VACUUM DRYING AND LEAKAGE CHECKING

18

1.Purpose of vacuum drying

Eliminating moisture in system to preventthe phenomena of ice-blockage and copper oxidation.

Ice-

blockage shall cause abnormal operation of system, while copper oxide shall damage compressor.

Eliminating the non-condensable gas (air) in system to prevent the components oxidizing, pressure

fluctuation and bad heatexchange during the operation of system.

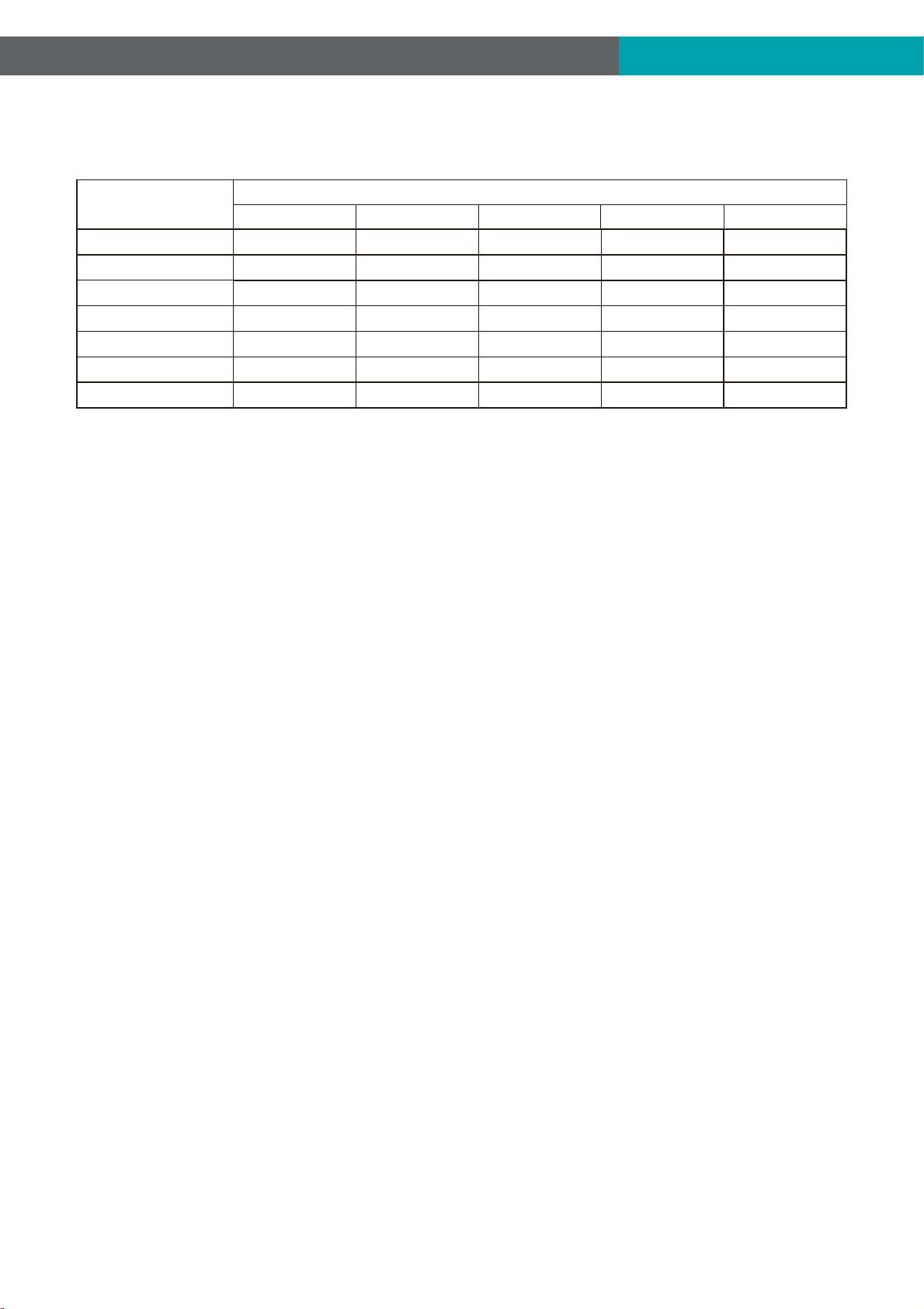

2.Selection of vacuum pump

The ultimate vacuum degree of vacuum pump shall be-756mmHg or above.

Precision of vacuum pump shall reach 0.02mmHg or above.

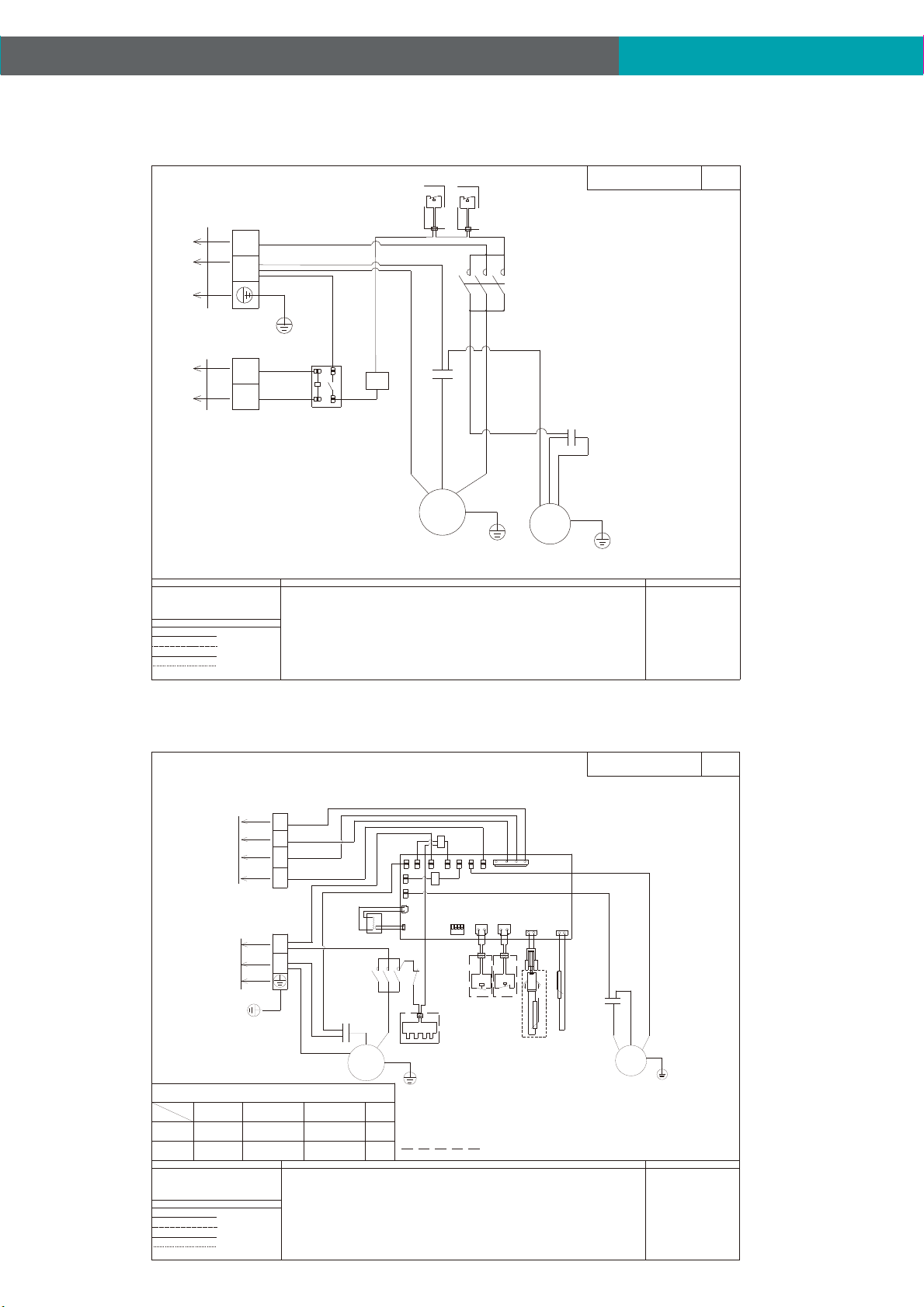

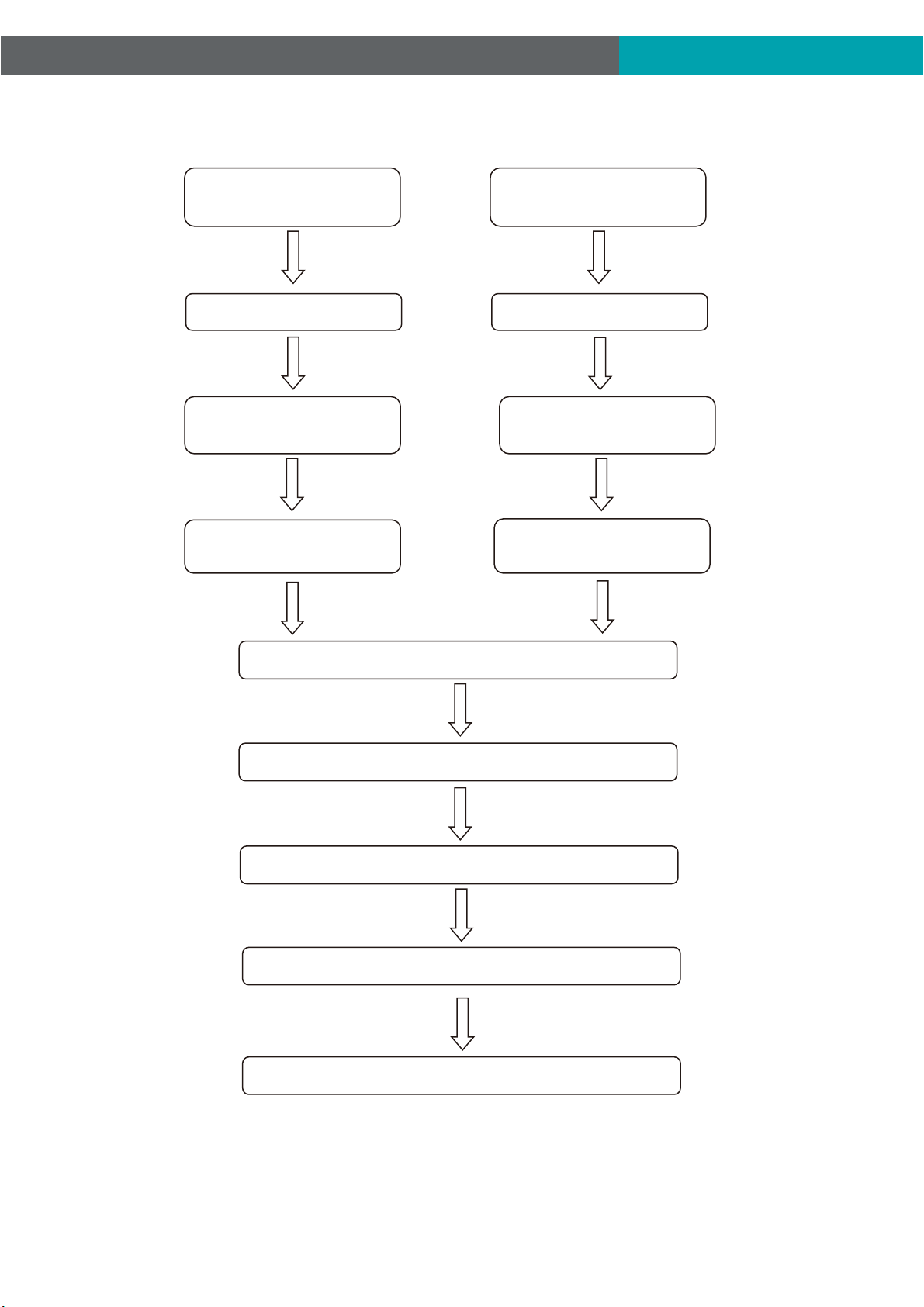

3.Operation procedure for vacuum drying

Due to different construction environment, two kinds of vacuum drying ways could be chosen, namely

ordinary vacuum drying and special vacuum drying.

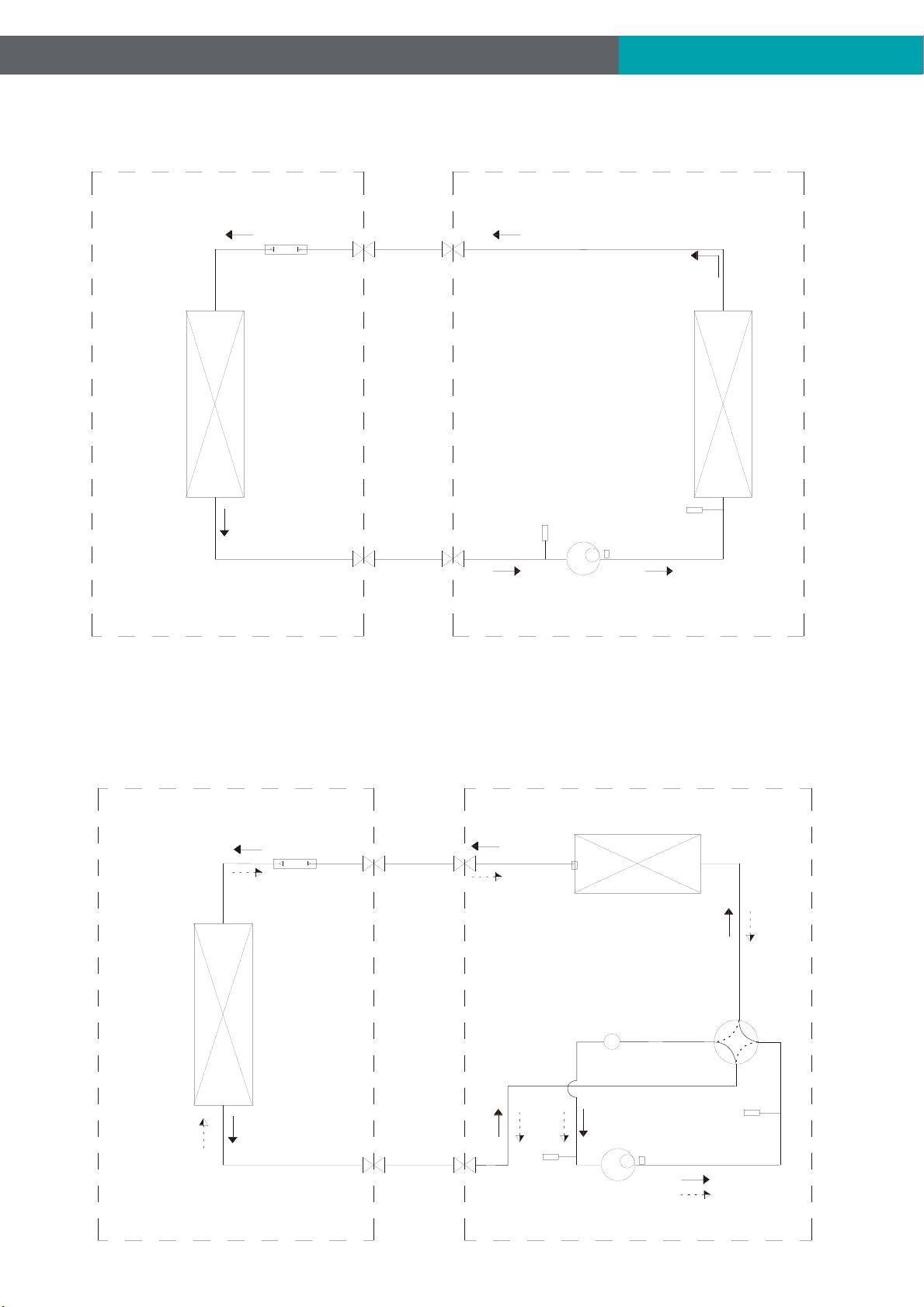

3.1 Ordinary vacuum drying

1. When conduct first vacuum drying, connect pressure gauge to the infusing mouth of gas pipe and liquid

pipe, and keep vacuum pump running for1hour (vacuum degree of vacuum pump shall bereached

-

755mmHg).

2If the vacuum degree of vacuum pump could not reach -755mmHg after 1hour of drying, it indicates

that there is moisture or leakage in pipeline system and need to go on with drying for half an hour.

3If the vacuum degree of vacuum pumpstill could not reach -755mmHg after 1.5 hours of drying, check

whether there is leakage source.

4Leakage test : After the vacuum degree reaches-755mmHg, stop vacuum drying and keep the pressure

for 1hour. If the indicator of vacuum gauge does not go up, it is qualified. If going up, it indicates that

there is moisture or leak source.

3.2 Special vacuum drying

The special vacuum drying method shall be adopted when:

1. Finding moisture during flushing refrigerant pipe.

2. Conducting construction on rainy day, because rain water might penetrated into pi peline.

3. Construction period is long, and rain water might penetrated into pipeline.

4. Rain water might penetrate into pipeline during construction.

Procedures of special vacuum drying are as follows:

1.V acuumdrying for 1hour.

2.V acuum damage, filling nitrogen to reach 0.5Kgf/cm2.

Because nitrogen is dry gas, vacuum damage could achieve the effect of vacuum drying, but this

method could not achieve drying thoroughly when there is too much moisture. Therefore, special

attention shall be drawn to prevent the entering of water and the formation of condensate water.

3.V acuum drying again for half an hour.

If the pressure reached-755mmHg, start to pressure leakage test. If it can not reached the value,

repeat vacuum damage and vacuum drying again for 1hour.

4Leakage test : After the vacuum degree reaches-755mmHg, stop vacuum drying and keep the pressure

for 1hour. If the indicator of vacuum gauge does not go up, it is qualified. If going up, it indicates that

there is moisture or leak source.