Page 3

EPS Stromversorgung GmbH

Alter Postweg 101 • 86159 Augsburg

Germany

Fon: +49 821 / 570451-0

Fax: +49 821 / 570451-25

www.eps-germany.de

info@eps-germany.de

PSB 9000 3U Slave Series

TABLE OF CONTENTS

1GENERAL

1.1 About this document......................................4

1.1.1 Retention and use..........................................4

1.1.2 Copyright........................................................4

1.1.3 Validity ............................................................4

1.1.4 Symbols and warnings ..................................4

1.2 Warranty.........................................................4

1.3 Limitation of liability ........................................4

1.4 Disposal of equipment ...................................5

1.5 Product key ....................................................5

1.6 Intended usage ..............................................5

1.7 Safety .............................................................6

1.7.1 Safety notices.................................................6

1.7.2 Responsibility of the user...............................6

1.7.3 Responsibility of the operator .......................7

1.7.4 User requirements .........................................7

1.7.5 Alarm signals..................................................8

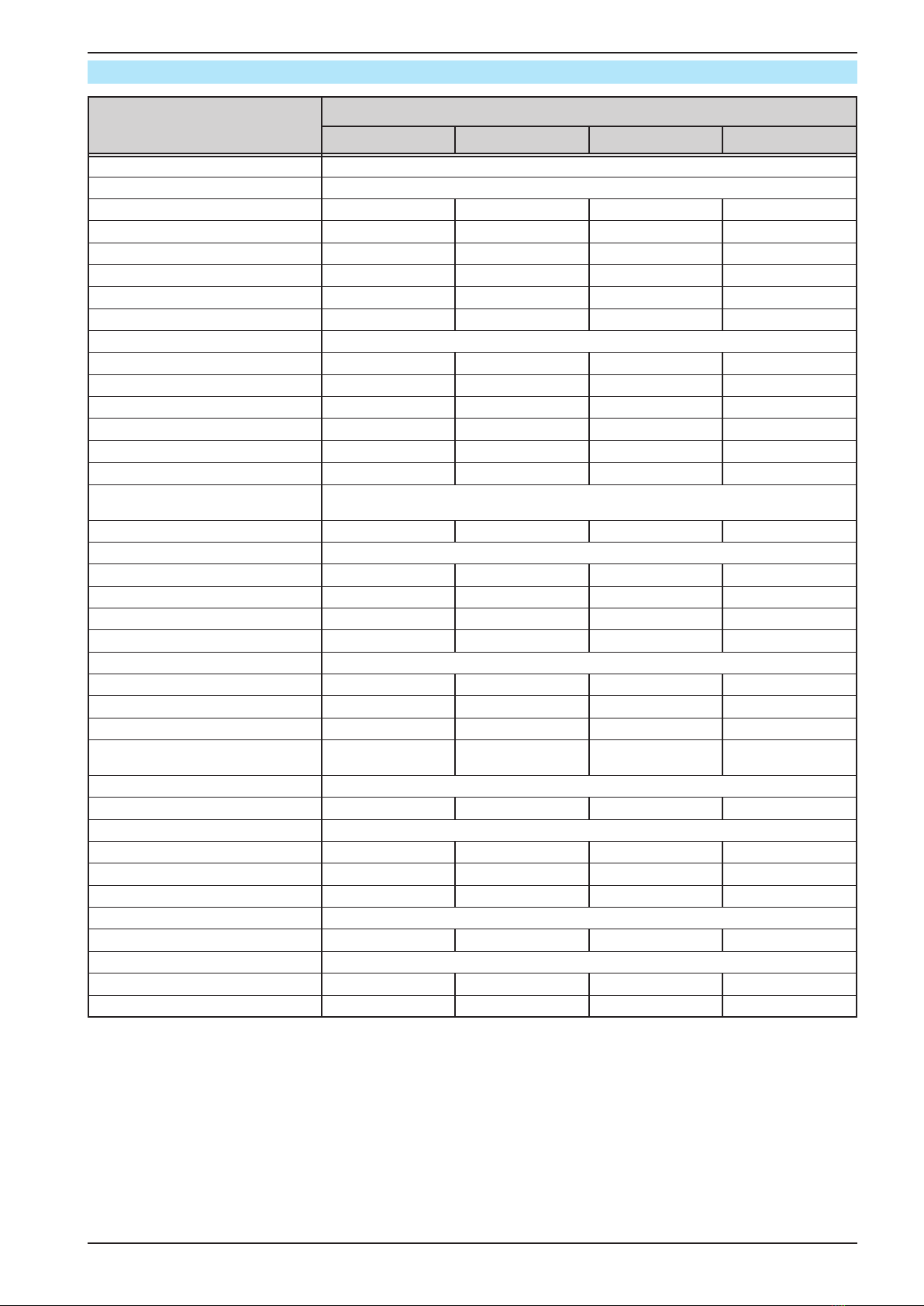

1.8 Technical Data ...............................................8

1.8.1 Approved operating conditions......................8

1.8.2 General technical data...................................8

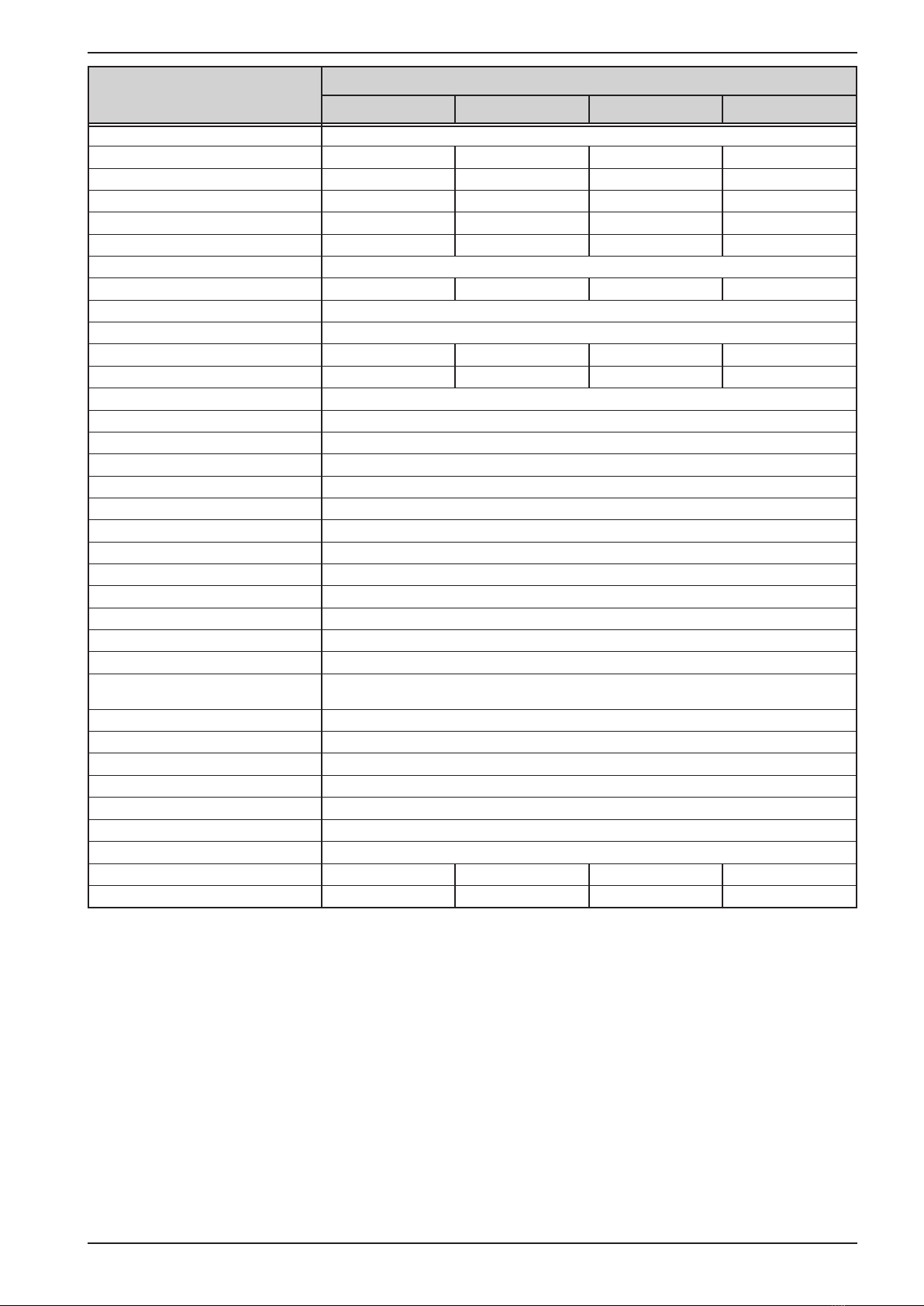

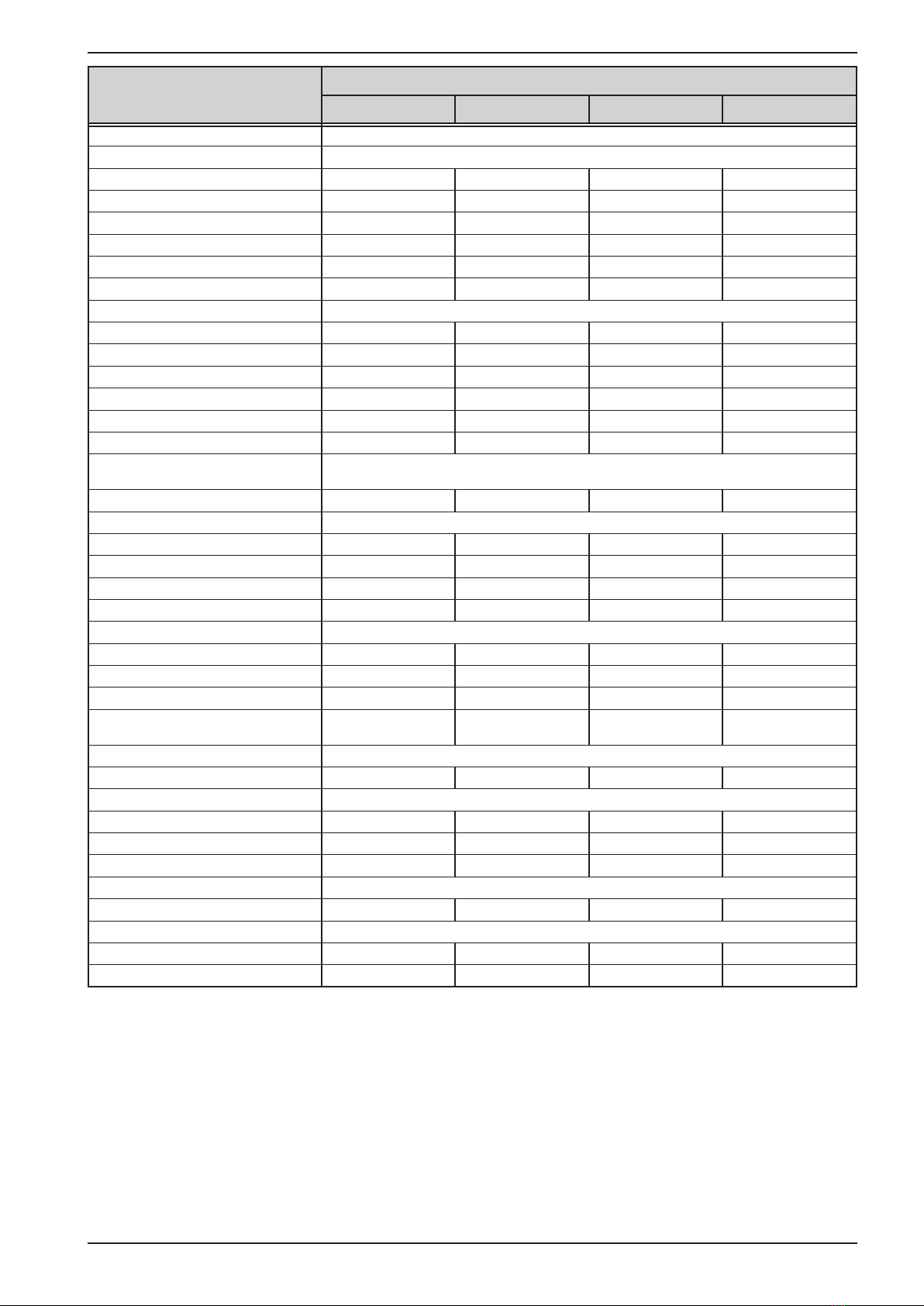

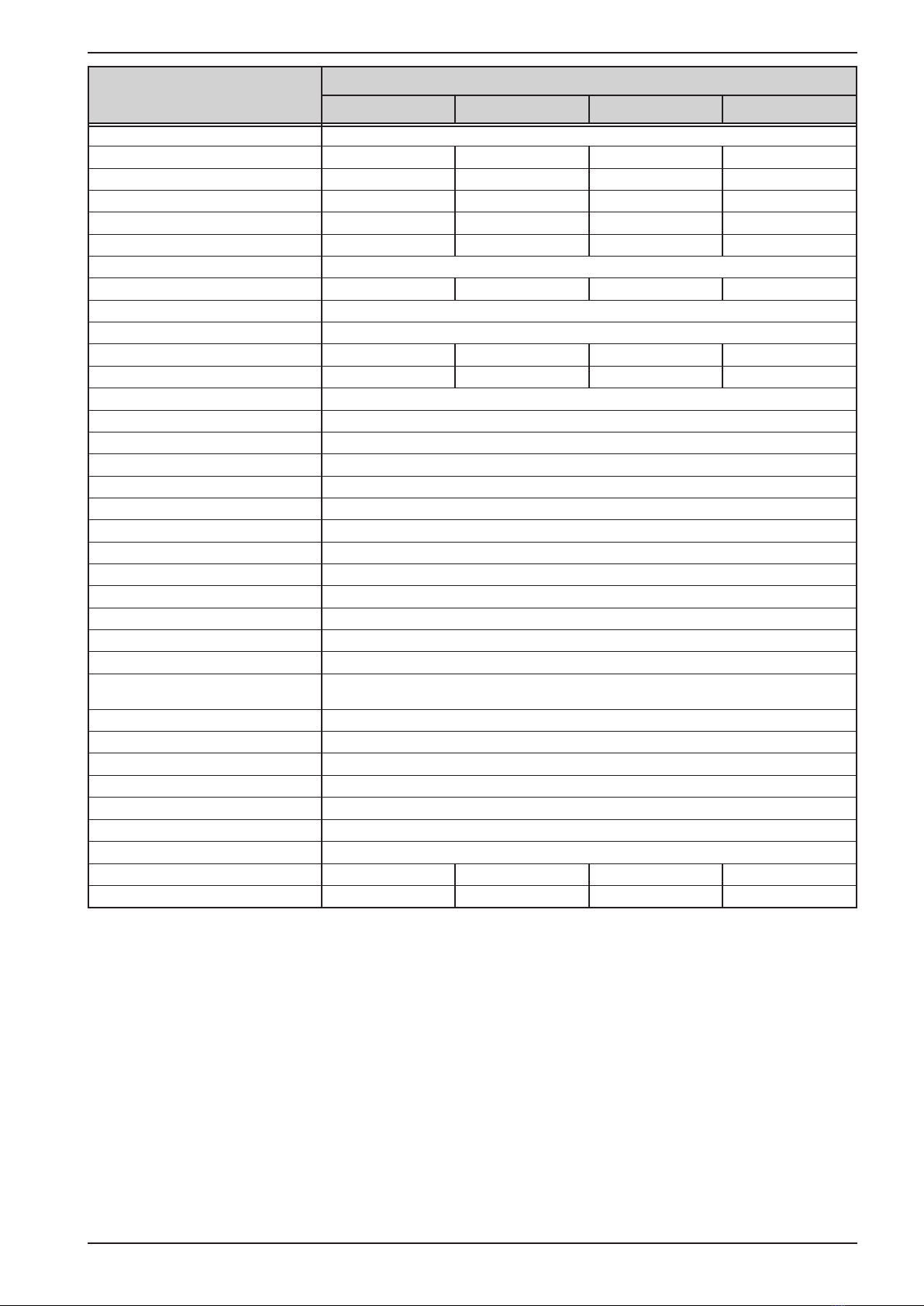

1.8.3 Specictechnicaldata...................................9

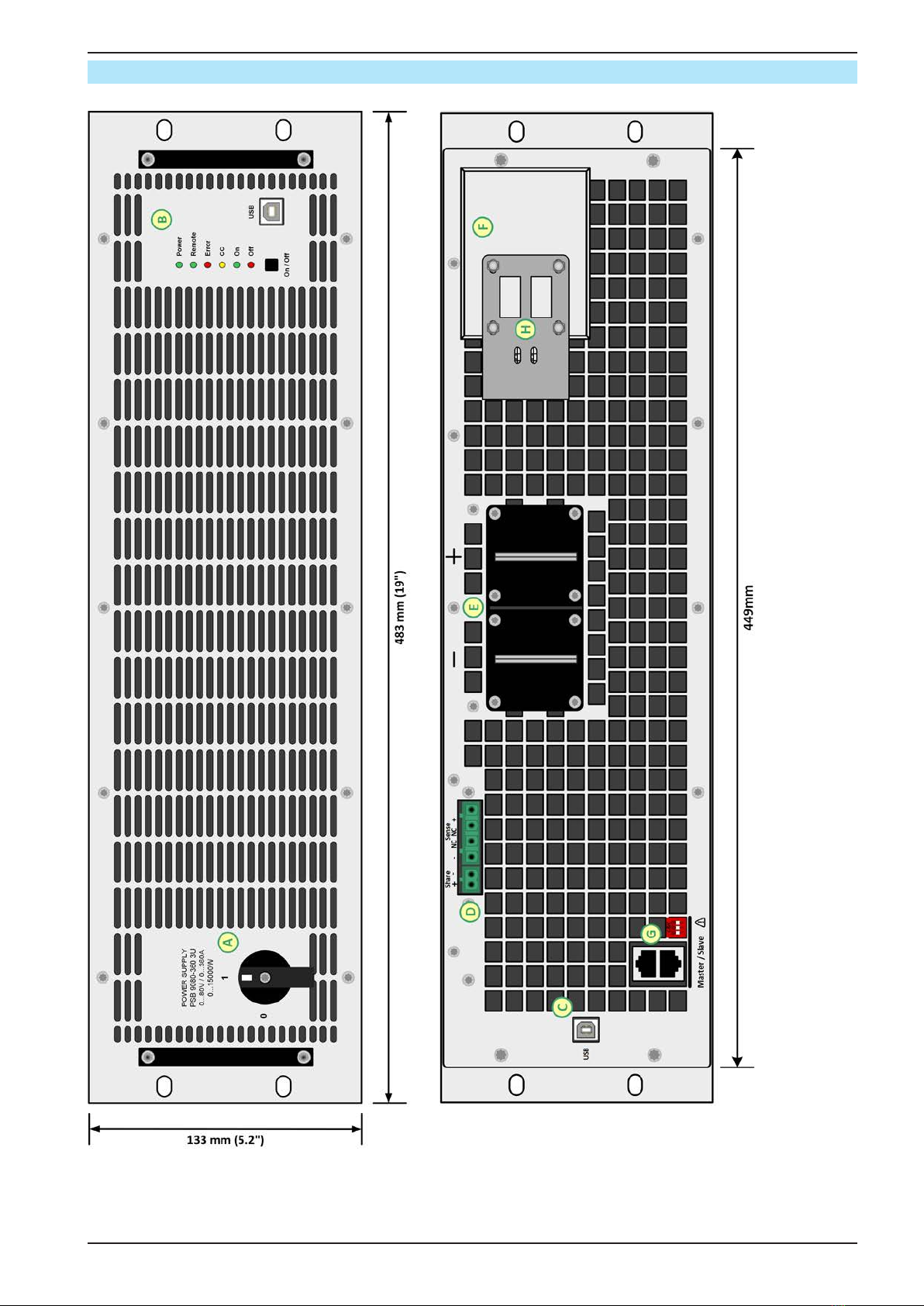

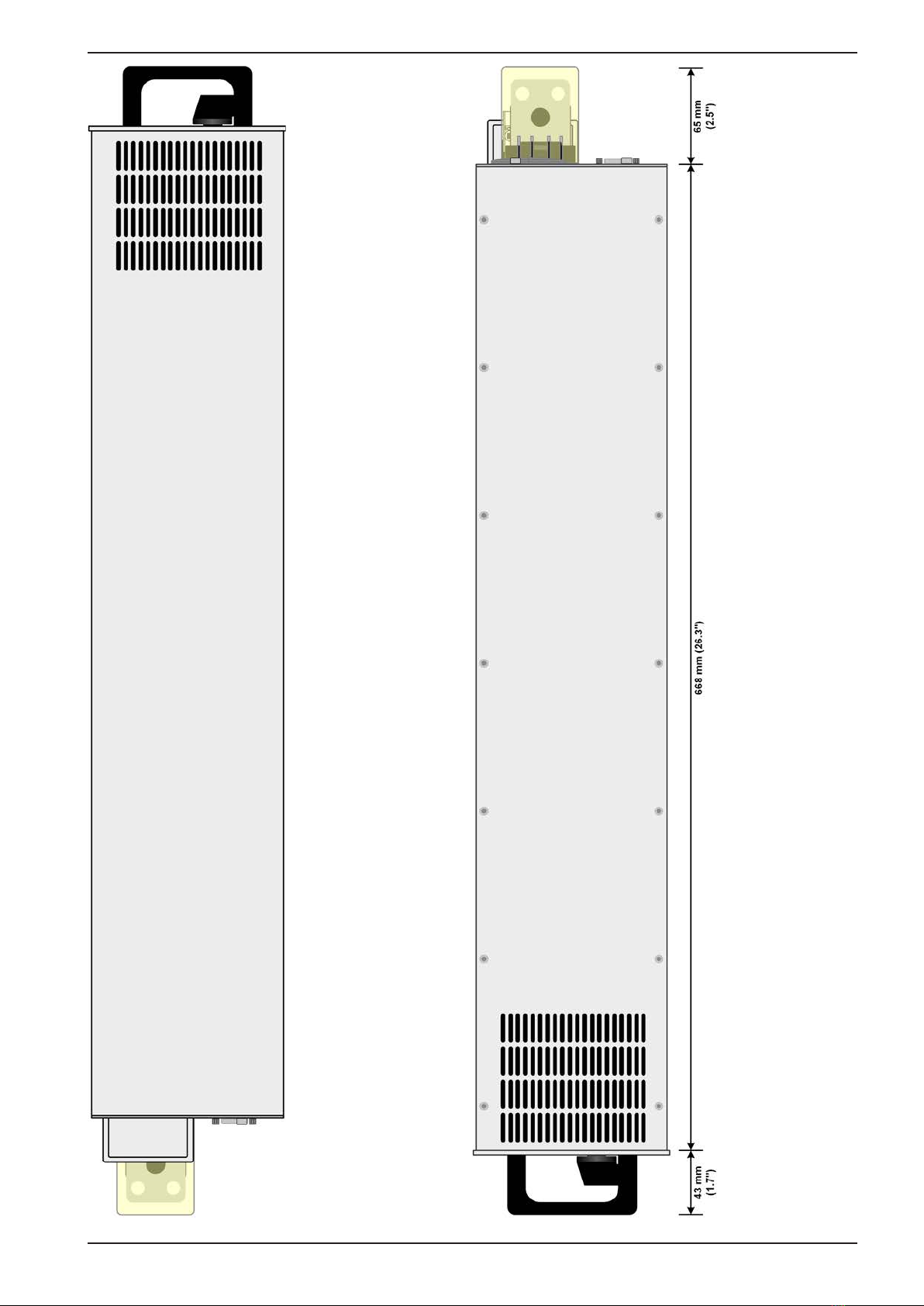

1.8.4 Views............................................................13

1.8.5 Control elements..........................................16

1.9 Construction and function............................17

1.9.1 General description......................................17

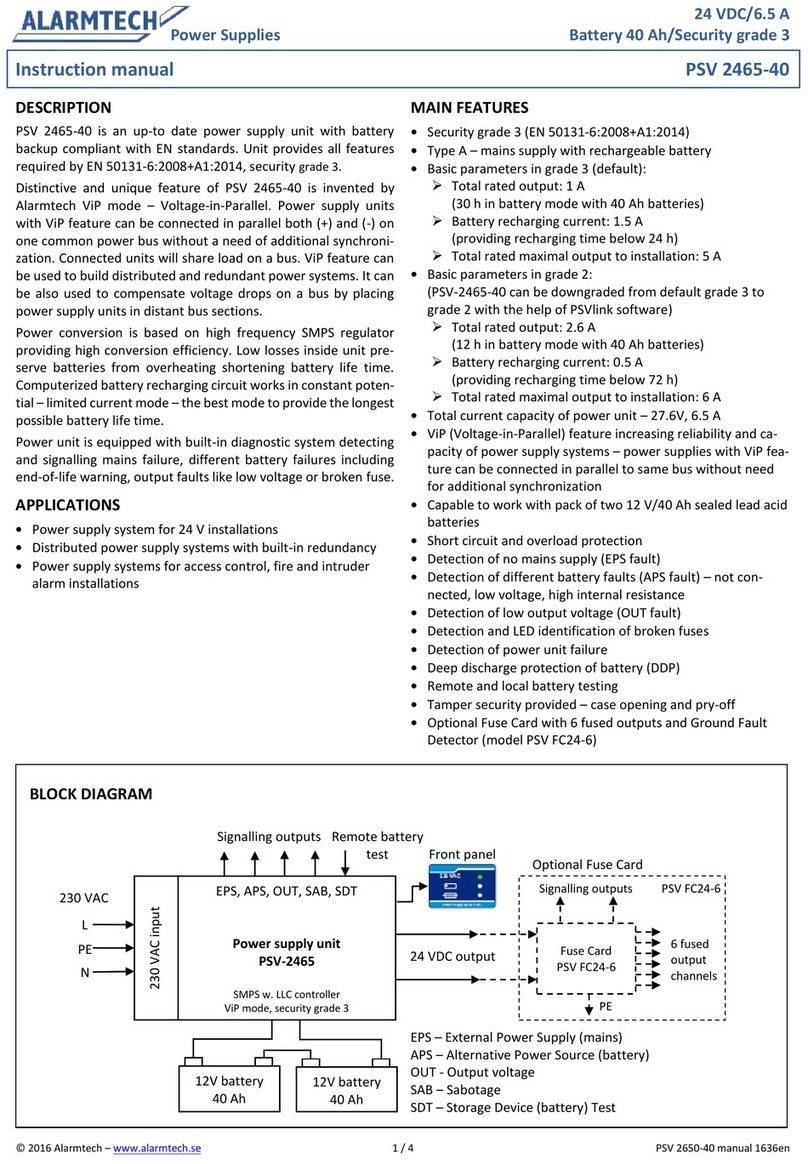

1.9.2 Block diagram ..............................................17

1.9.3 Scope of delivery .........................................18

1.9.4 The control panel (HMI)...............................18

1.9.5 USB port type B (rear side) .........................19

1.9.6 “Share” connector ........................................19

1.9.7 “Sense” connector (remote sensing)...........19

1.9.8 Master-Slave bus.........................................19

2INSTALLATION &

COMMISSIONING

2.1 Transport and storage .................................20

2.1.1 Transport ......................................................20

2.1.2 Packaging ....................................................20

2.1.3 Storage.........................................................20

2.2 Unpacking and visual check........................20

2.3 Installation ....................................................20

2.3.1 Safety procedures before installation and

use................................................................20

2.3.2 Preparation...................................................20

2.3.3 Installing the device .....................................22

2.3.4 Connection to AC supply .............................23

2.3.5 Connection to DC loads...............................25

2.3.6 Grounding of the DC terminal......................26

2.3.7 Connection of remote sense .......................26

2.3.8 Connecting the “Share” bus ........................27

2.3.9 Connecting the USB port.............................27

2.3.10 Initial commission.........................................28

2.3.11 Commissionafterarmwareupdateora

long period of non-use.................................28

3OPERATION AND APPLICATION

3.1 Terms............................................................29

3.2 Personal safety ............................................29

3.3 Operating modes .........................................29

3.3.1 Voltage regulation / Constant voltage .........29

3.3.2 Current regulation / constant current / current

limiting ..........................................................30

3.3.3 Power regulation / constant power / power

limiting ..........................................................30

3.3.4 Internal resistance regulation (source

mode) ...........................................................31

3.3.5 Resistance regulation / constant resistance

(sink mode) ..................................................31

3.3.6 Sink-source mode switching........................32

3.4 Alarm conditions ..........................................33

3.4.1 Power Fail ...................................................33

3.4.2 Overtemperature..........................................33

3.4.3 Overvoltage protection.................................33

3.4.4 Overcurrent protection.................................33

3.4.5 Overpower protection ..................................34

3.4.6 Safety OVP ..................................................34

3.5 Manual operation .........................................35

3.5.1 Powering the device ....................................35

3.5.2 Switchingthedeviceo...............................35

3.5.3 SwitchingtheDCterminalonoro.............35

3.6 Remote control.............................................36

3.6.1 General.........................................................36

3.6.2 Remote control via the rear USB ................36

3.6.3 Remote control via the front USB................36

3.6.4 Programming ...............................................37

3.7 Alarms and monitoring.................................38

3.7.1 Denitionofterms........................................38

3.7.2 Device alarm and event handling................38

3.8 Other applications........................................40

3.8.1 Parallel operation in master-slave (MS)......40

3.8.2 Series connection ........................................42

4SERVICE AND MAINTENANCE

4.1 Maintenance / cleaning................................43

4.2 Faultnding/diagnosis/repair...................43

4.2.1 Firmware updates ........................................43

5CONTACT AND SUPPORT

5.1 General.........................................................44

5.2 Contact options ............................................44