3

Introduction

Thank you for choosing Sumner’s GH3/4T Gantry Lift

to meet your material lifting needs. The GH3/4T Gantry

Lift has a load capacity of 3/4 metric tons (750 kg) or

1,650 lbs. Following proper procedures for use and

maintenance of Sumner’s GH3/4T Gantry Lift de-

scribed in this manual will provide you with years of

dependable service.

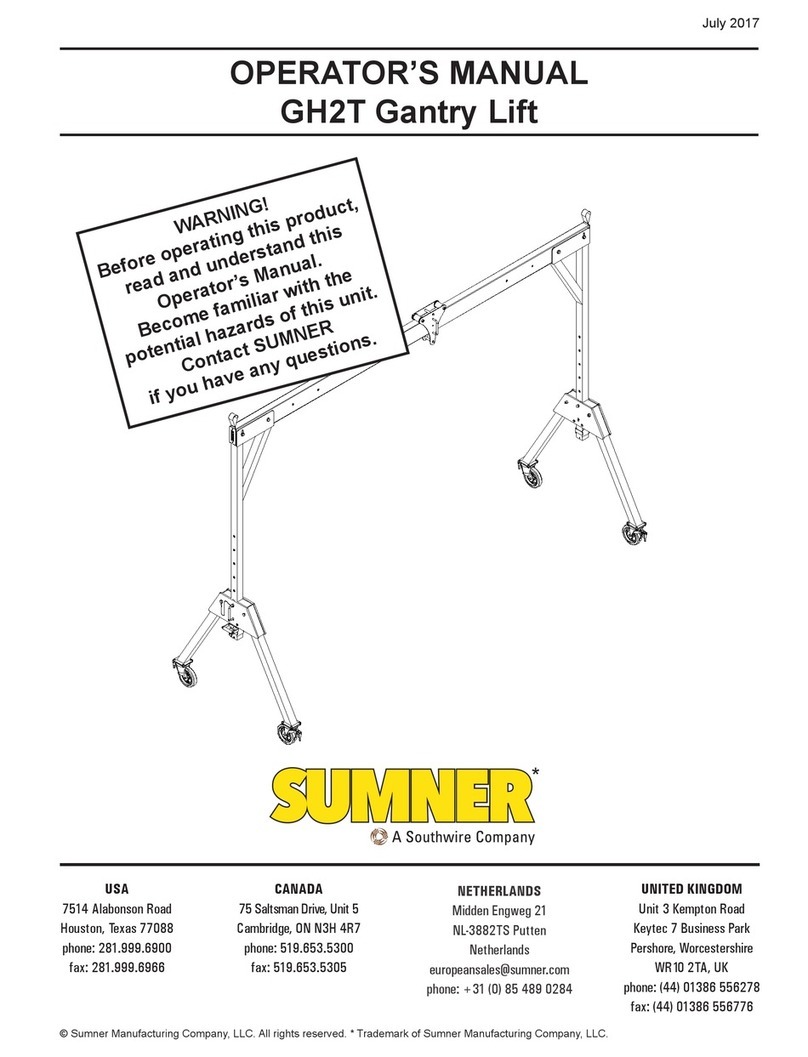

Gantry Components

Sumner’s GH3/4T Gantry Lift consists of the below

components. Before attempting to assemble Gantry

Lift be certain that all components are available.

• 2 - A-frames

• Cross Beam (3m, 4m, 5m, 8', 10', 12' or 15')

• Trolley

• Attaching hardware (4 bolts, 4 nuts & 8 washers)

Operator Safety Instructions

IMPORTANT

Read and understand this manual

prior to operating or performing main-

tenance on this lift.

1. ALWAYS Inspect all equipment prior to use to

make certain it is in proper working order.

2. NEVER use unit If any part of equipment appears

damaged or does not assemble properly.

3. ALWAYS use only Sumner replacement parts. Any

replacement parts not supplied by Sumner

Manufacturing will severely compromise the

quality and safety designed into this unit as well as

invalidate the warranty.

4. As a precaution, ALWAYS wear proper

clothing when operating unit, including hard hat,

work gloves and safety shoes.

5. ALWAYS avoid horseplay around equipment, and

keep bystanders at a safe distance. Do not allow

children to operate this unit and always keep them

out of work areas.

6. NEVER misuse the unit. Perform only the

functions for which the unit is designed. Never at-

tempt to operate the equipment at more than the

recommended capacity.

7. No riders on unit. This unit was designed for

material lifting purposes ONLY and is not designed

to function as a personnel lift or carrier.

8. NEVER stand under an elevated load.

9. NEVER exceed rated load capacity.

10. NEVER operate during high winds or electrical

storms.

11. NEVER use Gantry lift to support ladders or other

climbing devices.

12. When possible ALWAYS move loads by moving

the trolley on the Gantry cross beam while the lift

is stationary with all casters locked.

13. It is not recommended to move the Gantry lift with

a load. When moving the Gantry lift with a load

be sure to secure trolley in center of cross beam

to evenly distribute the weight across the unit and

lower load as close to the ground as possible.

Move lift by pushing the Gantry, not the load.

14. NEVER leave a load on the Gantry lift

unattended.

15. ALWAYS adjust A-frame heights prior to attaching

a load and make certain cross beam is level prior

to attaching a load. See instructions in this manual

on how to adjust A-frame heights.

16. NEVER adjust A-frame heights without rst

securing trolley to center of cross beam.

17. ALWAYS use Gantry lift on a hard, level, smooth

surface that is free of debris and obstructions. Be

certain the surface the Gantry is on can support

the full weight of the intended load.

18. NEVER move a fully assembled Gantry lift using a

fork lift or other lifting device.

19. NEVER use Gantry lift as an electrical ground.

20. ALWAYS ensure load is not secured to the ground

before attempting to lift it.

GH3/4T Gantry Lift Assembly

The following tools are required to properly assemble

the GH3/4T Gantry Lift:

• 1" wrench

• 1" socket wrench

• Ladder