Equalizer SG4TM User manual

Document Number: IM_SGM

Document Revision: 07

Document Revision Date: 14-DEC-2021

Document Language: English EN

Operation and Maintenance Manual

Secure-Grip Mechanical Flange Spreaders

SG4TM / SG6TM / SG11TM

To reduce the risk of injury, users must read and understand this document

before use.

IM_SGM_07 1

Contents

1. SAFETY ..................................................................................................................... 2

1.1 SAFETY PRECAUTIONS .................................................................................. 2

2. COMPLIANCE STATEMENT(S) ................................................................................ 4

3. FEATURES & COMPONENTS.................................................................................. 4

3.1 SG4TM, SG6TM, SG11TM FEATURES DIAGRAM .......................................... 4

3.2 SG4TM, SG6TM, SG11TM CAPABILITIES AND KIT CONTENTS .................. 5

4. TECHNICAL PRODUCT DATA ................................................................................. 8

4.1 SG4TM / SG6TM / SG11TM DIMENSIONS ..................................................... 8

4.2 SECURE GRIP FLANGE PULLER SPECIFICATIONS TABLE ......................... 9

5. OPERATION ............................................................................................................ 10

5.1 INITIAL SETUP AND INSPECTION ................................................................ 10

5.2 COLLET SELECTION ...................................................................................... 10

5.3 BOLT HOLE MEASUREMENT ........................................................................ 11

5.4 COLLET REPLACEMENT ............................................................................... 13

5.5 COLLET LEG SUB-ASSEMBLY - INSTALLATION ......................................... 13

5.6 TOOL INSTALLATION AND OPERATION...................................................... 14

6. STORAGE ................................................................................................................ 21

6.1 RECOMMENDED STORAGE .......................................................................... 21

6.2 LONG-TERM STORAGE - MAINTENANCE PLAN ......................................... 21

7. MAINTENANCE ...................................................................................................... 22

7.1 GENERAL MAINTENANCE............................................................................. 22

7.2 SG4TM/ SG6TM/ SG11TM DISASSEMBLY AND SERVICING...................... 22

8. PARTS LIST............................................................................................................. 24

9. TROUBLESHOOTING............................................................................................. 42

ANNEX 1 - SECURE GRIP TOOL RANGE OF APPLICATION ................................... 46

2IM_SGM_07

1. Safety

Indicates a hazardous

situation that, if not avoided, will result in

death or serious personal injury.

Indicates a hazardous

situation that, if not avoided, could result in

death or serious personal injury.

Indicates a hazardous

situation that, if not avoided, could result in

minor or moderate personal injury.

Indicates information

considered important, but not hazard

related (e.g. messages related to property

damage). Please note that the Safety Alert

Symbol will not be used with the signal

word.

DO: an illustration showing how the

tool should be used.

DON’T: an illustration showing an

incorrect way to use a tool.

1.1 Safety Precautions

Failure to observe and comply with the

following precautions could result in

death or serious personal injury. Property

damage could also occur.

• Read and completely understand the

safety precautions and instructions in this

manual before operating the SGM tools

or preparing them for use. Always follow

all safety precautions and instructions,

including those that are contained within

the procedures of this manual.

DANGER

WARNING

CAUTION

NOTICE

WARNING

Read all instructions carefully. Follow all

recommended safety precautions to avoid

personal injury as well as damage to the

product and / or damage to other property.

Equalizer cannot be responsible for any

damage or injury from unsafe use, lack of

maintenance, or incorrect operation. Do not

remove warning labels, tags, or decals. In

the event that any questions or concerns

arise, contact Equalizer or a local Equalizer

distributor for clarification.

Save these instructions for future use.

If you have never been trained on high-

pressure hydraulic safety, consult your

distributor or service center for information

about Equalizer Hydraulic Safety Courses.

This manual follows a system of safety

alert symbols, signals, words, and safety

messages to warn the user of specific

hazards. Failure to comply with these

warnings could result in death or serious

personal injury, as well as damage to the

equipment or other property.

The Safety Alert Symbol appears throughout

this manual. It is used to alert

you to potential physical injury

hazards. Pay close attention to

Safety Alert Symbols and obey

all safety messages that follow this symbol

to avoid the possibility of death or serious

injury.

Safety Alert Symbols are used in conjunction

with certain Signal Words that call attention

to safety messages or property damage

messages and designate a degree or level of

hazard seriousness. The Signal Words used

in this manual are DANGER, WARNING,

CAUTION, and NOTICE.

IM_SGM_07 3

• Be sure the operator has completed

safety induction training, specific to the

work surroundings. The operator should

be thoroughly familiar with the controls

and the proper use of the tool.

• Wear personal protective gear when

operating hydraulic equipment. Always

wear eye protection. Safety equipment

such as dust mask, non-skid safety

shoes, hard hats, gloves, or hearing

protection (used as appropriate) will

reduce personal injuries. The protective

clothing must not interfere with safe

operation of the tool or restrict the ability

to communicate with co-workers.

• Operatingprocedureswillvary,depending

on the system arrangement. Always

read, follow, and completely understand

all manufacturers’ instructions when

operating pumps, valves and all other

devices used with the SGM tools. Follow

all safety precautions contained in the

manufacturer’s manuals. Use only for

intended purpose.

• To minimize risk of personal injury, keep

hands and feet away from the tool and

workpiece during operation.

• Do not overload equipment.

• Immediately replace worn or damaged

parts. Use only genuine Equalizer parts

from approved distributors or service

centers. Equalizer parts have been

engineered and manufactured to be fit-

for-purpose.

• Use only a high-quality non-flammable

solvent for cleaning and degreasing

parts during wrench repair procedures.

To reduce the risk of fire or explosion, do

not use flammable solvents.

• Care should be taken when using the

lanyard to avoid entanglement with body

parts.

Failure to observe and comply with

the following precautions could result

in minor or moderate personal injury.

Property damage could also occur.

• Ensure components are protected from

external sources of damage, such as

excessive heat, flame, moving machine

parts, sharp edges, and corrosive

chemicals.

• Lubricate tools as directed in this manual

prior to operation. Use only approved

lubricants of high quality, following the

lubricant manufacturer’s instructions.

• Only use the designated anchor point

for fixing the lanyard. Do not attach the

lanyard to the plastic handle.

Failure to observe and comply with the

following precautions could result in

property damage and/or void the product

warranty.

• Always use Equalizer replacement parts.

• Always follow the inspection and

maintenance instructions contained in

this manual. Perform inspection and

maintenance after use, and at regular

intervals.

• Rope off working area and place warning

signs.

• To help ensure proper operation and

best performance, use of Equalizer oil is

strongly recommended

CAUTION

NOTICE

4IM_SGM_07

EU Declaration of Incorporation

These tools conform with the

requirements for CE.

•SG4TM •SG6TM •SG11TM

2. Compliance Statement(s)

Equalizer declares that this/ these product(s)

has/ have been tested and conforms to

applicable standards and is compatible to

all CE Requirements.

A copy of an EU Declaration of Incorporation

is enclosed with each shipment of this

product.

3. Features & Components

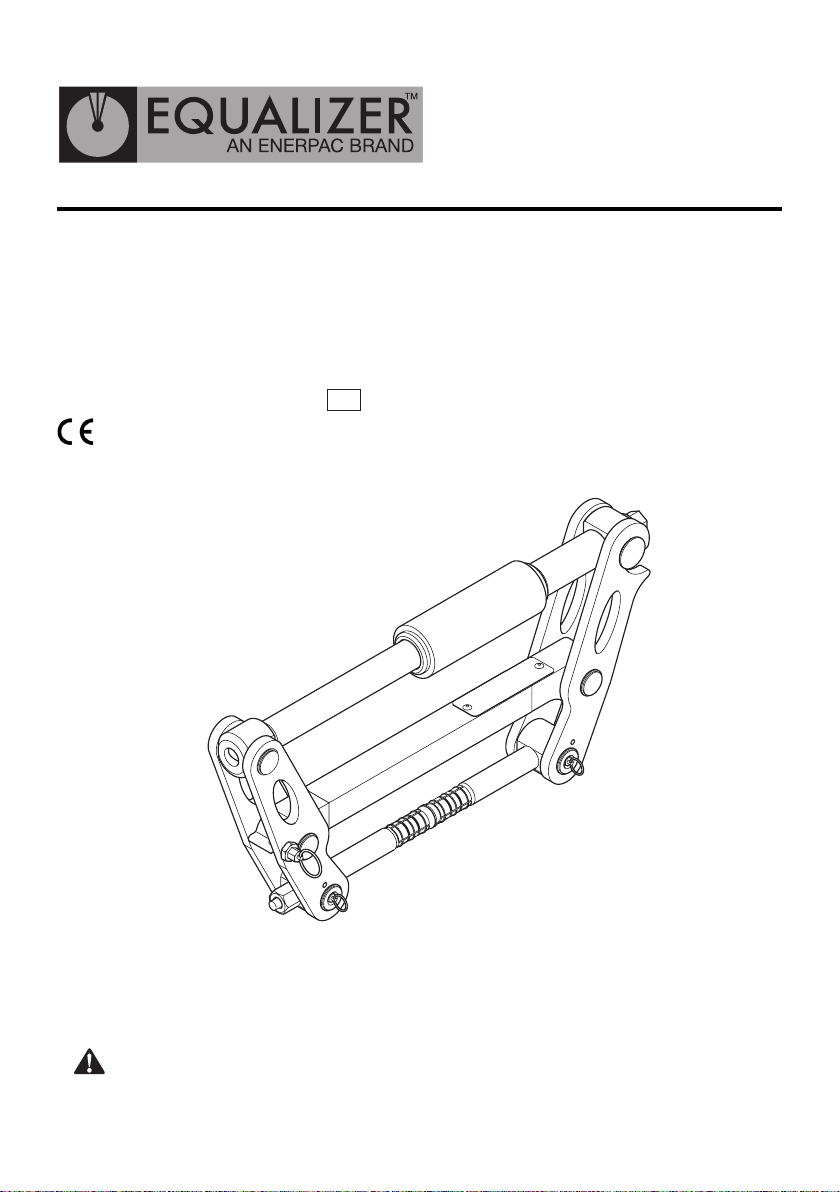

3.1 SG4TM, SG6TM, SG11TM Features Diagram

3

2

4

5

1

6

7

1. Actuator Assembly

2. Collet Holder Assembly

3. Leg Assemblies

4. Cantilever + Pins

5. Spring Plunger

6. Drive Nut

7. Spring Plunger

IM_SGM_07 5

3.2 SG4TM, SG6TM, SG11TM

Capabilities and Kit Contents

3.2.1 SG4TM Tool Capabilities and

Kit Contents

Spreading Force:

With the maximum torque of 47 N·m

[35 ft·lb] applied, each SG4TM can apply

3.7T [37kN] spreading force.

It is recommended that tools are used in

pairs positioned 180° apart, giving 2 x 3.7T

= 7.4T [74kN].

The spreading force can be determined by

pre-setting the torque wrench. The torque

wrench settings will produce a spreading

force as set out below.

Torque Wrench

Setting Spreading Force

27N·m [20ft·lb] 2.2T [22kN]

34N·m [25ft·lb] 2.5T [25kN]

41N·m [30ft·lb] 3.3T [33kN]

Max. 47N·m [35ft·lb] 3.7T [37kN]

Spreading Distance:

0mm - 75mm [0"-2.95"]

3.2.2 SG4TM Kit Contents

Product Code: SG4TMSTD

1 x SG4TM Tool

1 x 150mm [6"] Vernier Calliper

1 x 3/8" Drive Torque Wrench and 16mm

Socket

1 x Safety Block

2 x M16 [5/8"] Collets

2 x M20 [3/4"] Collets

1 x Instruction Manual

1 x Carry-Case with foam inserts

Carry-Case Dimensions:

520mm x 375mm x 165mm

[20.5" x 14.8" x 6.5"]

Gross Kit Weight: 12.8kg [28.2lb]

Tool only weight: 4.5kg [9.9lb]

6IM_SGM_07

3.2.3 SG6TM Tool Capabilities and

Kit Contents

Spreading Force:

With the maximum torque of 108 N·m

[80 ft·lb] applied, each SG6TM can apply

6T [60kN] spreading force.

It is recommended that tools are used in

pairs positioned 180° apart, giving 2 x 6T

= 12T [120kN].

The spreading force can be determined by

pre-setting the torque wrench. The torque

wrench settings will produce a spreading

force as set out below.

Torque Wrench

Setting Spreading Force

54N·m [40ft·lb] 2.8T [28kN]

67N·m [50ft·lb] 3.5T [35kN]

81N·m [60ft·lb] 4.5T [45kN]

95N·m [70ft·lb] 5T [50kN]

Max. 108N·m [80ft·lb] 6T [60kN]

Spreading Distance:

0mm - 80mm [0"-3.15"]

3.2.4 SG6TM Kit Contents

Product Code: SG6TMSTD

1 x SG6TM Tool

1 x 150mm [6"] Vernier Calliper

1 x 3/8" Drive Torque Wrench and 21mm

Socket

1 x Safety Block

2 x M24 [7/8"] Collets

2 x M27 [1"] Collets

1 x Instruction Manual

1 x Carry-Case with foam inserts

Carry-Case Dimensions:

640mm x 540mm x 165mm

[25.2" x 21.3" x 6.5"]

Gross Kit Weight: 16.0kg [35.3lb]

Tool only weight: 7.5kg [16.5lb]

IM_SGM_07 7

3.2.5 SG11TM Tool Capabilities and

Kit Contents

Spreading Force:

With the maximum torque of 120 N·m

[89ft·lb] applied, each SG11TM can apply

11T [110kN] spreading force.

It is recommended that tools are used in

pairs positioned 180° apart, giving 2 x 11T

= 22T [220kN].

The spreading force can be determined by

pre-setting the torque wrench. The torque

wrench settings will produce a spreading

force as set out below.

Torque Wrench

Setting

Spreading

Force

40N·m [30ft·lb] 3.7T [37kN]

60N·m [44ft·lb] 5.5T [55kN]

80N·m [59ft·lb] 7.4T [74kN]

100N·m [74ft·lb] 9.2T [92kN]

Max. 120N·m [89ft·lb] 11T [110kN]

Spreading Distance:

0mm - 90mm [0"-3.54"]

3.2.6 SG11TM Kit Contents

Product Code: SG11TMSTD

1 x SG11TM Tool

1 x 150mm [6"] Vernier Calliper

1 x 1/2" Drive Torque Wrench and 24mm

Socket

1 x Safety Block

2 x M30 [11/8"] Collets

2 x M33 [11/4"] Collets

2 x M36 [13/8"] Collets

1 x Instruction Manual

1 x Carry-Case with foam inserts

Carry-Case Dimensions:

640mm x 540mm x 165mm

[25.2" x 21.3" x 6.5"]

Gross Kit Weight: 20.0kg [44.1lb]

Tool only weight: 10.5kg [23.1lb]

8IM_SGM_07

4. Technical Product Data

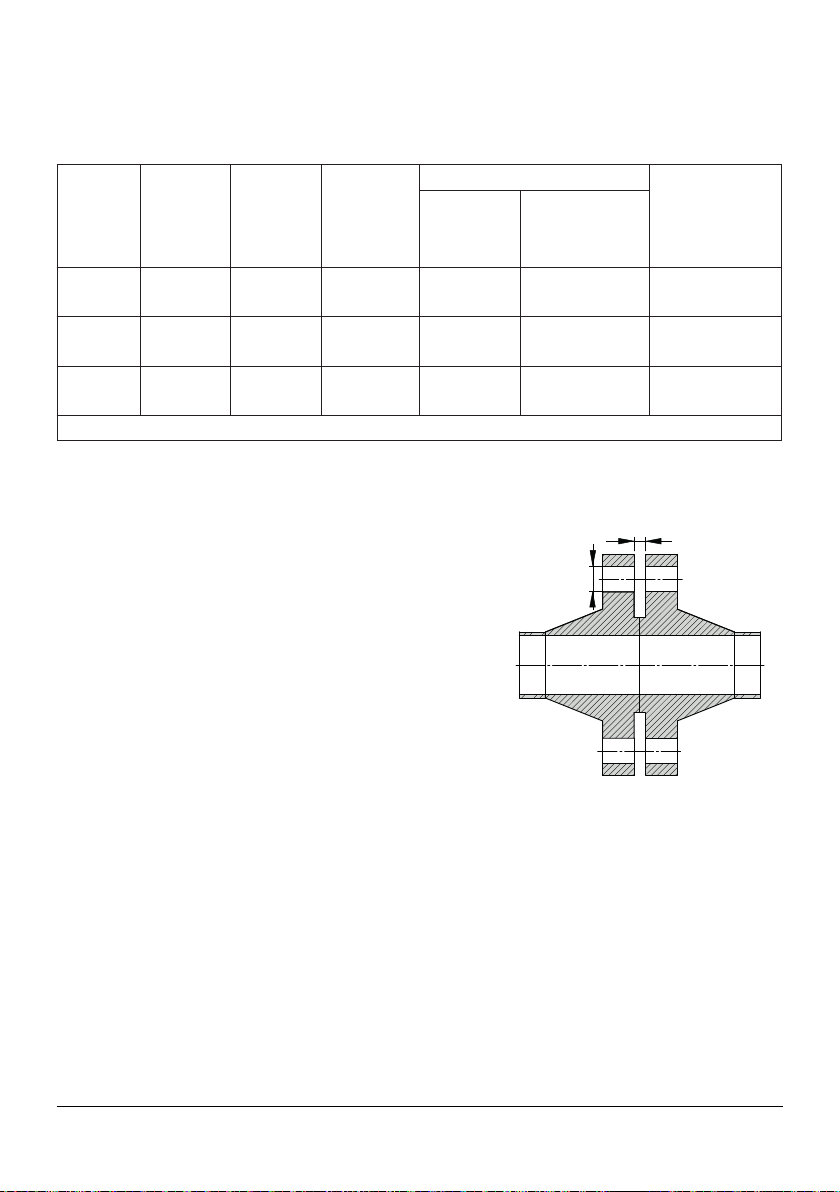

4.1 SG4TM / SG6TM / SG11TM Dimensions

Tool Dimensions Closed

Tool Dimensions Open

Tool Dimensions Table

TOOL SG4TM SG6TM SG11TM

A398mm [15.67"] 468mm [18.42"] 516mm [20.31"]

B 190mm [7.48"] 245mm [9.65"] 250mm [9.84"]

C 182mm [7.2"] 252mm [9.92"] 263mm [10.35"]

D 75mm [2.95"] 80mm [3.15"] 90mm [3.55"]

E 385mm [15.16"] 444mm [17.48"] 462mm [18.2"]

F 48mm [1.89"] 52mm [2.05"] 60mm [2.36"]

B

A

D

E

C

F

IM_SGM_07 9

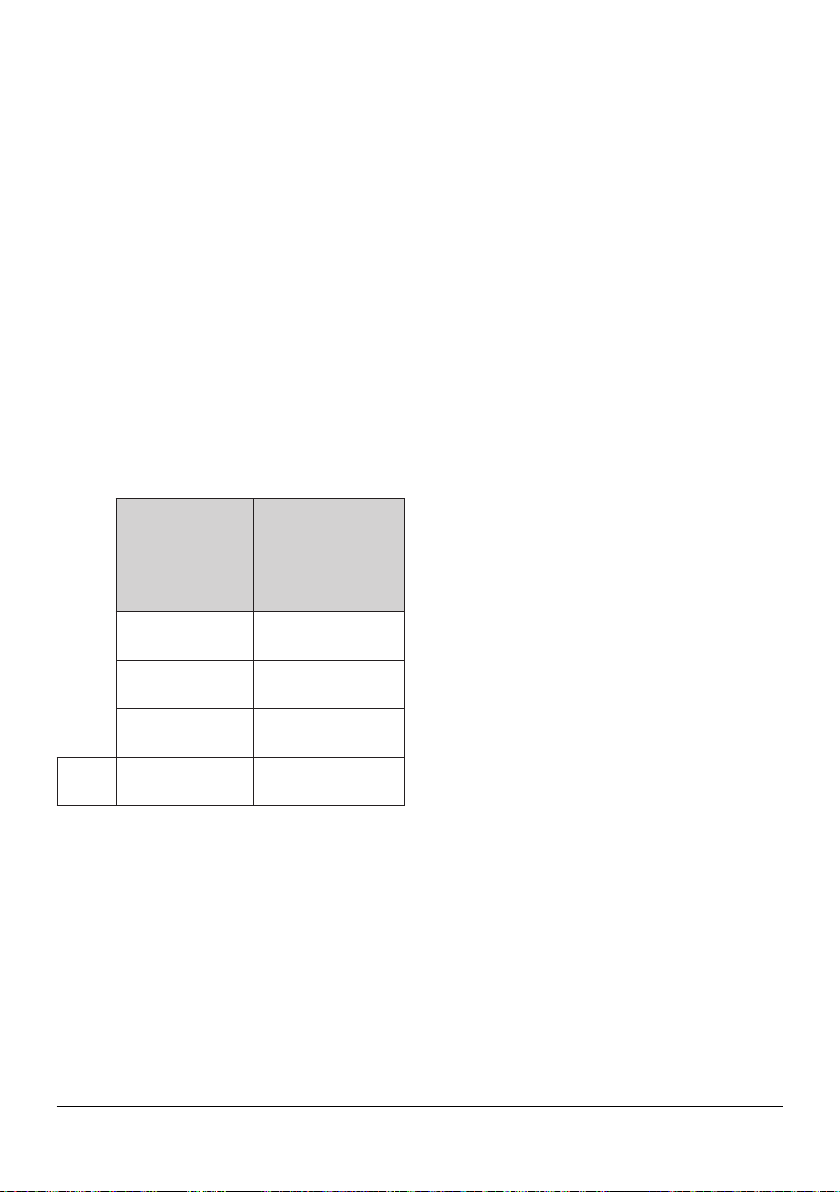

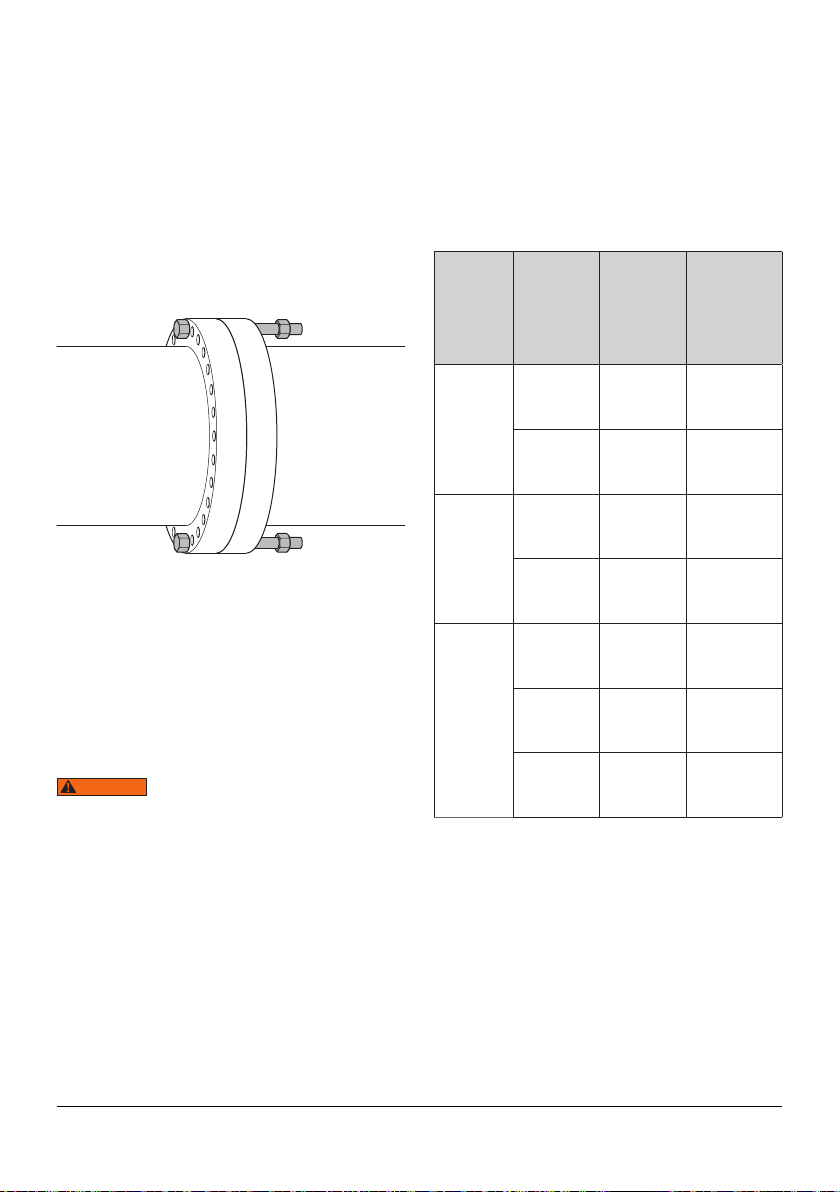

4.2 Secure Grip Flange Puller Specifications Table

(See Flange Dimensions for location of dimensions G + H)

Model

Number

Type

Maximum

Spreading

Force

Per Tool

[kN]

Spreading

Distance

Maximum

[mm]

Flange Dimensions Tool Weight

[kg]

Minimum

Access Gap

G

[mm]

Bolt-hole Diameter

Gap

H

[mm]

SG4TM

Mechanical

37.0

[4.16*]

75.0

[2.95in]

0

17.5 - 23.0

[0.69in - 0.91in]

4.5

[9.9lbs]

SG6TM

Mechanical

60.0

[6.74*]

80.0

[3.15in]

0

24.0 - 30.0

[0.94in - 1.18in]

7.5

[16.5lbs]

SG11TM

Mechanical

110.0

[12.36*]

90.0

[3.54in]

0

30.0 - 39.0

[1.18in - 1.54in

10.5

[23.1lbs]

* US tons

See Section 3.2.2 for case dimensions and kit contents

for SG4TM.

See Section 3.2.4 for case dimensions and kit contents

for SG6TM.

See Section 3.2.6 for case dimensions and kit contents

for SG11TM.

Flange Dimensions

G

H

10 IM_SGM_07

5. Operation

If the specification of the flange is unknown

then the vernier calliper supplied in the kit

should be used to determine the correct

collet.

TOOL COLLET

Minimum

bolt-hole

diameter

[mm]

Maximum

bolt-hole

diameter

[mm]

SG4TM

M16 [⅝"] 17.5mm

[0.69"]

19.5mm

[0.77"]

M20 [¾"] 20.5mm

[0.81"]

23mm

[0.91"]

SG6TM

M24 [⅞"] 24mm

[0.94"]

26.5mm

[1.04"]

M27 [1"] 27.5mm

[1.1"]

30mm

[1.18"]

SG11TM

M30

[1⅛"]

30mm

[1.18"]

33mm

[1.30"]

M33

[1¼"]

32mm

[1.26"]

36mm

[1.42"]

M36

[1⅜"]

35mm

[1.38"]

39mm

[1.54"]

5.1 Initial Setup and Inspection

The Secure Grip Tools spread flange joints

by engaging collets into the bolt-holes.

They can easily spread flange joints with

zero access gap, which traditional wedge-

type flange spreaders cannot spread.

The collets are suited to the sizes of the

bolt-holes and should be selected prior

to commencing work by following the

instructions in this section.

Replacement collets or different collets to

suit different bolt-hole sizes are available

from a local Equalizer distributor.

5.2 Collet Selection

It is important that the

correct size of collet is used. An undersized

collet could allow the collet holder to pull

through its bore. An oversized collet has

the potential to become jammed in the bolt-

hole.

The Secure Grip tools have a range of

collets which are applicable to the following

bolts and flange bolt-hole diameters shown

in the table below.

WARNING

IM_SGM_07 11

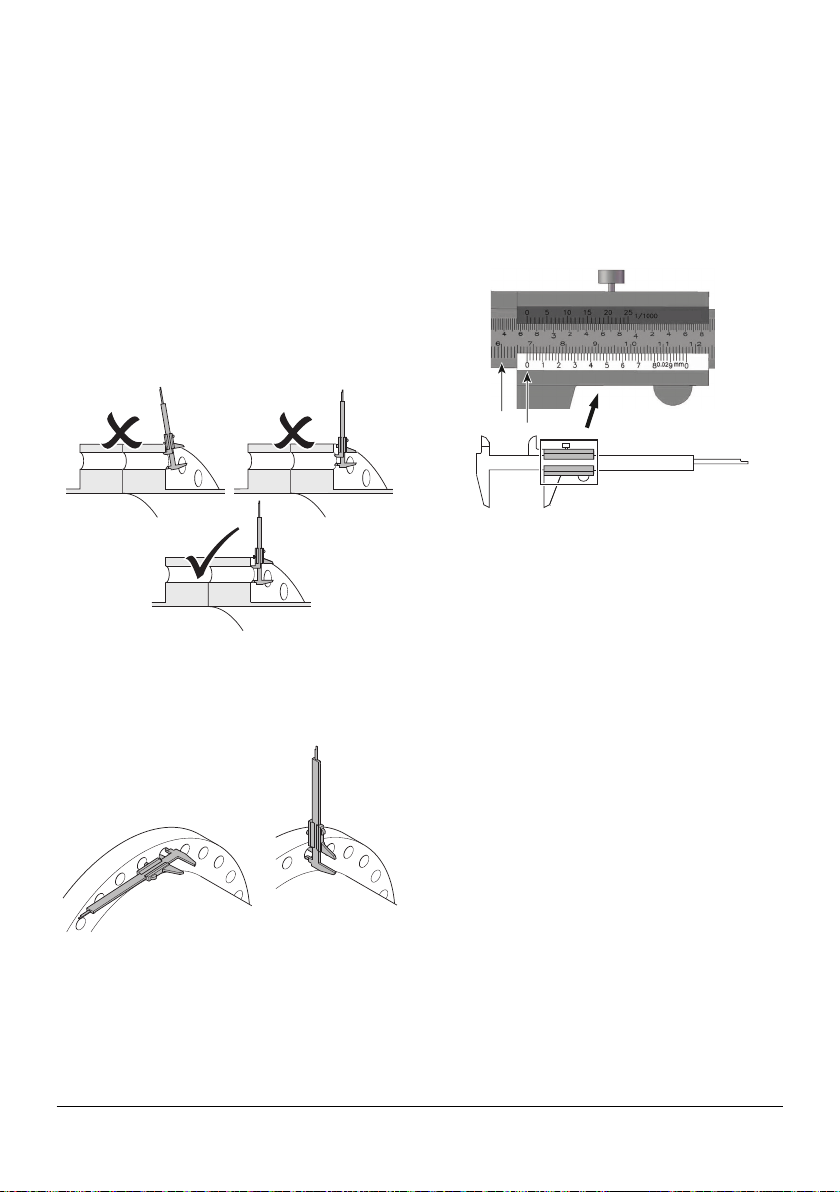

5.3 Bolt Hole Measurement

To ensure a true measurement is taken,

hold the vernier calliper:

• Square to the flange face,

• In the middle of the bolt-hole.

It is important that the vernier calliper is held

in the middle of the bolt-hole, and not held

at an angle to the flange face, nor used on a

bolt-hole which is worn, damaged or

distorted, as these actions may result in the

selection of an incorrect size of collet.

To confirm that the bolt-hole is round, take

two separate measurements with the vernier

calliper turned through 90° between

measurements.

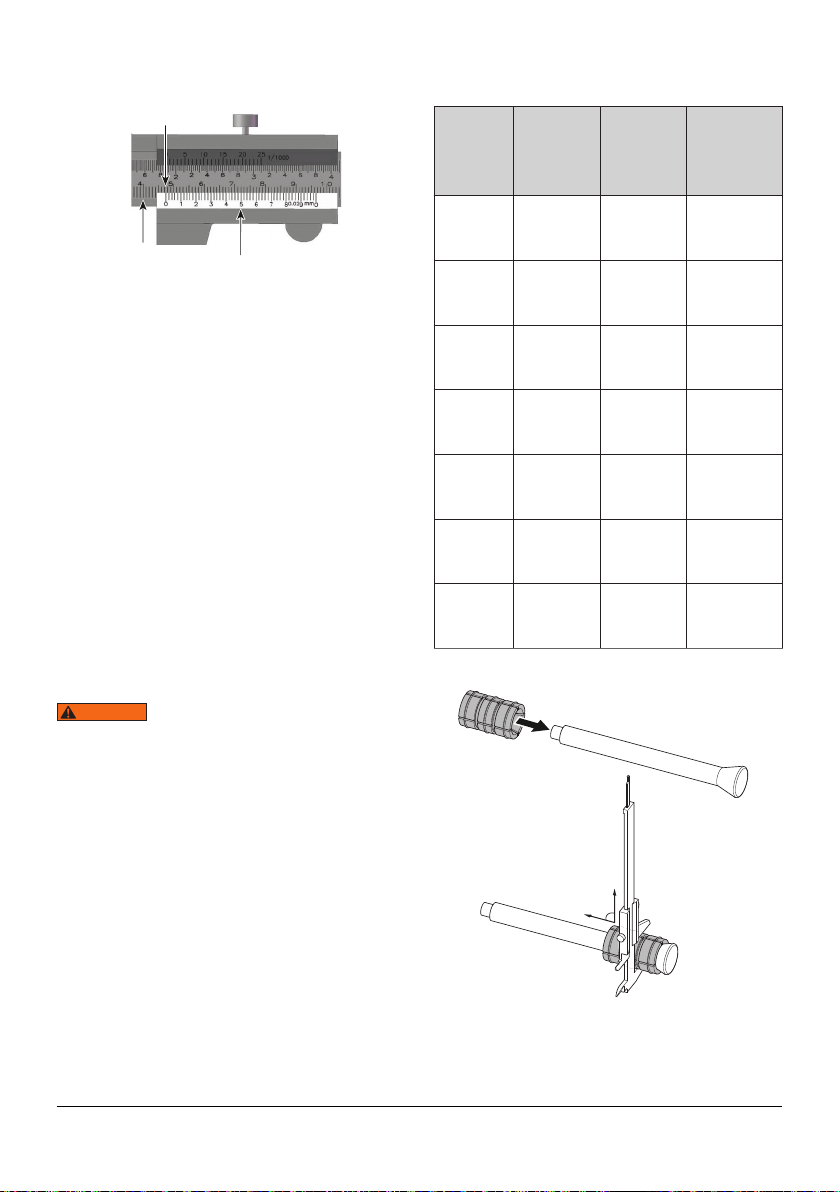

To read the measurement from the vernier

calliper, scan along the desired scale from

left to right. In this example, the major figure

is 60mm, this is added to the minor figure

of 8 mm (indicated by where the vernier

scale aligns with the main scale), giving a

total measurement of 68mm.

With a bolt-hole size of 68mm, the operator

can determine which collet and tool is

appropriate to this flange by referring to

the table. For example: 68mm falls within

the 63mm minimum and 69mm maximum

bolt-hole sizes.

Therefore, collet identification is M64 / 2½"

If the measurement contains fractions of a

millimetre the method of reading the vernier

calliper is slightly different. In this example,

the major figure is 40mm (read in the same

way as previously described). The minor

figure is 7mm (read to the left of the zero).

The fraction is 0.5mm (read from where the

vernier scale lines up with the main scale).

This gives a total measurement of 47.5mm.

Major

Figure Minor

Figure

12 IM_SGM_07

Each tool in the Secure Grip range comes

with the appropriate sizes of Collets for

that tool. If the Collet labelling is worn or

missing, then the Collet can be measured

to ensure that the correct size is selected.

An accurate measurement can only be

obtained with the Collet mounted on the

Collet Holder. To do this:

• Remove the Collet Head Assembly from

the tool and disassemble (see Section

5.4 for details)

• Slide the Collet over the Collet Holder

• Measure the centre section of the Collet

with the vernier calliper

• Identify the Collet using the chart below

and select the correct size for the flange.

The Secure Grip collets are

consumable items. The lifespan of a collet

will vary depending on the flange materials

with which it is used. To increase the lifespan

of the collets it is recommended that they

are flipped through 180° on the collet holder,

this will produce more even wear across the

four ridges on the outer profile of the collet.

See Section 5.4 for details on collet removal

and replacement.

Major

Figure Fraction

Minor Figure

WARNING

TOOL COLLET

Minimum

bolt-hole

diameter

[mm]

Maximum

bolt-hole

diameter

[mm]

16mm M16 [⅝"] 17.5mm

[0.69"]

19.5mm

[0.77"]

19mm M20 [¾"] 20.5mm

[0.81"]

23mm

[0.91"]

22.5mm

M24 [⅞"] 24mm

[0.94"]

26.5mm

[1.04"]

25.5mm

M27 [1"] 27.5mm

[1.1"]

30mm

[1.18"]

27mm M30

[1⅛"]

30mm

[1.18"]

33mm

[1.30"]

29.5mm

M33

[1¼"]

32mm

[1.26"]

36mm

[1.42"]

32.5mm

M36

[1⅜"]

35mm

[1.38"]

39mm

[1.54"]

90°

IM_SGM_07 13

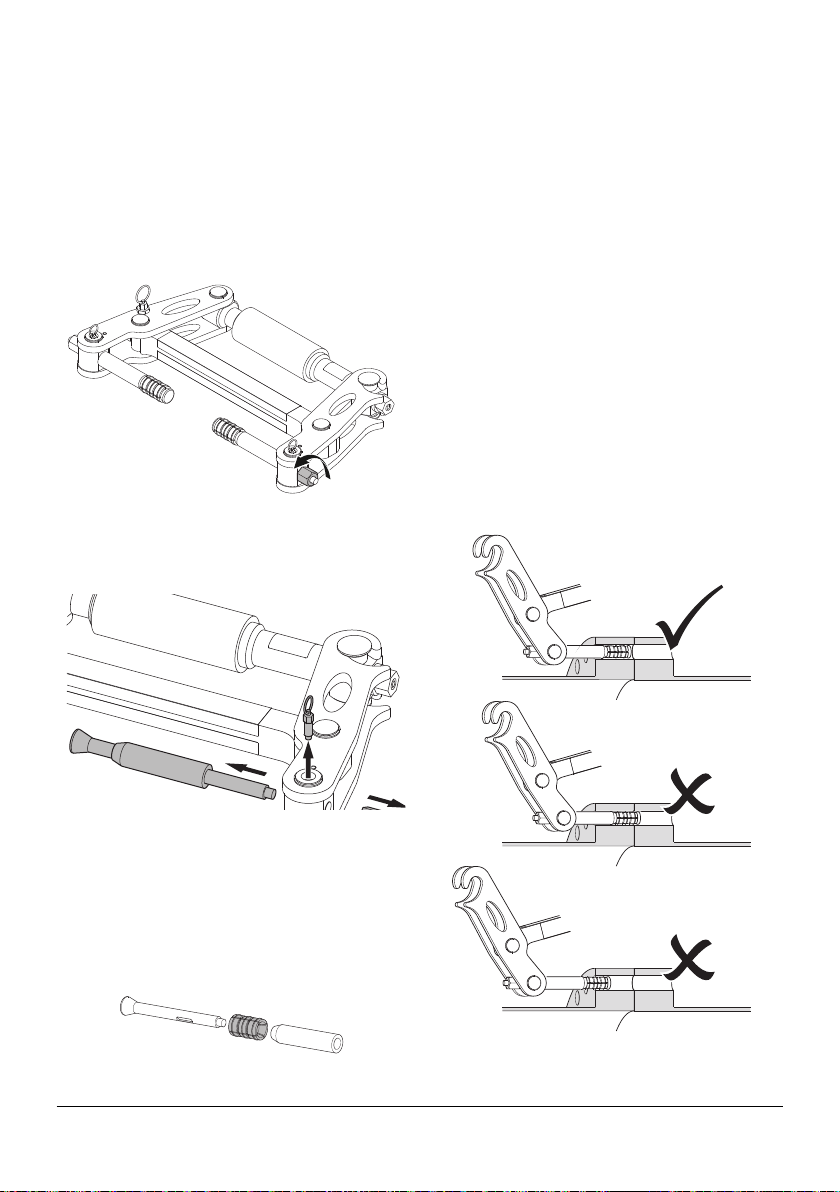

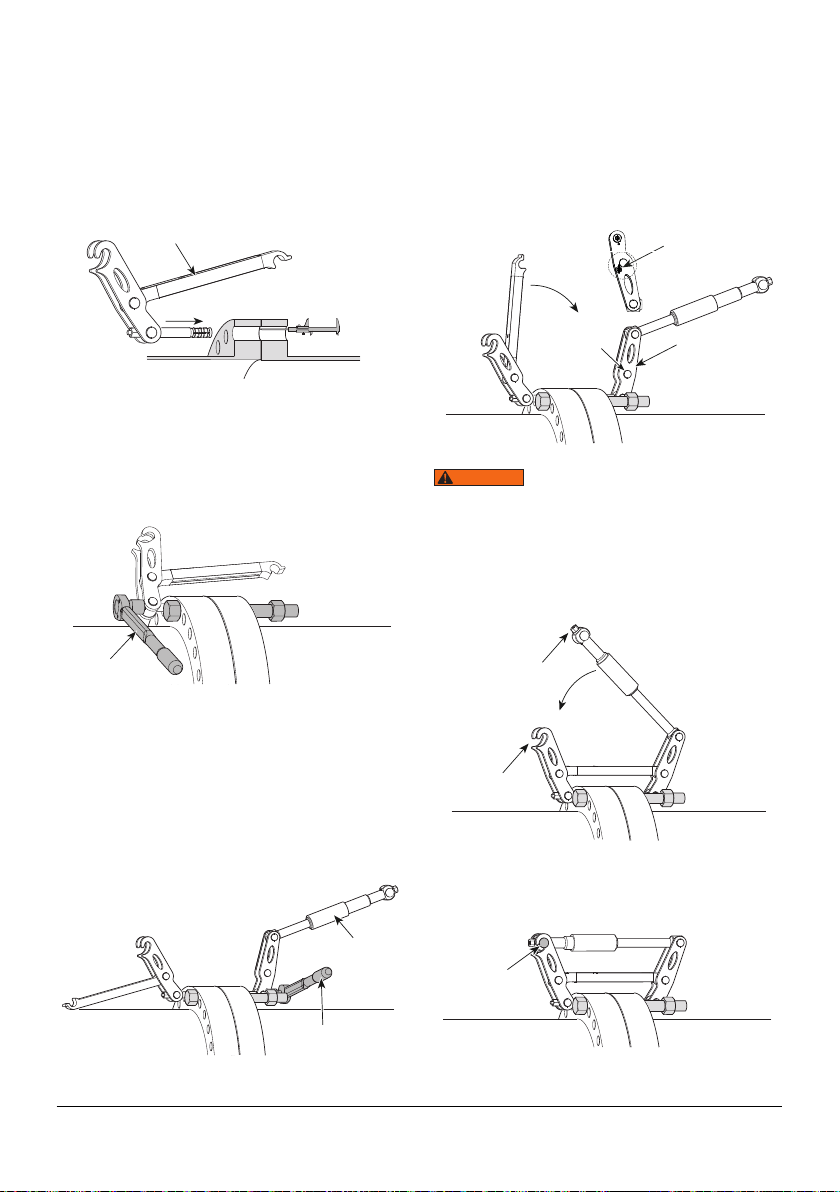

5.4 Collet Replacement

Once the correct collet has been selected it

may be necessary to change the collet on

the SG4TM, SG6TM, or SG11TM tool:

Place the tool on its side on a work bench or

flat surface. Unscrew and remove the collet

nut.

Pull the Collet Spring Plunger Ring to

release and remove the collet head

assembly.

Remove the Drive Cone and Collet from the

Collet Holder. Replace the Collet with the

applicable size for the flange joint as

selected in Section 5.2.

Repeat the operation for the opposite Collet

Leg Sub-assembly.

Reverse the procedure to re-assemble the

tool. Care should be taken to ensure the slot

in the Collet holder is aligned with the collet

plunger.

5.5 Collet Leg Sub-Assembly -

Installation

The Collet Leg Sub-assemblies, as used in

tools SG4TM, SG6TM, SG11TM; should be

the first parts of the tool fitted to the flange

joint.

The Collets from each assembly should be

installed into the bolt-hole of the flanges on

either side of the joint to be spread. Care

should be taken to ensure that the Collets

are engaged in the correct position.

14 IM_SGM_07

If a spacer, blind or valve is installed

between the flanges, care should be taken

to ensure that the Collet or Collet Holder do

not extend beyond the flange bolt hole.

5.6 Tool Installation and Operation

Once the correct Collet has been

selected and mounted, tool operation can

commence.

The two halves of the mechanical Secure

Grip are inserted into opposing flange bolt-

holes.

Both drive nuts are tightened, locking the

tool into the flange bolt-holes.

The cantilever followed by the actuator are

swung and locked into position.

Drive Nut

Drive Nut

Cantilever

Actuator

Cantilever

Actuator

The actuator is tensioned, spreading the

flange to the maximum load capacity or

maximum spreading distance of the tool.

Before attaching the tool

ensure at least two flange bolts remain in

place 180 degrees apart with nuts loosened

sufficiently enough for flange work to be

carried out. These bolts will reduce lateral

flange movement during flange spreading.

Mechanical Tool Operation

The mechanical Secure Grip tools use

mechanical torque to advance the actuator

and spread the tool. The torque is applied

using the supplied torque wrench, enabling

accurate control of the force applied.

Torque Wrench Usage

Holding the Torque Wrench in one hand,

unlock the knurled handle by turning the

locking knob anti-clockwise.

Select the torque setting by turning the

knurled handle until the required torque

value is indicated.

WARNING

IM_SGM_07 15

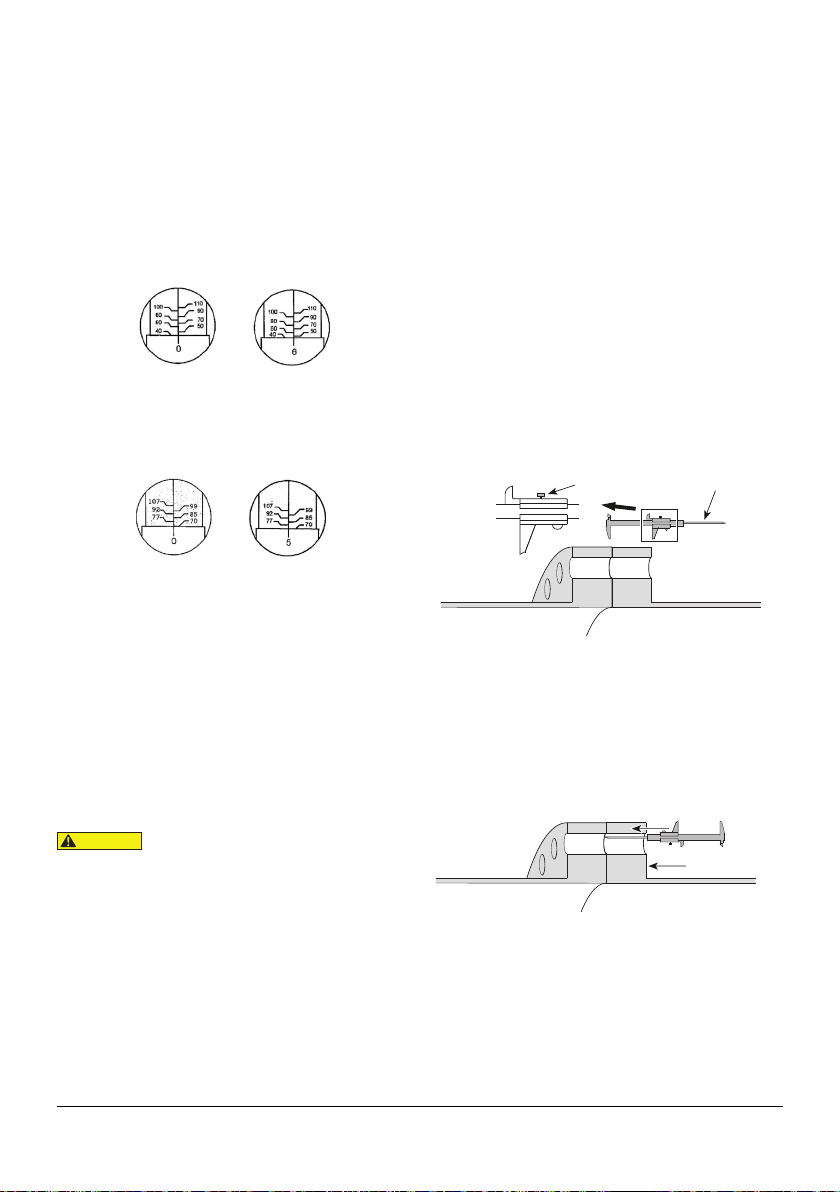

For example, to set the Torque Wrench to

46N·m: turn the knurled handle until the 0

on the fine scale aligns with 40N·m on base

scale; now turn slightly further until the 6 on

the fine scale aligns with the central line.

Setting an imperial torque [in ft·lb] is done in

exactly the same way.

Lock the handle by turning the locking knob

clockwise.

Install the supplied socket onto the Torque

Wrench and attach to the tool.

Slowly and smoothly pull the handle,

gradually applying more force until you feel

or hear the Torque Wrench click, indicating

that the selected torque has been achieved.

Do not continue to apply force after the

Torque Wrench has clicked. Special care

should be taken when using low torque

settings.

Do not attempt to turn the

grip while it is locked. Do not turn the grip

more than one turn below the lowest scale

reading or above the highest scale reading.

CAUTION

Torque Wrench Care

Prior to storing the Torque Wrench, and

between use, leave the Torque Wrench with

its lowest torque setting selected.

To clean the Torque Wrench, wipe gently

with a damp cloth. Avoid using any detergent

or solvent as this may detrimentally affect

the factory-fitted internal lubrication of the

mechanism.

Measure the thickness of the flange using

the vernier calliper provided. Adjust the

depth gauge to one half of the flange total

length and lock the calliper in position by

tightening the locking screw.

Select a suitable bolt-hole in which to attach

the tool.

Insert the depth gauge part of the vernier

calliper into the bolt-hole keeping the base

of the calliper flush with the bolting face of

the flange.

Depth Gauge

Locking Screw

Bolting Face

16 IM_SGM_07

Insert the collet on the cantilever half of the

tool into the opposite end of the same bolt-

hole until it touches the end of the depth

gauge (so that the Collet is fully through one

flange but not entering the other).

Set the torque wrench to 30N·m [22ft·lb]

and tighten the drive nut until the torque

wrench clicks.

The cantilever half of the tool will now have

a secure hold in the bolt-hole.

Insert the Collet on the actuator half of the

tool into the bolt-hole until it touches the

collet on the cantilever half of the tool.

Tighten the drive nut with the torque wrench

pre-set to 30N·m [22ft·lb] until it clicks. The

actuator half of the tool will now have a

secure hold in the bolt-hole.

Cantilever

Torque Wrench

30 Nm (22 ft lb)

Actuator

Torque Wrench

30 Nm (22 ft lb)

Rotate the cantilever into position hooking

it over the cantilever pin in the actuator half

of the tool.

A click should be felt from the spring plunger

when it is locked fully home.

Operating the tool without

the cantilever fully locked into position may

result in personnel injury and damage to the

tool.

Ensure the actuator bolt is fully unscrewed,

then swing the actuator down into position.

Tighten the actuator bolt until the lugs on

the actuator union engage in the hooks on

the open legs.

Spring Plunger

(reverse view)

Cantilever

Pin Spring Plunger

WARNING

Open Leg

Hooks

Actuator

Bolt

Actuator

Lugs

IM_SGM_07 17

Select the bolt-hole 180° opposite the tool

that has just been attached and repeat the

above steps for the second tool.

If more than two tools are

being used they should be attached at an

equal spacing around the flange joint.

With the torque wrench set at 30 N·m

[22 ft·lb], tighten the actuator bolt on one

tool until the torque wrench clicks and then

torque the actuator bolt on the other tool.

Continue tensioning the actuator bolts until

the flange spreads or the torque wrench

clicks. Care should be taken to ensure the

actuator bolts maintain an equal tension on

both tools.

CAUTION

When the torque wrench clicks, stop and

increase the torque wrench setting by

10N·m [6.5ft·lb]. Continue to tension both

tools evenly until the flange spreads or the

torque wrench clicks.

If the torque wrench clicks, continue

increasing the torque wrench setting in

10 N·m [6.5 ft·lb] increments until the

maximum for the tool has been reached

(see table below).

If a greater spreading force

is required then further tools can be added

around the flange joint.

Overloading the tool will

cause tool failure which may result in

personal injury.

SG4TM SG6TM

SG11TM

Max. Torque

Wrench

Setting

Nm 47 108 120

ft lb 35 80 89

Max.

Spreading

Force

T 3.7 6 11

Actuator Bolt

Actuator Bolt

NOTICE

WARNING

18 IM_SGM_07

Continue spreading the flange until the

access gap required has been achieved or

until the maximum tool travel has been

reached.

The Secure Grip mechanical

tools are fitted with an internal mechanical

stop which limits the travel. Forcing the tool

to travel further will result in tool failure.

Tool Max. Distance

SG4TM 75mm [2.95"]

SG6TM 80mm [3.15"]

SG11TM 90mm [3.50"]

Once the flange has been separated

and prior to any maintenance work, the

safety blocks must be inserted between

the flanges. These are held in position by

removing two of the flange bolts that are

reinserted with the safety block positioned

in-between the flange faces.

Maximum

Spreading

Distance

WARNING

Do not allow fingers, hands

or other body parts to come into contact

with the flange or tools during operations.

Never place fingers, hands or other body

parts into the flange gap.

Following any maintenance works and prior

to closing the flange joint, the safety blocks

must be removed.

To reduce the load on each tool rotate the

actuator bolt one full rotation. Repeat this

on both tools in turn until the tools have no

load on them and the joint is closed.

The tools can then be removed from the

flange by reversing the installation

procedure.

5.6.1 Valve, Spade, or Blind

Removal, Installation, and

Operation

The Secure Grip mechanical tools are also

ideal for the removal and insertion of blinds,

spades and valves.

Equalizer can supply Short Collet Holder

(SCH) Kits for each tool that will increase its

relative stroke.

Safety

Block

Flange Bolt

WARNING

Other manuals for SG4TM

1

This manual suits for next models

2

Table of contents

Popular Industrial Equipment manuals by other brands

Sonny's

Sonny's Pendulum 807W Combo owner's manual

ABB

ABB HT611646 Operation manual

SKIOLD

SKIOLD UNI-MIX 1000 GM: 590061 instruction manual

VALLEY CRAFT

VALLEY CRAFT F88565C7 instruction manual

ITALVIBRAS GIORGIO SILINGARDI

ITALVIBRAS GIORGIO SILINGARDI E Series Technical handbook

Ulvac

Ulvac EGO-40M instruction manual