- 5 -

951-230-018-EN

Version 01

EN

Table of contents

Table of contents

Explosion protection marking in accordance with Directive 2014/34/EU ...2

Classification as simple electrical equipment ..............................................3

Masthead .....................................................................................................4

Explanation of symbols and signs ...............................................................7

1. Safety instructions .........................................................................9

1.1 General safety instructions....................................................................9

1.2 General behavior when handling the product .....................................9

1.3 Intended use..........................................................................................10

1.4 Foreseeable misuse..............................................................................10

1.5 Painting plastic components ...............................................................11

1.6 Modifications to the product................................................................11

1.7 Prohibition of certain activities............................................................11

1.8 Inspections prior to delivery ................................................................11

1.9 Referenced documents ........................................................................12

1.10 Markings on the product......................................................................12

1.11 Notes on the type plate ........................................................................12

1.12 Note on CE marking..............................................................................13

1.13 Persons authorized to use the product ..............................................13

1.13.1 Operator...........................................................................................13

1.13.2 Qualified mechanic .........................................................................14

1.13.3 Qualified electrician ........................................................................14

1.13.4 Specialist in maintenance and servicing in potentially

explosive atmospheres ..................................................................14

1.14 Explosion protection marking in accordance with

Directive 2014/34/EU..........................................................................13

1.15 Instruction of outside fitters ................................................................14

1.16 Provision of personal protective gear.................................................14

1.17 Operation ...............................................................................................14

1.18 Emergency shutdown ..........................................................................15

1.19 Transport, assembly, maintenance, malfunction,

repair, shutdown, disposal ...................................................................15

1.20 First start-up, daily start-up ...............................................................16

1.21 Cleaning .................................................................................................17

1.22 Special safety instructions regarding explosion protection .............17

1.23 Nullification of ATEX approval..............................................................19

1.24 Operation in potentially explosive atmospheres ...............................19

1.25 Obligations of the operator..................................................................20

1.25.1 Identification of hazards.................................................................20

1.25.2 Explosion protection measures.....................................................20

1.26 Residual risks ........................................................................................21

1.27 Residual ATEX risks...............................................................................22

2. Lubricants ................................................................................... 24

2.1 General information .............................................................................24

2.2 Selection of lubricants..........................................................................24

2.3 Material compatibility...........................................................................25

2.4 Aging of lubricants................................................................................25

3. Overview, functional description ................................................ 26

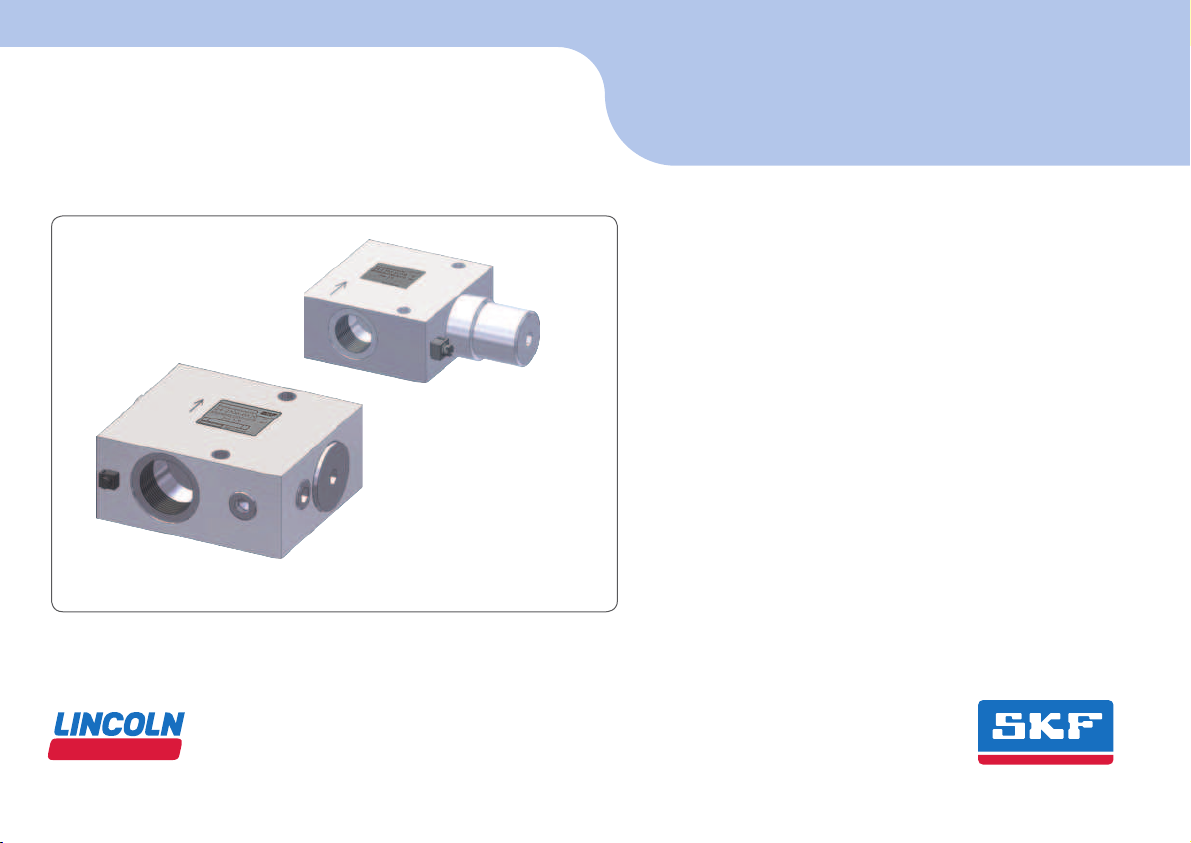

3.1 ATEX Flow limiter SP/SMB3 ................................................................26

3.1.1 Type designation.............................................................................27

3.2 ATEX Flow limiter SP/SMB6 ................................................................28

3.2.1 Type designation.............................................................................29

3.3 Functional description of a flow limiter ..............................................30

4. Technical data ............................................................................. 31

4.1 General technical data SP/SMB3 and SP/SMB6...............................31

4.2 Flow limiter SP/SMB3 ..........................................................................32

4.3 Flow limiter SP/SMB6 ..........................................................................32

4.4 Plug-in nozzle table SP/SMB3............................................................33

4.5 Plug-in nozzle table SP/SMB6............................................................34

4.6 Signal transmitter.................................................................................35