Equus 8200 User manual

INSTALLATION INSTRUCTIONS

1-1/2" & 2" GAUGE KITS VOLTMETER

AMMETER

OIL PRESSURE

TEMPERATURE

1. Read instructions completely before installation.

2. Install gauges only when engine is cool and ignition is off.

3. Make sure all necessary tools, materials, and parts are on hand.

4. Disconnect negative (–) battery cable before installing gauges.

NOTE: It may be necessary to reprogram your radio, clock,

etc. after reconnecting the battery.

5. Make sure mounting location does not impair visibility or

interfere with driving. Also check behind the mounting location

for any wiring or components before drilling.

6. Refer to your vehicle's service manual for the location of sensor

port, and/or charging system.

BEFORE YOU START

1NOTES:

• Some vehicles use temperature and pressure sensors for

engine control functions. Use a T-fitting if necessary when

installing gauge sensors.

• Whenever a T-fitting is used for temperature, gauge reading

will be lower than actual water temperature.

7. When connecting electrical wires, install and crimp or solder

terminals (purchased separately) and make wire splices as

needed. ALWAYS insulate wire splices with shrink tubing or

electrical tape to prevent shorting.

8. Follow all necessary safety procedures for protection.

WARNING: Check and maintain your engine regularly, and be

aware of any irregularities. Never rely on the gauges as the

ONLY means of protection.

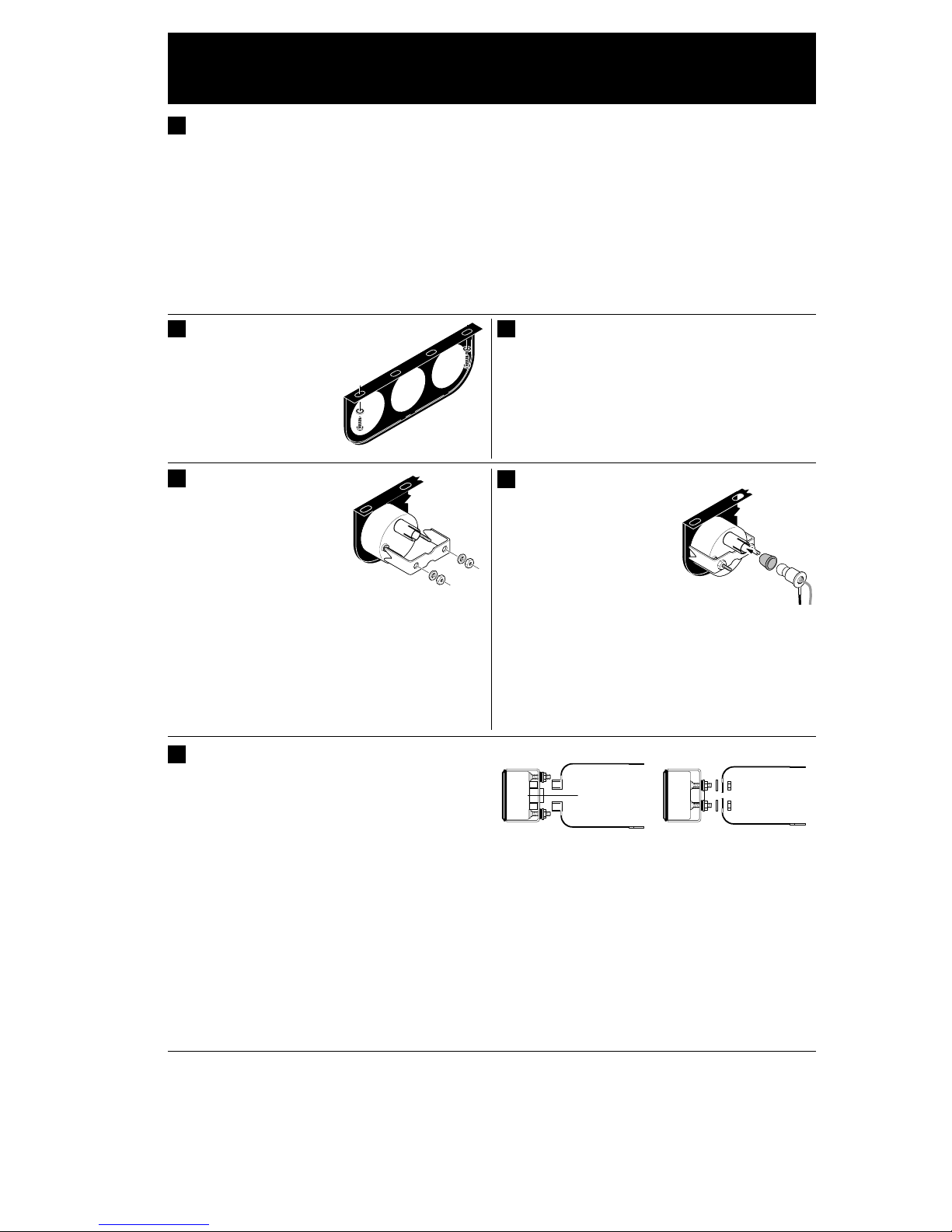

For on-dash or under-dash mounting.

1. Determine mounting location.

2. Using panel as a template, mark

locations for screws.

3. Drill small holes for the screws.

4. Hold panel in place and secure

with the screws and flat

washers provided.

PANEL INSTALLATION

21. Locate a position on the dashboard that can be cut out without

striking any objects from behind the dash.

2. Using a hole template, cut a 1-1/2" or 2" hole, as necessary,

through the dashboard.

3. Using a round file, smooth out the rough edges around the

drilled hole.

4. Install the gauge as described in step 4, GAUGE

INSTALLATION.

IN-DASH INSTALLATION

3

1. Insert gauge through front of

PANEL or hole in dashboard.

2. Install U-bracket over gauge

mounting studs and secure with

two nuts and flat washers

provided. TIGHTEN NUTS

FINGER-TIGHT ONLY.

NOTE: Ammeters and the 1-1/2"

voltmeter gauge utilize U-brackets which have two black

insulators installed in the mounting holes. MAKE SURE THESE

INSULATORS ARE PRESENT BEFORE INSTALLING THE

U-BRACKET.

3. Hold gauge case and rotate gauge, as needed, until gauge face

is positioned properly on front of panel.

4. After positioning, tighten mounting nuts securely to prevent

gauge movement. DO NOT OVERTIGHTEN NUTS OR U-

BRACKET MAY WARP.

GAUGE INSTALLATION

4

NOTE: Gauge backlighting color may

be changed to red or green by installing

the optional color filter over the bulb (not

available for all gauge kits).

1. Press snap-in light socket into

collar on back of the gauge.

2. Splice free end of light socket RED wire into an existing

hot wire from any vehicle instrument panel lamp controlled

by the headlight switch. Insulate splice with shrink tubing or

electrical tape to prevent shorting.

3. Connect light socket BLACK wire to a good chassis ground

(additional wire purchased separately).

4. The gauge lights are now connected to the lighting circuit

controlled by the headlight switch. If the vehicle is so equipped,

gauge light brightness will be controlled along with the

instrument panel lights.

GAUGE LIGHT INSTALLATION AND

CONNECTION

5

GAUGE CONNECTION

6

A. VOLTMETER

1. Using a multimeter or test light, find a 12 volt positive (+) location

which is hot ONLY when the ignition key is in the "ON" position

(possible locations: fuse panel accessory, radio and cigarette

lighter circuits).

NOTE: Voltmeter wiring must be purchased separately. Use 18

– 20 AWG wire.

2. Crimp or solder 1/4" female spade/ring terminals (purchased

separately) on one end of voltmeter positive (+) and negative (–)

wires, and connect wires to voltmeter positive (+) and negative (–)

terminal posts.

3. Splice positive (+) wire to an accessory location or line as

described in step 1 (route wires away from sharp edges and

mechanical moving parts to prevent electrical shorts).

4. Connect voltmeter negative (–) wire to a good bare metal

electrical chassis ground on the vehicle.

5. Reconnect negative (–) battery cable. With the ignition switch in

the "ON" position (and engine NOT RUNNING), voltmeter should

read on the lower half of green area (if color coded) or between

12.5 and 13.2 volts. A lower reading indicates a low battery, a

poor connection or defective battery cables.

6. Start and run engine. Voltmeter should read on the upper half of

green area (if color coded) or between 13.3 and 15.2 volts

(specifications vary, consult your vehicle's service manual). A

lower reading can indicate a faulty voltage regulator, slipping

belts, faulty alternator/battery, a poor connection or excessive

loads. A higher reading can indicate a faulty voltage regulator.

NOTE: If voltmeter fails to read, make sure positive (+) and

negative (–) connections on rear of gauge match. If voltmeter still

fails to read, recheck and tighten all connections.

–

+

BOTTOM

VIEW

TO ACCESSORY LINE (+)

"S" TERMINAL

(NOT USED)

S

TO GROUND (–)

–

+

BOTTOM

VIEW

TO ACCESSORY LINE (+)

TO GROUND (–)

2" VOLTMETER 1-1/2" VOLTMETER

Innova 1999 MRP #93-0161

WARRANTY AND SERVICE

The Manufacturer warrants to the original purchaser that this unit is free of defects in materials and workmanship under normal use and maintenance for a period of one (1)

year from the date of original purchase. If the unit fails within the one (1) year period, it will be repaired or replaced, at the Manufacturer's option, at no charge, when

returned prepaid to the Service Center with Proof of Purchase. Installation labor is not covered under this warranty. The sales receipt may be used for this purpose. All

replacement parts, whether new or re–manufactured, assume as their warranty period only the remaining time of this warranty. This warranty does not apply to damage

caused by improper use, accident, abuse, improper voltage, service, fire, flood, lightning, or other acts of God, or if the product was altered or repaired by anyone other

than the Manufacturer's Service Center. The Manufacturer, under no circumstances shall be liable for any consequential damages for breach of any written warranty of this

unit. This warranty gives you specific legal rights, and you may also have rights which vary from state to state. THIS WARRANTY IS NOT TRANSFERABLE. For service,

send (prepaid) via U.P.S. (if possible) to: EQUUS PRODUCTS INC., 17291 Mt. Herrmann St., Fountain Valley, CA 92708 Attn: Service. Allow 3–4 weeks service time. If

you have any questions, please contact your local store, distributor or the Manufacturer's Service Center. USA & Canada: (800) 544–4124; All others: (714) 241–6802

(8:00–4:00, Monday–Friday PST); FAX: (714) 432–7910 (24 hr.)

Innova 1999

B. AMMETER

WARNING: Make sure the maximum capacity of your charging

system does not exceed the ammeter's dialface capabilities.

NOTE: We strongly recommend professional installation or

assistance when installing an ammeter.

1. Determine routing for ammeter wiring. Use an existing firewall

grommet, or drill a hole through firewall to accommodate wires.

Install a rubber grommet (purchased separately) in hole, use

shrink tubing, or wrap with electrical tape to protect wiring from

chaffing or other damage.

NOTE: Ammeter wiring must be purchased separately. Use 10

AWG wire minimum.

2. Crimp or solder ring terminals (purchased separately) on ammeter

positive (+) and negative (–) wires. Connect wires to ammeter using

two nuts and flat washers. TIGHTEN NUTS SECURELY.

PROPERLY INSULATE ALL CONNECTIONS.

NOTE: This is an "in–line" attachment gauge. NEVER GROUND

GAUGE STUDS OR WIRES.

3. Route wiring through grommet in firewall.

4. Connect ammeter wiring to charging system:

■For magnetic starter switch systems (Ford/Chrysler), see Wiring

Diagram A. Remove nut and washer from starter solenoid switch

battery connection post "A". Remove all wires except wire going

to battery. Connect ammeter positive (+) lead to post "A";

reinstall washer and nut. Connect ammeter negative (–) wire to

wire(s) removed from post "A" using screw, lockwasher, and nut

(purchased separately).

■Insulate terminal lug connection using shrink tubing or

electrical tape to prevent shorting.

+

–

BOTTOM

VIEW

NUT

WASHER TERMINAL

LUG

TO

BATTERY

TO

STARTER

NUT

WASHER TERMINAL

LUG

SCREW

EXISTING WIRE(S) REMOVED FROM

STARTER SOLENOID SWITCH TERMINAL "A"

AMMETER

NEGATIVE (–)

WIRE

AMMETER

POSITIVE (+)

WIRE

AMMETER CONNECTION DIAGRAM A(FORD/CHRYSLER)

STARTER

SOLENOID

SWITCH

"A"

+

–

■For voltage regulator/horn relay circuit systems (GM/Chrysler)

see Wiring Diagram B. Splice ammeter positive (+) and

negative (–) wires into wire from battery positive (+) to voltage

regulator.

■For most starter solenoid circuits (GM/AMC), see Wiring

Diagram C. Remove nut and washer from starter solenoid

battery connection post "A". Remove all wires except wire

going to battery. Connect ammeter positive (+) wire to post

"A"; reinstall washer and nut. Connect ammeter negative (–)

wire to wires removed from post "A" using screw, lockwasher,

and nut (purchased separately).

■Insulate terminal lug connection using shrink tubing or

electrical tape to prevent shorting.

5. Reconnect negative (–) battery cable. Turn on headlights and

observe ammeter. Ammeter should indicate "–". If ammeter

reads backwards, reverse the positive (+) and negative (–)

connections. If ammeter fails to read, turn off headlights and

recheck connections.

NOTE: If none of the diagrams matches your vehicle's system,

consult your vehicle's service manual or a qualified mechanic.

+

–

BOTTOM

VIEW AMMETER

NEGATIVE (–)

WIRE

AMMETER

POSITIVE (+)

WIRE

AMMETER CONNECTION DIAGRAM B(GM/CHRYSLER)

BATTERY POSITIVE

(+) CABLE TO

STARTER

SPLICE

SPLICE

CUT AND

REMOVE

TO VOLTAGE

REGULATOR

BATTERY

TERMINAL

+

–

X

+

–

BOTTOM

VIEW

NUT

WASHER TERMINAL

LUG

TO

BATTERY

NUT

WASHER TERMINAL

LUG

SCREW

EXISTING WIRES REMOVED FROM

STARTER SOLENOID

AMMETER

NEGATIVE (–)

WIRE

AMMETER

POSITIVE (+)

WIRE

AMMETER CONNECTION DIAGRAM C(GM/AMC)

STARTER

SOLENOID

+

–

"A"

GAUGE CONNECTION (Continued)

6

1/4"

TRIM INSULATION INSTALL TERMINAL

C. MECHANICAL OIL PRESSURE

NOTE: Before installation, use shop cloths and drip pans to protect

vehicle interior from potential leaks.

1. Determine routing for nylon tubing. Use an existing firewall

grommet, or drill a 3/8" (9.5 mm) diameter hole through firewall to

accommodate nylon tubing. Install a rubber grommet (purchased

separately) in hole, use shrink tubing, or wrap with electrical tape to

protect nylon tubing from chaffing or other damage.

NOTE: Some gauges (i.e. #6520) require tubing kit #6801 for

installation.

2. Connect nylon tubing to gauge using compression sleeve and

compression nut. Tighten compression nut until tubing is secure.

3. Route nylon tubing through grommet in firewall.

4. If necessary, install adapter in appropriate pressure port on

engine.

5. Connect nylon tubing to pressure port adapter using tube

connector, compression sleeve and compression nut. Tighten

compression nut until tubing is secure.

6. Secure tubing along its route to prevent damage from sharp

edges, moving parts or hot engine components.

7. Reconnect negative (–) battery cable. Start and run engine for

approximately 30 seconds. Turn off engine and check gauge

installation for leaks. Tighten or reseal joints as needed and

retest.

OPTIONAL

GROMMET

COMPRESSION

SLEEVE COMPRESSION

NUT

COMPRESSION

NUT COMPRESSION

SLEEVE

TUBE

CONNECTOR*

OPTIONAL

ADAPTER*

*USE TEFLON SEALING TAPE ON NOTED THREAD JOINTS.

NYLON

TUBING

ENGINE

BLOCK

GAUGE

PORT*

1/8"

1/8"

D. MECHANICAL TEMPERATURE

1. Determine routing for temperature sensor. Use an existing

firewall grommet, or drill a 7/8" (22 mm) hole through firewall to

accommodate capillary tube with sensor. Install a rubber

grommet (purchased separately) in hole, use shrink tubing, or

wrap with electrical tape to protect capillary tube from chaffing or

other damage.

2. Route capillary tube through grommet in firewall.

3. Remove existing temperature sensor. Install adapter in sensor

hole and tighten securely. Insert temperature sensor in adapter

and tighten sensor nut securely. DO NOT ROTATE SENSOR OR

CAPILLARY TUBE WHILE TIGHTENING NUT OR CAPILLARY

TUBE MAY BE DAMAGED.

4. Secure capillary tube along its route to prevent damage from

sharp edges, moving parts or hot engine components. DO NOT

CRIMP THE CAPILLARY TUBE.

5. Reconnect negative (–) battery cable. Start and run engine and

check gauge installation for leaks. Tighten or reseal joints as

needed and retest.

NOTE: An adapter must be used to seat the sensor.

OPTIONAL

GROMMET SENSOR

NUT*

TEMPERATURE

SENSOR ENGINE

BLOCK

OPTIONAL

ADAPTER*

*USE TEFLON SEALING TAPE ON NOTED THREAD JOINTS.

GAUGE

TEMPERATURE

SENSOR

ENGINE

BLOCK

OPTIONAL

TEE FITTING*EXISTING

TEMPERATURE

SENSOR/SWITCH

ALTERNATE CONNECTION DIAGRAM

SENSOR

NUT*

NOTE: The capillary tube is under pressure and filled with ether.

NEVER CUT THE TUBE OR ATTEMPT TO REMOVE FROM

GAUGE PORT.

Table of contents

Popular Automobile Accessories manuals by other brands

ULTIMATE SPEED

ULTIMATE SPEED 279746 Assembly and Safety Advice

SSV Works

SSV Works DF-F65 manual

ULTIMATE SPEED

ULTIMATE SPEED CARBON Assembly and Safety Advice

Witter

Witter F174 Fitting instructions

WeatherTech

WeatherTech No-Drill installation instructions

TAUBENREUTHER

TAUBENREUTHER 1-336050 Installation instruction