOR CONFIGURATION......……………..…………….…………………

8

MODBUS SETUP & MEMORY MAP……………………….............………………….…………

17

FACTORY DEFAULTS…………(also see page 25)……………….……………………………….

22

23

HEVAC CONTROL AGENCIES PTY LTD. 7/54 HOWLEYS RD. NOTTINGHILL, VIC. 95627888 www.hevac.com.au 28/11/19

PAGE

TYPICAL CONNECTIONS & EXTERNAL INTERLOCKS OVERVIEW……..........……….. 24

NIGHT PURGE VENTILATION SETUP………………………………………………….....……….. 21

4, 5

TECHNICAL NOTES …………………………………………………..............................………….

X2 REMOTE SET POINT CONFIGURATION.............…………………….……………..……. 17

AUXILLARY TIME SWITCH (2) ……….……………………………………………………….……… 11

13

RELAY 5 FAN CONTROL METHOD (CONTINUOUS OR CYCLE)...................……….. 15

X4 AUXILIARY TEMPERATURE (MEASUREMENT ONLY) SENSOR.……….…......….. 19

HOLIDAY OFF OVERRIDE...................................................................................

INPUT PASSIVE OR ACTIVE HARDWARE SETTINGS............................................ 19

CONTROLLER MAIN MODE OF OPERATION - T/SW. OR TEMP CONTROL............ 23

USER PROGRAM INFORMATION FORMS……..........……….................................... 25-27

SITE & SYSTEM NOTES (blank page)........................................................ 28

3/28

OVERVIEW

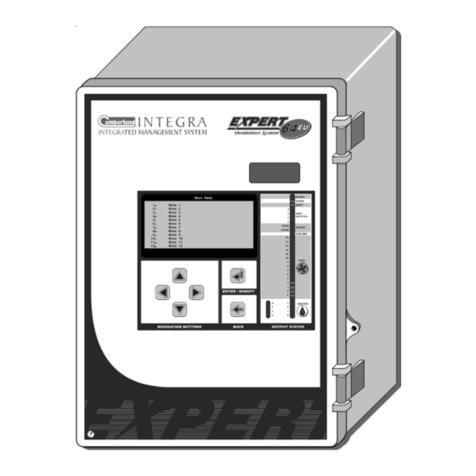

•The Hevac ENDEAVOUR is a fully programmable microprocessor based Temperature

(+ CO2) controller, with optional use of an internal 365 day Time Switch, an independent Auxiliary

Time Switch and a Run Timer all in the one model. The controller has 7 analogue inputs, 4 digital

inputs, 5 relay outputs and 2 analogue (0-10vDC) outputs. Controller I/O, time & date etc. is

displayed via a backlit LCD screen giving plain English status information together with 5 dedicated

LED’s showing the relays on/off state. The controller is primarily intended for Air Conditioning

temperature control applications where On/Off control of Heating and Cooling stages and /or

modulating P+I control of actuators / devices requiring a variable 0-10vdc control signal is required.

Typically used to control DX Air Conditioning units, Electric heating stages, modulating Heating &

Cooling Valves, VSD’s & Economy Cycle Damper sets etc. Note with this latest software version, the

Endeavour can now also be set to "Time Switch only" mode with all other none timer capabilities

disabled allowing this module to be used as a 2 channel 365 day Time Switch or Run Timer only.

•Four of the five relays are programmable for their mode of operation ie :Heat, Cool or Both (both

means the relay operates as both a heating and cooling stage), and also new to this version, relays

can now be programmed as On/Off CO2 stages or as an extra independent Auxiliary Time Switch.

The relay program menu allows individual settings of mode, deadbands, switching differentials &

time delays. The 5th relay is dedicated as a System Run (Fan / Main Time Switch) relay which can

now also be set to operate continuously whilst the controller is enabled or to cycle on & off with the

compressor (which is typical for domestic A/C systems). The two available Analogue 0-10vDC

output signals can be individually programmed for Mode of operation (heat /cool or both), start point

(deadband), range (proportional band) & method of control (P or P+I) plus also new to this version

the minimum & maximum "Y" output 0-10vdc signals can now be range limited, with any minimum

value setting automatically overridden to zero when the system is off, which is perfect for EC fan time

switch control with a minimum speed requirement.

EXTERNAL OVERRIDES & OPTIONAL CONNECTIONS

•The controller has Modbus communications capability for connecting of up to 32 controllers to our

HMI colour wall display panel for zone status, individual setpoint adjustment & system Auto/Off/On

override. Alternatively upto 247 controllers can be connected to a 3rd party BMS system for remote

control & monitoring. For added BMS monitoring, analogue input "X4" can be used to measure an

auxiliary temperature (typically the supply air temperature), "D3" is a dedicated A/C fault monitoring

input & "D4" is a general purpose on/off status input that could be used for example to monitor &

prove supply air fan running operation via a mechanical pressure switch.

•Remote System AUTO/OFF & AHR operation can be easily added by simply connecting a normally

open (N/O) switch anywhere convenient in parallel with the main temperature sensor wires X1 & M.

Momentarily shorting X1 & M results in triggering a run timer function (typically as an after hours

timer function) or / & constant shorting of X1 & M results in a system OFF function. These functions

are also duplicated on the controller terminals "D1 & M" for AUTO/OFF & AHR operation, plus

connecting a switch to "D2 & M" sets a forced manual Time switch "24/7 ON" override.

•With an optional O/A sensor connected, the Economy cycle damper operation (Y1 output) for

temperature control can be interlocked for free heating, cooling or both when the outside air

temperature conditions are favorable. The fresh air sensor (X3) is compared to the room (or return

air) temperature sensor (X1), & if the outside air temperature is measured to be more suitable for

free temperature control the motorized damper output signal (Y1) will modulate to F/A mode per

room temperature demand. The use of outside air for temperature control can also be inhibited if the

outside air temperature falls below an adjustable minimum O/A temperature (factory set at 16C for

DX or FCU coil protection ).

•With an optional CO2 sensor connected, economy cycle dampers can also be proportionally driven

to the fresh air mode to reduce high CO2 levels. The maximum damper output signal for CO2

control can be restricted in extreme O/A temperatures so as not to lose temperature control, all

settings are user adjustable. The CO2 input can now also control relays for on/off CO2 control.

•Remote Set Point devices (either passive or active) can be connected to the controller. If a passive

adjuster is connected (default setting), the controller will automatically detect and hand over set point

adjustment authority to the remote device (then ignoring the controllers UP & DOWN buttons for set

point adjustment). The remote set point potentiometer can be built into a room temperature sensor

(SRT-DSP) or as a separate stand alone device giving remote setpoint control only (SPA-D). The

range of the passive remote setpoint is fixed at 18 to 25 degrees over 0 to 10K. If an active remote

setpoint device is used the 0-10vDC is +/-5c adjustable for 0v & the top end range adjustable upto

100c. Also new : Any remote setpoint device can now be temporarily virtually disconnected by

holding the UP & DOWN buttons together for 5 seconds which hands conventional setpoint control

back to the controller to aid in commissioning & testing, but will automatically reset to remote control

after 10 minutes or can be canceled anytime by again pushing the UP & DOWN buttons together.

HEVAC Control Agencies Pty Ltd www.hevac.com.au Ph +613 95627888 28/11/19

Technical Data

Operating Voltage 12 to 24 Volts AC or DC

Set point Setting Range 5-35 oC in 0.1 oC Increments

Relay Switch ON Points

(Dead band)

0.1-19.9 oC

Relay Hysteresis

(Switching Differential)

0.1-9.9 oC

Relay to Energise Time Delay 0.1-42 Minutes

General Specifications

200mA

At 24vDC Volts

At 24vAC Volts 5 VA

Power Consumption

Voltage AC 0….250 Volts

Current 8.0 (2.5) Amps

Switching Capacity of Relays

Y1/Y2 Output Voltage Range 0-10VDC

Y1/Y2 Start Point (Dead band) 0-19.9 oC

0.5-25 oC

Output Indication

Relay On/Off Status

LCD Display

Display Resolution

5 x Red LED

2 x 16 character LCD

0.1 Increments

Y1/Y2 Range

(Proportional Band)

Y1/Y2 Integral action

(P+I triggers >10% P output)

Off-60 minutes

Communication :

Terminal's X5 & X6 configurable as RS485 MODBUS Outputs

X7 can be set to ground (via a 100 ohm resistor) for use as a

comms shield connection if not used as a CO2 sensor connection.

ANALOG INPUTS

X1 : Main Temperature Sensor Input configurable (with jumper & software) as

Active (0-10vdc ~0 to 100c (adjustable) or Passive (4.2k@22c).

X2 : Remote Set point configurable (with jumper & software) as passive using 10K

Potentiometer (18-25c Range) or 0-10vdc (top end range configurable).

X3 : Outside temperature sensor configurable (with jumper & software) as Active

(0-10v~0-100c) or Passive (4.2k@22c).

X4 : Auxiliary Measurement Temperature Sensor, Input configurable (with jumper)

as Active (0-10vdc ~0 to 100c (adjustable) or Passive (4.2k@22c).

X7 : Room or R/A Duct CO2 Sensor input to override economy cycle operation or

to control internal relays (R1-4) not used for temperature control.

HEVAC Control Agencies Pty Ltd www.hevac.com.au Ph +613 95627888 28/11/19

( NOTE MINIMUM & MAXIMUM Y OUTPUT VOLTAGE USER ADJUSTABLE )

4/28

Technical Data (Cont.)

Environmental Conditions

0...45oC

< 85 % RH (Non Condensing)

Operation

Ambient Temperature

Humidity

Storage and Transport

Ambient Temperature -5...65oC

Humidity < 90 % RH (Non Condensing)

COMPLIES TO ALL RELEVENT AUSTRALIAN STANDARDS including 6mm

segregation between high & low voltage connections

Including Packaging 600 grams

Product Standards

Weight

Housing

Colour Grey

Material ABS POLYCARB

UV Stabilised YES

Fire Retardant YES

Size L105mm x W105mm x D60mm

Mounting Method 35mm Din Rail Mountable

3Relay 1 Normally Open

4

5Relay 3,4 & 5 Common

6Relay 3 Normally Open

7Relay 4 Normally Open

1Relay 1 & 2 Common

2Relay 1 Normally Closed

8Relay 5 Normally Open (FAN)

MSignal ground

Y1 Analog Modulating Output 0-10 vDC

Y2 Analog Modulating Output 0-10 vDC

X1 Main Temperature Sensor Input (Passive or Active)

X2 Remote S/P input (Passive or Active) (Optional connection)

X3 O/A sensor input (Passive or Active) (Optional connection)

X4 Auxiliary Temperature measurement sensor.

X5 MODBUS RS485 - A Terminal

X6 MODBUS RS485 - B Terminal

Terminal Designations

Relay 2 Normally Open

-12-24 Volt Supply Neutral

(internally connected to terminals M)

+12-24 Volt AC or DC Supply Active

M Common sensor & signal ground

D1 Manual System OFF &/or AHR trigger input

D2 Manual System ON Override (T/Sw. override)

D3 External FAULT I/P (for indication)

D4 External On/Off status I/P for BMS monitoring

E & M future Expansion module local comms.

X7 CO2 sensor (default) or MODBUS SHIELD (GND)

HEVAC Control Agencies Pty Ltd www.hevac.com.au Ph +613 95627888 28/11/19

5/28

D1 D2 D3 D4

HEVAC CONTROL AGENCIES PTY LTD. 7/54 HOWLEYS RD. NOTTINGHILL, VIC. 95627888 www.hevac.com.au 22/10/19

6/28

USER INTERFACE

The controllers face plate has four push buttons to access & edit controller settings.

“ENTER” ACTS AS THE SAVE OR MENU OPEN BUTTON

“ESC” ACTS AS THE EXIT OR JUMP BACK TO PREVIOUS MENU BUTTON

“UP & “DOWN” BUTTONS ADJUST SETPOINT, SCROLL MENUS & TO EDIT VALUES.

The controller has a backlit (16x2) LCD screen & 5 red LED’s to give controller input & output

status. The LCD screen will automatically cycle through relevant screens displaying applicable

information as per the users programmed use of the controller ie : Room Temperature,

Setpoint, System “On By”, Time & Date, Analogue Output Values, Outside Air Temperature,

CO2 ppm levels, Supply Air temperature, analogue output levels etc.

To access the menu list as shown on page 7, press the ENTER button & use the UP & DOWN

arrow buttons to scroll through the menus, pressing ENTER to open a particular menu to edit.

The relay assignments are user programmable and as such the relay “use identifier” text box

above each LED is not factory marked and is for optional labeling by the commissioning

technician. The factory default settings for these relays, from left to right is : COMP3, COMP2,

COMP1, R/V HEAT, FAN, but could for example be assigned and marked as per the labeling

shown bottom of this page. The analogue outputs Y1 & Y2 if used, are shown as a LCD

display screen.

The keyboard can be set in three lock levels, level 0 is unlocked, level 1 allows setpoint

adjustment only, level 2 allows no adjustment. To access the lock levels press & hold all four

button for 5 seconds & release to display the existing level, adjust using the UP or DOWN

arrow buttons and press the ENTER button to set & return to the running screen.

The LCD screens will automatically cycle through each relevant display.

*example of optional identification of

output relays by installation contractor

****

PROGRAM MENUS

HEVAC Control Agencies Pty Ltd www.hevac.com.au Ph +613 95627888 28/11/19

7/28

MENU

Set CLOCK :

Set "START BY " METHOD :

TO SET THE CONTROLLERS TIME, DATE AND ENABLE DAY LIGHT SAVING

SET SYSTEM ON/OFF OPERATION "BY" the internal TIMESWITCH (1), Internal RUN

TIMER (Triggered by remote push button) or by a remote MANUAL ON / OFF SYSTEM

SWITCH (by shorting out sensor X1 & M wires or D1 & M terminals).

SET MAIN TIME SWITCH (1) : PROGRAM MAIN (SYSTEM) TIME SWITCH (1) DAYS & ON OFF TIMES .

SET AUX. TIME SWITCH (2) : PROGRAM AUXILIARY INDEPENDENT 7 DAY TIME SWITCH (2) ON & OFF TIMES.

SET RUN / AHR TIMER PERIOD : SET RUN TIMER DURATION FOR USE AS AN AFTER HOURS RUN TIMER OR AS A

SYSTEM RUN (FOR) TIMER ( with or without use of the main time switch ).

SET HOLIDAYS : PROGRAM INDIVIDULE OR GROUP HOLIDAYS SYSTEM OFF OVERRIDE DATES.

VIEW EVENT HISTORY : VIEW "ON" EVENT HISTORY - DATE , TIME & EVENT.

R1-4 RELAY PROGRAMMING : SET MODE & SETTINGS FOR THE 4 PROGRAMMABLE RELAYS (R1-4).

R5 FAN CONTROL METHOD : PROGRAM R5 (FAN) TO CYCLE WITH HEAT / COOL CALL OR CONTINUOUS.

Y1 & Y2 ANALOGUE PROGRAMMING :SET MODE & SETTINGS FOR THE 2 PROGRAMMABLE ANALOGUE (Y1 &Y2) O/P's

X1 SENSOR CONFIGURATION : SET MAIN CONTROL SENSOR (WHICH RELATES TO THE CONTROLLERS SETPOINT)

AS ACTIVE or PASSIVE, CAL OFFSET & RANGE ADJUSTMENT.

X2 REMOTE S/P CONFIGURATION : SET TYPE OF OPTIONALLY CONNECTED REMOTE SETPOINT AS PASSIVE 0-10K

(FIXED RANGE OF 18-25C) or 0-10VDC (MAX RANGE ADJUSTABLE).

X3 O/AIR TEMP. SENSOR CONFIG. : ENABLE & ADJUST SETTINGS FOR O/A TEMPERATURE SENSOR & ITS AFFECTS

X4 SUPPLY AIR SENSOR CONFIG : ENABLE MONITORING (ONLY) OF AN AUX. SENSOR ..ie S/A TEMPERATURE.

X7 CO2 SENSOR CONFIGURATION : ENABLE & ADJUST SETTINGS FOR A ROOM or (R/A DUCT) CO2 SENSOR

FUNCTION

ENABLE NIGHT PURGE :

MODBUS SETUP :

SET CONTROL APPLICATION :

RESTORE FACTORY DEFAULTS :

EXIT MENU :

ENABLE & CONFIGURE TIME AND TEMP. CONDITIONS FOR NIGHT VENT MODE

ENABLE MODBUS & SET BAUD RATE & ADDRESS SETTINGS

SET ENDEAVOUR IN STANDARD TEMPERATURE. or TIME SWITCH ONLY MODE

CLEARS & RESETS ALL SETTINGS BACK TO FACTORY DEFAULTS

EXIT THIS MENU LIST AND RETURN TO OPERATING SCREENS

*

*

*

*

*

*

*

* these menu settings have no affect in TIME SWITCH ONLY application

8/28

SET CLOCK (TIME & DATE SETTINGS)

To edit the controllers time and date settings, press the fascia button labeled “ENTER”

to have the LCD display jump to the 1st menu item in the menu tree…. “SET CLOCK"

Press the ENTER button to check and edit the controllers time, date and day

light saving enable (or disable) settings. Daylight saving, if enabled, starts on the

1st Sunday in October (at 2am) and finishes on the 1st Sunday in April (3am)

HEVAC CONTROL AGENCIES PTY LTD. 7/54 HOWLEYS RD. NOTTINGHILL, VIC. 95627888 www.hevac.com.au 22/10/19

9/28

SET *START BY* METHOD (A/C START / STOP CONTROL)

To set the A/C system "START BY" method, press the fascia button labeled “ENTER”

then press the DOWN arrow button once to have the LCD display show the 2nd item in the

menu tree (after SET CLOCK) :

“ SET START BY METHOD "

Press the ENTER button to open this menu & see the existing setting, use the UP &

DOWN buttons to cycle through the 3 choices :

“MANUAL”, “TIME SWITCH” or “RUN TIMER”.

Select your choice by pressing the “ENTER” button. The display will then return to this

parent menu. Exit to the normal running screens by pressing the “ESC” button or scroll to

another main menu item to edit or check using the “UP” or “DOWN” arrow buttons.

1.) MANUAL - System ON/OFF state set only by an external “System Switch” or

external interlock wired in parallel with the 2 sensor wires connected to our

passive temperature sensor or alternatively shorting the controllers D1 & M

terminals which has the same affect, results in a “System Off” mode, with all

relays and analogue outputs de-energized, Opening the switch allows 24/7

operation until the switch or interlock is closed again.

2.) TIME SWITCH (1) System enabled by the controllers internal main 7 day Time Switch,

which can be programmed for a total of 18 possible switching events for

individual or groups of days (allowing multiple on/off times per day).

3.) RUN (for) TIMER System operation triggered by a momentary on/off pulse from a

switch wired in parallel with the 2 (passive) sensor wires or across the

controllers D1 & M terminals. Adjust the timer for the required time i.e. 8 hours.

HEVAC CONTROL AGENCIES PTY LTD. 7/54 HOWLEYS RD. NOTTINGHILL, VIC. 95627888 www.hevac.com.au

22/10/19

10/28

SET MAIN TIME SWITCH (1)

The controller's internal main time switch (1) (if enabled for use) can be easily programmed

for any combination of ON/OFF switching times for any day of the week. The controller

comes preset with factory default settings for operating the system: Monday to Friday from

08:00 (event 01) until 17:30 (event 02). To edit settings, press the fascia button labeled

“ENTER” and scroll down through the menu tree until “SET MAIN TIME SWITCH (1) ” is

displayed. Press the “ENTER” button to open this menu. The existing detail for switching

event 01 is displayed. Unlike other time switches, this controller has very flexible

unassigned switching events (instead of fixed sequential ON then OFF routines). Time

switching events can be set to switch (change state) at any time & day/s, and set as a

switching ON event or OFF event. Typically the switching events would be programmed in

the order of ON events (with common days & time) followed by an OFF event with matching

days and common OFF time, but any variation is easily programmed. As an example:

switching events could be programmed such that switching event 1 (01) turns the system

ON for Monday to Friday at 08:30, followed by event 2 (02) turning the system ON Saturday

& Sunday at 09:00, then event 3 turning the system OFF Monday to Sunday at 17:30. With

this programming approach, multiple & varied ON / OFF events can be set on individual or

groups of days, plus there is no issue switching past midnight which most other time

switches cant achieve. 18 switching events are available.

HEVAC CONTROL AGENCIES PTY LTD. 7/54 HOWLEYS RD. NOTTINGHILL, VIC. 95627888 www.hevac.com.au 06/11/19

Set EVENT as an

ON or OFF

switching event

enable the event

set days

set time

switching events

11/28

SET AUXiliary TIME SWITCH (2)

The controller's independent Auxiliary Time Switch (2), if enabled for use, can be assigned to

any spare relay not used as a Temperature or CO2 on/off control relay, and is assigned to a

spare relay in the Relay Programming Menu. The Auxiliary Time Switch is basically intended

as a simple auxiliary time switch for controlling other equipment not directly associated with

temperature control ie : toilet exhaust fans etc, and is programmed using a more conventional

time switch technique with programmable "ON" time events followed by "OFF" time events for

the relevant days of the week. Note : This Auxiliary time switch has only two sets of ON &

OFF settings (paired events) which would typically cover the separate on & off times for week

days and weekends. To edit settings, press the fascia button labeled “ENTER” and scroll

down through the menu tree until "SET AUX TIME SWITCH (2) "is displayed. Press the

“ENTER” button to open this menu. If previously unused the 1st event (01) will display

"**UNUSED**". Press the ENTER button to start editing. Press the UP button to change this

event to "ENABLED" which is the 1st fixed "ON" event. Press ENTER which will then display

an LCD screen to 'enable' the required days , use the UP / DOWN & ENTER buttons to

sequentially set "Y" to all days that are to be enabled for this 1st (same) "ON" time ( leave as

"--" for disabled days) .After Sunday is entered the display will jump to the "ON" time setting

screen - use the UP / DOWN buttons to set the "ON" time, then press ENTER. The controller

will then ask should this Auxiliary Time Switch be overridden (to OFF) by the programmed

holidays ? (as set in the controllers "HOLIDAY" assignment menu), set "YES" or "NO" using

the controller's UP / DOWN buttons and press ENTER. The display returns to this event

screen (01). Press the DOWN arrow button to move to the next event screen (02) which is the

1st fixed "OFF" event setting screen, which is in respect to the previous "ON" setting -press

ENTER. IF not already "ENABLED" press the DOWN arrow button to ENABLE this event,

Press ENTER. Repeat the Y / -- setting for each day of the week which should be set to

match the previous "ON" settings, then set the common "OFF" time for these days, press

ENTER. Press the ESC button to exit Time Switch 2 programming if only one common on/off

times for the week is required or press the DOWN arrow button until event (03) is displayed

which is a 2nd (fixed as) 'ON' setting ~ Repeat the procedure per events (01) & (02) to set the

ON (03) & OFF (04) times & days for these events. The Auxiliary Time Switch is now

programmed , press "ESC" a few times to exit out to the main running screen.

HEVAC CONTROL AGENCIES PTY LTD. 7/54 HOWLEYS RD. NOTTINGHILL, VIC. 95627888 www.hevac.com.au

06/11/19

This is only asked after 1st ON setting but

is common to both sets of on/off settings

Set each required ON & OFF

event to "ENABLED"

enable the event

set days

set time

RUN /AHR TIMER

LOAD HOLIDAYS (OFF OVERRIDE) SETUP

Individual or group of dates can be programmed as holiday time switch “OFF”

overrides. To edit or set Holiday dates, Press the fascia button labeled “ENTER” to

have the LCD display jump to the 1st menu item in the menu tree - "SET CLOCK"

HEVAC CONTROL AGENCIES PTY LTD. 7/54 HOWLEYS RD. NOTTINGHILL, VIC. 95627888 www.hevac.com.au

23/10/19

12/28

scroll down through the menu tree with the “DOWN” arrow button until

“LOAD HOLIDAYS” is displayed. Pressing the “ENTER" button will then display either

the 1st existing Holiday date or HOLIDAY DISABLED. If disabled, press the “DOWN”

button to change to ENABLED. Once enabled, the 1st holiday default start date of 1st

JAN (01) will be displayed, (01) means the 1st holiday. Using the “UP or DOWN”

buttons scroll through calendar dates until the required 1st HOLIDAY START date is

displayed, press “ENTER” to then also program the 1st HOLIDAY END date which can

either be the same as the start date (if a single day holiday) or a future inclusive date

for a group of days (i.e.: Easter or a school holiday term break). The controller asks

after each holiday is set whether this holiday OFF override event should only execute

once or repeat each year on the same date(/s), set as either ONCE or REPEAT using

the “UP” or “DOWN” buttons, press “ENTER” to accept settings then the “DOWN”

button to jump to the next holiday start date to program. Repeat this procedure until all

holiday dates are set.

Whether the Run Timer is used as a short duration type “After Hours”(AHR) Run timer

(if the system normally operates by the controllers internal time switch), or set for a

longer period, typically as a “Run For Timer", the procedure to set up the timer is the

same.

13/28

HEVAC CONTROL AGENCIES PTY LTD. 7/54 HOWLEYS RD. NOTTINGHILL, VIC. 95627888 www.hevac.com.au 07/11/19

VIEW EVENT HISTORY

This latest version of the ENDEAVOUR now incorporates a basic

event logger that records the last 7 "ON" switching events.

example 01 : RELAY 3 ON 15/10/2019 16:30

02 : RELAY 2 ON 15/10/2019 16:50

03 : NIGHT PURGE ON 16/10/2019 04:35

The history can be reset & cleared by pressing the UP button from the

1st event which prompts an "erase history message" question ..pressing

ENTER clears the history.

RELAY PARAMETERS PROGRAMMING

To set or edit the Relay modes of operation and switching parameters etc, Press the fascia

button labeled “ENTER” to have the LCD display jump to the 1st menu item in the menu tree :

“SET CLOCK”, scroll down through the menu tree with the “DOWN” arrow button until “RELAY

PROGRAMMING” is displayed. Press the “ENTER” button to open this menu. A "summary

screen" (not editing screen) is then be displayed for Relay 1, the other 3 relay summary

screens can be seen by simply scrolling up or down this sub menu using the “UP or DOWN”

arrow buttons. To edit the parameters for a particular relay, whilst at its summary screen press

the “ENTER” button to display its 1st item to edit which is “MODE” of operation -: the relays

can be set as "UNUSED" , "COOL ONLY" (C), "HEAT ONLY" (H), "HEAT & COOL" (B)

(which is short for acting as BOTH a heating & a cooling mirrored stage), "CO2" (0) control or

as an (auxiliary) TIME SWITCH (2) relay. If a relay is not required, to save confusion, set it to

“UNUSED” (it’s associated led will also be disabled).

14/28

MODE : Sets what control function the relay serves : HEAT, COOL, BOTH,

CO2 or as an Auxiliary Time Switch relay.

DEADBAND : The temperature gap in degrees C, from the controllers setpoint

until the relay is enabled to turn ON.

SW(itch) DIFF(erential) : The amount of temperature change in degrees C back towards

the setpoint to turn the stage off again.

SW(itch ON) DELAY : Delay in Minutes & Seconds until the relay stage turns on after

exceeding the deadband setting.

RELAY SUMMARY SCREEN EXAMPLES

R

M

= RELAY # (1-4)

= MODE OF OPERATION (H,C, B, 0, TIME SW2)

D_B = DEADBAND (0-25c)

S_D = SWITCHING DIFFERENTIAL(0.1-20c)

Tdly = TIME DELAY (0-99 min)

HEVAC CONTROL AGENCIES PTY LTD. 7/54 HOWLEYS RD. NOTTINGHILL, VIC. 95627888 www.hevac.com.au 07/11/19

RELAY PARAMETERS PROGRAMMING... continued

0 = CO2 MODE

SELECT RELAY TO EDIT

CO2 SUMMARY SCREEN

A HEATING STAGE SUMMARY SCREEN

RELAYS 1-4 CAN BE ASSIGNED FOR USE AS :

UNUSED

: COOL ONLY (C)

: HEAT ONLY (H)

: HEAT & COOL (B)

: CO2 (0)

: TIME SW. 2

SUMMARY SCREEN MODE SETTINGS

SETTING SCREEN LABEL DESCRIPTIONS

HEVAC CONTROL AGENCIES PTY LTD. 7/54 HOWLEYS RD. NOTTINGHILL, VIC. 95627888 www.hevac.com.au 06/11/19

R5 FAN CONTROL METHOD

15/28

Another update with this latest version of the ENDEAVOUR is the ability to choose, whilst this air

conditioning system is enabled to run (whether that be "ON BY" : Time Switch, Run Timer or set to

operate by Manual on/off switch), that the fan relay - R5, can be set to remain ON continuously

(default) during the ON running period of the system or for the fan (R5) be set to cycle on & off when a

relay programmed as a heating or cooling temperature control stage enables. To set the fan control

method of R5, press the fascia button labeled “ENTER” and scroll down through the menu tree until “ R5

FAN CONTROL METHOD ” is displayed. Press the “ENTER” button to open this menu. The existing

method is displayed. The fan cycle method is a typical mode of fan operation in a domestic installation to

save on power & noise but in commercial buildings typically regulations call for the fan to remain on

continuously whilst the building is occupied to meet minimum building ventilation requirements, if

however minimum ventilation is achieved by some other means, it may be preferable to have the fan

cycle with the heating or cooling as required to reduce drafts & noise when the temperature is

comfortable.

To set or edit the two analogue outputs (Y1 & Y2) for mode of operation and output characteristics,

Press the fascia button labeled “ENTER” to have the LCD display jump to the 1st menu item in the menu

tree..“SET CLOCK”, scroll down through the menu tree with the “DOWN” arrow button until

“Y1 & Y2 ANALOGUE PROGRAMMING” is displayed. Press the “ENTER” button to open this menu. A

summary screen is then displayed for Analogue output Y1, The other analogue output Y2 summary

screen can be seen by simply scrolling down this sub menu using the “DOWN” arrow button. To edit the

parameters for a particular analogue output, whilst at its summary screen press the “ENTER” button to

display its 1st item to edit which is “MODE” of operation -: the analogue outputs can be set as a

HEATING ONLY, COOLING ONLY, “BOTH” mode output or DISABLED. Both means the analogue

output will function as both a heating and a cooling output with its parameters mirrored to operate on

either side of the controller’s setpoint: if for example the deadband is set to 1 degree, then the analogue

output will start to produce a DC output voltage from 1 degree above and 1 degree below setpoint. If an

analogue output is not needed it can be set to “DISABLED”. If both Y1 & Y2 are both disabled they will

not appear in the scrolling running display screens. It is also now possible to set each Y outputs min & max

O/P values, but note the minimum value is overridden and set to 0v when the controller is in the OFF mode.

Y1 & Y2 ANALOGUE (OUTPUTS) PROGRAMMING

16/28

MODE

DEADBAND

: Y output used as a Heating O/P, a Cooling O/P or set to act as BOTH a Heating &

Cooling O/P.

: The temperature gap from the controller’s setpoint till the Y produces an O/P

PROB(portional) BAND : The change of temperature over which the Y O/P would increase to 10volts

INT(egral) TIME : Time in minutes that the integral action adds the P only output to itself over the

integral time setting. Note P+I action starts as the output produced by proportional

only O/P exceeds 10%.

EXAMPLE OF ANALOGUE SUMMARY SCREEN

Y= ANALOGUE O/P # (Y1 or Y2)

M= MODE OF OPERATION (H,C or B)

D_B = DEADBAND (0-25c)

P_B = PROPOTIONAL BAND (1-25c)

P+I = INTEGRAL TIME (1-60min or -P-only)

HEVAC CONTROL AGENCIES PTY LTD. 7/54 HOWLEYS RD. NOTTINGHILL, VIC. 95627888 www.hevac.com.au 07/11/19

OR

OR

USE UP & DOWN BUTTONS

TO EDIT VALUE THEN

PRESS ENTER

P only or upto 60 mins.

OR

SELECT Y OUTPUT TO EDIT

MODE

Y1 & Y2 ANALOGUE (OUTPUTS) PROGRAMMING...CONTINUED

Another possible alternative use for the Y1 & Y2 analogue outputs could be for use as an EC FAN time switch

controlled run & speed setting module, the controller could be set to time switch only mode but with Y1 (as

an example) set to a minimum output of 50% (which is still accessible even in time switch only mode). When

the time switch 1 is ON, Y1 would produce 5v (EC fan ~ 50%) and when the time switch turns off the Y1

output would return to 0v output.

X1 TEMP. SENSOR CONFIGURATION (sensor type & span settings)

X1 is the main temperature sensor input that the operating setpoint relates to. The input can be set either

as a Passive (Hevac type -D sensors) (default) or as an Active type (0-10vdc) in software but must also

be selected as a passive or active type in hardware with a small jumper (CN1) on the bottom circuit

board to match the software setting. Offset (cal) adjustment is settable for both passive & active

types & for active sensors the maximum range is also adjustable ie: 10v = 20 ~ 100c

X2 REMOTE SET POINT CONFIGURATION

A Remote Set Point device (either passive or active) can be connected to the

controller. If a passive adjuster is connected (default setting), the controller will

automatically detect and hand over set point adjustment authority to the remote

device (then ignoring the controllers UP & DOWN buttons for set point adjustment).

A (passive) remote set point potentiometer can be built into a room temperature

sensor - Hevac room sensor model SRT-DSP or supplied as a separate stand

alone device model SPA-D. The range of the passive remote set point is fixed at 18

to 25 degrees over 0 to 10K. If an active remote set point is used the 0-10vDC

signal is configurable from -5 to +5c for 0v & adjustable upto 100c for 10v.

HEVAC CONTROL AGENCIES PTY LTD. 7/54 HOWLEYS RD. NOTTINGHILL, VIC. 95627888 www.hevac.com.au 21/10/19

17/28

LAST STATE DISPLAYED

Note if active sensor type is selected, it is also necessary to reposition a physical

input select jumper on the controller's bottom pcb. Remove screws holding the lid

to base and hinge lid to the right, locate the row of red jumpers located under the

X1-X7 terminal strip. Reposition the very left jumper to short the top two pins (V

position) for active sensor selection. The bottom two pins (T position) are used

for passive resistance type sensors selection (factory default)...SEE PAGE 19.

For active sensors also note 0v equates to 0c unless offset by the offset setting.

Note if an active 0-10vdc remote setpoint input is selected, it is also necessary

to reposition a physical input select jumper on the controller's bottom pcb.

Remove screws holding the lid to base and hinge lid to the right, locate the row

of red jumpers located under the X1-X7 terminal strip. Reposition the 2nd

jumper from the left to short the top two pins (V position) for active S/P selection.

The bottom two pins (T position) are used for passive resistance 0-10K

potentiometric type selection (factory default)...SEE PAGE 19.

For active remote setpoints also note 0v equates to 0c unless offset by the offset

setting (+/- 5c), wheras 0 k ohm = 18c (which can also be offset by +/- 5c)

(=)

18/28

X3 O/AIR TEMPerature SENSOR CONFIGURATION

Economy cycle operation using analogue output Y1 can be interlocked with an

outside air temperature sensor (either passive or active) connected to terminal X3,

such that the use of a modulating motorised economy cycle damper set is inhibited

for temperature control unless the outside air temperature is more favorable for

temperature control then using recycled air from the controlled space. A low limit

outside air temperature can also be set to inhibit Y1 economy cycle output if the

O/A temperature is below an adjustable setting.

To enable this feature, Press the fascia button labeled “ENTER” to have the LCD

display jump to the 1st item in the menu tree “SET CLOCK”, then scroll down the menu

tree list with the “DOWN” arrow button until “X3 O/AIR TEMP.CONFIGURATION” is

displayed. Press the “ENTER” button to open this menu and the existing status is

displayed. If “DISABLED” is displayed press the “DOWN” arrow button to change the

setting to ‘ENABLED” then press “ENTER”.

The following user setting can then be edited using the “UP, DOWN & ENTER buttons:

SENSOR TYPE: PASSIVE: 4K@25C 2 wire Sensor (SOT-D) or

ACTIVE: 0-10V~0-100C 3 wire Sensor (OSAO)

O/A TEMP Y1 low limit O/P lock out : < 0-20C (factory default =16c)

ALLOW Y1 IF O/A BETTER (then room) BY : 0.3-10C (factory default=0.5)

HEVAC CONTROL AGENCIES PTY LTD. 7/54 HOWLEYS RD. NOTTINGHILL, VIC. 95627888 www.hevac.com.au

21/10/19

set temperature

that 10vdc =

sensor calibration

or offset adjustment

Note : if the O/A X3 sensor is set as an active type in software, an internal

red jumper marked as CN2-1 on the bottom PCB (3rd of 7 jumpers from

left) has to be relocated from the factory default position "T" to the "V"

position....SEE IMAGE ON PAGE 19

X4 SUPPLY AIR TEMP. SENSOR CONFIGURATION

X4 is an auxiliary sensor input mainly intended for supply air measurement as

feedback on the performance of the air conditioning supply air output, but currently

performs no other function (In future updates this sensor could be used for room to

supply air cascade control or supply air min / max limitation). This sensor reading is

also available in the modbus output for zone display information on the Hevac HMI

panel or for use by 3rd party BMS suppliers. The input can be set as either a Passive

(Hevac type -D sensors) or as Active type (0-10vdc) in software but must also be

selected as a passive or active type in hardware with a small jumper (CN2-2) on

the bottom circuit board to match the software setting. Offset (cal) adjustment is

settable for both passive & active types & for active sensors the maximum

range is also adjustment ie: 10v = 20 ~ 100c

LAST SET STATE DISPLAYED

Note if active sensor type is selected, it is also necessary to reposition a physical input

select jumper on the controller's bottom pcb. Remove screws holding the lid to base and

hinge lid to the right, locate the row of red jumpers located under the X1-X7 terminal strip.

Reposition the CN2-2 jumper (4th of 7 jumpers from left) to short the top two pins

(V position) for active sensor selection. The bottom two pins (T position) are used for

passive resistance type sensors selection (factory default)... SEE IMAGE ABOVE.

For active sensors also note 0v equates to 0c unless offset by the software offset setting...

(=)

HEVAC CONTROL AGENCIES PTY LTD. 7/54 HOWLEYS RD. NOTTINGHILL, VIC. 95627888 www.hevac.com.au 21/10/19

TO USE ACTIVE SENSORS INSTEAD OF

PASSIVE , MOVE JUMPERS AS INDICATED.

MODBUS ( TERMINALS X5 & X6) ARE

FACTORY SET TO COMMS MODE "C"

USING THE CN3-1 & 2 JUMPERS. ALSO

IF X7 ISNT BEING USED AS A CO2 SENSOR

INPUT, MOVE CN3-3 TO THE C POSITION &

USE X7 FOR CABLE SHIELD CONNECTION.

19/28

CONTROLLER BOTTOM PCB SHOWING SENSOR PASSIVE / ACTIVE RED SELECTION PINS

CN1-1 :X1 MAIN SENSOR

CN1-2 :X2 REMOTE SETPOINT

CN2-1 : X3 O/A SENSOR

CN2-2 :X4 AUX. SENSOR

CN3-1 : X5 MODBUS A

CN3-2 : X6 MODBUS B

CN3-3 : X7 CO2 SENSOR

OR MODBUS SHIELD

20/28

X7 CO2 ECONOMY CYCLE OVERRIDE SETTINGS

HEVAC CONTROL AGENCIES PTY LTD. 7/54 HOWLEYS RD. NOTTINGHILL, VIC. 95627888 www.hevac.com.au 18/10/19

Enable this feature if a CO2 sensor is connected to the controller for air quantity

control to reduce CO2 build up, by either overriding the economy cycle damper

operation connected to analogue output terminal Y1 (to increase fresh air intake)

or / & to control an internal relay set for on/off CO2 control. Typical settings (factory

default if enabled ) are to proportionally modulate open the economy cycle damper

set to the fresh air mode as CO2 levels exceeds 700 ppm and cause full fresh air

mode if levels reach 1000 ppm, or with this latest update can now alternatively just

operate a relay for on/off CO2 control ..ie for energising a fresh air fan.

To edit settings, press the fascia button labeled “ENTER” to have the LCD display

jump to the 1st menu item in the menu tree “SET CLOCK”, using the DOWN arrow

button scroll down the menu until “X7 CO2 SENSOR CONFIGURATION” is

displayed. To then enable this feature, Press the “ENTER” button followed by the

“DOWN” arrow button to change the “DISABLED” setting to ‘ENABLED”. Either

except the default settings of (Y1 damper output) start at 700 and range over 300

ppm or edit the values with the “UP” or “DOWN” buttons, press “ENTER” to confirm

settings. Note so as not to lose temperature control in extreme outside air

temperatures, O/A temperature limits can be set to inhibit full fresh mode due to

high CO2 levels when the outside air temperature is either to hot or too cold

(adjustable). In this menu set the high and low outside air temperatures where fresh

air mode output signal (due to CO2 control) should be restricted (factory settings

are: below 10c and above 35c), the now restricted CO2 generated Y1 output signal

is adjustable from 0 to 100% (factory setting is 50%).

Table of contents