Hinowa LightLift 15.70 3S Installation and operation manual

1

TECHNICAL COURSE BOOKLET

LightLift 15.70 3S

PERFORMANCE

TTLL1570021702

2

INDEX

1. INTRODUCTION.............................................................................................................................6

1.1 PARTS DENOMINATION..............................................................................................................6

1.2 SERIAL NUMBER LOCATION .....................................................................................................8

2. LL15.70 DATA................................................................................................................................. 9

2.2 TECHINCAL SPECIFICATIONS..................................................................................................9

2.3 LL15.70 DIMENSIONS...............................................................................................................11

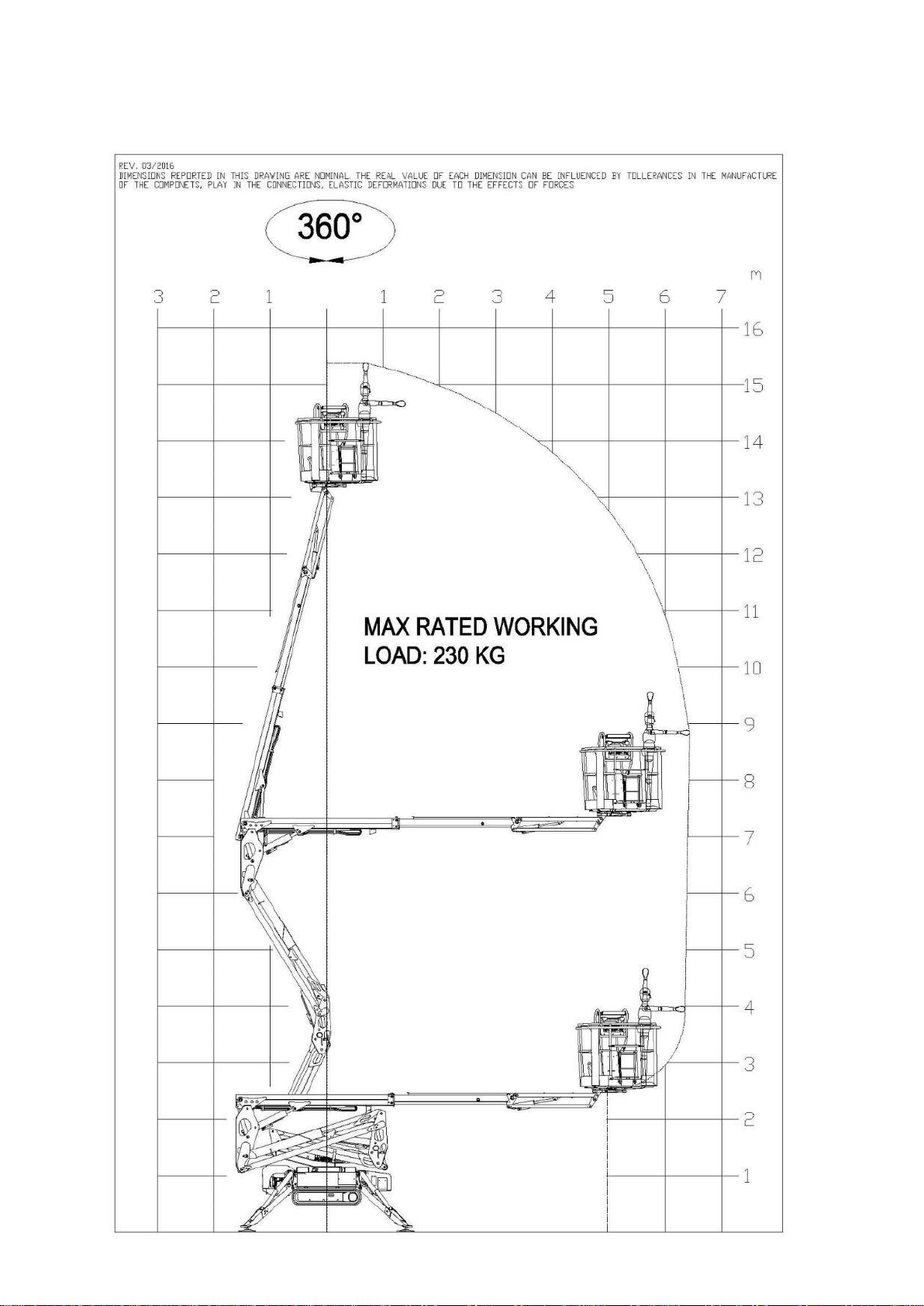

2.4 LL15.70 WORKING AREA - 230 KG UNRESTRICTED CAPACITY ...............................13

3. MACHINE OPERATIONAL INTRODUCTION ........................................................................14

3.1 MACHINE IGNITION...................................................................................................................14

3.2 STOP BUTTONS............................................................................................................................16

3.3 REMOTE CONTROL FUNCTIONS ............................................................................................16

4. GROUND PART MOVEMENTS ..................................................................................................18

4.1 TRACKS MOVEMENTS................................................................................................................18

4.1.1 TRACKS WIDENING ...........................................................................................................21

4.1.2 TRACKS MOVEMENT SPEED SELECTION ...................................................................21

4.1.3 TRACKS AUTOMATIC SPEED CONTROL .....................................................................22

4.2 OUTRIGGERS MOVEMENTS.....................................................................................................23

4.2.1 AUTOMATIC STABILIZATION .........................................................................................24

4.2.2 OUTRIGGERS AUTO-RETRACTION...............................................................................25

4.2.3 SINGLE OUTRIGGER MOVEMENTS...............................................................................27

5. AERIAL PART MOVEMENTS .....................................................................................................28

5.1 ENGINE CARTER CONTACT PREVENTION SYSTEM........................................................30

6. PEDAL (OPTIONAL) ....................................................................................................................31

7. EMERGENCY OPERATIONS ......................................................................................................32

7.1 EMERGENCY DEVICES AND TOOLS LOCATION...............................................................32

7.2 AERIAL PART EMERGENCY OPERATIONS ..........................................................................34

7.2.1 GRAVITY EMERGENCY DESCENT ......................................................................................35

7.2.2 OPERATIONS FROM GROUND CONTROL POSITION..................................................36

7.2.3 EMERGENCY DESCENT WITH SAFETIES BY-PASS .....................................................37

7.2.4 EMERGENCY DESCENT FROM THE GROUND WITH HAND PUMP.......................... 38

7.3 GROUND PART EMERGENCY MOVEMENTS........................................................................40

7.3.1 TRACKS MOVEMENT WITH SAFETIES BY-PASS..........................................................40

7.3.2 OUTRIGGERS MOVEMENT WITH THE HAND PUMP....................................................41

3

7.4 ENGINE EMERGENCY START PROCEDURE ........................................................................44

7.4.1 GASOLINE –HONDA iGX390 EMERGENCY START.....................................................45

7.4.2 DIESEL - HATZ 1B40 EMERGENCY START ....................................................................46

8. HYDRAULIC SYSTEM..................................................................................................................47

8.1 MAIN COMPONENTS IDENTIFICATION AND LOCATION ..............................................47

8.2 HYDRAULIC DIAGRAM...............................................................................................................49

8.2.1 HYDRAULIC DIAGRAM INDEX ............................................................................................ 49

8.2.2 PUMPS AND UNDERCARRIAGE PART HYDRAULIC DIAGRAM.................................50

8.2.3 AERIAL PART HYDRAULIC DIAGRAM...............................................................................51

8.3 PUMPS AND HYDRAULIC LINES SYSTEM...........................................................................52

8.4 GROUND PART HYDRAULIC SYSTEM...................................................................................55

8.4.1 OUTRIGGERS............................................................................................................................56

8.4.2 DRIVE GEAR MOTORS...........................................................................................................57

8.4.3 TRACKS WIDENING ...............................................................................................................59

8.5 AERIAL PART HYDRAULIC SYSTEM......................................................................................60

8.5.1 FIRST AND SECOND BOOMS.............................................................................................. 61

8.5.2 THIRD BOOM ............................................................................................................................62

8.5.3 TELESCOPE................................................................................................................................62

8.5.4 JIB.................................................................................................................................................62

8.5.5 BASKET LEVELING..................................................................................................................62

8.5.6 BASKET ROTATION ................................................................................................................62

8.5.7 TURRET ROTATION ................................................................................................................63

8.5.8 EMERGENCY GRAVITY DESCENT SYSTEM.....................................................................63

9. ELECTRICAL SYSTEM.................................................................................................................64

9.1 ELECTRONIC BOARDS INTRODUCTION AND LOCATION.............................................64

9.2 SOFTWARE ....................................................................................................................................65

9.3 CAN-BUS SYSTEM.......................................................................................................................65

9.4 SENSORS COMMUNICATING THROUGH CAN-BUS ........................................................66

9.5 SENSORS AND DEVICES NOT COMMUNICATING THROUGH CAN-BUS.................68

9.6 INCLINATION SENSOR SYSTEM............................................................................................73

9.7 LOAD CELL SYSTEM ...................................................................................................................73

9.8 ELECTRIC MOTOR (NOT FOR LITHIUM VERSION) .........................................................74

9.9 12 VOLT BATTERY.......................................................................................................................75

9.10 BATTERY CHARGE SYSTEM .................................................................................................75

4

10. DIAGNOSE AND SETTINGS.....................................................................................................76

10.1 DIAGNOSE AND SETTINGS BY REMOTE CONTROL ...................................................76

10.1.1 DISPLAY ICONS ...................................................................................................................76

10.1.2 INPUT.......................................................................................................................................78

10.1.3 LANGUAGE.............................................................................................................................85

10.1.4 ERRORS ..................................................................................................................................86

10.1.5 RAMPS .....................................................................................................................................87

10.1.6 CURRENTS .............................................................................................................................87

10.1.7 WORKING HOURS...............................................................................................................88

10.1.8 JOYSTICK ...............................................................................................................................88

10.1.9 SETUP ......................................................................................................................................88

10.1.9.1 ROTATION..........................................................................................................................89

10.1.9.2 VERSION.............................................................................................................................89

10.1.9.3 TIME .....................................................................................................................................89

10.1.9.4 PASSWORD........................................................................................................................89

10.1.9.5 DATE ....................................................................................................................................89

10.1.9.6 LOAD SENSOR..................................................................................................................90

10.1.9.7 INCLINATION SENSOR..................................................................................................90

10.1.9.8 EXTRA..................................................................................................................................90

10.1.9.8.1 FIRMWARE.....................................................................................................................90

10.1.9.8.2 CARDS............................................................................................................................. 90

10.1.9.8.3 MODEM............................................................................................................................91

10.1.9.8.4 GPS...................................................................................................................................91

10.1.9.8.5 OPTIONAL (PAGE1) ....................................................................................................91

10.1.9.8.5.1 PEDAL ..........................................................................................................................91

10.1.9.8.5.2 BEEPER........................................................................................................................92

10.1.9.8.5.3 SECOND SPEED .......................................................................................................92

10.1.9.8.5.4 ELECTRIC MOTOR ...................................................................................................92

10.1.9.8.5.5 LAMPS..........................................................................................................................92

10.1.9.8.5.6 CHK INC......................................................................................................................92

10.1.9.8.6 OPTIONAL (PAGE 2)...................................................................................................93

10.1.9.8.6.1 SERVICE .....................................................................................................................93

10.1.9.8.6.2 RC SPEED...................................................................................................................93

10.1.9.8.6.3 RC MOVE ....................................................................................................................93

5

10.1.9.8.6.4 AD TEST...................................................................................................................... 93

10.1.9.8.6.5 AS TEST ......................................................................................................................93

10.1.9.8.6.6 SKYGUARD.................................................................................................................94

10.1.9.8.7 OPTIONAL (PAGE 3)...................................................................................................94

10.1.9.8.7.1 CHG SET .....................................................................................................................94

10.1.9.8.7.2 INV SET.......................................................................................................................94

10.2 REMOTE CONTROL CONNECTION ON THE GROUND CONNECTOR .....................95

11. POWER SYSTEM...........................................................................................................................97

11.1 GASOLINE MACHINE WITH ENGINE HONDA IGX390.....................................................99

11.2 DIESEL MACHINE WITH ENGINE HATZ 1B40 ............................................................101

11.3 LITHIUM MACHINE WITH 36V LITHIUM BATTERY SYSTEM......................................103

APPENDIX 1 –TILT SENSOR CALIBRATION...............................................................................109

APPENDIX 2 - LOAD CELL BOARD (ECM3) CALIBRATION ....................................................110

APPENDIX 3 - REMOTE CONTROL JOYSTICK CALIBRATION................................................111

APPENDIX 4 –REMOTE CONTROL STOP BUTTON BY-PASS ................................................112

APPENDIX 5 –PHOTOCELLS SETTING AND CALIBRATION..................................................113

APPENDIX 6 –MASTER BOARD (ECM1) REPLACEMENT AND SETTING ..........................114

APPENDIX 7 –ACOUSTIC RECALL DEVICES..............................................................................117

APPENDIX 8 –SKYGUARD.................................................................................................................118

APPENDIX 9 –CODE MENU...............................................................................................................119

APPENDIX 10 - TROUBLESHOOTING ............................................................................................125

APPENDIX 11 –INPUT MENU OLDER THAN RELEASE 2.0 ....................................................132

6

THE PRESENT MANUAL HAS TO BE CONTEMPLATE WITH INDICATIVE

PURPOSE, IT DOESN'T REPLACE ANYHOW MACHINE USE AND

MAINTENANCE MANUAL.

UNANNOUNCED VARIATIONS AND CORRECTIONS COULD BE APPLIED

ON MACHINES AND ON THE PRESENT DOCUMENT.

THEREFORE ALWAYS REFER TO USE AND MAINTENANCE MANUAL FOR

ORDINARY AND EXTRAORDINARY USAGE, FOR MAINTENANCE, FOR

PROBLEM SOLVING AND GENERALLY FOR ANYTHING REGARDING THE

MACHINE.

1. INTRODUCTION

This booklet describes the technical and safety features, the electrical system

and the hydraulic system of the Hinowa LightLift 15.70 3S Performance.

It does not include how to operate the machine, for this purpose refer to the

Operation and Maintenance Manual.

The first two digits of numerical part of the LightLift name identify the machine

maximum working height in meters, while the last two digits indicate the

maximum outreach in decimetres.

The aerial platform is equipped with an hydraulic system and an electrical

system that interact to ensure safe operating in any situation.

The present manual describes those two systems and how they interact.

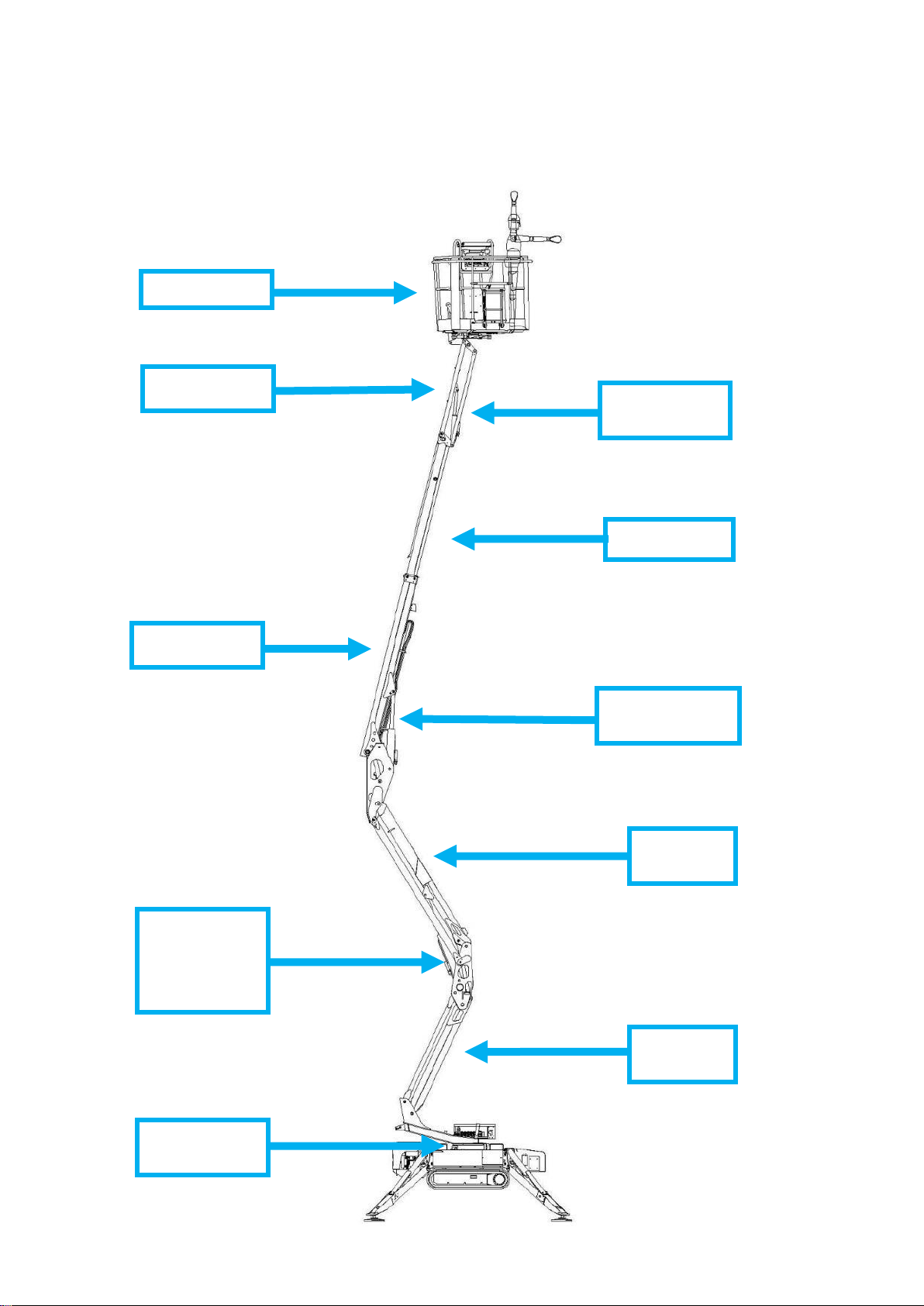

1.1 PARTS DENOMINATION

The base sides of the machine are established looking from inside the basket,

which is positioned in the rear side as indicated in the draft below.

The aerial part booms are numerated looking from the base, i.e. from the turret

slew ring, to the basket as indicated in the draft below.

All the machine movements are controlled by the machine remote control

supplied with the machine. Usually, the remote control is positioned in the

LEFT

SIDE

REAR

SIDE

FRONT

SIDE

RIGHT

SIDE

OUTRIGGER

N.1

OUTRIGGER

N.4

OUTRIGGER

N.3

OUTRIGGER

N.2

7

specific seat in the basket, anyway there are others options illustrated and

described later.

TELESCOPE

FIRST

BOOM

THIRD BOOM

CYLINDER

SECOND

BOOM

JIB

CYLINDER

BASKET

THIRD BOOM

FIRST AND

SECOND

BOOMS

CYLINDER

TURRET

SLEW RING

JIB

8

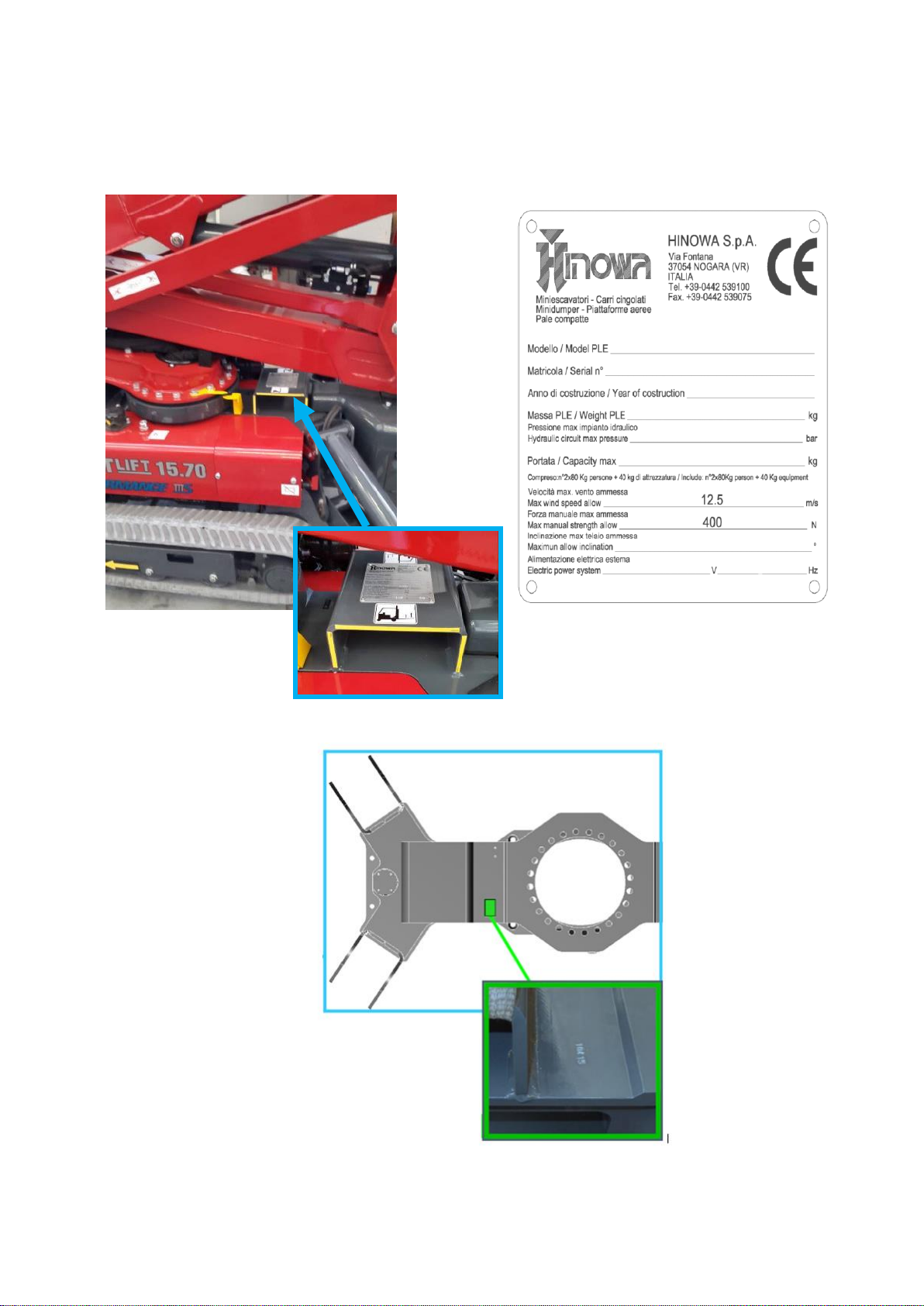

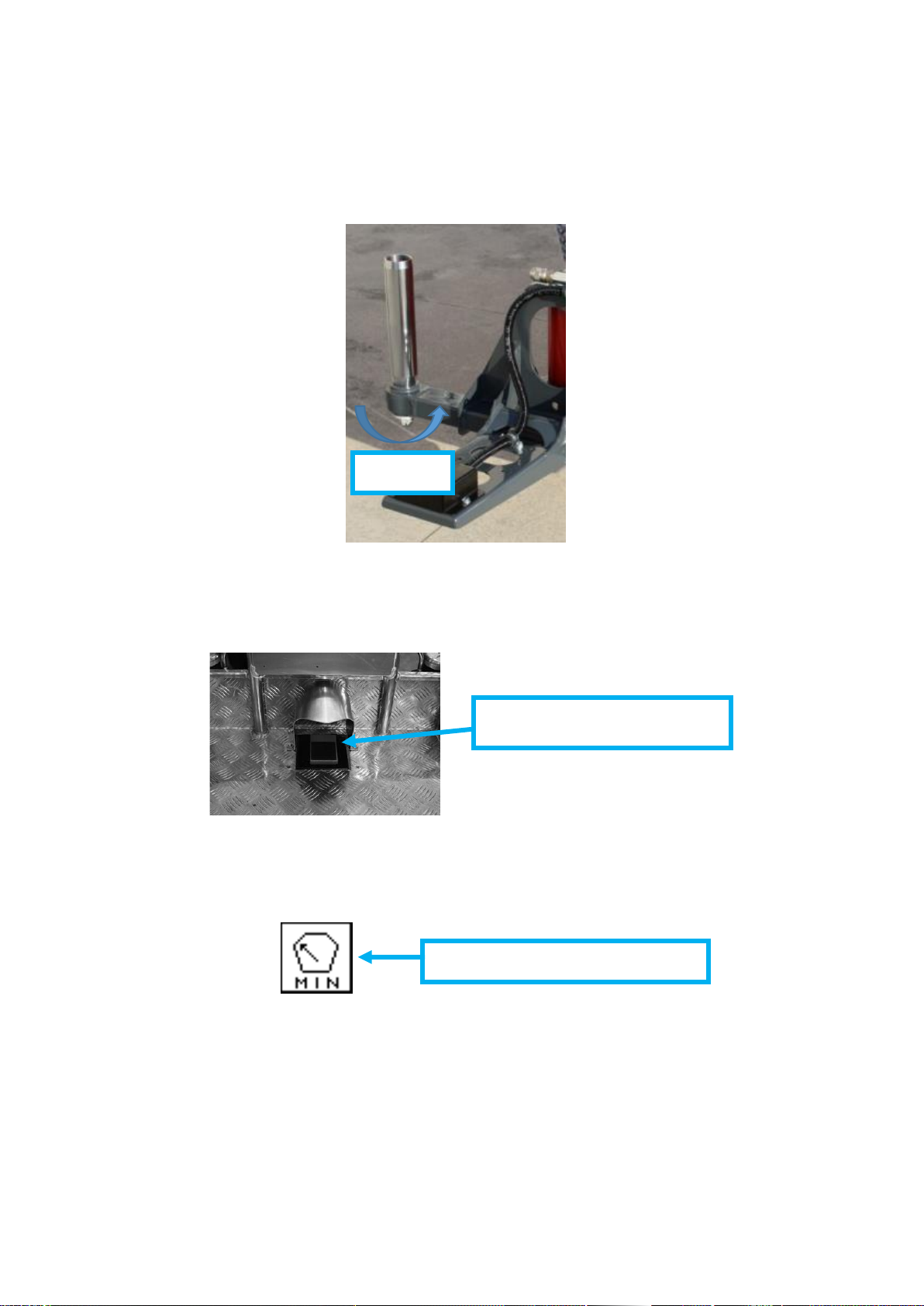

1.2 SERIAL NUMBER LOCATION

To identify the machine a serial number plate is affixed on to the frame of the

machine. The following illustrations showing its location.

The machine serial number is also printed on the frame.

SERIAL NUMBER PLATE

LOCATION

9

2. LL15.70 DATA

2.2 TECHINCAL SPECIFICATIONS

MACHINE ENGINE TECHNICAL

Platform capacity

230 Kg

Max height (basket floor level)

13,30 m

Max working height

15,40 m

Up & Over height

7,0 m

Max working horizontal extension

6,60 m

Basket dimensions (standard two persons basket)

1335x690xH1100mm

Length with basket installed

4020 mm

Length with basket off

3400 mm

Height

1990 mm

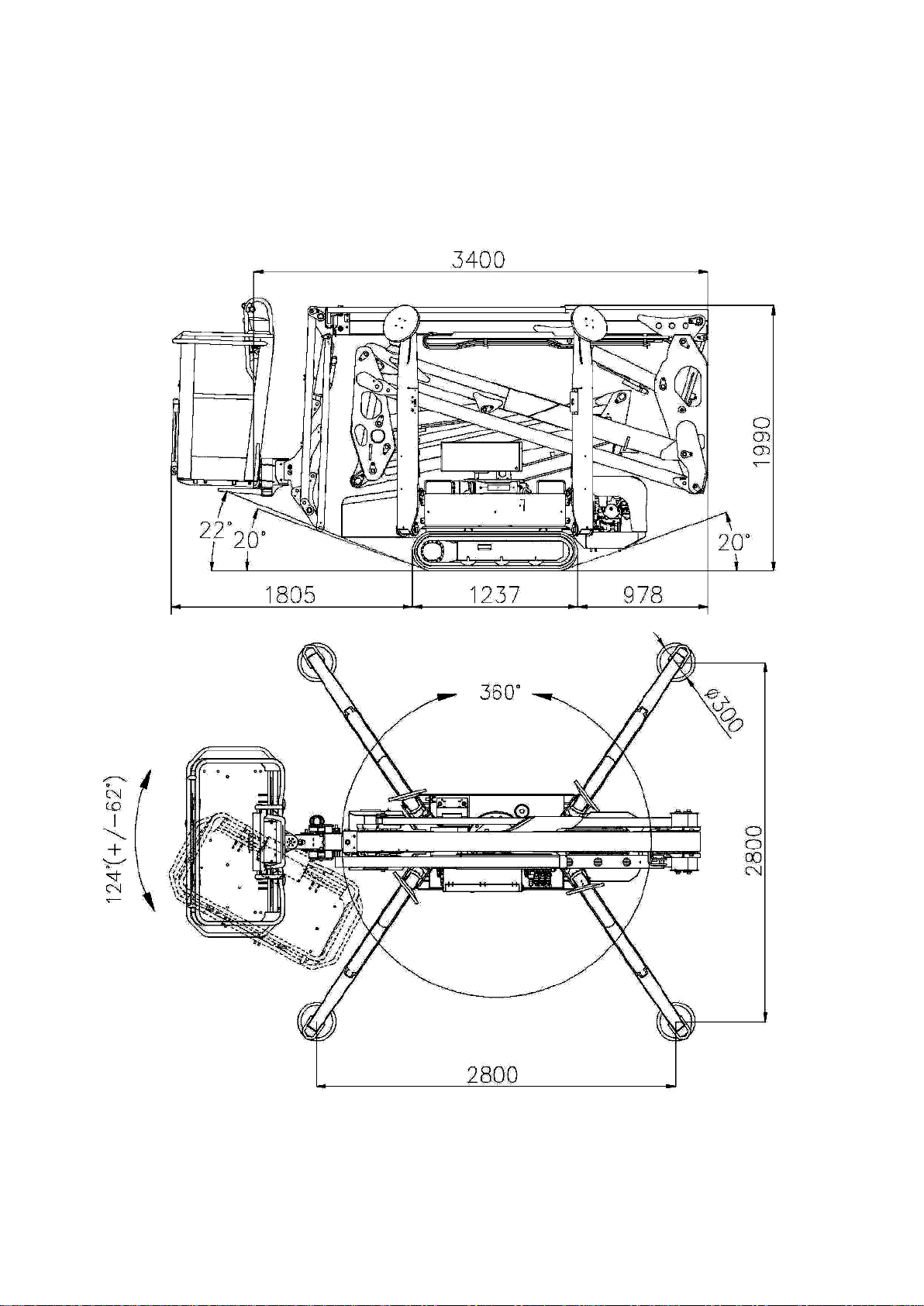

Undercarriage width (Retracted/Extended)

748 / 1100 mm

Stabilization area

2800x2800 mm

Rotation (non-continuous)

360°

Basket rotation

124° (+/- 62°)

Max reaction on the ground for outrigger

1670 daN

Max pressure on the ground for outrigger

2,36 daN/cm²

N° of operators

2

N° operators for optional one person basket

1

Jib function

89° (+0° / -89°)

Max aerial part working inclination

1°/ 1,75%

Max stabilization angle

15°

Gasoline machine operating weight (without operator)

1940 Kg

Diesel machine operating weight (without operator)

1960 Kg

Lithium machine operating weight (without operator)

1992 Kg

Gasoline/Diesel machine Max drive speed with double

speed

0,7/1,4/2,6 Km/h

Lithium machine Max drive speed with double speed

0,4/0,8/1,6 Km/h

Angle of attack

20° / 36%

Max admitted translation inclination in translation direction

(with tracks automatic speed control activated)

16° / 28,7%

Max admitted translation inclination in the translation

orthogonal direction (with tracks automatic speed control

activated)

13° / 23,1%

Max wind speed

12,5 m/s

Max manual force allowed

400 N

Hydraulic pressure of ground part (tracks-outriggers)

180 bar with engine

Hydraulic pressure aerial part

165 bar with engine

Hydraulic oil tank capacity

24 litres

Engine pumps capacity

double 2x3,15 cm³

Electric motor pumps capacity

double 2x3,15 cm³

Lithium electric motor pumps capacity

double 2x3,15 cm³

Electric system tension

12V

10

Battery

60Ah - 680A - 12V

Gasoline engine alternator current

10 A at 3600rpm

Diesel engine alternator current

14÷15 A at 3600rpm

Electric motor rated voltage

230V - 110V - 120V

Electric motor frequency

50Hz - 50Hz - 60Hz

Electric motor rated powers

2,2 Kw - 2,2 Kw - 1,2 Kw

DATA DIESEL ENGINE TECHNICAL

Brand/model

HATZ 1B40

Fuel/cooling

Diesel / Air

Power SAEJ1349

7,5 Kw (10HP) at

3600rpm

Max rated engine speed

3600 rpm

Max torque

25 Nm at 2000rpm

No. of cylinders

1

Displacement

462 cm³

Tank capacity

5 litres

GASOLINE ENGINE TECHNICAL DATA

Brand/model

HONDA iGX 390

Fuel/cooling

Gasoline / Air

Power SAEJ1349

8,7 kw (11,7HP) at

3600rpm

Max rated engine speed

3600 rpm

Max torque

26,4 Nm at 2500rpm

No. of cylinders

1

Displacement

389 cm³

Tank capacity

5,3 litres

LITHIUM PACK TECHNICAL DATA

Battery

100Ah

Electric motor rated voltage

36 V

Electric motor rated power

2 KW

On-board battery charger

220V±30V 50÷60 Hz

110V±30V 50÷60 Hz

11

2.3 LL15.70 DIMENSIONS

MACHINE IS SHOWN HERE BELOW WITH THE 2 PERSONS BASKET,

DIMENSIONS REPORTED IN THIS DRAWING ARE NOMINAL, THE REAL VALUE

OF EACH DIMENSION CAN BE INFLUENCED BY COMPONETS MANUFACTURE

TOLLERANCES AND ELASTIC DEFORMATIONS DUE TO THE FORCES EFFECTS.

12

13

2.4 LL15.70 WORKING AREA - 230 KG UNRESTRICTED CAPACITY

14

3. MACHINE OPERATIONAL INTRODUCTION

The LL15.70 aerial platform is divided into two main parts:

Ground part (or undercarriage part)

Aerial part

Driving or using the outriggers we are using the ground part.

Moving the booms or the turret rotation we are using the aerial part.

All of those movements are carried out by the remote control.

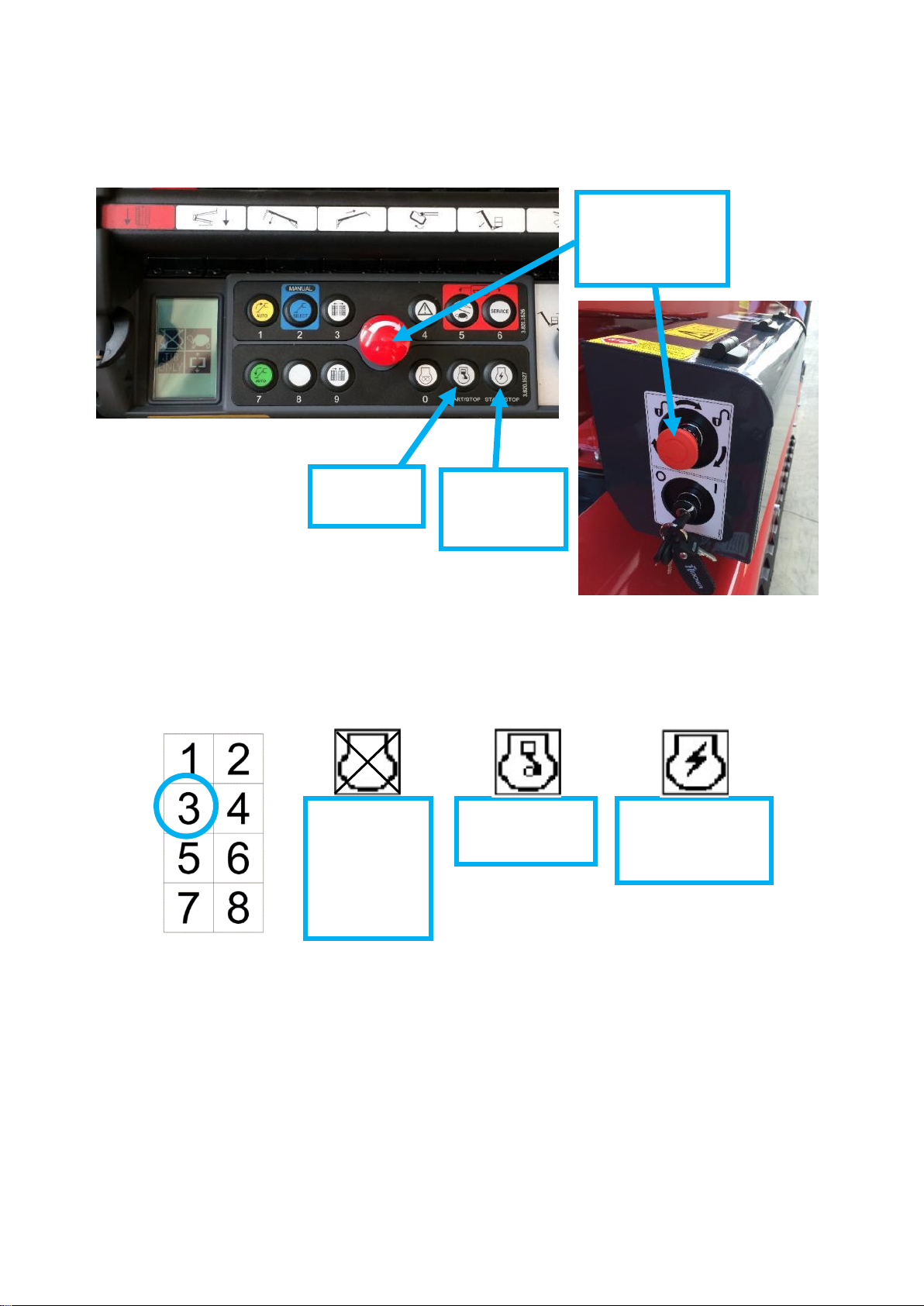

3.1 MACHINE IGNITION

To start up the machine the battery cutter must be active, when main key on

ground control box is turned ON display will show the following icon indicating

to press and release the remote control emergency stop button to initialize the

machine.

After stop button will be pressed and released the machine is ready to be used

and main display indications will be visualized.

INcas e ofnec

To switch ON the electric motor the machine need to be plugged to the local

electric network with a proper cable, shorter than 10m and with a minimum

section of 2,5mm2 (220V network) or 4mm2 (110V network).

To ignite engine or electric motor, both the emergency stop buttons, on the

remote control and on the ground control box, must be released.

MAIN KEY

TURNED

“ON”

BATTERY

CUTTER

INITIALIZATION

ICON

PRESS AND

RELEASE

THE STOP

BUTTON

15

Operator has to press the remote control “ENGINE”button to start it, or he

has to press the remote control “ELECTRIC MOTOR” button to switch it ON.

While engine or electric motor are running, the same relevant “ENGINE”or

“ELECTRIC MOTOR” buttons have to be used to switch them OFF. Also pressing

one emergency stop button engine or electric motor will be switched OFF.

Engine and electric motor cannot run together and the system avoids it, looking

at the display icon in position 3 it’s always possible to verify their condition.

To start the engine, on display position 3 has to be shown the first icon here

above.

After that machine has been used it must be switched OFF by the main key on

ground control box.

When outriggers are not touching the ground and both engine and electric

motor are switched OFF, but main key is still ON, remote control emits an

intermittent acoustic signal to remind the operator about to switch OFF the

main key.

NOTE: It’s not possible to start engine/electric motor while a joystick is pressed

ELECTRIC

MOTOR

RUNNING

ENGINE

REUNNING

NO

ENGINE/

ELECTRIC

MOTOR

RUNNING

ENGINE

BUTTON

EMERGENCY

STOP

BUTTONS

ELECTRIC

MOTOR

BUTTON

16

3.2 STOP BUTTONS

Machine is equipped with two emergency stop buttons, one on the remote

control that could be always use by the operator holding the remote control,

and another one outside the ground control box.

Pressing an emergency stop button the engine or the electric motor will be

switched OFF, avoiding any machine movement.

If the operator tries to start up the machine with one stop button pressed, the

"STOP PRESSED" icon will appear in the middle of the screen.

The emergency stops buttons work with dedicated 12 Volt lines not used by the

other machine sensors or devices.

In case of emergencies it’s possible to by-pass the remote control stop button

following the procedure indicated at APPENDIX 10.

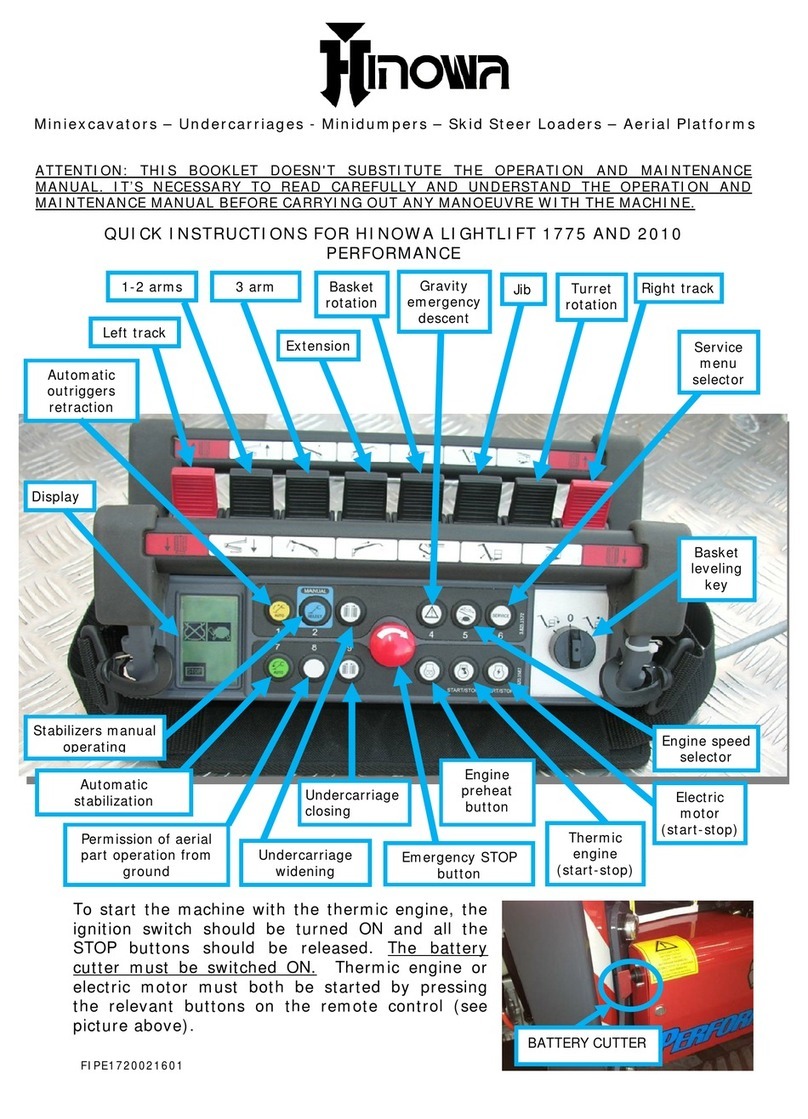

3.3 REMOTE CONTROL FUNCTIONS

The remote control is essential for the machine: it displays all the information

on the platform status and any error message in case of incorrect use of the

controls. It is also possible to access the SERVICE menu, which indicates any

anomalies or malfunctioning of machine components.

The main icons on the display are disposed in 8 different positions, as illustrated

here above, other icons could be visualized in the middle of the screen.

“STOP PRESSED”

ICON

17

NOTE: The remote control joystick should not be kept pressed before to

initialize the machine, if one joystick is kept pressed before it will be deactivated

after initialization, in this case that’s enough to restart the machine to reset it.

NOTE: Lithium machine remote control has blank stickers on the position of

ENGINE PREHEATING, ENGINE (START-STOP) and ELECTRIC MOTOR (START-

STOP).

ENGINE

WARM UP

(ONLY FOR

GASOLINE

MACHINE)

OR

GRAVITY

EMERGENCY

DESCENT

LEFT TRACK

1-2 ARMS

JIB

TURRET

ROTATION

RIGHT TRACK

THIRD

BOOM

BASKET

ROTATION

TELESCOPE

ELECTRIC

MOTOR

(START-STOP)

ENGINE

(START-STOP)

UNDERCARRIAGE

CLOSING

AUTO-

STABILIZATION

ENGINE SPEED

SELECTOR

SINGLE

OUTRIGGER

MOVEMENT

SELECTOR

SERVICE

MENU

SELECTOR

DISPLAY

EMERGENCY

STOP

BUTTON

GROUND ASSENT

UNDERCARRIAGE

WIDENING

BASKET

LEVELING

KEY

OUTRIGGERS

AUTOMATIC

RETRACTION

18

4. GROUND PART MOVEMENTS

4.1 TRACKS MOVEMENTS

To allow tracks movements none of the outriggers have

to be touching the ground, doesn’t matter if completely

lifted up or just lifted, doesn’t matter if opened or in

stowed position.

When machine is not closed and aligned, if operator try to

move an outrigger display will remind that machine need

to be closed and aligned by the error message aside.

The operator has to act on the two external remote control red joysticks to

move the tracks.

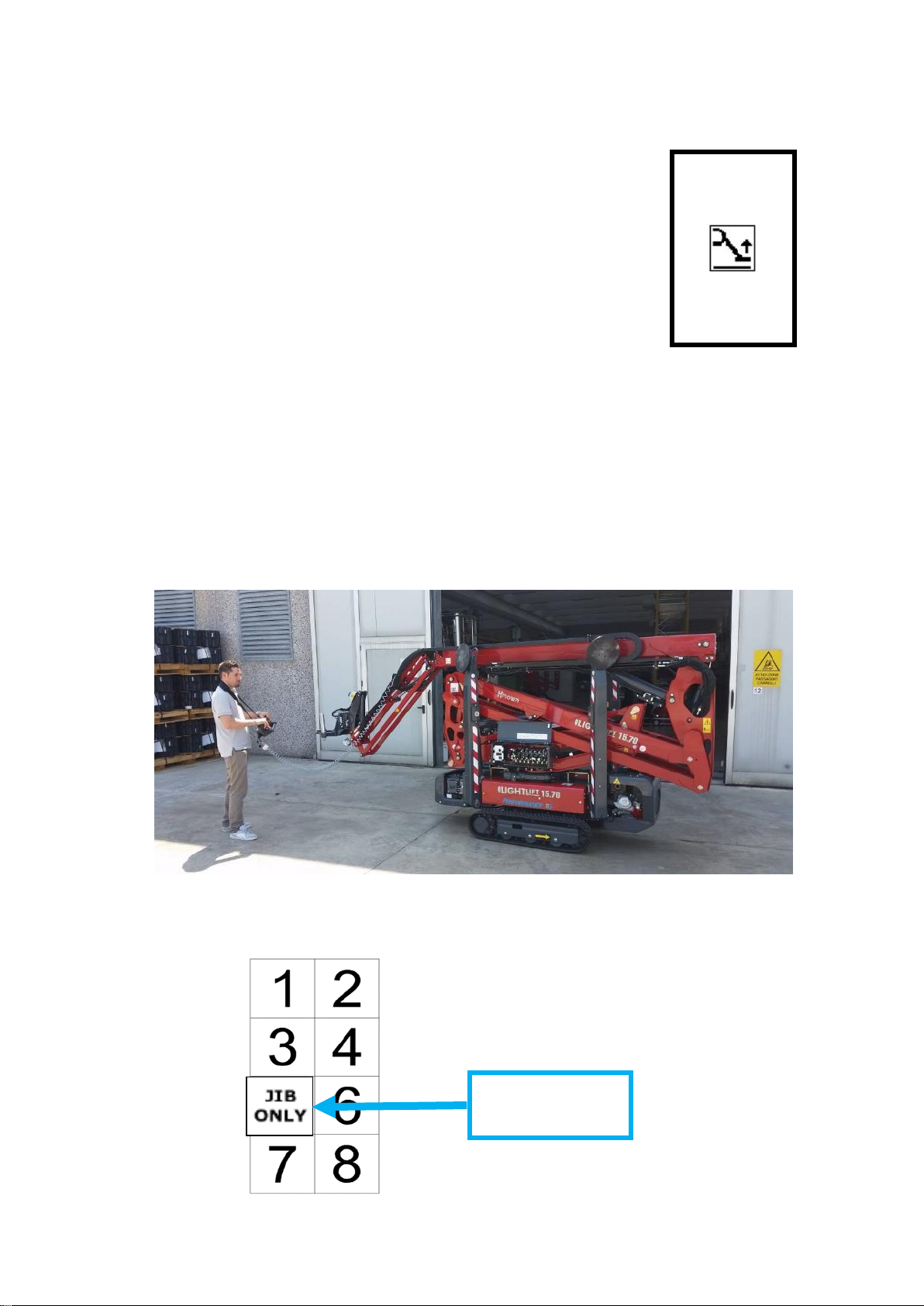

With the jib closed, it’s possible to drive the tracks standing on the ground or

standing on the basket.

To drive the tracks with jib opened the basket must be taken off its support

and operator will keep remote control in his hand.

NOTE: With Skyguard installed, to unload the basket it has to be

disconnected the Skyguard connector.

While none of the outriggers is touching the ground and basket is taken off its

support on the display is visualized the “JIB ONLY” icon.

“JIB ONLY”

ICON

ERROR

19

If in the basket is still on its support, it will be not possible to move the jib or

to drive the tracks with jib already opened.

In those cases the error message “UNLOAD THE BASKET” will be displayed.

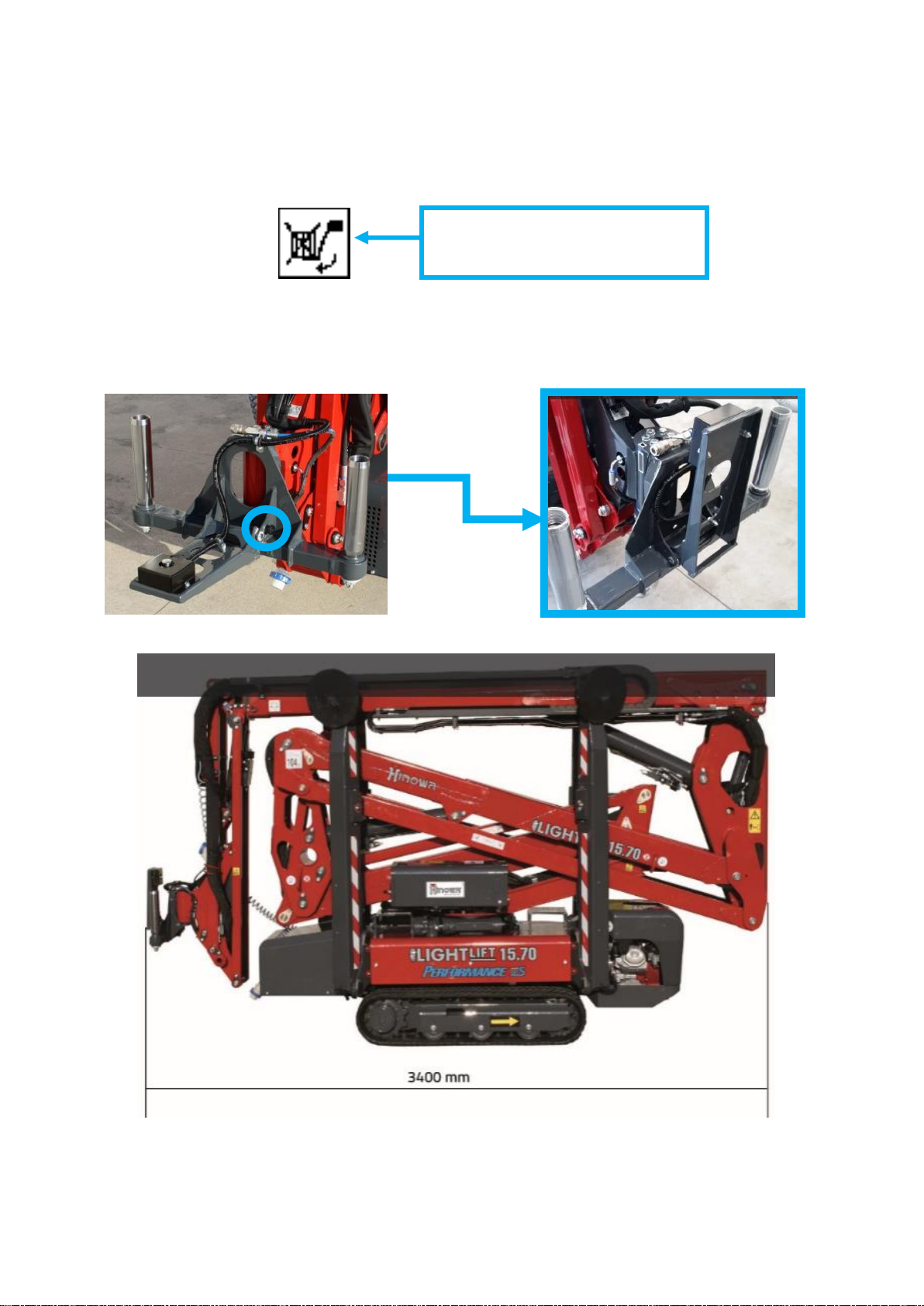

To reach the total length of 3400 mm the basket must be unloaded and its

support must be lifted acting on its pin, as indicated below.

“UNLOAD THE BASKET”

ICON

20

When basket is installed back on its support the two pins stoppers must be

completely screwed.

NOTE: In case of need, basket pin must be screwed at 50Nm.

If pedal option is active and the remote control is on its basket support the

operator standing into the basket has to press the pedal while moving the

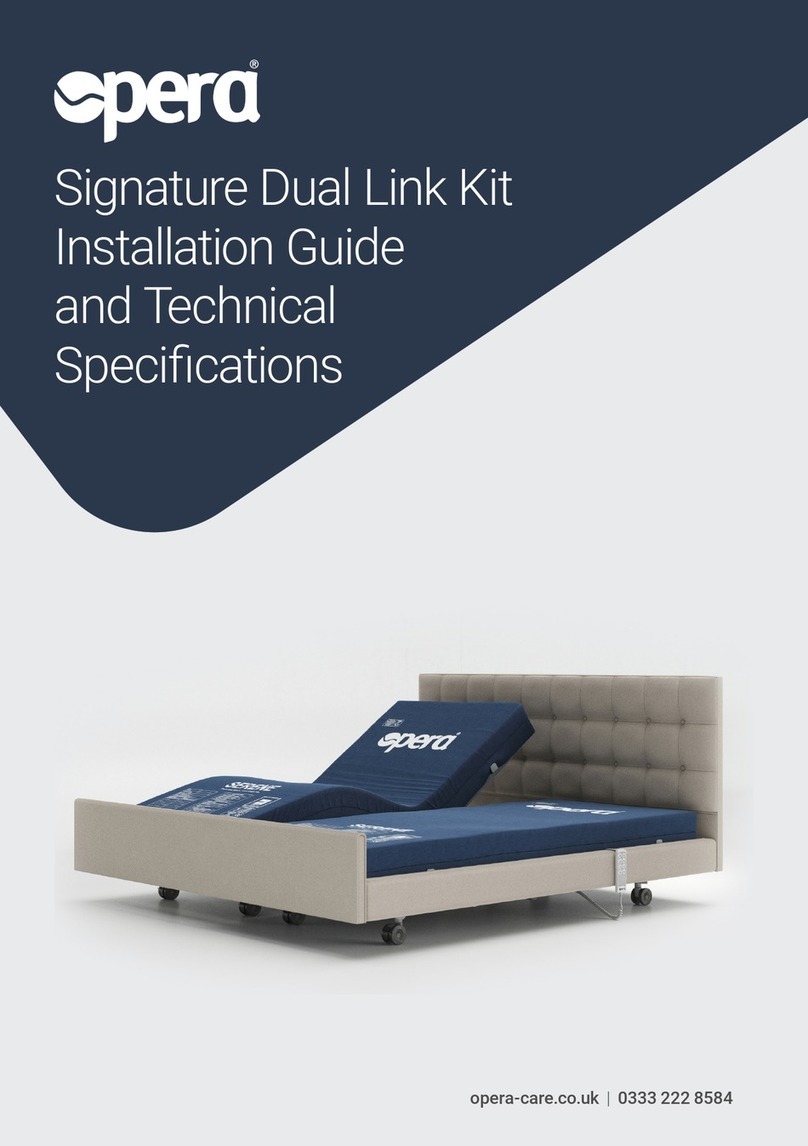

tracks.

For safety reason, as soon as the basket is lifted from the load cell sensor, the

aerial part movements are disabled and display shows “LOAD MIN”icon.

NOTE: If pedal option is active and the remote control is on its basket support

the operator standing into the basket has to press the pedal while moving the

tracks.

“LOAD MIN” ICON

50Nm

PEDAL IN THE BASKET

Table of contents

Other Hinowa Lifting System manuals

Popular Lifting System manuals by other brands

Atlas

Atlas BP8000 How to Do

Opera

Opera Signature Dual Link Kit Installation guide and technical specifications

Wilo

Wilo DrainLift XXL Series Installation and operating instructions

Snorkel

Snorkel S3010E Parts & service manual

Grundfos

Grundfos Multilift MD1 Installation and operating instructions

LGMG

LGMG SR1018D Operation manual