EquipSolutions Tempest 2.0 Owner's manual

Tempest 2.0

OperaƟon Manual & Programming Guide

www.equip-solutions.com 888-200-1800

Tempest 2.0

Operation & Programming Manual

Tempest 2.0 Polymer Feed and Control Station – Sept 2020 - Rev. 1.0

1

Table of Contents

Introducon 3

Selecon & Pump Guide 5

Layout 6

Water & Neat Polymer Connecons 7

Tempest 2.0 Controller 8

ControllerOverview8

ElectricalConnecons9

MainPanel10

MenuNavigaon10

RemoteStart/StopOverview11

LocalModeOverview11

RemoteModeOverview12

AlarmOverview12

Tempest 2.0 Controller Programming Overview 13

LocalModeStart/Stop13

SengtheFeedMode14

Local%Concentraon14

LocalFeedRate14

GeneralTimerSengs15

LowWaterAlarmSeng15

FlushTimerSengs16

RemoteStart/StopSengs17

Remote%Concentraon&FeedRateSengs18

RemoteUnitsofMeasureSengs19

ResengtheRemoteInputCalibraonCurve20

ResengAlarmCondions21

DataLogging&Graphing22

Grundfos DDA Smart Digital Pump 23

ControlElements23

PumpCalibraon23

Tempest 2.0 Maintenance & Troubleshoong 24

Tempest 2.0 Polymer Feed and Control Station – Sept 2020 - Rev. 1.0

Tempest 2.0

Operation & Programming Manual

2

Table of Contents (cont.)

Tempest 2.0 Polymer Feed System 25

Installaon&Start‐Up25

PrimingthePolymerPump25

DiluonWater 26

SengtheDiluonWaterFlow26

PostDiluonOperaon26

Specificaons 27

Appendix 28

Tempest2.0ProgrammingGuide29

SengFeedMode29

SengLocal%Concentraon29

SengLocalFeedRate29

SengGeneralTimers30

SengLowWaterFlowAlarm30

SengFlushCycles31

SengRemote%ConcentraonorRemoteRate32

SengRemoteInputEngineeringUnits33

ResengRemoteInputCalibraonCurve34

ResengAlarms35

General Arrangement Drawings 36

Tempest 2.0

Operation & Programming Manual

Tempest 2.0 Polymer Feed and Control Station – Sept 2020 - Rev. 1.0

3

Copyright ©2020EquipSoluonsAllrightsreserved

Nopartofthispublicaonmaybeduplicatedand/orpublishedthroughprinng,photo‐copying,microfilm,

electronicallyorviaaudiotapesorbestoredinanyothermannerwithoutpriorwrienconsentfromthe

ThankyouforyourinvestmentinthenewTempest2.0PolymerFeed

andControlStaon.

TheTempest2.0Seriesofliquidpolymerfeedandcontrolstaonsare

designedtoprovidemaximizedpolymerperformancewithoutthe

hasslesandheadachestheseapplicaonscauseforwatertreatment

professionals.

Thesystemdesignprovidestherighttypeofmixingenergyatthe

cricalmomentofinialwengandtapersthatenergythrougha

mul‐stageregimeofhydrangzones.

Thenetresultisafullyhydratedpolymersoluonwithmaximum

chargesiteexposurewhichassuresopmizedpolymerusageandper‐

formance.Thedesigneliminatesunwantedagglomeraons,plugging

andthecostlymessofdealingwiththeseissues.

ThenewTempest2.0controllerprovidesareal‐medisplayof

yourcricalapplicaonparameters.Inaddion,thenewcon‐

trolleroffersabroadrangeofenhancedcapabiliesincluding

addionI/Oopons,andon‐boarddataloggingwithgraphicdis‐

play.

Primarydiluonwaterflowiscontrolledbyasolenoidvalve

whichallowswatertoentertheunit.

Primarydiluonwaterflowratedataismeasuredconnuouslytoassurethatadequateflowispresent

andfedbacktotheTempest2.0controller.Usingcalculaonsderivedfromthecalibraonstage,the

unitautomacallyadjuststhepolymerpumpoutputtoachievethedesired

concentraon.

Undercondionsofhighorlowconcentraon,alossofwaterfloworpolymer

feed(oponal)thesystemautomacallyshutsdownandnofieswithan

alarm.Eachfeedcycleisfollowedbyanadjustable,mul‐stageflushcycleto

eliminateanyplugging.Thesystemcanbeoperatedremoteviaa4‐20mAor

simpleon/offsignal.

TheTempest2.0isbackedbyaOneYearWarranty.Pleasecallusifwecanbe

ofassistanceinanyway.

Introducon

Tempest 2.0 Polymer Feed and Control Station – Sept 2020 - Rev. 1.0

Tempest 2.0

Operation & Programming Manual

4

TheTempest™2.0PolymerFeedSystemisaself‐

containedsystemdesignedtocontrolfeedwaterand

polymerandcombinethemtoproduceahighquality

soluon.ThesystemisdesignedtoreceiveanEmulsion,

SoluonorMannichpolymerandmixwithfeedwaterto

produceanddischargeaqualitysoluonfromthesys‐

tem.

TheTempest™2.0PolymerFeedSystemcanbeenabled

inlocalmode(simpleOn/Offoperaon)orremotelyvia

acustomersupplieddrycontactwhichwillStop/Start

theTempest™PolymerFeedSystem.

Inlocalmode,theTempest™2.0PolymerFeedSystem

canbeoperatedbasedon“override”manualsetpoints

orinternalflowpacingsetpoints.Themanual

“override”modeallowstheusertomanuallyadjustthe

rotameterandpumpcapacieslocally.Theinternal

flowpacingmode,allowstheControllertopacetheneat

polymermeteringpumpvolumeoutputtotheflowof

watertoholdthesoluonatasetconcentraonpoint

whichisselectedintheTempest2.0controller.

Inremotemode,theTempest™2.0PolymerFeedSystemofferstwocontroloponsaswell.Inthe

RemoteConcentraonmode,theControllerreceivesaremoteanalogsignaltoadjustthedesired

concentraonsetpointwhilethediluonwaterflowremainsconstant.RemoteRatemodereceives

aremoteanalogsignaltoadjusttothepumpspeed.Eitherremotemodeoponcanbeachieved

withtheremotedisableseleconontheONorOFFposion.

Acompleteskidmountedsystem;theTempest™2.0PolymerFeedSystemisequippedwithallthe

necessarycomponentsforeasyinstallaon,reliableperformanceandsafeoperaon.Thedesign

incorporatesanelectricsolenoidvalve(water),thenewEndress+Hausermagflowmeter,manually

adjustablerotometer,electricsolenoiddiaphragmpump(Polymer),thenewTempest2.0controller,

manualballvalves,calibraoncolumn,PVCpipingandcomponents,allonaSSframetoprovidethe

durabilitytowithstandharshcondionsandminimizemaintenance.

ThismanualisdesignedtoprovidesimpleexplanaonsonhowtousetheSystem.Thelayoutsinthis

manualweredoneinaneffortto“literally”walkyouthroughthesystem’soperaons.

Introducon

Tempest 2.0

Operation & Programming Manual

Tempest 2.0 Polymer Feed and Control Station – Sept 2020 - Rev. 1.0

5

Tempest 2.0 Selecon and Pump Guide

Primary Diluon Water Range Neat Polymer Range

Model Number Rated GPH Min GPH Max Inlet Pressure Min GPH Max GPH

TP2‐300‐2 300 30 100 PSI 0.02 4.5

TP2‐600‐4.5 600 60 100 PSI 0.02 4.5

TPS‐1200‐4.5 1200 120 100 PSI 0.04 4.5

TPSG‐1200‐15.8 1200 120 100 PSI 0.02 15.8

Connecons

Model Range Water Inlet Polymer Inlet Soluon Outlet VAC

TP2‐300 1" FNPT 1/2" FNPT 1" FNPT 120/1/60

TP2‐600 & 1200 1‐1/2" FNPT 1/2" FNPT 1‐1/2" FNPT 120/1/60

TheTempest2.0featurestheGrundfosSmartDDAmeteringpumpsthatal‐

lowsfortheconsolidaonofmodelsandmaximumapplicaonflexibility.The

standardTempest2.0seriesoffersaneatpolymerfeedrangeof.02–15.8gph.

AllTempest2.0pumpshavespringloadedchecksandaPVDFheadformaxi‐

mumcompability.Thestandardpumpshaveaturn‐downof1000:1andcan

handleveryhighviscosiesviatheslowmodefeature.

Tempest 2.0 Specificaons

WeedMaterials:

Water:PVC,Brass,Bronze,Buna‐N,Acrylic,316SS

NeatPolymer:PVC,Acrylic,PTFE,PP,316SS

Electrical:120VAC/1Phase/60Hz

Dimensions:30”Wx36”Dx60”H

Weight:

Tempest2.0UnitWeight190lbs.

TotalPackagedWeight:260lbs.

Tempest 2.0 Polymer Feed and Control Station – Sept 2020 - Rev. 1.0

Tempest 2.0

Operation & Programming Manual

6

Tempest 2.0 Layout

Front View

Back View

Tempest 2.0

Operation & Programming Manual

Tempest 2.0 Polymer Feed and Control Station – Sept 2020 - Rev. 1.0

7

SOLUTION OUTLET

1” or 1‐1/2” FNPT CONNECTION

POLYMER INLET

3/4” FNPT CONNECTION

WATER INLET

1” OR 1‐1/2” FNPT CONNECTION

Tempest 2.0 Water & Neat Polymer Connecons

Tempest 2.0 Polymer Feed and Control Station – Sept 2020 - Rev. 1.0

Tempest 2.0

Operation & Programming Manual

8

TheTempest2.0systemissuppliedwithastandardUSthreeprongplugwithcordfor120VAC,Single

Phasepower.Powerispre‐wiredintotheTempest2.0controllerandsupplieselectricityforthe

Tempest2.0Controllerandtheneatpolymermeteringpumpthroughasplash‐proofGFIreceptacle.

Tempest 2.0 Electrical

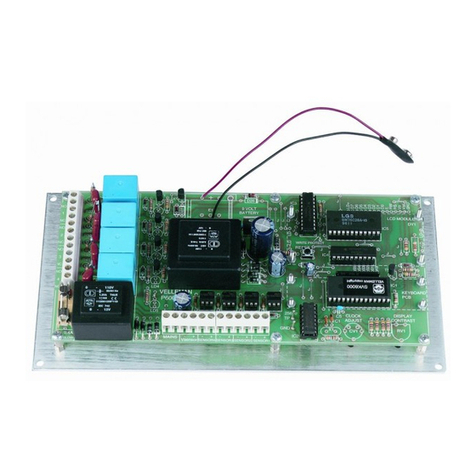

Tempest 2.0 Polymer Dosing Controller ‐Overview

ThenewTempest2.0PolymerDosingControlleroffersprecisecontrol,

easy‐to‐useoperaonalongwithI/Oenhancements.Thecontrollernow

providesourcustomerswiththelatestcontroltechnologieswiththe

capabiliesfromexpandingsensor/analoginputsandoutputstocloud‐

basedcommunicaons.

ThestandardTempest2.0controllercomespre‐programmedforplugand

playoperaon.BasiccontrollerI/Oincludes:

Two(2)AnalogInputs

One(1)forDiluteWaterMeterFlow

One(1)forRemote%Concentraon/FeedRateInput

Eight(8)DigitalInputs

One(1)forRemoteStart/Stop

One(1)forPolymerFeedPumpAlarm

Two(2)Unused(reservedforBatchControlCapability)

Four(4)Unused

Eight(8)RelayOutputs(PoweredorUnpowered)

One(1)forDiluteWaterSolenoidValve

One(1)forGeneralAlarmOutput(120VAC)

Two(2)Unused(reservedforBatchControlCapability)

Four(4)Unused

TheadvancesoftheTempest2.0controllerallowsforunparalleledexpansioninpolymerfeedtechnol‐

ogywhenusingtheExpansionModuleincluding:

MulpleAnalogandDigitalI/O

SpecialtySensorInputs(i.e.Turbidity,SuspendedSolids,pH,TankLevel)

CommoncommunicaonsprotocolsincludingEthernetandcellular

Cloud‐baseddataacquision

ForaddionalinformaonregardingthesefeaturescontactEquipSoluonsat888‐200‐1800

Tempest 2.0

Operation & Programming Manual

Tempest 2.0 Polymer Feed and Control Station – Sept 2020 - Rev. 1.0

9

Tempest 2.0 Controller ‐Electrical Connecons

12345678

14‐20mAInputfromWaterFlowMeter

2FromCustomer:RemoteStart/Stop(DryContact)

3PolymerFeedPumpAlarmInput(DryContact)

4FromCustomer:Remote4‐20mAInputfor%ConcentraonorFeedRate

5GeneralAlarmRelayOutput(120VAC)

6WaterSolenoidValveRelayOutput

7PolymerFeedPump4‐20mAControlOutput

8120VACPowerIn

Tempest 2.0 Polymer Feed and Control Station – Sept 2020 - Rev. 1.0

Tempest 2.0

Operation & Programming Manual

10

Tempest 2.0 Polymer Dosing Controller Main Panel

uSDCardAccess

LCDDisplay

PowerOnLED

AlarmLED

DisplaySoBuons

MenuNavigaonandEnterBuons

QRInformaonCode

WhentheTempest2.0ispoweredon,thePolymerControl

HomeScreendisplayistheanalyzerdefault.Thisscreen

displaysthePolymerFeedRateoftheneatPolymerPump

(inGPH),theControlOutput(%mAOutputtothePolymer

Pump),theWaterFlowRate(inGPM),andthePercent

Concentraon.Belowtheparametersindicatewhetherthe

Tempest2.0isinLocalorRemotemodeofoperaon.

AttheboomoftheHomeScreen,three(3)choicesare

availableincludingMenu,Start/Stop(wheninLocalcon‐

trolmode)andEdit(usedtoprogrammodeofoperaon).

Seleconofanyboommenubuonischosenusingthe

adjacentDisplaySoBuondirectlybelowtheindicator.

NOTE: Please refer to the Programming Guide on Page XX

for detailed programming informaon.

Tempest 2.0 Menu Navigaon

Tempest 2.0

Operation & Programming Manual

Tempest 2.0 Polymer Feed and Control Station – Sept 2020 - Rev. 1.0

11

Tempest 2.0 Polymer Dosing Controller—Local Mode Overview

WheninLocalmodeofoperaon,theusercanchooseto

eitherfeedbasedon%ConcentraonorPolymerFeedRate.

Theboomofthedisplayshowswhichmodeofoperaon

thecontrollerisin.

ToStartthedosingcycle,pressthesobuonunderthe

Starticononthemenu.Theunitwillrunconnuouslyunl

thesobuonunderStopispress.Theunitwillenterthe

pre‐programmedflushcycleandstopunltheStartbuonis

pressedagain.TheLocalcontrolcycleworksthesame

whetherin%ConcentraonofPolymerFeedRateControl.

Tochangefrom%ConcentraoncontroltoPolymerFeed

RateControl(orvisa‐versa),ortomakeparameterchanges,

selectthesobuonundertheEditicon.Thisdirectsyouto

thePolymerControl1.1Screenwhichallowsyoutheenter

parametervaluechangesortochangethemodeofopera‐

on.

Toexitbacktothemainmenu,selectthesobuonunder

theHomeicon.

NOTE: Please refer to the Programming Guide on Page XX

for detailed programming informaon.

Tempest 2.0 Polymer Dosing Controller—Remote Start/Stop Overview

TheTempest2.0systemcanbegindosingwithaRemote

Start/StopdrycontactintheLocalModeofOperaonif

required.ToacvatetheRemoteStart/Stop,selectEdit

fromtheMainMenutoenterthePolymerController1.1

screen.SelectOpons>Setup>SignalSetupfromthe

Menu.ArrowdowntotheInterlockfieldandSelectRemote

Start‐Stop1.1.PressthesobuonundertheHomeicon

toreturntotheHomeScreen.TodisableRemoteStart/

StopselectDisabledfromthemenu.

Tempest 2.0 Polymer Feed and Control Station – Sept 2020 - Rev. 1.0

Tempest 2.0

Operation & Programming Manual

12

Duringeitherlocalorremoteoperaon,theTempest2.0

systemalarmwillacvateifeitherthewaterflowisbelow

thepresentlowlevelsetpoint,ifthe%concentraonlevel

cannotbesasfiedcausedbyinadequatewatervolumeor

inadequatepumpingcapacityorifthePolymerFeedpump

goesintoanalarmcondion.

Wheninanalarmcondion,theTempest2.0willautoma‐

callyshutoffthePolymerFeedPumpandenterthepro‐

grammedflushcycle.Immediatelyfollowingtheflushcyclethecontrollerwillacvatethe120VAC

alarmrelay.ThecontrollerdisplaywillturnREDandindicatewhatparameteracvatedthealarm.To

resetthealarm,theuserselecttheMenusobuon,arrowtohighlightthePolymerController1.1le

andpressthesobuonundertheReseticontoplacethe

systembackintostandbymode.

TheLowWaterFlowThreshold(Alarm)andFlushCyclesare

programmabletomeetcustomerrequirements.ThePolymer

FeedPumpalarmsaregeneratedfromthepumpandusea

relaycontactconnectedtothecontrollertoacvateany

pumpalarm.

Tempest 2.0 Polymer Dosing Controller—Remote Mode Overview

TheRemoteModeofOperaonallowstheusertousearemote4‐20mAsignaltocontroltheRemote

%Concentraon(upto1.5%)orthePolymerFeedRate(from0‐100%).WhenintheRemoteMode,

theStart/StopiconisnolongeravailablefromtheMainMenuScreen.RemoteOperaoncanonlybe

runusingtheremoteStart/Stopdrycontactinput.Note: To run in the Remote Mode, the Remote

Start/Stop dry contact input must be used to acvate and deacvate the feed cycle.

FromtheHomeScreenSelecttheEditsobuontoaccess

thePolymerController1.1screen.ArrowdowntoModeand

presstheEnterbuon.ArrowUporDowntoselectModeof

OperaonandpressEnterandselectHome.Notethatthe

boomoftheHomeScreenwillnowdisplaycurrentcontrol

mode.

IfswitchingFeedModeforRemote%ConcentraontoRe‐

moteFeedRate,aseriesofprogrammingcommandsneedto

beenteredintotheTempest2.0Controller.Thesestepsin‐

cludechangingthecontrol,rescalingandtaggingthenew

input(%orGPH)andelectronicallyrecalibrangthe4‐20mA

inputfortheremotesignal.Detailedinstruconsareprovid‐

edintheProgrammingGuide.

Tempest 2.0 Polymer Dosing Controller—Alarm Overview

Tempest 2.0

Operation & Programming Manual

Tempest 2.0 Polymer Feed and Control Station – Sept 2020 - Rev. 1.0

13

Tempest 2.0 Polymer Dosing Controller—Programming Overview

WhentheTempest2.0ispoweredon,thePolymerControlHomescreen

istheanalyzerdefault.ThisscreendisplaysthePolymerFeedRateof

theneatPolymerPump(inGPH),theControlOutput(%mAOutputto

thePolymerPump),theWaterFlowRate(inGPM),andthePercentCon‐

centraon.BelowtheparametersindicatewhethertheTempest2.0isin

LocalorRemotemodeofoperaon.AttheboomoftheHomeScreen,

three(3)choicesareavailableincludingMenu,Start/Stop(wheninLocal

controlmode)andEdit(usedtoprogrammodeofoperaon).Selecon

ofanyboommenubuonischosenusingtheadjacentdisplaySo

Buondirectlybelowtheindicator.

Local Mode Start/Stop:

ToiniateTempest2.0PolymerSysteminLocalMode,presstheStartBuonadjacenttotheStart

indicator.ThiswilliniatetheTempest2.0toopenthewatersolenoidvalveforapre‐programmed

meperiodandthenenergizethePolymerFeedpumptobeginmaking‐downthepolymersoluon.

ToStopthesystempresstheStopBuonadjacenttothedisplayindicator.TheTempest2.0withstop

thePolymerFeedpumpandconnuewiththepre‐programmedwaterflushcycleunlcomplete.At

thatpointthesystemgoesintoStand‐Bymodewaingforthenextstart

Tempest 2.0 Polymer Feed and Control Station – Sept 2020 - Rev. 1.0

Tempest 2.0

Operation & Programming Manual

14

Tempest 2.0 Polymer Dosing Controller—Local/Remote Mode Seng

To Set Tempest 2.0 Feed Mode:

1.FromtheHomeScreen>SelectEdit

2.ArrowDowntoMode&PressEnter

3.ArrowUp/DowntoSeleconandPressEnter>SelectHome

To Set Tempest 2.0 to Local % Concentraon

1.FromtheHomeScreen>SelectEdit

2.ArrowDowntoControl&PressEnter

3.ArrowUp/DowntoConcentraonSeleconandPressEnter

4.ArrowtohighlightConcentraon&Enter

5.UsetheArrowKeystochangetodesired%andPressEnter.SelectHome

To Set Tempest 2.0 to Local Feed Rate

1.SelectEdit

2.ArrowDowntoControl&PressEnter

3.ArrowUp/DowntoRateSeleconandPressEnter

4.ArrowtohighlightRate&Enter

5.UsetheArrowKeystochangetoFeedRateandChangeunitstoGPH.

6.EnteryourdesiredFeedRate.PressEnter.SelectHome.

Tempest 2.0

Operation & Programming Manual

Tempest 2.0 Polymer Feed and Control Station – Sept 2020 - Rev. 1.0

15

Tempest 2.0 Polymer Dosing Controller—Timer & Low Water Alarm Seng

To Set Tempest 2.0 Timers:

TheTimerseconsallowstoprogramgeneralalarmdelayme,start‐upfeedmedelayandauto‐

primeme‐out

1.HomeScreen>SelectEdit

2.SelectOpons>Setup>TimerSetup

3.ArrowUp/DowntoTimerSeleconandPressEnter

4.UseArrowKeystoadjustdesiredmeandPressEnter.SelectHome

To Set Tempest 2.0 Low Water Flow Alarm:

ThedefaultLowWaterFlowThreshold(Alarm)issetfor10%offullcapacity.Followtheinstruconsto

changetheLowWaterFlowsetpoint.HomeScreen>SelectEdit

1.SelectOpons>Setup>DosingPumpSetup

2.ArrowUp/DowntomakeTimerSeleconandPressEnter

3.UseArrowKeystoadjustdesiredmeandPressEnter.SelectHome.

15.8

Tempest 2.0 Polymer Feed and Control Station – Sept 2020 - Rev. 1.0

Tempest 2.0

Operation & Programming Manual

16

Tempest 2.0 Polymer Dosing Controller—Flush Cycle Seng

To Set Tempest 2.0 Flush Cycles:

1.SelectEdit>Opons

2.SelectSetup>FlushSetup

3.ArrowandSelectFlushDuraon(howlongtoflushmixchamber).PressEnter

4.ArrowandSelectFlushInterval(mebetweenflushduraon).PressEnter

5.ArrowandSelectCount(numberofflushcycles).PressEnter&SelectHome

Tempest 2.0

Operation & Programming Manual

Tempest 2.0 Polymer Feed and Control Station – Sept 2020 - Rev. 1.0

17

Tempest 2.0 Polymer Dosing Controller—Remote Start/Stop Sengs

To Set Tempest 2.0 to Remote Start/Stop

1.HomeScreen>SelectEdit

2.ArrowUp/DowntoModeandPressEnter.SelecttheRemoteBuonandPressEnter.

3.SelectOpons>Setup>SignalSetup

4.ArrowDowntotheInterlockField

5.ArrowDowntoSelectRemoteStartStop1.1andPressEnter&SelectHome

NOTE: The Home Screen will display the system is in Remote (% Concentraon or Rate) Mode and

the Local Start/Stop buons are no longer visible. The Tempest 2.0 will only run in Remote % Con‐

centraon or Remote Feed Rate with a customer supplied Remote Start/Stop Dry Contact closure.

Tempest 2.0 Polymer Feed and Control Station – Sept 2020 - Rev. 1.0

Tempest 2.0

Operation & Programming Manual

18

Tempest 2.0 Polymer Dosing Controller—Remote % Concentraon or Remote

Polymer Feed Rate Feed Sengs

To Set Remote Rate or % Concentraon Input

Note: To switch from Remote % Concentraon to Remote Rate, the Remote Input 1.2 requires

rescaling, changing engineering units, and a calibraon reset. The following steps outline this proce‐

dure

1.HomeScreen>SelectMenu

2.ArrowDowntoHighlightRemoteSetPoint1.2TileandPressEnter

3.SelectOpons>Setup>SetPoint.PressEnter

4.SelectOpons>Setup>SignalSetup

5.ArrowDowntotheRangeField.

Note: This Field will show the Min and Max Seng for the Pump (Remote Rate) or the Min and Max

Seng for % Concentraon (0‐1.5%). If changing from Rate to % Concentraon or % Concentraon

to Rate, the Units will need to be changed and the Calibraons Curve will need to be Reset.

1.SelectUnitstoopenUnitsofMeasureMenus

2.Tochangeto%,ArrowRighttothe1stTypebuonandPressEnter.

3.ArrowDowntoopenthefolderlabeledMiscellaneous.ArrowDowntoSelectpercent.

4.EnterDone.

Tempest 2.0

Operation & Programming Manual

Tempest 2.0 Polymer Feed and Control Station – Sept 2020 - Rev. 1.0

19

Tempest 2.0 Polymer Dosing Controller—Programming Remote Polymer Feed

Rate or Remote % Concentraon Input Units of Measure

To Set Engineering Units for Remote % Concentraon or Remote Rate and Rescaling Input

Note: This Field will show the Min and Max Seng for the Pump (Remote Rate) or the Min and Max

Seng for % Concentraon (0‐1.5%). If changing from Rate to % Concentraon or % Concentraon

to Rate, the Units will need to be changed and the Calibraons Curve will need to be Reset.

1.FromtheParameterSetupScreen,SelectUnitstoopenUnitsofMeasureMenus

2.Tochangeto%,ArrowRighttothe1stTypebuonandPressEnter.

3.ArrowDowntoopenthefolderlabeledMiscellaneous.

4.ArrowDowntoselectpercent.PressEnter

5.ArrowRightto2ndTypebuonandPressEnter

6.ArrowtotopofmenuandselectNone.PressEnter.EnterDone.

1.ToChangefrom%toGPH,ArrowRightto1stTypebuonandPressEnter.

2.ArrowtoVolumefolderandselectgallonandPressEnter.

3.ArrowRightto2ndTypebuonandPressEnter

4. ArrowtoTimefolderandselectHour.PressEnter.

This manual suits for next models

7

Table of contents

Popular Controllers manuals by other brands

Precision Digital Corporation

Precision Digital Corporation NOVA PD540 Series instruction manual

Gestetner

Gestetner 27AO Technical manual

cashco

cashco 48 Series Installation, operation & maintenance manual

SEAWIN Electricals

SEAWIN Electricals 10A Series product manual

Deprag

Deprag SZG Controller 6 operating manual

Siemens

Siemens SINUMERIK 840 sl manual