Equalizer VLW18TE Assembly instructions

OPERATOR INSTRUCTION MANUAL

EQUALIZER INTERNATIONAL LTD

www.equalizerinternational.com

HYDRAULIC

VERTICAL

LIFTING WEDGES

VLW18TE

VLW18TI

OPERATOR INSTRUCTION MANUAL

IM_VLW_Rev16_A4 (colour)

VLW18TE; VLW18TI HYDRAULIC VERTICAL LIFTING WEDGES

1

CONTENTS

1. INTRODUCTION

2. TOOL SAFETY

2.1 GENERAL SAFETY

2.2 PERSONNEL COMPETENCY

2.3 DISCLAIMER

2.4 DEFINITION OF TERMS

2.5 HAZARDS

3. TOOL CAPABILITIES

4. VLW18TE HYDRAULIC VERTICAL LIFTING WEDGE

4.1 HOW THE VLW18TE WORKS

4.2 TOOL FUNCTION

4.3 USING THE STEPPED BLOCK ACCESSORY

4.4 KIT CONTENTS

4.5 TOOL DIMENSIONS

4.6 TOOL MAINTENANCE

5. VLW18TI INTEGRAL HYDRAULIC VERTICAL LIFTING WEDGE

5.1 HOW THE VLW18TI WORKS

5.2 TOOL FUNCTION

5.3 USING THE STEPPED BLOCK ACCESSORY

5.4 KIT CONTENTS

5.5 TOOL DIMENSIONS

5.6 TOOL MAINTENANCE

7. TROUBLESHOOTING

7.1 VLW18TE TROUBLESHOOTING

7.2 VLW18TI TROUBLESHOOTING

8. REGULATORY INFORMATION

8.1 REGISTERED HEAD OFFICE

9. PARTS LISTS & SERVICE KITS

03/11/2017

OPERATOR INSTRUCTION MANUAL

IM_VLW_Rev16_A4 (colour)

VLW18TE; VLW18TI HYDRAULIC VERTICAL LIFTING WEDGES

2

1.

INTRODUCTION

The Equalizer VLW18TE/TI Hydraulic Vertical Lifting

Wedge is an aid for assisting with the lifting and

installation of plant and heavy equipment.

●Access gap required:

9.5 mm (0.37”)

●Lifting force:

10,000 psi (700 bar) = 18 T (180 kN)

It is essential that the user familiarises themselves

with the contents of this manual prior to using the

tool.

This manual contains information for the following

tools:

• VLW18TE Hydraulic Vertical Lifting Wedge

• VLW18TI Integral Hydraulic Vertical Lifting Wedge

2.

SAFETY INFORMATION

2.1

GENERAL SAFETY

These instructions cover the safe operation and

maintenance of THE EQUALIZER VLW18TE and

VLW18TI HYDRAULIC VERTICAL LIFTING WEDGES.

The use of these tools should be as part of a broader

task-based risk assessment, which should be carried

out by the operation supervisor or other competent

person.

Failure to comply with the safety information

contained within this manual could result in personal

injury or equipment damage. Read all instructions,

warnings and cautions carefully, and follow all safety

precautions.

The safety of the operator, any assisting personnel

and the general public is of paramount importance.

Always work in accordance with applicable national,

local, site & company-wide safety procedures.

2.2

PERSONNEL COMPETENCY

Only personnel deemed competent in the use of

mechanical and hydraulic equipment should use

these tools.

2.3

DISCLAIMER

Equalizer cannot be held responsible for injury or

damage resulting from unsafe product use, lack of

maintenance or incorrect product and/or system

operation. If in doubt as to the safety precautions

and applications, contact Equalizer using the contact

details at the back of this manual.

OPERATOR INSTRUCTION MANUAL

IM_VLW_Rev16_A4 (colour)

VLW18TE; VLW18TI HYDRAULIC VERTICAL LIFTING WEDGES

3

2.4

DEFINITION OF TERMS

A CAUTION is used to indicate correct operating or

maintenance procedures and practices to prevent damage

to, or destruction of equipment or other property.

A WARNING indicates a potential danger that requires

correct procedures or practices to avoid personal injury.

A DANGER is only used when your action or lack of action

may cause serious injury or even death.

DO: an illustration showing how the tool should

be used.

DON’T: an illustration showing an incorrect way

to use a tool.

2.5

HAZARDS

WARNING: ensure all hydraulic components

are rated to a safe working pressure of 700 bar

(10 000 psi).

WARNING: Do not overload equipment. The

risk of hydraulic overloading can be minimised

by using the Equalizer Hand Pump, which has a

factory-set safety valve preventing the safe

working pressure being exceeded.

If alternative hydraulic pumps are used, ensure

that there are adequate systems to limit the

working pressure to 700 bar (10 000 psi).

CAUTION: ensure components are protected

from external sources of damage, such as

excessive heat, ame, moving machine parts,

sharp edges and corrosive chemicals.

CAUTION: Take care to avoid sharp bends and

kinks in hydraulic hoses. Bends and kinks can

cause severe back-up pressure and cause hose

failure. Protect hoses from dropped objects; a

sharp impact may cause internal damage to

hose wire strands. Protect hoses from crush

risks, such as heavy objects or vehicles; crush

damage can cause hose failure.

WARNING: Applying pressure to a damaged

hose may cause it to rupture.

WARNING: Immediately replace worn or

damaged parts. Use only genuine Equalizer

parts from approved distributors or service

centres. Equalizer parts have been engineered

andmanufacturedtobet-for-purpose.

DANGER: To minimise risk of personal injury

keep hands and feet away from the tool and

workpiece during operation.

WARNING: Always wear suitable clothing and

Personal Protective Equipment (PPE).

WARNING: Do not handle pressurised hoses;

escaping oil under pressure can penetrate the

skin, causing serious injury. Seek medical

attention immediately if oil penetration is

suspected.

WARNING: Only pressurize complete and fully

connected hydraulic systems. Do not pressurize

systems that contain unconnected couplers.

CAUTION: Do not lift hydraulic equipment by

the hoses or couplers. Use only the designated

carrying handles.

CAUTION: Lubricate tools as directed in this

manual prior to operation. Use only approved

lubricants of high quality, following the lubricant

manufacturers instructions.

OPERATOR INSTRUCTION MANUAL

IM_VLW_Rev16_A4 (colour)

VLW18TE; VLW18TI HYDRAULIC VERTICAL LIFTING WEDGES

4

3.

TOOL CAPABILITIES

The EQUALIZER VLW18TE and VLW18TI hydraulic

vertical lifting wedges will generate 18 Tons (180 kN)

lifting force from 10,000 psi (700 bar) of hydraulic

pressure. The tools require a minimum access

gapof9.5mm(0.37”)ontherststepandwilllift

vertically.

Using two VLW18TE/TI wedges will allow a lift of 36

Tons

Using four VLW18TE/TI wedges will allow a loft of

72 Tons

OPERATOR INSTRUCTION MANUAL

IM_VLW_Rev16_A4 (colour)

VLW18TE; VLW18TI HYDRAULIC VERTICAL LIFTING WEDGES

5

4.

VLW18TE

HYDRAULIC VERTICAL

LIFTING WEDGE

4.1

HOW THE VLW18TE WORKS

The hydraulic hose and hand pump are attached to

the tool and the tool is inserted into the access gap

The hand pump is primed which powers the

hydraulics that lift the load

The load is secured using the safety block

4.2

VLW18TE TOOL FUNCTION

The operation procedure is exactly the same for both

the VLW18TE Mini and Standard Kits. The VLW18TE

Mini Kit does not contain either a 10,000 psi (700

bar) hydraulic hand pump or a 10,000 psi (700 bar)

hydraulic hose. These items will come from the user’s

inventory.

1. Assemble the kit by connecting one end of the

hydraulic hose to the hand pump, and the other

end to the hydraulic cylinder.

HAND

PUMP

HYDRAULIC

CYLINDER

HYDRAULIC

HOSE

CONNECT

2. Ensure the access gap under the item to be lifted

measures 9.5 mm (0.37”) or greater.

MIN.

9.5 mm

(0.37”)

OPERATOR INSTRUCTION MANUAL

IM_VLW_Rev16_A4 (colour)

VLW18TE; VLW18TI HYDRAULIC VERTICAL LIFTING WEDGES

6

3. Place the wedge under the item to be lifted. The

step to be used must be fully inserted into the

access gap - ensure that the heel of the step is in

contact with the outer surface of the object to be

lifted and that the wedge is positioned centrally.

4. Close the return valve on the hand pump (by

turning clockwise) and advance the wedge by

priming the pump.

N.B. The HP350S Hand Pump has a self contained non-

vented oil system. This means that the pump will function

without the need for an air vent to be opened. This allows

the pump to be used verticaly, horizontaly or upsides down

should the situation require. Having no open vent eliminates

the risk of hydraulic oil spillage during use.

PRIME

PUMP

RETURN

VALVE

5. Once the item has been lifted to the desired

height, or to the maximum height on the step

used, the safety block should be inserted into the

gap. Secure the load by releasing the pressure

onto the block.

SAFETY

BLOCK

6. If required, the wedge should then be re-insert-

ed on the next step and steps 3 - 5 repeated to

lift the item further.

WARNING: Never place ngers under an

item being lifted.

Always ensure that both the wedge and the

safety block are inserted under the item until

the heel of the step is in contact with the side of

the item to be lifted and the step is positioned

centrally

(see VLW18TE TOOL FUNCTION step 3)

WARNING: Care should be taken not to drop

any of the component parts when removing

them from the lifted load. This action will

prevent injuries to either the operator’s lower

limbs, or to passers by.

OPERATOR INSTRUCTION MANUAL

IM_VLW_Rev16_A4 (colour)

VLW18TE; VLW18TI HYDRAULIC VERTICAL LIFTING WEDGES

7

4.3

USING THE STEPPED BLOCK

ACCESSORY

The Equalizer Stepped Block enables the VLW18TE

Hydraulic Vertical Lifting Wedge to be used to lift an

item with a larger gap, and will lift the item further

with less penetration

Attach the stepped block to the tool using the M6

countersunk screw

STEPPED

BLOCK

COUNTERSUNK

SCREW

Insert the tool under the item to be lifted. Ensure

there is a minimum hold of 15 mm (0.59”) and that

the full width of the block is used

MIN.

15 mm

(0.59”)

OPERATOR INSTRUCTION MANUAL

IM_VLW_Rev16_A4 (colour)

VLW18TE; VLW18TI HYDRAULIC VERTICAL LIFTING WEDGES

8

4.4

VLW18TE KIT CONTENTS

MINI KIT COMPONENTS

Product Code: VLW18TEMIN

1 x VLW18TE Wedgehead

1 x 10,000 psi (700 bar) Hydraulic Cylinder

1 x Safety Block

1 x Stepped Block

1 x Instruction Manual

1 x Hex Key

1 x Countersunk Screw

1 x Cardboard Packaging

Packaging Dimensions:

145 x 170 x 365mm

(5.71” x 6.69” x 14.37”)

Tool only Weight: 8.5 kg (18.7 lb)

Gross Kit Weight: 9.8 kg (21.5 lb)

STANDARD KIT COMPONENTS

Product Code: VLW18TESTDSPB

1 x VLW18TE Wedgehead

1 x 10,000 psi (700 bar) Hydraulic Hose, 2 m

(78.75”)

1 x 10,000 psi (700 bar) Hydraulic Cylinder

1 x 10,000 psi (700 bar)

HP350S Sealed Hand Pump with Gauge

1 x Safety Block

1 x Stepped Block

1 x Hex Key

1 x Countersunk Screw

1 x Instruction Manual

1 x Carry-Case

Carry Case Dimensions:

920 x 520 x 210mm

(36.22” x 20.47” x 8.26”)

Tool only Weight: 8.5 kg (18.7 lb)

Gross Kit Weight: 21.5 kg (47.4 lb)

OPERATOR INSTRUCTION MANUAL

IM_VLW_Rev16_A4 (colour)

VLW18TE; VLW18TI HYDRAULIC VERTICAL LIFTING WEDGES

9

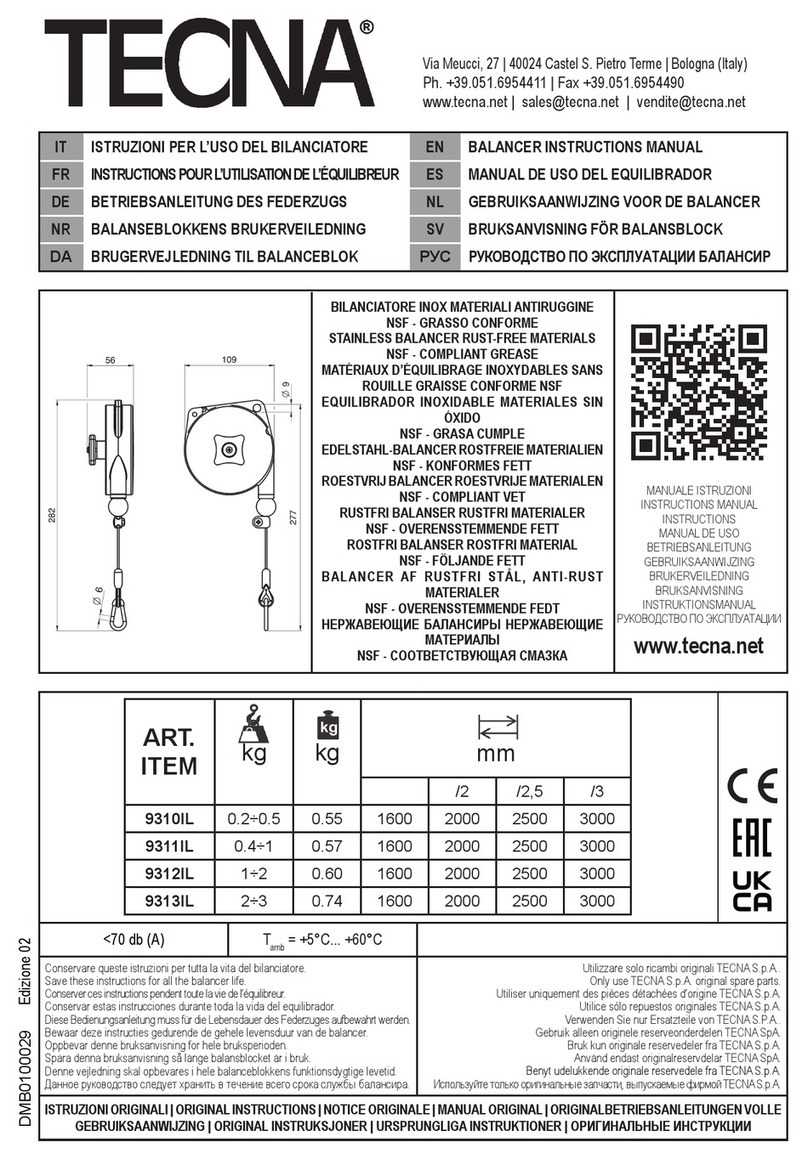

4.5

VLW18TE TOOL DIMENSIONS

MINIMUM EXTENSION

335 mm

13.19”

121 mm

4.76”

9.5 mm

0.37”

376 mm

14.80”

29.5 mm

1.16”

140 mm

5.50”

MAXIMUM EXTENSION

(USING STEPPED BLOCK)

39.5 mm

1.50”

59.5 mm

2.34”

MAXI KIT COMPONENTS

Product Code: VLW18TEMAXSPB

2 x VLW18TE Wedgeheads

2 x 10,000 psi (700 bar) Hydraulic Hoses, 2 m

(78.75”)

2 x 10,000 psi (700 bar) Hydraulic Cylinders

1 x 10,000 psi (700 bar)

HP350D Sealed Hand Pump with Gauges

2 x Safety Blocks

2 x Stepped Blocks

2 x Hex Key

2 x Countersunk Screw

1 x Instruction Manual

1 x Carry-Case

Carry-Case Dimensions:

920 x 520 x 210mm

(36.22” x 20.47” x 8.26”)

Tool only Weight: 8.5 kg (18.7 lb)

Gross Kit Weight: 33 kg (72.8 lb)

OPERATOR INSTRUCTION MANUAL

IM_VLW_Rev16_A4 (colour)

VLW18TE; VLW18TI HYDRAULIC VERTICAL LIFTING WEDGES

10

• Screw the grease nipple into the jaw, attach the

grease gun and squeeze grease into the wedge

• Screw the grease nipple into the base of the tool,

attach the grease gun and squeeze grease into

the wedge

OR

• Connect the hose to the wedge and advance the

wedge forward, smear grease onto the surfaces

of the wedge

GREASE

GREASING THE SLIDE PINS

• Simply smear some grease into the slots. Also

ensure the slide pins are free from grit.

GREASE

SAFETY BLOCK

139 mm

5.47” 27 mm

1.06” 34 mm

1.34” 41 mm

1.61” 48 mm

1.89”

55 mm

2.17”

STEPPED BLOCK

63.8 mm

2.51”

31.7 mm

1.25”

30 mm

1.18” 38 mm

1.51”

4.6

VLW18TE TOOL MAINTENANCE

• On return from each job and before allocation

against subsequent work the completeness of

the Equalizer VLW18TE kit must be established

and items examined to ensure that they are

serviceable.

• Any missing or damaged items are to be replaced

as soon as possible and prior to the tool being

used again.

• Store the tool in a cool dry place and ensure all

machined surfaces are greased

• Grease all moving parts each and every time the

tool is used:

GREASING THE WEDGE

• Remove the grease nipple from the handle of the

tool

GREASE

NIPPLE

OPERATOR INSTRUCTION MANUAL

IM_VLW_Rev16_A4 (colour)

VLW18TE; VLW18TI HYDRAULIC VERTICAL LIFTING WEDGES

11

5.2

VLW18TI TOOL FUNCTION

1. Before installing the wedge, ensure that it is

fully retracted and tighten the return valve in a

clockwise direction to the closed position.

Also ensure the air vent is not obstructed in any

way as this will result in a vacuum within the

system and the wedge will not advance.

RETURN

VALVE

AIR VENT

2. Ensure the access gap under the item to be lifted

measures 9.5 mm (0.37”) or greater.

MIN.

9.5 mm

(0.37”)

5.

VLW18TI

INTEGRAL HYDRAULIC

VERTICAL LIFTING

WEDGE

5.1

HOW THE VLW18TI WORKS

The tool is inserted into the access gap

The hand pump is primed which powers the

hydraulics that lift the load

The load is secured using the safety block

OPERATOR INSTRUCTION MANUAL

IM_VLW_Rev16_A4 (colour)

VLW18TE; VLW18TI HYDRAULIC VERTICAL LIFTING WEDGES

12

5. Once the item has been lifted to the desired

height, or to the maximum height on the step

used, the safety block should be inserted into the

gap. Secure the load by releasing the pressure

onto the block.

SAFETY

BLOCK

6. If required, the wedge should then be re-insert-

ed on the next step and steps 3 - 5 repeated to

lift the item further.

WARNING: Never place ngers under an

item being lifted.

Always ensure that both the wedge and the

safety block are inserted under the item until

the heel of the step is in contact with the side of

the item to be lifted and the step is positioned

centrally

(see VLW18TI TOOL FUNCTION step 3)

WARNING: Care should be taken not to drop

any of the component parts when removing

them from the lifted load. This action will

prevent injuries to either the operator’s lower

limbs, or to passers by.

3. Place the wedge under the item to be lifted. The

step to be used must be fully inserted into the

access gap - ensure that the heel of the step is in

contact with the outer surface of the object to be

lifted and that the wedge is positioned centrally.

4. Advance the wedge by priming the pump.

PRIME

PUMP

OPERATOR INSTRUCTION MANUAL

IM_VLW_Rev16_A4 (colour)

VLW18TE; VLW18TI HYDRAULIC VERTICAL LIFTING WEDGES

13

5.3

USING THE STEPPED BLOCK

ACCESSORY

The Equalizer Stepped Block enables the VLW18TI

Integral Hydraulic Vertical Lifting Wedge to be used

to lift an item with a larger gap, and will lift the

item further with less penetration

Attach the stepped block to the tool using the M6

countersunk screw

STEPPED

BLOCK

COUNTERSUNK

SCREW

Insert the tool under the item to be lifted. Ensure

there is a minimum hold of 15 mm (0.59”) and that

the full width of the block is used

MIN.

15 mm

(0.59”)

OPERATOR INSTRUCTION MANUAL

IM_VLW_Rev16_A4 (colour)

VLW18TE; VLW18TI HYDRAULIC VERTICAL LIFTING WEDGES

14

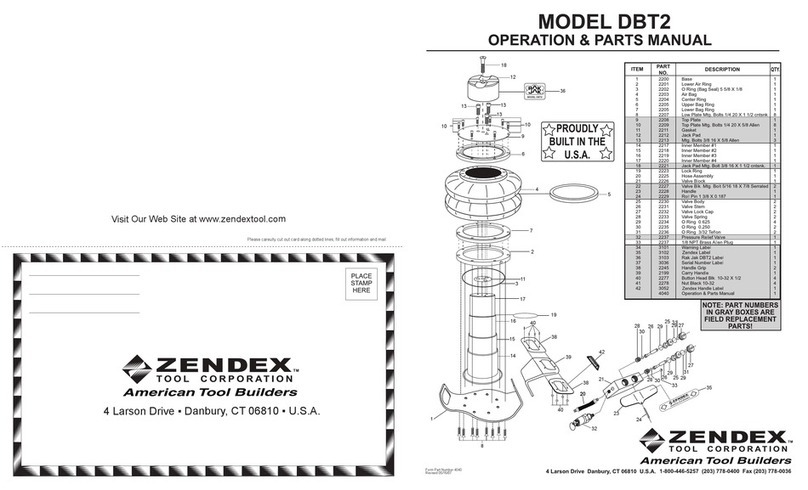

5.5

VLW18TI TOOL DIMENSIONS

MINIMUM EXTENSION

380 mm

14.95”

126 mm

4.98”

9.5 mm

0.37”

535 mm

21.04”

29.5 mm

1.16”

575 mm

22.62”

MAXIMUM EXTENSION

(USING STEPPED BLOCK)

39.5 mm

1.56”

59.5 mm

2.34”

5.4

VLW18TI KIT CONTENTS

KIT COMPONENTS

Product Code: VLW18TISPB

1 x VLW18TI Wedgehead

1 x 10,000 psi (700 bar) Integral Hydraulic Pump/

Cylinder

1 x Safety Block

1 x Stepped Block

1 x Hex Key

1 x Countersunk Screw

1 x Instruction Manual

1 x Carry-Case

Carry Case Dimensions:

580 x 340 x 180mm

(22.8” x 13.4” x 7.1”)

Tool only Weight: 10 kg (22 lbs)

Gross Kit Weight: 13.5 kg (29.8 lbs)

OPERATOR INSTRUCTION MANUAL

IM_VLW_Rev16_A4 (colour)

VLW18TE; VLW18TI HYDRAULIC VERTICAL LIFTING WEDGES

15

• Screw the grease nipple into the jaw, attach the

grease gun and squeeze grease into the wedge

• Screw the grease nipple into the base of the tool,

attach the grease gun and squeeze grease into

the wedge

OR

• Advance the wedge forward, smear grease onto

the surfaces of the wedge

GREASE

GREASING THE SLIDE PINS

• Simply smear some grease into the slots. Also

ensure the slide pins are free from grit.

GREASE

SAFETY BLOCK

139 mm

5.47” 27 mm

1.06” 34 mm

1.34” 41 mm

1.61” 48 mm

1.89”

55 mm

2.17”

STEPPED BLOCK

63.8 mm

2.51”

31.7 mm

1.25”

30 mm

1.18” 38 mm

1.51”

5.6

VLW18TI TOOL MAINTENANCE

• On return from each job and before allocation

against subsequent work the completeness of

the Equalizer VLW18TI kit must be established

and items examined to ensure that they are

serviceable.

• Any missing or damaged items are to be replaced

as soon as possible and prior to the tool being

used again.

• Store the tool in a cool dry place and ensure all

machined surfaces are greased

• Grease all moving parts each and every time the

tool is used:

GREASING THE WEDGE

• Remove the grease nipple from the handle of the

tool

GREASE

NIPPLE

OPERATOR INSTRUCTION MANUAL

IM_VLW_Rev16_A4 (colour)

VLW18TE; VLW18TI HYDRAULIC VERTICAL LIFTING WEDGES

16

HOSES ARE CONNECTED AND THE TOOL

ADVANCES WITH MAXIMUM PRESSURE ON

THE PUMP HANDLE BUT THE LOAD WILL NOT

LIFT

POSSIBLE CAUSE:

The pressure required to lift the load is greater than

that of the tools you are using.

RECOMMENDED ACTION:

Add another tool and try again.

HOSES ARE CONNECTED AND THE TOOL

ADVANCES BUT THERE IS MINIMAL

PRESSURE ON THE PUMP HANDLE; THE

HANDLE IS RISING BACK OF ITS OWN

ACCORD

POSSIBLE CAUSE:

There is dirt or a damaged valve seat within the

pump unit.

RECOMMENDED ACTION:

The pump should be sent to an authorised Equalizer

distributor for repair.

7.

TROUBLESHOOTING

7.1

VLW18TE TROUBLESHOOTING

HOSES ARE CONNECTED BUT THE TOOL DOES

NOT ADVANCE. THE PRESSURE ON THE PUMP

HANDLE IS MINIMAL

POSSIBLE CAUSE:

The release valve is in the retract (open) position.

RECOMMENDED ACTION:

Close the release valve . CLOSE RELEASE

VALVE

HOSES ARE CONNECTED AND THE PUMP

QUICKLY REACHES MAXIMUM PRESSURE

BUT THE TOOL HAS NOT ADVANCED

POSSIBLE CAUSE:

One or more of the connectors are not fully tightened

and the hydraulic oil cannot pass through from the

pump to the cylinder.

RECOMMENDED ACTION:

Check all connectors are fully tightened and the

release valve is in the fully closed position.

OPERATOR INSTRUCTION MANUAL

IM_VLW_Rev16_A4 (colour)

VLW18TE; VLW18TI HYDRAULIC VERTICAL LIFTING WEDGES

17

AIRLOCK REMOVAL PROCEDURE:

CLOSE RELEASE

VALVE

OPEN RELEASE

VALVE

NUTS

MAIN

HANDLE

OIL

RESERVOIR

ACTUATOR

COUPLER

THE WEDGE IS ADVANCING BUT DOES NOT

REACH FULL PRESSURE.

POSSIBLE CAUSE:

Air could be present in the hydraulic system.

RECOMMENDED ACTION:

Follow the airlock removal procedure:

1. Connect the hand pump to the tool with the

hydraulic hose.

2. Close the release valve on the pump, and prime

the pump until the hydraulic cylinder is fully

extended and a small pressure is achieved

3. With the hand pump held above the tool and

the tool in an upright position, open the release

valve causing any air that is within the system to

be forced up through the pump and vented into

the oil reservoir

4. Repeat steps 1 - 3 three or four times to ensure

that all air is removed from the system and the

tool will reach full working pressure

5. Disconnect the hand pump from the hydraulic

hose, grip the baseplate of the hand pump body

in a vice with the pump body vertical and the

main handle at the top

6. Remove the four nuts holding the main handle

and lift off

7. Grip the relling plug with pliers and extract it

by pulling and twisting simultaneously. Ensure

the reservoir body is held down when removing

therellingplugaspullinguponthereservoir

body will release the bladder within, and oil will

spill out.

8. Fill the reservoir to the top with a good quality

hydraulic oil of the grade 15 cSt

9. Reinsert the relling plug, wipe away any oil,

and reassemble by reversing the disassembly

process

OPERATOR INSTRUCTION MANUAL

IM_VLW_Rev16_A4 (colour)

VLW18TE; VLW18TI HYDRAULIC VERTICAL LIFTING WEDGES

18

7.2

VLW18TI TROUBLESHOOTING

WEDGE ADVANCES 50% AND THEN STOPS

FUNCTIONING

POSSIBLE CAUSE:

A sticker has been placed over the air vent

RECOMMENDED ACTION:

Remove sticker

POSSIBLE CAUSE:

Theoperatoriscoveringtheairventwithhisnger

while operating the pump

RECOMMENDED ACTION:

One hand should be on the handle of the tool while

the other hand operates the pump handle

POSSIBLE CAUSE:

The air vent has become blocked with dirt

RECOMMENDED ACTION:

Carefully unblock the air vent using a small blunt

object

NO WEDGE MOVEMENT

POSSIBLE CAUSE:

Air lock within system

RECOMMENDED ACTION:

Open release valve and prime pump to circulate oil

around the system

POSSIBLE CAUSE:

Insufcientoil

RECOMMENDED ACTION:

Rellwithcleanoilandbleedsystem

POSSIBLE CAUSE:

Release valve open

RECOMMENDED ACTION:

Close release valve

POSSIBLE CAUSE:

Air accumulates around pump inlet when used

upside down

RECOMMENDED ACTION:

Bleed out air from reservoir. Look for any oil leaks

on reservoir which may indicate a perished bladder.

Refer to an approved Equalizer distributor for further

instructions.

POSSIBLE CAUSE:

Inlet check or intermediate valve ball stuck

RECOMMENDED ACTION:

Dismantle check valve, free and clean balls. Refer

to an approved Equalizer distributor for further

instructions.

WEDGE MOVES BUT UNDER LOAD FEELS AS

IF IT IS NOT REACHING FULL PRESSURE

POSSIBLE CAUSE:

Intermediate valve not seating / relief valve leaking

RECOMMENDED ACTION:

Check ball for dirt then re-seat using a hammer and

punch. Refer to an approved Equalizer distributor

for further instructions.

PRESSURE LEAKS AWAY, HANDLE RISES OF

ITS OWN ACCORD

POSSIBLE CAUSE:

Outlet check valve leaking

RECOMMENDED ACTION:

Check ball for dirt then re-seat using a hammer and

punch. Refer to an approved Equalizer distributor

for further instructions.

OPERATOR INSTRUCTION MANUAL

IM_VLW_Rev16_A4 (colour)

VLW18TE; VLW18TI HYDRAULIC VERTICAL LIFTING WEDGES

19

PRESSURE LEAKS AWAY, HANDLE REMAINS

STATIC

POSSIBLE CAUSE:

Release valve leaking

RECOMMENDED ACTION:

Release lever may not be tight enough. Refer

to an approved Equalizer distributor for further

instructions.

POSSIBLE CAUSE:

Piston seal leaking

RECOMMENDED ACTION:

Look for oil leaking from cylinder bearing. Refer

to an approved Equalizer distributor for further

instructions.

POSSIBLE CAUSE:

Leaks on cylinder or pump body

RECOMMENDED ACTION:

Check blanking plugs for leaks, tighten. Refer

to an approved Equalizer distributor for further

instructions.

SPONGY ACTION

POSSIBLE CAUSE:

Air in system

RECOMMENDED ACTION:

Bleed system. Refer to an approved Equalizer

distributor for further instructions.

This manual suits for next models

1

Table of contents

Popular Lifting System manuals by other brands

Direct-Lift

Direct-Lift PP8 Plus Installation & owner's manual

Aqua Creek Products

Aqua Creek Products Patriot-AT1 instruction manual

Sun Microsystems

Sun Microsystems ALIGNMENT EELR124A Installation and operation manual

FACAL

FACAL CAPO-1 Use and maintenance handbook

TMG

TMG TMG-ALSP60 product manual

REID LIFTING

REID LIFTING T-DAVIT Series Assembly & operation