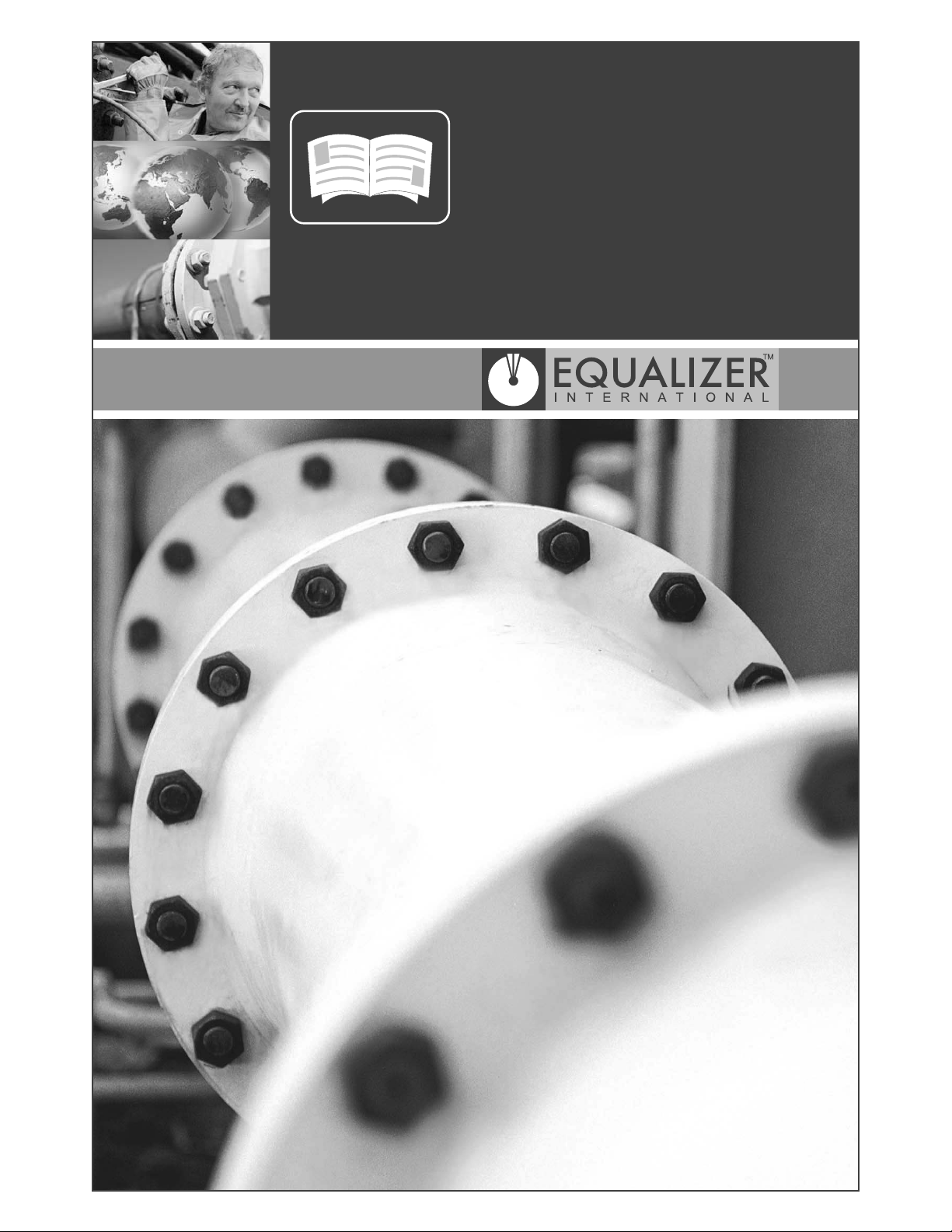

Equalizer International SG13TE Assembly instructions

info@equalizerinternational.com

www.equalizerinternational.com

INNOVATI ON IN I TS MOST FUNCTI ONAL FORM

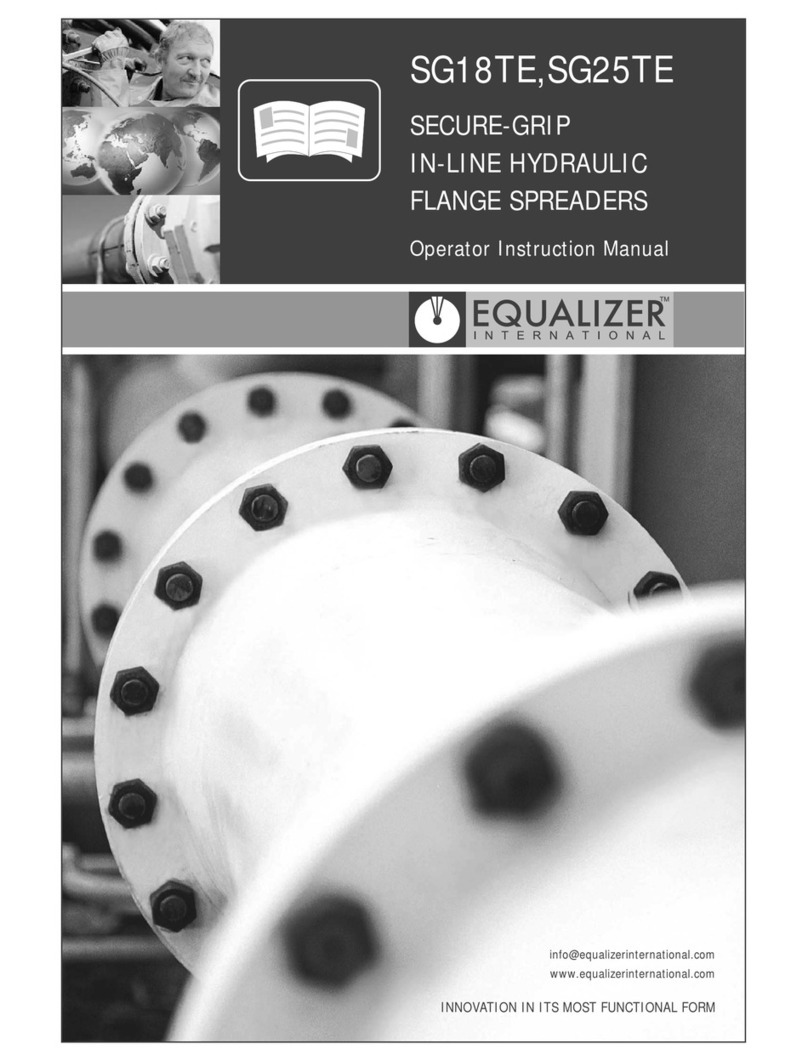

SG13TE, SG15TE

SECURE-GRIP HYDRAULIC

FLANGE SPREADERS

Operator Instruction Manual

SECURE-GRI P HYDRAULIC FLANGE SPREADERS

OPERATOR I NSTRUCTI ON MANUAL PAGE 1

SECTI ON CONTENTS PAGE NO.

1 INTRODUCTION 1

2 SAFETY INFORMATI ON 2-3

3 KIT COMPONENTS 4

4 TECHNICAL DATA 5

5 HOW THE SECURE-GRI P HYDRAULI C TOOLS WORK 6

6 INSTALLATI ON AND OPERATION 7

6.1 COLLET SELECTI ON BASED ON FLANGE SPECI FICATI ON 7

6.2 COLLET SELECTI ON BASED ON BOLT-HOLE MEASURMENT 8-10

6.3 COLLET REMOVAL AND REPLACEMENT 11

6.4 STANDARD I NSTALLATI ON AND OPERATI ON 12-16

6.5 RESTRI CTED ACCESS INSTALLATION AND OPERATI ON 17

6.6 VALVE, SPADE OR BLIND REMOVAL I NSTALLATION AND OPERATION 18

7 MAINTENANCE AND LUBRI CATI ON 19-20

8 PARTS LISTS 21-23

9 WEI GHTS AND DI MENSI ONS 24

10 TROUBLESHOOTI NG 25-28

11 SECURE-GRIP TOOL RANGE 29

12 RANGE OF APPLICATION CHARTS 30-39

The Equalizer Secure-Grip Flange Spreading Tools are a range of tools designed to assist in

WKHPDLQWHQDQFHDQGLQVWDOODWLRQRISLSHOLQHÀDQJHDVVHPEOLHV

7KH+\GUDXOLF6HFXUH*ULS)ODQJH6SUHDGLQJ7RROVDUHXVHGWRVSUHDGÀDQJHVZLWKOLWWOHRUQR

access gap producing a spreading force of up to:

ł26T ( 260kN) for the SG13TE when used in pairs

ł30T ( 300kN) for the SG15TE when used in pairs

INDEX

1. INTRODUCTION

SGH IM REV 03

06/06/ 2014

SECURE-GRI P HYDRAULIC FLANGE SPREADERS

OPERATOR I NSTRUCTI ON MANUAL PAGE 2

2. SAFETY INFORMATION

The operator MUST read this manual prior to using the tools.

Failure to comply with the following cautions and w arnings could cause equipment

damage and personal injury; read the manual fully!

Read all the following instructions, warnings and cautions carefully. Follow all safety

precautions to avoid personal injury or property damage during system operation.

(TXDOL]HU,QWHUQDWLRQDO/WGFDQQRWEHUHVSRQVLEOHIRUGDPDJHRULQMXU\UHVXOWLQJIURPXQVDIH

product use, lack of maintenance or incorrect product and/ or system operation. Contact

(TXDOL]HU,QWHUQDWLRQDO/WGZKHQLQGRXEWDVWRWKHVDIHW\SUHFDXWLRQVDQGDSSOLFDWLRQV7R

protect your warranty, use only good quality hydraulic oil of the grade 15cSt.

Only people competent in the use of hydraulic equipment should use these tools.

,QDOOLQVWDOODWLRQVWKHVLWHVDIHW\UHTXLUHPHQWVPXVWEHDGKHUHGWR$/62WKHVDIHW\RIWKH

operator, and when present, any assisting personnel, is of paramount importance along with

WKHVDIHW\RIRWKHUVLQFOXGLQJZKHQSUHVHQWWKHJHQHUDOSXEOLF

These instructions are only to cover the safe operation of THE EQUALIZER SG13TE & SG15TE

SECURE-GRI P HYDRAULI C TOOLS during normal maintenance/ installation operations. All oth-

HUVDIHW\DVSHFWVPXVWEHFRQWUROOHGE\WKHRSHUDWLRQVXSHUYLVRU

SECURE-GRI P HYDRAULIC FLANGE SPREADERS

OPERATOR I NSTRUCTI ON MANUAL PAGE 3

A CAUTI ON is used to indicate correct operating or maintenance procedures and practices to

prevent damage to, or destruction of equipment or other property.

A WARNI NG indicates a potential danger that requires correct procedures or practices to avoid

personal injury.

A DANGER is only used when your action or lack of action may cause serious injury or even

death.

I MPORTANT:2SHUDWRUPXVWEHFRPSHWHQWLQ

the use of hydraulic equipment. The operator

must have read and understood all instructions,

VDIHW\ LVVXHV FDXWLRQV DQG ZDUQLQJV EHIRUH

starting to operate the Equalizer equipment.

WARNI NG: To avoid personal injury and

SRVVLEOH HTXLSPHQW GDPDJH PDNH VXUH DOO

hydraulic components are rated to a safe

ZRUNLQJ SUHVVXUH RI EDU SVL

WARNI NG: Do not overload equipment. Over-

ORDGLQJ FDXVHV HTXLSPHQW IDLOXUH DQG SRVVLEOH

personal injury.

7KHULVNRIRYHUORDGLQJFDQEHDYRLGHGE\XVLQJ

the Equalizer Hand Pump, which has its safety

YDOYHVHWWREDUE\WKHIDFWRU\,IDOWHUQDWLYH

pumps are used, ensure they are rated at a safe

ZRUNLQJSUHVVXUHRIEDUSVL

CAUTI ON: Make sure that all system compo-

nents are protected from external sources of

GDPDJH VXFK DV H[FHVVLYH KHDW ÀDPH PRY-

ing machine parts, sharp edges and corrosive

chemicals.

CAUTI ON: $YRLG VKDUS EHQGV DQG NLQNV WKDW

ZLOO FDXVH VHYHUH EDFNXS SUHVVXUH LQ KRVHV

Bends and kinks lead to premature hose failure.

'RQRWGURSKHDY\REMHFWVRQWRKRVHV$VKDUS

impact may cause internal damage to hose wire

strands; applying pressure to a damaged hose

may cause it to rupture. Do not place heavy

weights on the hoses, or allow vehicles to roll

over the hoses; crush damage will lead to pre-

mature hose failure.

WARNI NG: Immediately replace worn

or damaged parts with genuine Equalizer

SDUWV (TXDOL]HU SDUWV DUH GHVLJQHG WR ¿W

properly and withstand rated loads. For

repair or maintenance service contact your

(TXDOL]HUGLVWULEXWRURUVHUYLFHFHQWUH

DANGER: To avoid personal injury keep

hands and feet away from the tool and

workpiece during operation.

WARNI NG: $OZD\VZHDUVXLWDEOHFORWKLQJ

DQG3HUVRQDO3URWHFWLYH(TXLSPHQW33(

DANGER: Do not handle pressurised hos-

es. Escaping oil under pressure can pen-

etrate the skin, causing serious injury. If

oil is injected under the skin, seek medical

attention immediately.

WARNI NG: Never pressurize unconnected

couplers. Only use hydraulic equipment in

a connected system.

I MPORTANT: Do not lift hydraulic equip-

PHQWE\WKHKRVHVRUFRXSOHUV8VHWKHFDU-

rying handle or other means of safe trans-

port.

WARNI NG: 1HYHU SODFH ¿QJHUV LQ D MRLQW

KHOGE\DQDFWLYDWHGWRRO

CAUTI ON: Never hammer of force the tool

LQWRDEROWKROHLILWGRHVQRW¿WHDVLO\\RX

are using the wrong size of tool.

CAUTI ON: Do not operate the equipment

ZLWKRXW OXEULFDWLQJ DOO PRYLQJ SDUWV DV LQ

VHFWLRQ8VHRQO\KLJKSUHVVXUHPRO\EGH-

num disulphide grease.

SECURE-GRI P HYDRAULIC FLANGE SPREADERS

OPERATOR I NSTRUCTI ON MANUAL PAGE 4

3. KIT COMPONENTS

SG13TE KI T COMPONENTS

1 x SG13TE Tool c/ w Hydraulic Cylinder

[SVLEDU+366HDOHG+DQG3XPS

with Gauge

[SVLEDU+\GUDXOLF+RVHP´

[PP´9HUQLHU&DOOLSHU

[ò´6TXDUH'ULYH)OH[LEOH+DQGOH

[PPƗ´'ULYH6RFNHW

1 x Safety Block

[0ò´&ROOHWV

[0ƙ´&ROOHWV

[0ô´&ROOHWV

1 x Instruction Manual

1 x Carry-Case with Protective Foam I nserts

Product Code: SG13TESTD

SG15TE KI T COMPONENTS

1 x SG15TE Tool c/ w Hydraulic Cylinder

[SVLEDU+366HDOHG+DQG3XPS

with Gauge

[SVLEDU+\GUDXOLF+RVHP´

[PP´9HUQLHU&DOOLSHU

[ò´6TXDUH'ULYH)OH[LEOH+DQGOH

1 x 36 mm Drive Socket

1 x Safety Block

[0ƚ´&ROOHWV

[0´&ROOHWV

[0ó´&ROOHWV

1 x Instruction Manual

1 x Carry-Case with Protective Foam I nserts

Product Code: SG15TESTD

SECURE-GRI P HYDRAULIC FLANGE SPREADERS

OPERATOR I NSTRUCTI ON MANUAL PAGE 5

4. TECHNICAL DATA

SG13TE TECHNI CAL DATA

Spreading force = 13 T ( 130 kN) per tool

,WLVUHFRPPHQGHGWKDWWRROVDUHXVHGLQSDLUVJLYLQJ[ 7N1

,IXVLQJWKH(TXDOL]HU+36+DQG3XPSRULIDK\GUDXOLFSUHVVXUHJDXJHLV¿WWHGWKH

VSUHDGLQJIRUFHSHUWRROFDQEHGHWHUPLQHGE\WDNLQJDUHDGLQJIURPWKHJDXJH

*DXJHSUHVVXUHVZLOOSURGXFHVSUHDGLQJIRUFHVDVVHWRXWEHORZ

Pressure Bar 138 276 414 552 690

psi 2000 4000 6000 8000 10,000

Spreading force T2.6 5.2 7.8 10.4 13

kN 26 52 78 104 130

Spreading distance = 0 - 115mm (0 - 4.53”)

+\GUDXOLFRLOJUDGHFHQWLVWRNHVF6W#&WHVWHGE\$670'

SG15TE TECHNICAL DATA

Spreading force = 15 T ( 150 kN) per tool

,WLVUHFRPPHQGHGWKDWWRROVDUHXVHGLQSDLUVJLYLQJ[ 7N1

,IXVLQJWKH(TXDOL]HU+36+DQG3XPSRULIDK\GUDXOLFSUHVVXUHJDXJHLV¿WWHGWKH

VSUHDGLQJIRUFHSHUWRROFDQEHGHWHUPLQHGE\WDNLQJDUHDGLQJIURPWKHJDXJH*DXJH

SUHVVXUHVZLOOSURGXFHVSUHDGLQJIRUFHVDVVHWRXWEHORZ

Pressure Bar 138 276 414 552 690

psi 2000 4000 6000 8000 10,000

Spreading force T3691215

kN 30 60 90 120 150

Spreading distance = 0 - 100mm (0 - 3.94”)

+\GUDXOLFRLOJUDGHFHQWLVWRNHVF6W#&WHVWHGE\$670'

SECURE-GRI P HYDRAULIC FLANGE SPREADERS

OPERATOR I NSTRUCTI ON MANUAL PAGE 6

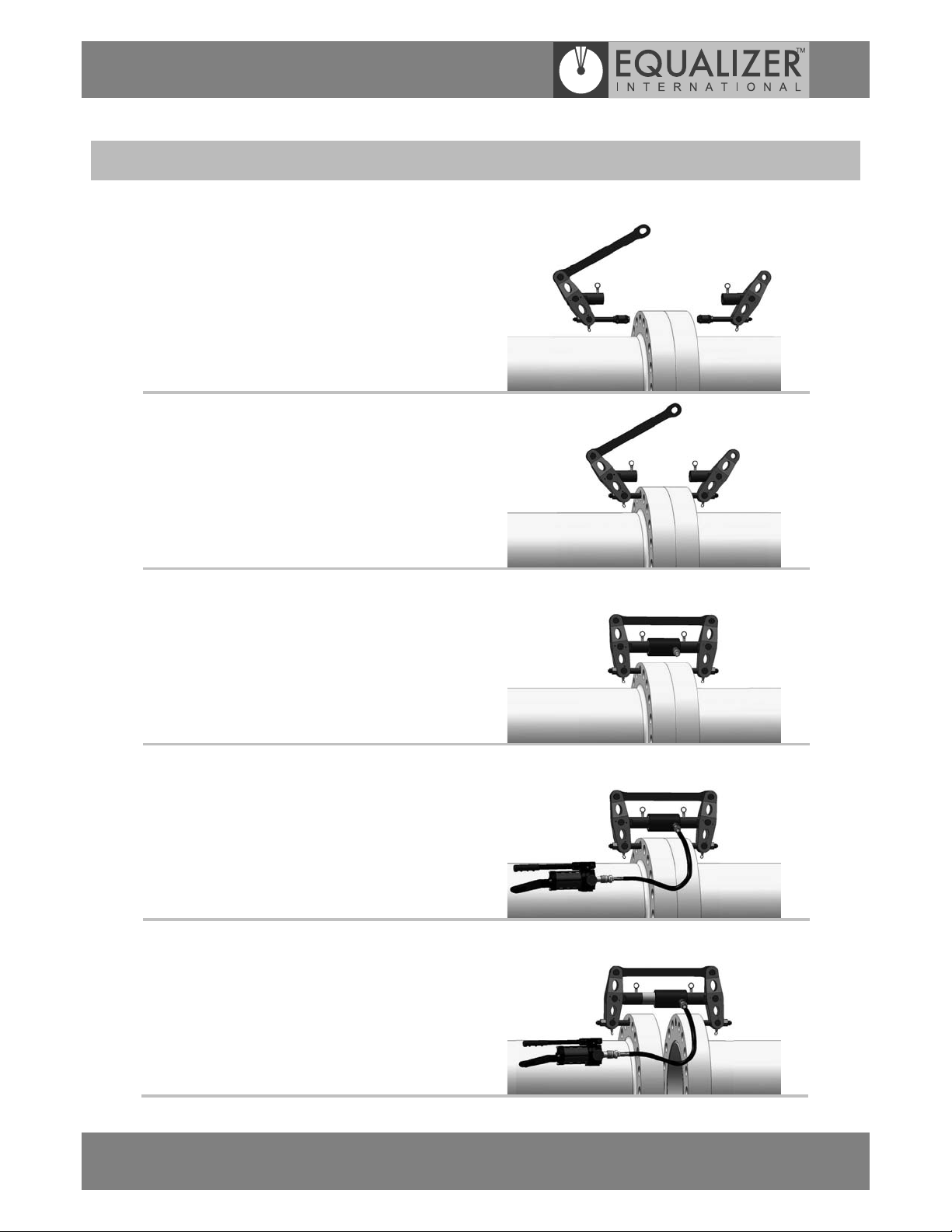

5. HOW THE SECURE-GRIP HYDRAULIC TOOLS WORK

1. The two halves of the hydraulic

Secure-Grip tool are inserted into

RSSRVLQJÀDQJHEROWKROHV

2. Both drive nuts are tightened locking

WKHWRROLQWRWKHÀDQJHEROWKROHV

3. 7KHDFWXDWRUIROORZHGE\WKHFDQWLOHYHU

are locked into position

4. The hydraulic hose and hand pump

are attached

5. The hand pump is actuated which

powers the hydraulics that spread the

ÀDQJH

SECURE-GRI P HYDRAULIC FLANGE SPREADERS

OPERATOR I NSTRUCTI ON MANUAL PAGE 7

6. I NSTALLATI ON AND OPERATI ON

6.1 COLLET SELECTION BASED ON FLANGE SPECI FICATION

7RVHOHFWWKHDSSOLFDEOHWRRODQGFROOHWIRU\RXUÀDQJHSOHDVHUHIHUWRWKH6HFXUH*ULS

DSSOLFDWLRQFKDUWVDWWKHEDFNRIWKLVPDQXDOVHFWLRQSDJHV

7KH6HFXUH*ULSK\GUDXOLFWRROVKDYHDUDQJHRIFROOHWVZKLFKDUHDSSOLFDEOHWRWKHIROORZLQJ

EROWVDQGÀDQJHEROWKROHGLDPHWHUV

Collet type Minimum

bolt-hole

diameter

Maximum

bolt-hole

diameter

Metric coarse

bolt

UNC bolt Tool

M39 1 ½ ” 38 42 M39 ò´ SG13TE

0ƙ´ 41 45 M42 ƙ´ SG13TE

M45 1 ¾ ” 44 49 M45 ô´ SG13TE

0ƚ´ 47.5 52 M48 ƚ´ SG15TE

M52 2” 50.5 56 M52 ´ SG15TE

M56 2 ¼ ” 55.5 62 M56 ó´ SG15TE

,IWKHVSHFL¿FDWLRQRIWKHÀDQJHLVXQNQRZQWKHQWKHYHUQLHUFDOOLSHUVXSSOLHGLQWKHNLW

VKRXOGEHXVHGWRGHWHUPLQHWKHFRUUHFWFROOHWDVVKRZQLQVHFWLRQSDJHV

,PSRUWDQW7KH6HFXUH*ULSFROOHWVDUHFRQVXPDEOHLWHPV7KHOLIHVSDQRI

DFROOHWZLOOYDU\GHSHQGLQJRQWKHÀDQJHPDWHULDOVZLWKZKLFKLWLVXVHG

To increase the lifespan of the collets it is recommended that they are

ÀLSSHGWKURXJKGHJUHHVRQWKHFROOHWKROGHUWKLVZLOOSURGXFHPRUH

HYHQZHDUDFURVVWKHIRXUULGJHVRQWKHRXWHUSUR¿OHRIWKHFROOHW

See section 6.3 for details on collet removal and replacement

It is important that the correct size of collet is used!

$QXQGHUVL]HGFROOHWFRXOGDOORZWKHFROOHWKROGHUWRSXOOWKURXJKLWVERUH

$QRYHUVL]HGFROOHWKDVWKHSRWHQWLDOWREHFRPHMDPPHGLQWKHEROWKROH

SECURE-GRI P HYDRAULIC FLANGE SPREADERS

OPERATOR I NSTRUCTI ON MANUAL PAGE 8

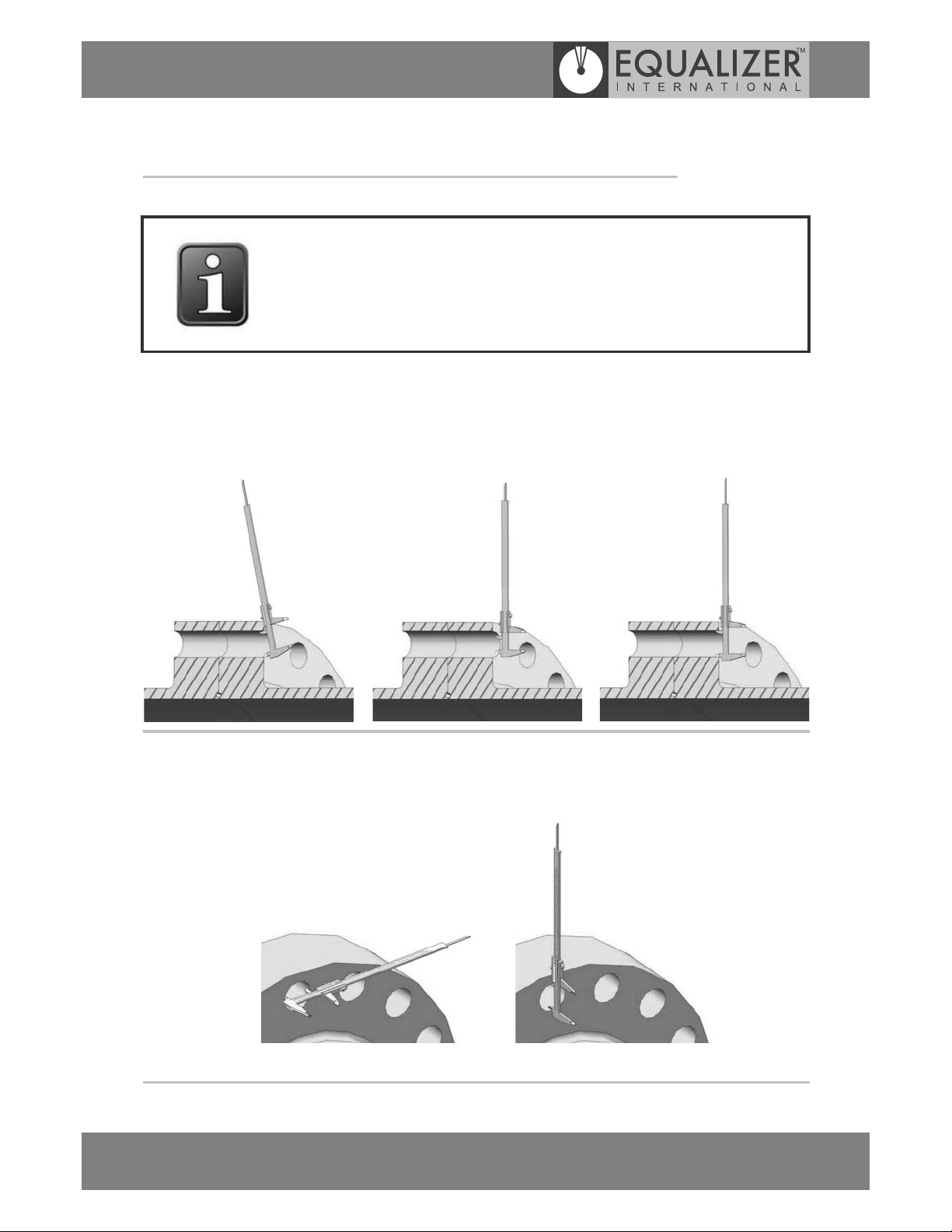

Note: I t is important that the vernier calliper is held in the middle of the

EROWKROHDQGQRWKHOGDWDQDQJOHWRWKHÀDQJHIDFHQRUXVHGRQDEROW

hole which is worn, damaged or distorted, as these actions may result in

the selection of an incorrect size of collet

6.2 COLLET SELECTION BASED ON BOLT-HOLE MEASUREMENT

1. To ensure a true measurement is taken, hold the vernier calliper:

VTXDUHWRWKHÀDQJHIDFH

LQWKHPLGGOHRIWKHEROWKROH

2. 7RGHWHUPLQHZKHWKHUWKHEROWKROHLVURXQGWDNHWZRVHSDUDWHPHDVXUHPHQWVZLWK

WKHYHUQLHUFDOOLSHUWXUQHGWKURXJKÛEHWZHHQPHDVXUHPHQWV

223

SECURE-GRI P HYDRAULIC FLANGE SPREADERS

OPERATOR I NSTRUCTI ON MANUAL PAGE 9

3. To read the measurement from the

vernier calliper, scan along the

desired scale from left to right. In

WKLVH[DPSOHWKHPDMRU¿JXUHLV

60mm, this is added to the minor

¿JXUHRIPPLQGLFDWHGE\ZKHUH

the vernier scale aligns with the

PDLQVFDOHJLYLQJDWRWDO

measurement of 68mm.

:LWKDEROWKROHVL]HRIPPWKH

operator can determine which

collet and tool is appropriate to this

ÀDQJHE\UHIHUULQJWRWKH6HFXUH

Grip Tool Range chart in section 11,

page 27. For example: 68mm falls

within the 63mm minimum and

PPPD[LPXPEROWKROHVL]HV

7KHUHIRUHFROOHWLGHQWL¿FDWLRQLV

0ò´DQGWKHWRROWREHXVHG

is the SG18TE.

4. If the measurement contains

fractions of a millimetre the

method of reading the vernier

calliper is slightly different. In this

H[DPSOHWKHPDMRU¿JXUHLVPP

UHDGLQWKHVDPHZD\DV

SUHYLRXVO\GHVFULEHG7KHPLQRU

¿JXUHLVPPUHDGWRWKHOHIWRI

WKH]HUR7KHIUDFWLRQLVPP

UHDGIURPZKHUHWKHYHUQLHUVFDOH

OLQHVXSZLWKWKHPDLQVFDOH

This gives a total measurement of

47.5mm.

MAJOR

FIGURE

MINOR

FIGURE

MAJOR

FIGURE

MINOR

FIGURE

FRACTI ON

SECURE-GRI P HYDRAULIC FLANGE SPREADERS

OPERATOR I NSTRUCTI ON MANUAL PAGE 10

6. Each tool in the Secure-Grip range comes with the appropriate sizes of collets for that

WRRO,IWKHFROOHWODEHOOLQJLVZRUQRUPLVVLQJWKHQWKHFROOHWFDQEHPHDVXUHGWR

HQVXUHWKDWWKHFRUUHFWVL]HLVVHOHFWHG$QDFFXUDWHPHDVXUPHQWFDQRQO\EH

REWDLQHGZLWKWKHFROOHWPRXQWHGRQWKHFROOHWKROGHU7RGRWKLV

UHPRYHWKHFROOHWKHDGDVVHPEO\IURPWKHWRRODQGGLVDVVHPEOHVHHVHFWLRQ

SDJHIRUGHWDLOV

- slide the collet over the collet holder

- measure the centre section of the collet with the vernier calliper

LGHQWLI\WKHFROOHWXVLQJWKHFKDUWEHORZDQGVHOHFWWKHFRUUHFWVL]HIRUWKHÀDQJH

Centre

section Ø

Collet type Min.

bolt-hole Ø

Max.

bolt-hole Ø

Metric coarse

bolt

UNC bolt

36mm M39 1 ½ ” 38mm 42mm M39 ò´

39mm 0ƙ´ 41mm 45mm M42 ƙ´

40.5mm M45 1 ¾ ” 44mm 49mm M45 ô´

44.5mm 0ƚ´ 47.5mm 52mm M48 ƚ´

47.5mm M52 2” 50.5mm 56mm M52 ´

52.5mm M56 2 ¼ ” 55.5mm 62mm M56 ó´

SECURE-GRI P HYDRAULIC FLANGE SPREADERS

OPERATOR I NSTRUCTI ON MANUAL PAGE 11

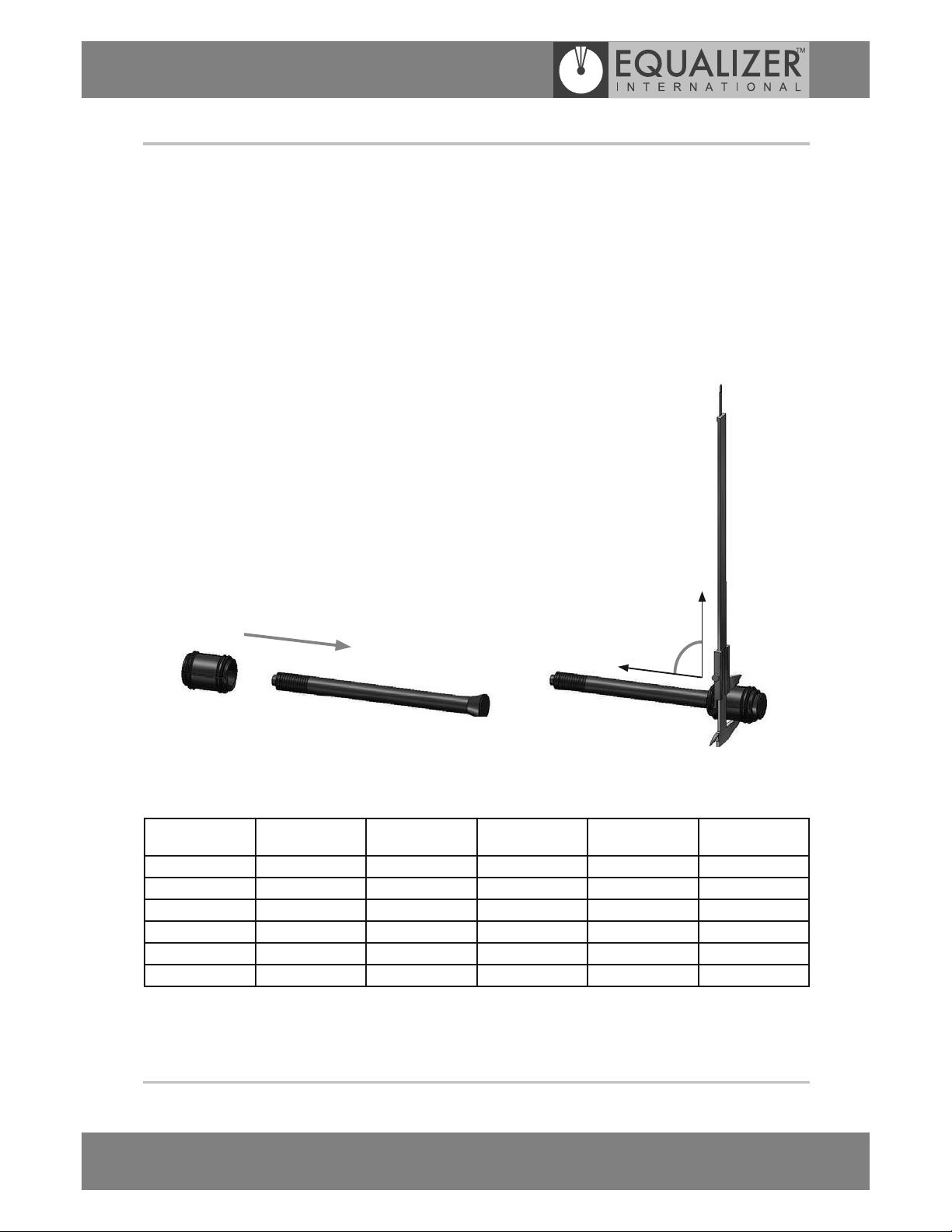

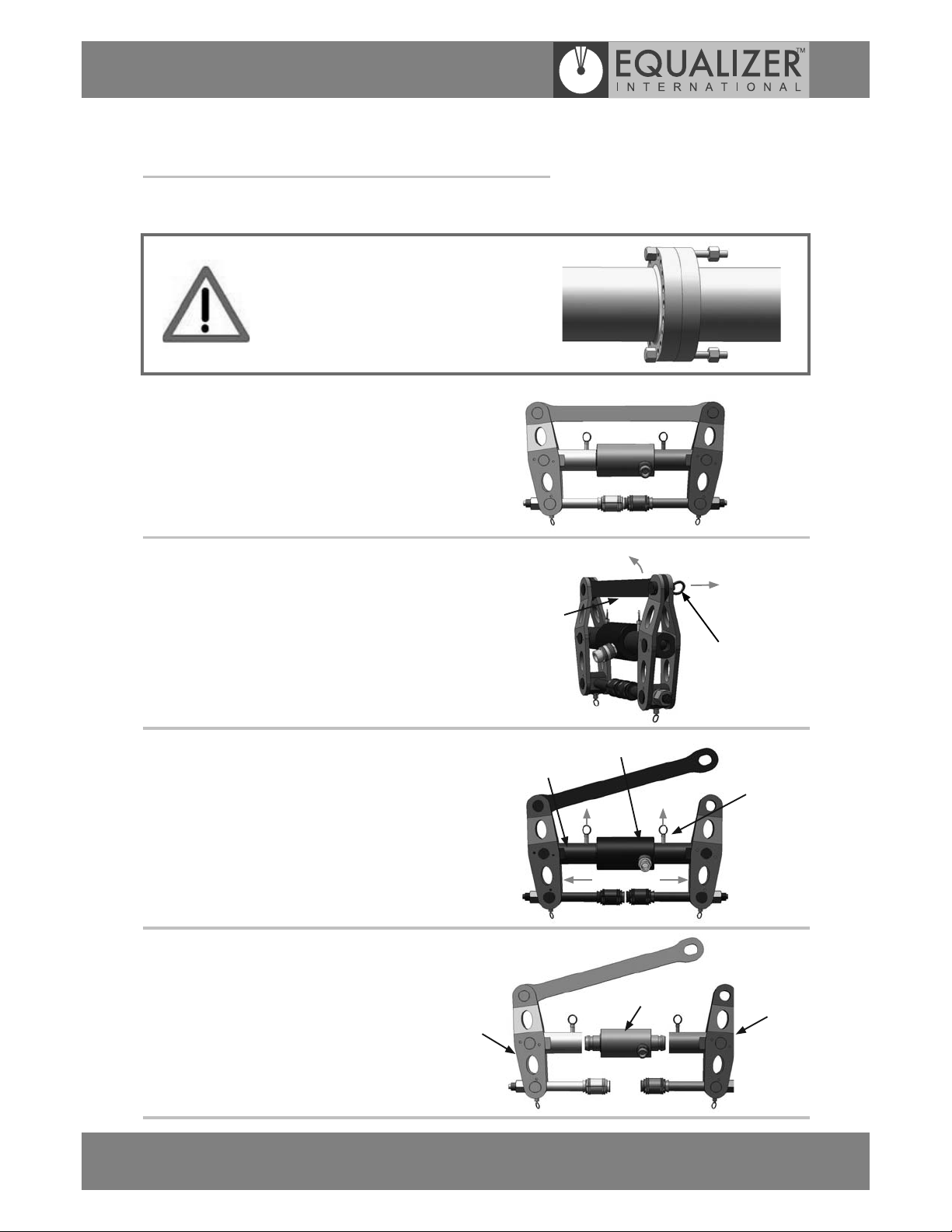

6.3 COLLET REMOVAL AND REPLACEMENT

2QFHWKHFRUUHFWFROOHWKDVEHHQVHOHFWHGLWPD\EHQHFHVVDU\WRFKDQJHWKHFROOHWRQWKHWRRO

1. Place the tool on its side on a work

EHQFKRUÀDWVXUIDFHDQGXQVFUHZ

and remove the drive nut

2. Pull the collet spring plunger ring

out, and remove the collet head

DVVHPEO\IURPWKHWRRO

3. 6OLSWKHGULYHWXEH

and drive cone off the collet

holder

4. Remove the collet from the collet

holder and replace it with the

FRUUHFWFROOHWIRUWKHÀDQJHWREH

separated

5. 5HYHUVHWKHDERYHSURFHGXUHWRUH

DVVHPEOHWKHWRRO

&DUHVKRXOGEHWDNHQWRHQVXUHWKH

slot in the collet holder is aligned

with the collet spring plunger

DRIVE

NUT

COLLET SPRI NG

PLUNGER RING

DRIVE TUBE

COLLET

HOLDER

DRIVE CONE

COLLET

SECURE-GRI P HYDRAULIC FLANGE SPREADERS

OPERATOR I NSTRUCTI ON MANUAL PAGE 12

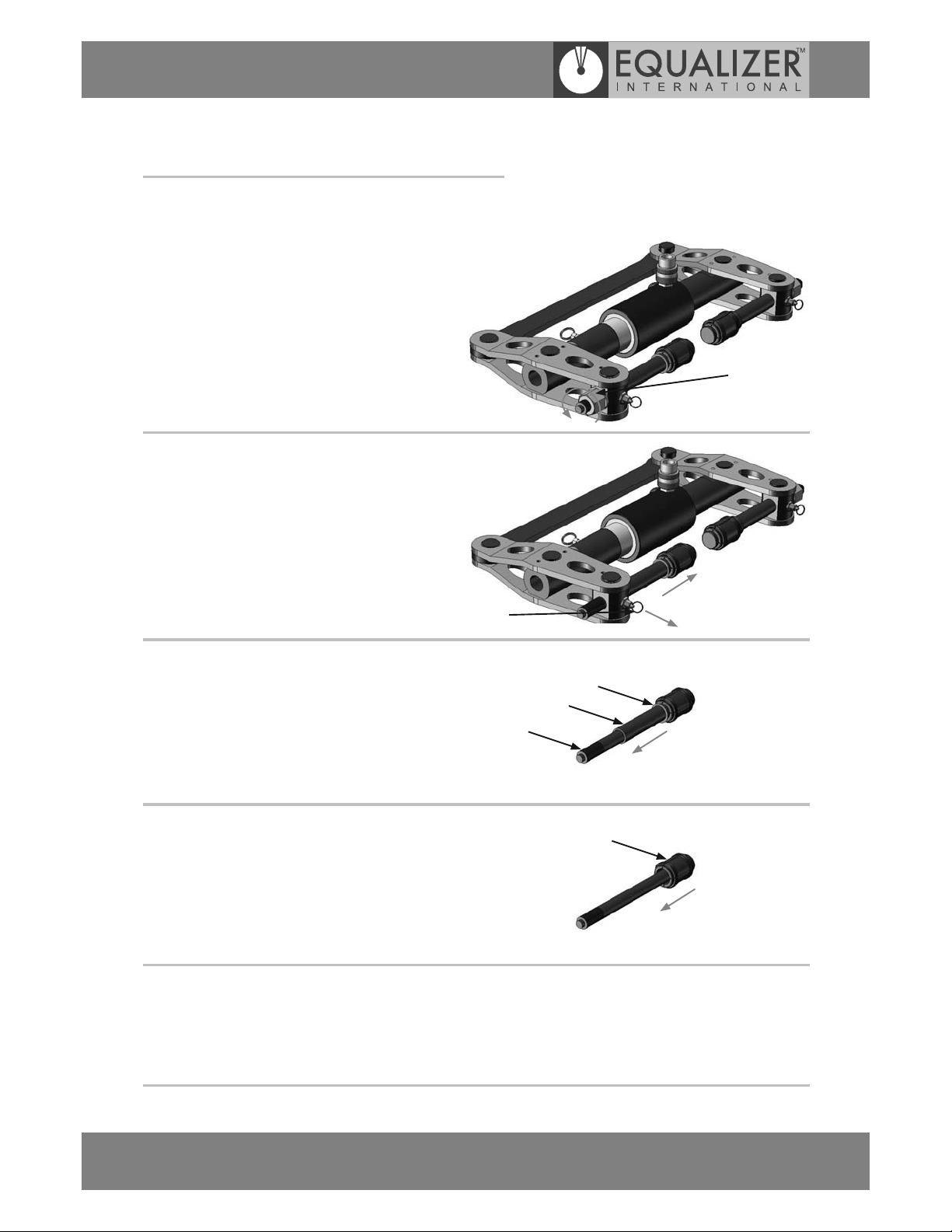

6.4 STANDARD INSTALLATI ON AND OPERATION

2QFHWKHFRUUHFWFROOHWKDVEHHQVHOHFWHGDQGPRXQWHGWRRORSHUDWLRQFDQFRPPHQFH

1. %HIRUHLQVWDOODWLRQFDQEHJLQWKH

WRROPXVWEHGLVPDQWOHGLQWRWKUHH

parts

2. /D\WKHWRRORQDÀDWVXUIDFH

Pull the cantilever pin out and rotate

the cantilever out of position.

3. Pull on the left hand actuator spring

plunger and pull the actuator from

the actuator to leg connector.

Repeat this on the right hand side

4. 7KHWRROVKRXOGQRZEHLQWKUHH

parts - two halves and the actuator

ACTUATOR

SPRING

PLUNGER

ACTUATOR

TO LEG

CONNECTOR

ACTUATOR

CANTI LEVER

CANTI LEVER

PI N

TOOL HALF

2

TOOL HALF

1

ACTUATOR

Before attaching the tool ensure at least

WZRÀDQJHEROWVUHPDLQLQSODFH

degrees apart with nuts loosened

VXI¿FLHQWO\HQRXJKIRUÀDQJHZRUNWR

EHFDUULHGRXW7KHVHEROWVZLOOUHGXFH

ODWHUDOÀDQJHPRYHPHQWGXULQJÀDQJH

spreading.

SECURE-GRI P HYDRAULIC FLANGE SPREADERS

OPERATOR I NSTRUCTI ON MANUAL PAGE 13

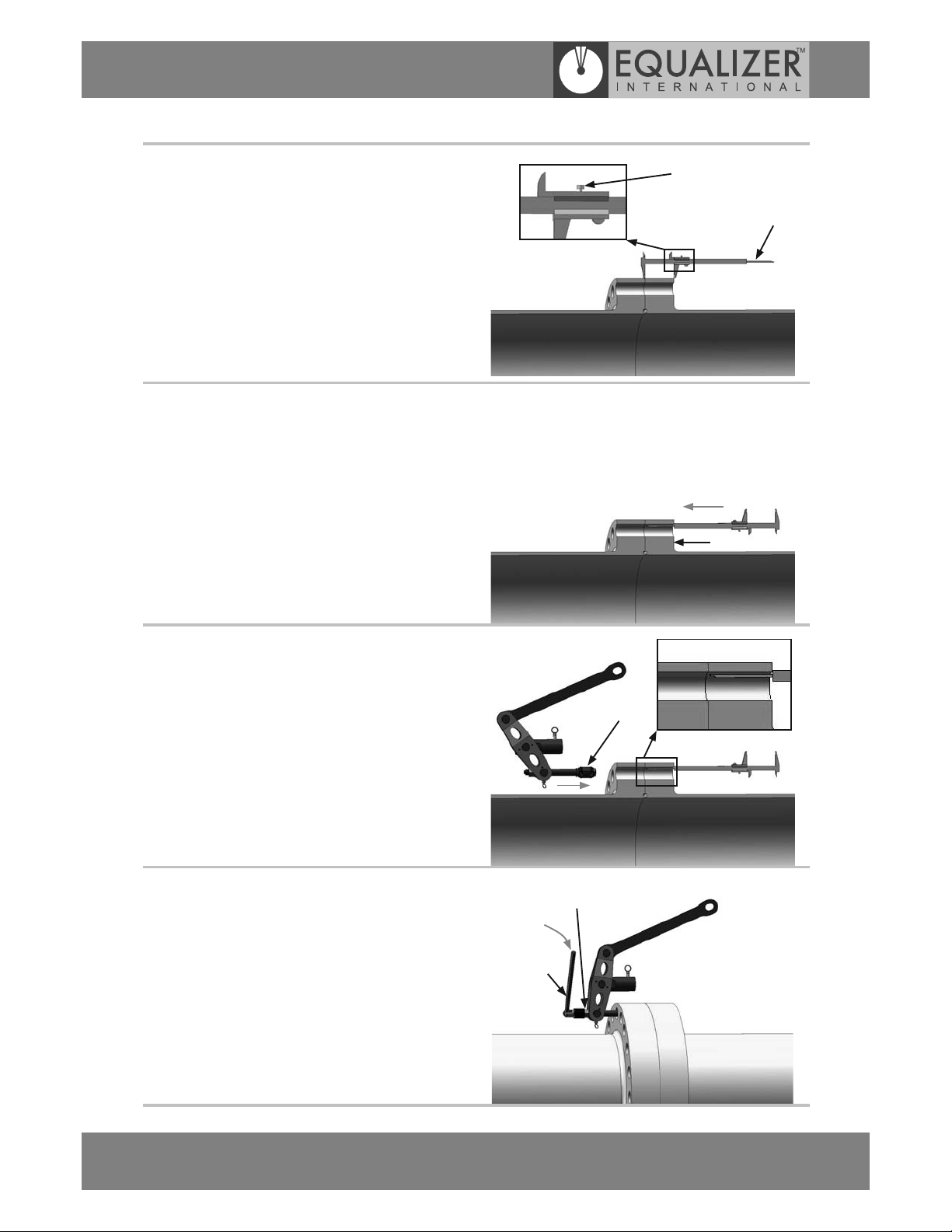

5. 0HDVXUHWKHWKLFNQHVVRIWKHÀDQJH

using the vernier calliper

provided. Lock the calliper in

SRVLWLRQE\WLJKWHQLQJWKHORFNLQJ

screw

6. 6HOHFWDVXLWDEOHEROWKROHLQZKLFK

to attach the tool.

Insert the depth gauge part of the

YHUQLHUFDOOLSHULQWRWKHEROWKROH

NHHSLQJWKHEDVHRIWKHFDOOLSHU

ÀXVKZLWKWKHEROWLQJIDFHRIWKH

ÀDQJH

7. ,QVHUWWKHFROOHWRQWKH¿UVWKDOIRI

the tool into the the opposite end of

WKHVDPHEROWKROHXQWLOLWWRXFKHV

WKHHQGRIWKHGHSWKJDXJHVR

that the collet is fully through one

ÀDQJHEXWQRWHQWHULQJWKHRWKHU

8. Tighten the drive nut with the

ò´VTXDUHGULYHÀH[LEOHKDQGOH

7KH¿UVWKDOIRIWKHWRROZLOOQRZ

KDYHDVHFXUHKROGLQWKHEROWKROH

LOCKING

SCREW

DEPTH

GAUGE

BOLTING FACE

COLLET

´648$5(

DRIVE FLEXI BLE

HANDLE

DRIVE

NUT

SECURE-GRI P HYDRAULIC FLANGE SPREADERS

OPERATOR I NSTRUCTI ON MANUAL PAGE 14

9. Insert the collet on the second half

RIWKHWRROLQWRWKHEROWKROHXQWLOLW

WRXFKHVWKHFROOHWRQWKH¿UVWKDOIRI

the tool, and tighten the drive nut

XVLQJWKHò´VTXDUHGULYHÀH[LEOH

handle. The second half of the tool

will now have a secure hold in the

EROWKROH

10. Insert one side of the actuator into

each ‘actuator to leg connector’.

2QERWKVLGHVSXVKWKHDFWXDWRU

until you feel the actuator spring

plunger click.

11. Rotate the cantilever into position,

DQGVHFXUHE\VOLGLQJWKH

FDQWLOHYHUSLQWKURXJKWKHKROH

at the top of the leg and the hole

LQWKHFDQWLOHYHUXQWLOIXOO\KRPH

ACTUATOR

ACTUATOR

TO LEG

CONNECTOR

ACTUATOR

SPRING

PLUNGER

CANTI LEVER

CANTI LEVER

PI N

LEG

SECURE-GRI P HYDRAULIC FLANGE SPREADERS

OPERATOR I NSTRUCTI ON MANUAL PAGE 15

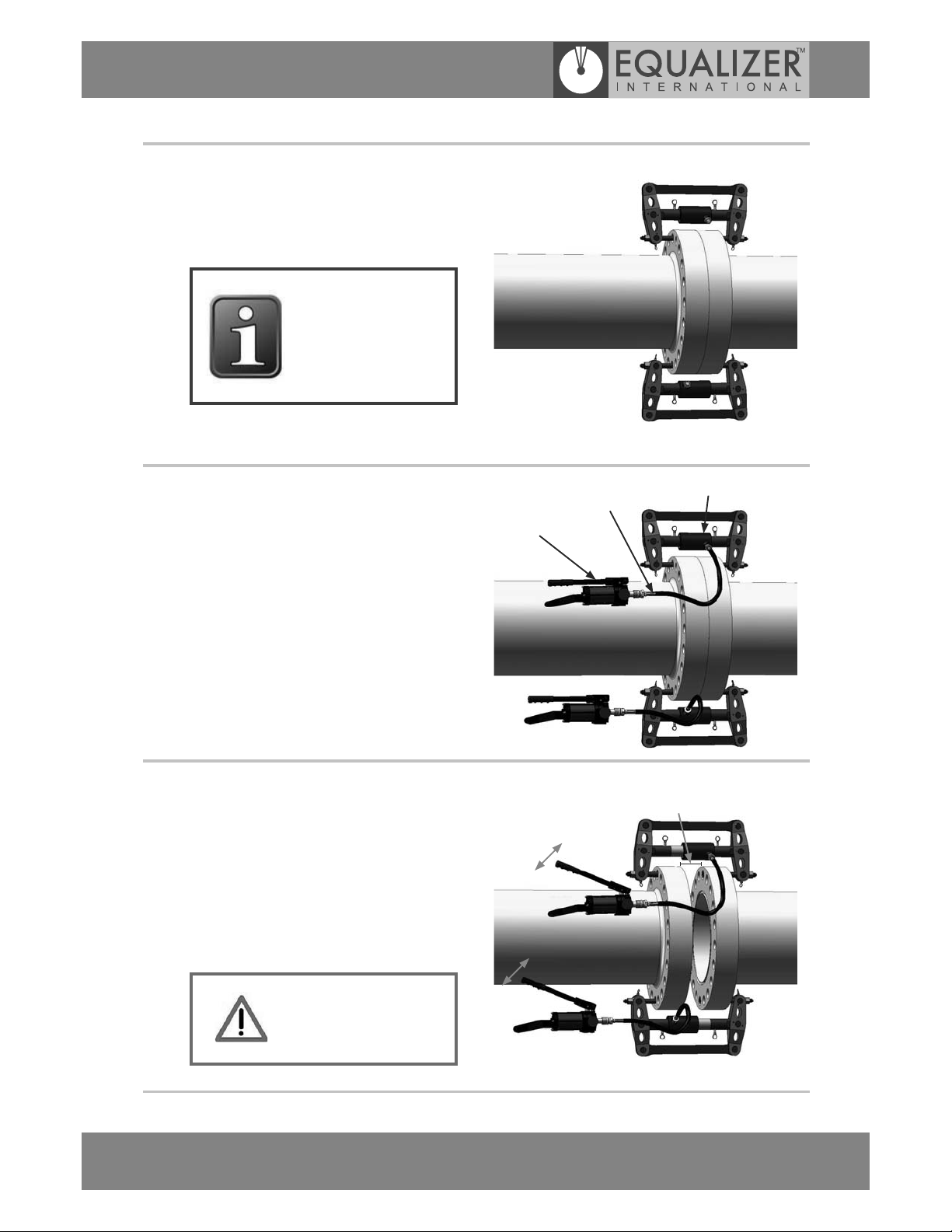

12. 6HOHFWWKHEROWKROHRSSRVLWH

the tool you have just attached and

repeat steps 2 to 7 for the second

tool

13. Connect the hand pumps to the

hydraulic hoses, and the

hydraulic hoses to the actuators

on each tool. Ensure that all

couplers are fully hand tightened

and the release valves are closed

hand tight

14. )ODQJHVSUHDGLQJFDQQRZEHJLQ

*LYHWKH¿UVWWRROIRXUVWURNHVRQ

the hand pump, then give the

VDPHWRWKHVHFRQG$VWKHÀDQJH

is separating, measure the gap

DWERWKWRROVDQGLIQHFHVVDU\

DGMXVWWKHQXPEHURIVWURNHVRQ

RQHVLGHWRHQVXUHWKHÀDQJHIDFHV

are kept parallel.

Note: I f more than

WZRWRROVDUHEHLQJ

XVHGWKH\VKRXOGEH

attached at an equal

spacing around the

ÀDQJHMRLQW

HAND PUMP

HYDRAULIC

HOSE

ACTUATOR

MEASURE

DISTANCE

x 4

x 4

WARNI NG: Never

SODFH¿QJHUVLQD

MRLQWKHOGE\DQ

activated tool

SECURE-GRI P HYDRAULIC FLANGE SPREADERS

OPERATOR I NSTRUCTI ON MANUAL PAGE 16

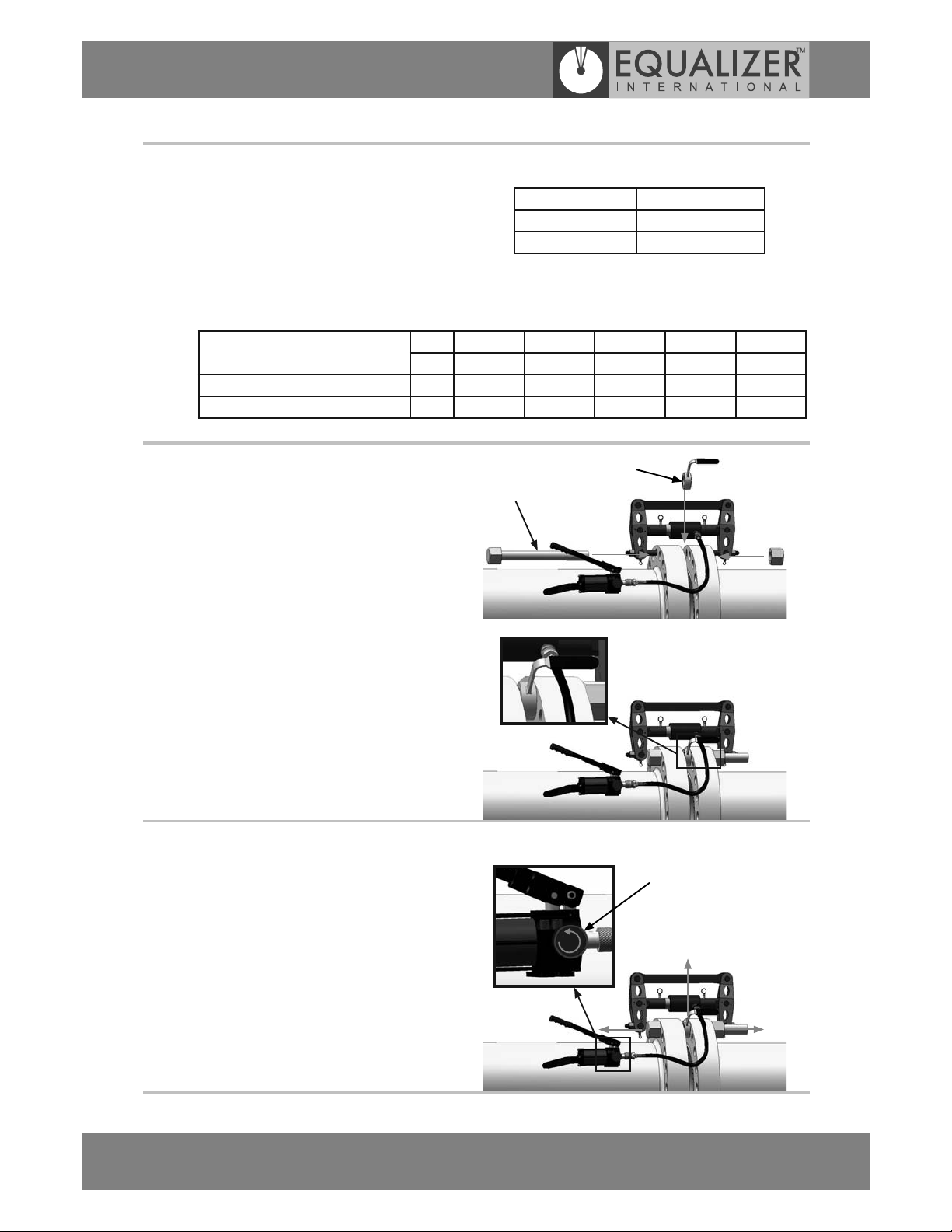

15. &RQWLQXHVSUHDGLQJWKHÀDQJHXQWLO

the access gap required is achieved,

or until the maximum pressure or

WRROWUDYHOKDVEHHQUHDFKHG

,IWKHÀDQJHGRHVQRWVSUHDGUHIHU

to section 10

16. 2QFHWKHÀDQJHKDVEHHQVHSDUDWHG

and prior to any maintenance

ZRUNVWKHVDIHW\EORFNVPXVWEH

LQVHUWHGEHWZHHQWKHÀDQJHV

7KHVHDUHKHOGLQSRVLWLRQE\

UHSODFLQJWZRRIWKHÀDQJHEROWV

17. Following any maintenance works

DQGSULRUWRFORVLQJWKHÀDQJHMRLQW

WKHVDIHW\EORFNPXVWEHUHPRYHG

The release valves on the hand

SXPSVVKRXOGQRZEHWXUQHGDQWL

clockwise gently and evenly,

adjusting as necessary to keep the

ÀDQJHVSDUDOOHOXQWLOWKHÀDQJHLV

fully closed and there is no load on

WKHWRROV7KHWRROVFDQWKHQEH

UHPRYHGE\UHYHUVLQJWKH

LQVWDOODWLRQSURFHGXUHVWHSV

Tool type Max. distance

SG13TE PP´

SG15TE PP´

MAX.

Pressure Bar 138 276 414 552 690

psi 2000 4000 6000 8000 10,000

SG13TE spreading force T 2.6 5.2 7.8 10.4 13

SG15TE spreading force T3691215

FLANGE

BOLT

SAFETY

BLOCK

RELEASE

VALVE

SECURE-GRI P HYDRAULIC FLANGE SPREADERS

OPERATOR I NSTRUCTI ON MANUAL PAGE 17

6.5 RESTRI CTED ACCESS I NSTALLATI ON AND OPERATION

7KH6HFXUH*ULSK\GUDXOLFWRROVDUHDOVRLGHDOIRUXVHZKHUHDFFHVVWRWKHÀDQJHLVUHVWULFWHG$V

LQWKHVWDQGDUGRSHUDWLRQWZRWRROVVKRXOGEHXVHGLQRUGHUWRDYRLGÀDQJHGLVWRUWLRQZLWKWKH

WRROVSRVLWLRQHGIURPHDFKRWKHURQWKHÀDQJH

%HIRUHEHJLQQLQJWKHIROORZLQJSURFHGXUHFRPSOHWHVWHSVRIWKHVWDQGDUGLQVWDOODWLRQ

SURFHGXUHVHHVHFWLRQSDJHV

1. On one half of the tool unscrew and

remove the drive nut. Pull the

collet spring plunger ring out,

and remove the collet head

DVVHPEO\IURPWKHWRRO

2. 3DVVWKHFROOHWKHDGDVVHPEO\

WKURXJKERWKEROWKROHVIURPWKH

open access side

3. 5H¿WWKHWRROKDOIRQWRWKHFROOHW

holder

4. 5H¿WWKHGULYHQXW

5. 0HDVXUHWKHWKLFNQHVVRIWKHÀDQJH

with the vernier calliper provided

and using the vernier calliper as a

depth gauge, adjust the position of

the collet until it touches the end

RIWKHGHSWKJDXJHVRWKDWWKH

FROOHWLVIXOO\WKURXJKRQHÀDQJH

EXWQRWHQWHULQJWKHRWKHU

7KHSURFHGXUHFDQQRZEHFRPSOHWHGE\IROORZLQJVWHSVRIWKHVWDQGDUGLQVWDOODWLRQ

SURFHGXUHVHHVHFWLRQSDJHV

DRIVE

NUT

COLLET HEAD

ASSEMBLY

COLLET

SPRING

PLUNGER

VERNIER

CALLIPER

RESTRICTED

ACCESS

SECURE-GRI P HYDRAULIC FLANGE SPREADERS

OPERATOR I NSTRUCTI ON MANUAL PAGE 18

6.6 VALVE,SPADE OR BLIND REMOVAL, I NSTALLATION AND OPERATI ON

7KH6HFXUH*ULSK\GUDXOLFWRROVDUHDOVRLGHDOIRUWKHUHPRYDODQGLQVHUWLRQRIEOLQGVVSDGHVDQG

valves. Equalizer I nternational can supply a short collet holder kit that will increase the relative

stroke of the tool.

1. please refer to section 6.3 notes

1-4 for instruction on how to

remove the standard collet holder

DQGGULYHWXEH7KHVHDUHWKHQ

replaced with the short collet

KROGHUVDQGVKRUWGULYHWXEHZLWK

the appropriate collet.

2. Please follow section 6.4 for

instruction on how to attach and

activated the secure-grip hydraulic

tool.

SHORT COLLET

HOLDERS AND DRIVE

TUBE

TOOL collet holder C min C Max

SG13TE standard PP´ PP´

SG13TE short PP´ PP´

SG15TE standard PP´ PP´

SG15TE short PP´ PP´

C

Other manuals for SG13TE

1

This manual suits for next models

1

Table of contents

Other Equalizer International Spreader manuals