EQUYSIS ULTRA-E-F User manual

ULTRA-E-F

Transit Time Ultrasonic Flow Meter

Clamp-on

Manual

CONTENTS

PART-1 INTRODUCTION ...................................................................................................1

General ...............................................................................................................................................1

Principleof measurement.................................................................................................................... 1

Applications........................................................................................................................................2

Features ..............................................................................................................................................2

Specifications .....................................................................................................................................3

Parts Identification...............................................................................................................................4

PART-2 CLAMP-ON TRANSDUCER INSTALLATION.................................................... 6

General ...............................................................................................................................................6

Mounting Location ............................................................................................................................ 6

Transducer Spacing ............................................................................................................................7

Transducer Mounting..........................................................................................................................8

Transducer Mounting Inspection and CouplantApplication..............................................................13

PART-3 TRANSMITTER INSTALLATION AND OPERATION INSTRUCTIONS ...14

Transmitter Installation .....................................................................................................................14

Transmitter Wirings............................................................................................................................... 15

KeypadConfiguration...................................................................................................................... 16

PART-4 WINDOWS DISPLAYEXPLANATIONS ..........................................................20

PART-5 OUTPUT FUNCTIONS ........................................................................................28

4-20mAOutput..........................................................................................................................28

OCT Pulse Output...........................................................................................................................28

RelayOutput..............................................................................................................................29

RS485 Output....................................................................................................................................... 29

MODBUS-RTU Protocol................................................................................................................29

Data Storage Function ....................................................................................................................31

PART-6 HOW TO USE MENU FUNCTIONS..................................................................33

Use Menu Windows for Transducer Mounting Inspection..............................................................33

How to Judge Whether the Instrument works Well on Site.............................................................34

How to Judge the LiquidFlowing Direction..............................................................................35

How to Reset theDefault Setups ...............................................................................................35

How to Stabilize the Flow...............................................................................................................36

How to Use the Low FlowCutoff Function....................................................................................36

How to Setup Zero Point ................................................................................................................36

How to Use Scale Factor ...........................................................................................................36

How to Do When all keys or ENTER Key is invalid................................................................37

How to Set Date and Time.................................................................................................................37

ON/OFFTotalizer.................................................................................................................. 37

Units Options...........................................................................................................................37

PART-7 TROUBLESHOOTINGAND FAQ...............................................................................38

Troubleshooting....................................................................................................................................38

Frequently Asked QuestionsandAnswers......................................................................................40

PART-8 WARRANTYAND SERVICE ..............................................................................42

Warranty.......................................................................................................................................................42

Service.............................................................................................................................................42

APPENDIX 1 INSERTION TRANSDUCER INSTALLATION.........................................43

A, Menu Configuration..........................................................................................................................43

B, Installation Locating..........................................................................................................................43

C, Mountingthe Transducers................................................................................................................46

D, Transducer wirings...........................................................................................................................47

E, How to Obtain Good Signal Strength andSignalQuality.................................................................48

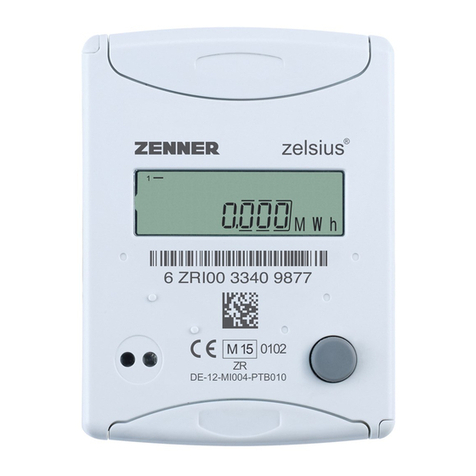

APPENDIX 2 ENERGYFUNCTION INSTRUCTION...................................................49

1. Introduction ................................................................................................................................. 49

2. Wires Connection..............................................................................................................................49

3. EnergyCalculation ...........................................................................................................................49

4. Temperature Range ...........................................................................................................................50

5. Pt1000 Temperature Sensors.............................................................................................................50

6. Clamp-On TemperatureSensors Installation.....................................................................................50

7. Insertion TemperatureSensors Installation .......................................................................................51

APPENDIX 3 MOUNTING FRAME INSTALLATION.......................................................52

0B

Int

1

ro

.

duction

........................................................................................................................................ 52

1B-2M. Mounting Frame Installation ..........................................................................................................52

Parts List of M-Mounting Frame...................................................................................................................52

Installation Steps for V and W Transducer Mounting Methods .....................................................................53

Installation Steps for Z and N Transducer Mounting Methods......................................................................56

3. S-Mounting Frame Installation.........................................................................................................58

Parts List of S-Mounting Frame....................................................................................................................58

Installation Steps for V and W Transducer Mounting Methods .....................................................................59

Installation Steps for Z and N Transducer Mounting Methods......................................................................60

APPENDIX 4 FUILD CHARACTERISTIC (SOUND SPEED)......................................62

1. Fluid Properties ................................................................................................................................62

2. Water Sound Speed...........................................................................................................................63

3. Pipe Material SoundSpeed Table................................................................................................................64

1

ULTRA-E-F

PART-1 INTRODUCTION

General

It is the engineers and technicians' hope to measure the flow on the non-invasive pipeline

reliably. Series ULTRA-E-F are state-of–the-art universal transit-time ultrasonic flow meters,

fit to measure flow of full pipe line, providing a measuring system with unsurpassed accuracy,

versatility, ease of installation and dependability. Although designed primarily for cleaner

liquids, the flow meter is tolerant of liquids with the small amount of air bubbles or suspended

solids found in most industrial environments.

Principle ofmeasurement

The ULTRA-E-F ultrasonic flow meter is designed to measure the fluid velocity of liquid

within a closed pipe. The transducers are a non-invasive, clamp-on type, which will provide

benefits of non-fouling operation and easy installation.

The ULTRA-E-F transit time flow meter utilizes two transducers that function as both ultrasonic

transmitters and receivers. The transducers are clamped on the outside of a closed pipe at a

specific distance from each other. The transducers can be mounted in V-method where the

sound transverses the pipe twice, or W-method where the sound transverses the pipe four times,

or in Z-method where the transducers are mounted on opposite sides of the pipe and the sound

crosses the pipe once. This selection of the mounting method depends on pipe and liquid

characteristics. The flow meter operates by alternately transmitting and receiving a frequency

modulated burst of sound energy between the two transducers and measuring the transit time

that it takes for sound to travel between the two transducers. The difference between the transit-

time is directly and exactly related to the velocity of the liquid in the pipe, as shown in Figure 1.

V=K*

△

t

Q=S*V

Where: V Liquidvelocity

K Constant

△

t

Differenceintimeofflight

Q Flow rate

S Sectional area ofpipe

Figure 1

2

ULTRA-E-F

Applications

1. Water,sewage (with low particle content) and sea water

2. Water supply and drainagewater

3. Process liquids; Liquors

4. Milk, yoghourtmilk

5. Gasoline; Kerosene; Diesel;Oil

6. Powerplant

7. The flowpatrolling and examining

8. Metallurgy, Laboratory

9. Energy-conservation, economize onwater

10. Food and medicine

11 Heat measures, Heatbalance

12 On-the-spot check-up, standard, the data are judged, Pipeline leak detection

Features

Built-In large capacity memory and USB data download function. The downloaded data can

be opened by EXCELdirectly.

Clamp-On transducers are easy to install, non-invasive, cost effective, and require no pipe

cutting or processing interrupt. Since the transducers do not contact with the liquid, fouling

and maintenance areeliminated.

Insertion transducers are hot-tapped installation, no pipe line flow interrupted.

Apair of sensors can satisfy different materials , wide different pipe diameters

Clear, user-friendly menu selections make ULTRA-E-F series simple and convenient to use

4 Lines display, can display total flow, flow rate, velocity and meter run status. Parallel

operation of positive, negative and net flow totalizes.

U.S., British and Metric measurement units are available. Meanwhile, almost all-universal

measurement units worldwide may be selected to meet customer’s requirements.

The heat measurement by configuring with Pt1000 temperature sensors.

Remote operation by the wireless handheld operator. No matter the pipeline in high altitude

or underground, users can install or adjust the transducer more convenient. The

communication range is about 100 meters in free range space, and 10 meters in through-wall

distance. Compared to the short distance of Bluetooth, it is more convenient and practical.

This wireless handheld operator has wireless remote reading function and it also can

operate the meters instead of paneloperations.

3

ULTRA-E-F

Specifications

Transmitter

Transducer

Description

Specifications

Liquid types

Virtually most any liquid containing less than 5% total suspended solids

(TSS) or aeration.

Suited Liquid temperature

Standard Temp. Transducer: -40 to 240F [-40 to 121℃]

High Temp. Transducer : -40 to 480F [-40 to 250℃] for Clamp-on

-40 to 300F [-40 to 150℃] for Insertion

Transducer to Transmitter

Cable distance

Shield cable, standard 6 meters, (opt) Lengths to 300 meters

Pipe size

M transducer: 40-1000mm pipe I.D; L transducer: 1000-4500mm; S&K

transducer: 20-50mm; Insertion transducer: 80-4500mm

Pipe material

All kind of steel and cast iron, PVC etc.

Description

Specifications

Principle of Measurement

Principle of Transit Time, DSP technology and MultiPulse Transducer

Technology

Power Requirements

100-240VAC 50/60Hz ±15% or 12-36VDC

Velocity

0.003 to 12 m/s, bi-directional

Outputs

Optional

All outputs are isolated from earth and system grounds.

Data storage function

4-20mA: 1000 ohm max, Accuracy: 0.1%

Frequency output: (From F.out), for flow rate or total flow

Relay output for total flow or alarm

RS485 (Modbus-RTU) output

Option: Wireless handheld operator, GPRS

Display

4 line×16 English letters LCD, it can display total flow, flow rate,

velocity and meter run statusetc.

Units

Rate

Totalizer

User Configured (English and Metric)

Flow Rate and Velocity Display

Forward total; Reverse total; Net Total(difference between forward and

reverse flow)

Ambient Conditions

-40 to 131F [-40 to 55℃], 0-95% relative humidity, non-condensing

Enclosure

NEMA 4X [IP65]

261H×193W×80D mm

Accuracy Flow Rate

±1.0% of reading at rates >0.5 m/s

±0.005 m/s of reading at rates<0.5 m/s

Repeatability

0.2%

Responding Time

500ms display refresh, sampling cycle 7.5ms

Security

Keypad lock and system lock, access code enable

Approvals(option)

ATEX (ExdⅡBT6) certified. (LCIE 09 ATEX 3088)

Other functions

Automatic record incident and functions of management of flow

Remember the state of the flow meter; Diagnosis

4

ULTRA-E-F

Parts Identification

Transmitters:

Standard wall-mounted

Transducers:

Ex-proof type (ATEX) K transducer High temperaturetransducer

S-Transducer M-Transducer L-Transducer

M-Mounting Frame (V method andZ method) S-Mounting Frame (V method and Zmethod)

Accessories:

Stainless Steel Strap Flexible belts Couplant

5

ULTRA-E-F

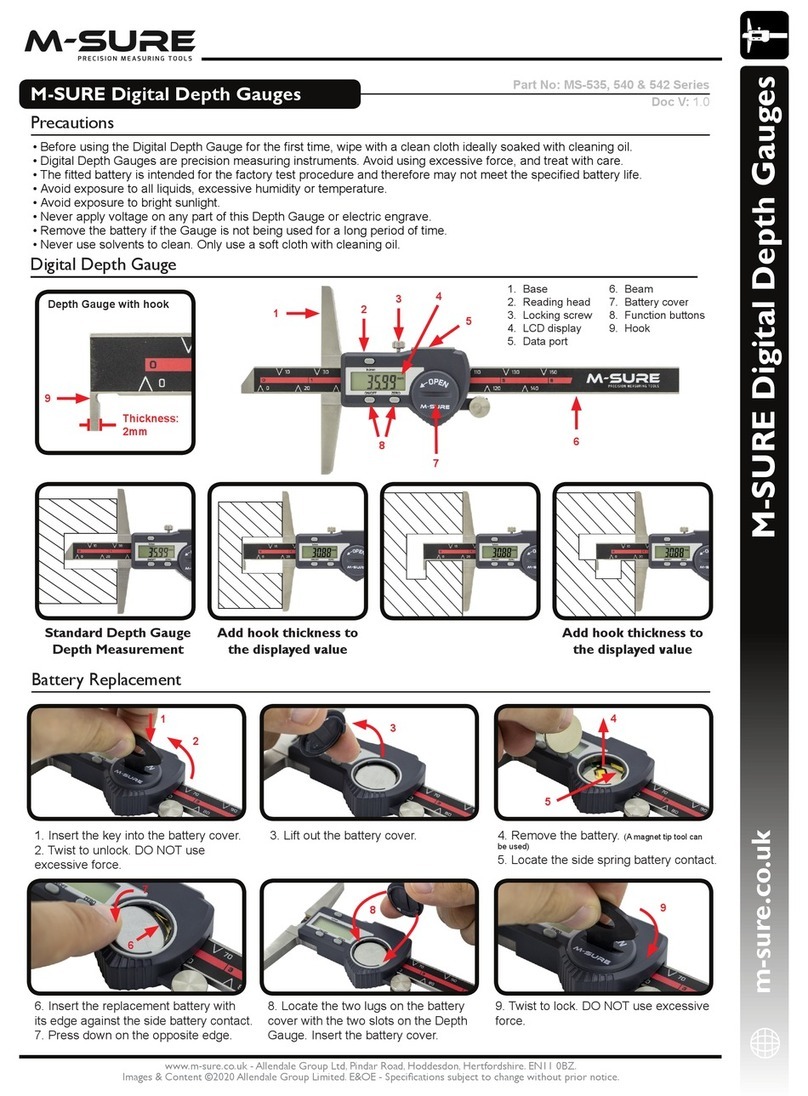

K mode transducers:

Size

A

B

C

D

K1:

3/4", 1"

55

39

42

34

K2:

3/4", 1", 1-1/4"

64

46

42

43

K3:

1-1/4", 1-3/4", 2"

80

46

42

61

6

ULTRA-E-F

PART-2 CLAMP-ON TRANSDUCER INSTALLATION

General

The transducers that are utilized by the Series ULTRA-E-F contain piezoelectric crystals for

transmitting and receiving ultrasound signals through walls of liquid piping systems. The

transducers are relatively simple and straight-forward to install, but spacing and alignment of

the transducers is critical to the system's accuracy and performance. Extra care should be taken

to ensure that these instructions are carefully executed.

Mounting of the clamp-on ultrasonic transit time transducers is comprised of three steps:

Selection of the optimum location on a piping system.

Entering the necessary parameters into the ULTRA-E-F keypad. (ULTRA-E-F will

calculate proper transducer spacing based on these entries (menu 25))

Pipe preparation and transducermounting.

MountingLocation

The first step in the installation process is the selection of an optimum location for the flow

measurement. For this to be done effectively, a basic knowledge of the piping system and its

plumbing is required.

An optimum location is defined as:

A piping system that is completely full of liquid when measurements are being taken. The

pipe may become completely empty during a process cycle - which will result in an error code

being displayed on the flow meter while the pipe is empty. Error codes will clear automatically

once the pipe is filled with liquid. It is not recommended to mount the transducers in an area

where the pipe may become partially filled. Partially filled pipes will cause erroneous and

unpredictable operation of the meter.

A piping system that contains lengths of straight pipe such as those described in Table

2.1. The optimum straight pipe diameter recommendations apply to pipes in both horizontal

and vertical orientation. The straight runs in Table 2.1 apply to liquid velocities that are

nominally 7 FPS [2.2 MPS]. As liquid velocity increases above this nominal rate, the

requirementfor straight pipe increases proportionally.

Mount the transducers in an area where they will not be inadvertently bumped or

disturbed during normal operation.

Avoid installations on downward flowing pipes unless adequate downstream head pressure

is present to overcome cavitations in the pipe.

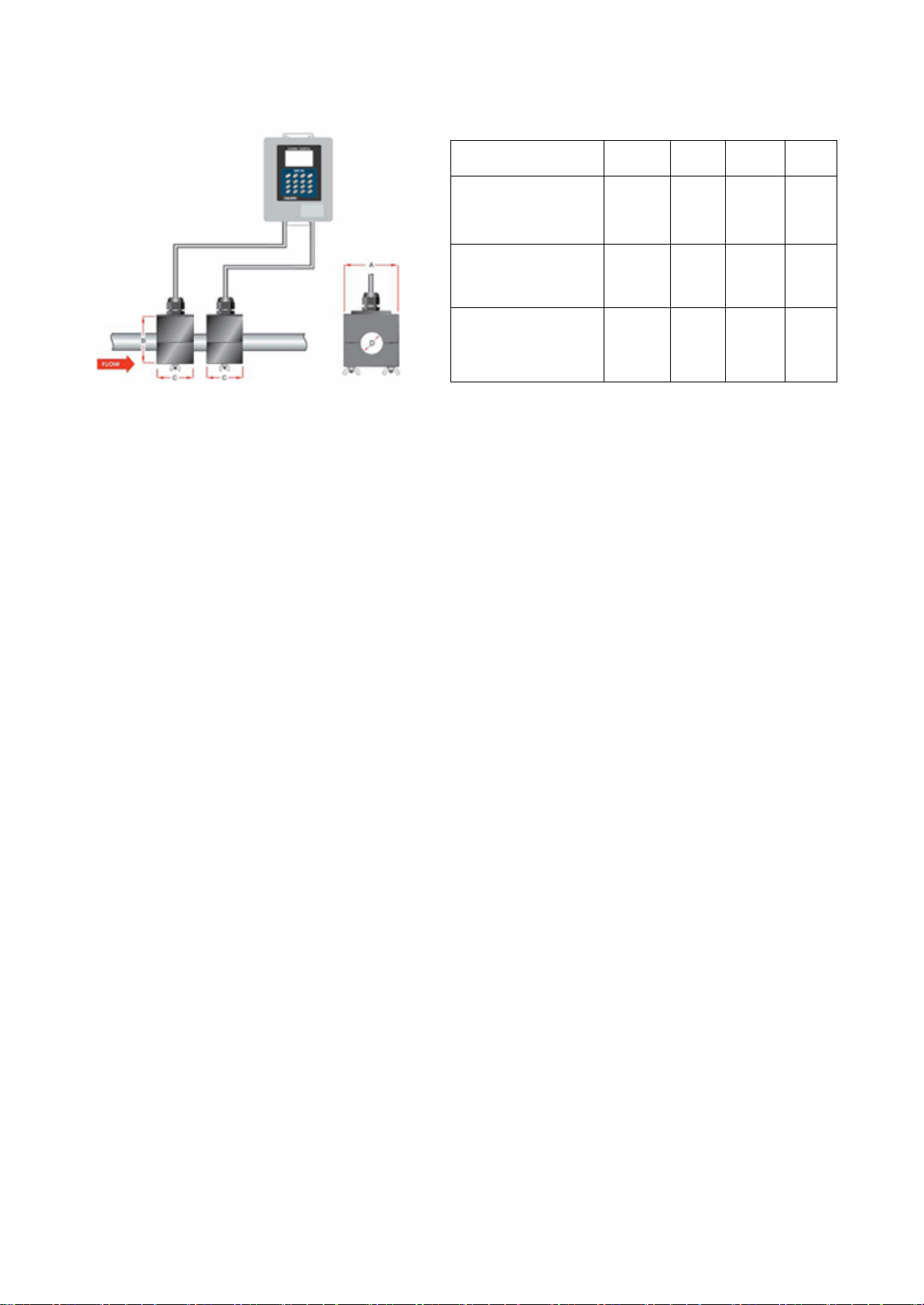

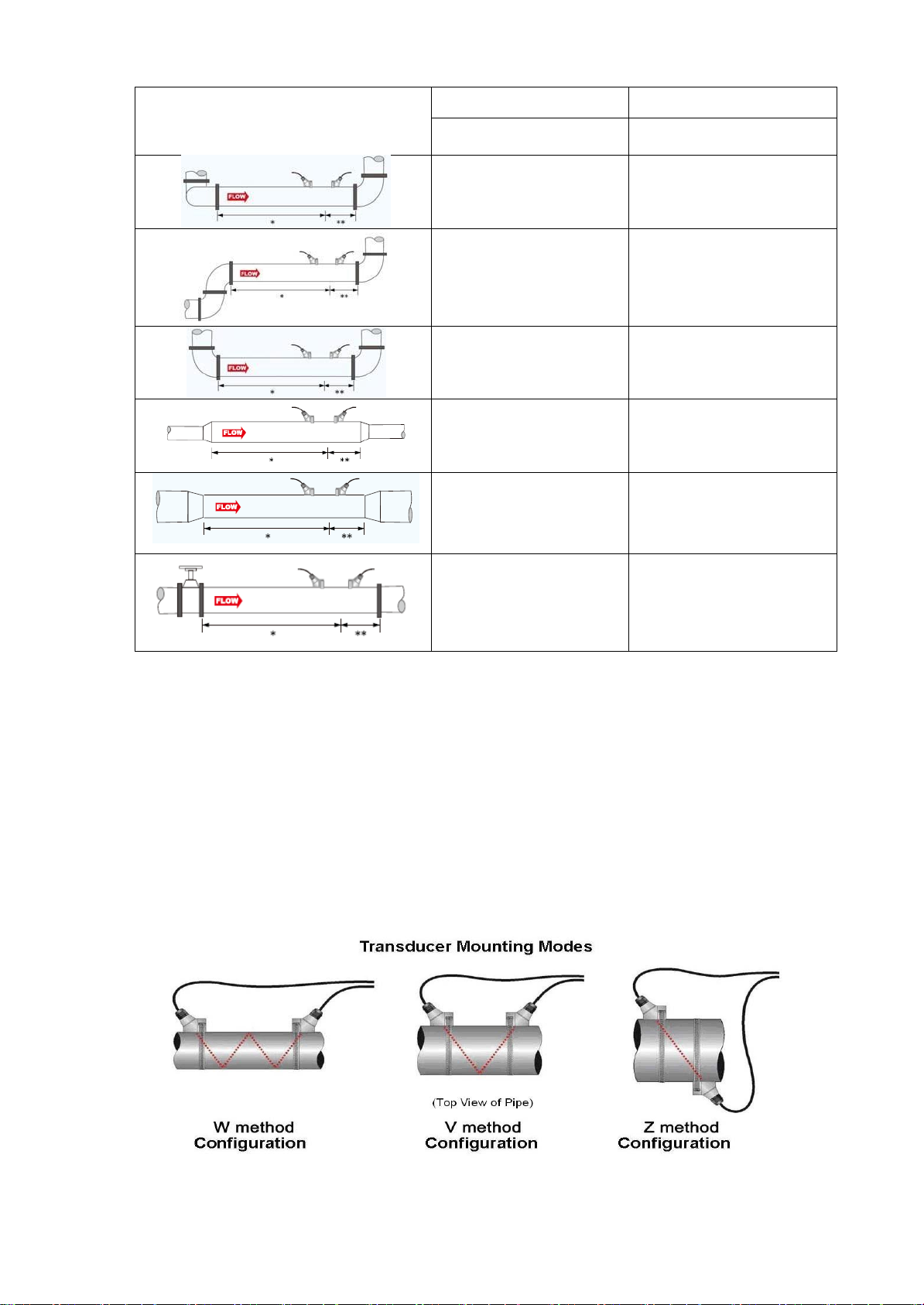

Table 2.1 Requirement of Straight Pipe Length

7

ULTRA-E-F

Piping configuration

And transducer position

Upstream Dimension

Downstream Dimension

Pipe Diameters (*)

Pipe Diameters (**)

24

5

14

5

10

5

10

5

8

5

24

5

TransducerSpacing

ULTRA-E-F transducers are clamped on the outside of a closed pipe at a specific distance

from each other. The transducers can be mounted in V-mode where the sound transverses the

pipe two times, W-mode where the sound transverses the pipe four times, or in Z-mode where

the transducers are mounted on opposite sides of the pipe and the sound crosses the pipe once.

W-mode provides the longest sound path length between the transducers - but the weakest

signal strength. Z-mode provides the strongest signal strength - but has the shortest sound path

length.

8

ULTRA-E-F

The ULTRA-E-F system calculates proper transducer spacing by utilizing piping and

liquid information entered by the user.

The following information is required before programming the instrument. Note that much of

the data relating to material sound speed, viscosity and specific gravity are preprogrammed

into the ULTRA-E-F flow meter. This data only needs to be modified if it is known that a

particular liquid data varies from the reference value. Refer to Part 3 of this manual for

instructions on entering configuration data into the ULTRA-E-F flow meter via the meter

keypad.

1.

Pipe OuterDiameter

2.

Pipe wall thickness

3.

Pipe material

4.

Pipe sound speed

5.

Pipe relativeroughness

6.

Pipe line thickness

7.

Pipe linematerial

8.

Pipe line sound speed

9.

Fluid type

10.

Fluid sound speed

Nominal values for these parameters are included within the ULTRA-E-F operating system.

The nominal values may be used as they appear or may be modified if exact system values are

known.

After entering the data listed above, the ULTRA-E-F will calculate proper transducer spacing

for the particular data set. This distance will be in inches if the ULTRA-E-F is configured in

English units, or millimeters if configured in metric units.

TransducerMounting

After selecting an optimum mounting location and successfully determining the proper

transducer spacing, the transducers may now be mounted onto the pipe.

The transducers must be properly oriented on the pipe to provide optimum reliability and

performance. On horizontal pipes, the transducers should be mounted 180 radial degrees from

one another and at least 45 degrees from the top-dead-center and bottom-dead-center of the

pipe. See Figure 2.1. Figure 2.1 does not apply to vertically oriented pipes.

9

ULTRA-E-F

Pipe Preparation

Before the transducers are mounted onto the pipe surface, two areas slightly larger than the flat

surface of the transducer heads must be cleaned of all rust, scale and moisture. For pipes with

rough surfaces, such as ductile iron pipe, it is recommended that the pipe surface be ground flat.

Plastic pipes typically do not require surface preparation other than soap and water cleaning.

Observe Signal Strength while placing the transducers into position. Signal Strength can be

displayed on Menu 90.

V-Mode and W-Mode Installation

1. For ULTRA-E-F transducers, place a single bead of couplant, approximately 0.5 inch [15

mm] width, on the flat face of the transducer. See Figure 2.2. Generally, silicone-based grease

is used as an acoustic couplant, but any grease-like substance that is rated not to “flow” at the

temperature that the pipe may operate will be acceptable.

Figure 2.2

2.

P

lace the up

s

tream tra

ns

ducer in po

s

ition and

s

ecure

w

ith a mounting

s

trap.

S

trap

s

s

hould be

placed in the arched groove on the end of the transducer. A screw is provided to help hold the

transducer onto the strap. Verify that the transducer is stick to the pipe - adjust as necessary.

Tighten the transducer strap securely.

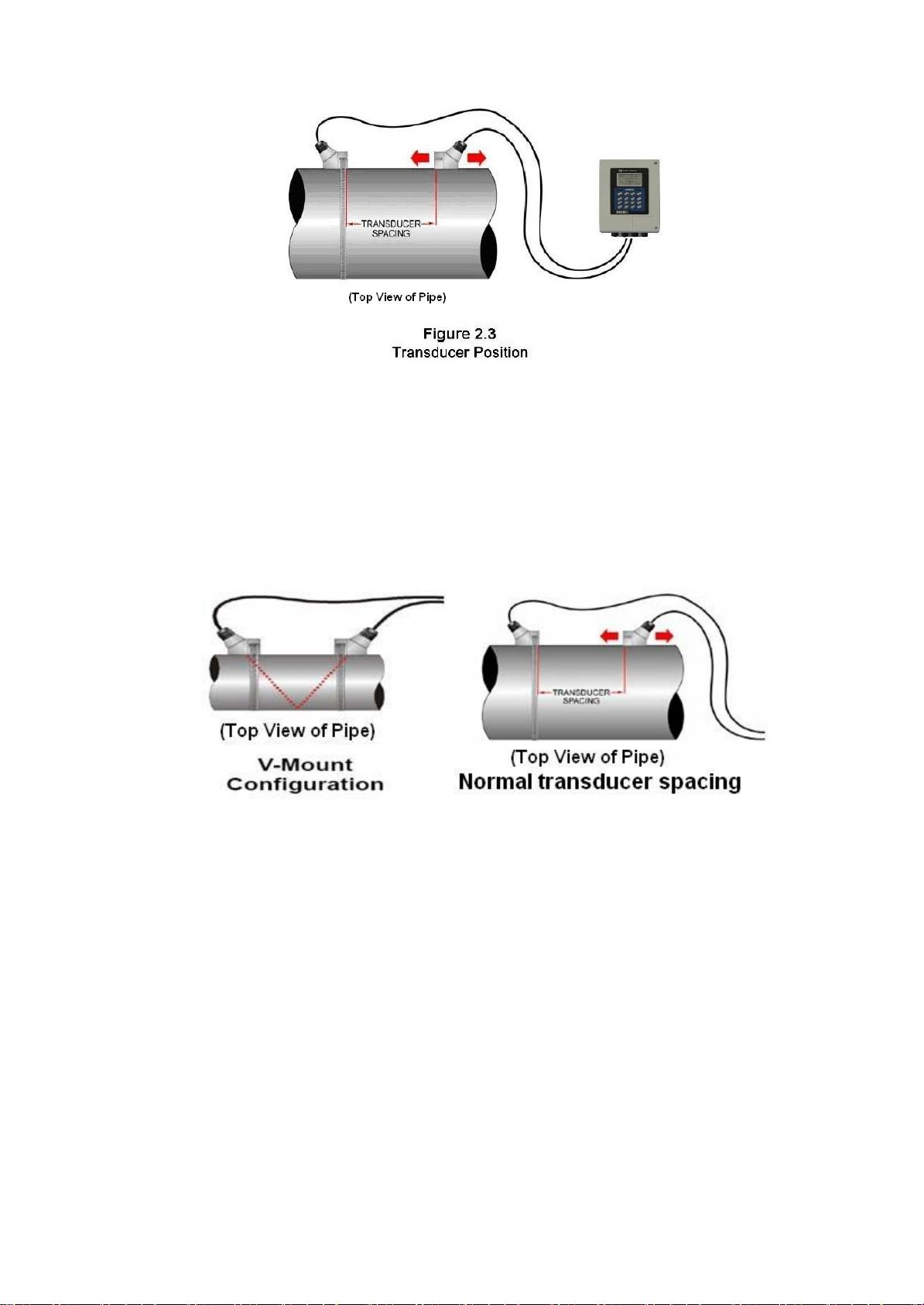

3.Place the downstream transducer on the pipe at the calculated transducer spacing. See

Figure 2.3. Using firm hand pressure, slowly move the transducer both towards and away

from the upstream transducer while observing Signal Strength. Clamp the transducer at the

position where the highest Signal Strength is observed. A Signal Strength (Menu 90) between

60 and 95 is acceptable.

4. If after adjustment of the transducers, the Signal Strength (Menu 90) does not rise to above

60, then an alternate transducer mounting method should be selected. If the mounting method

was W-mode, then reconfigure the ULTRA-E-F for V-mode, reset the ULTRA-E-F, move the

downstream transducer to the new location and repeat step 3.

10

ULTRA-E-F

V-Mount is the STD installation method, it is convenient and accurate, Reflective type

(transducers mouthed on one side of the pipe) of installation used primarily on pipe size in the

(50mm~400mm) internal diameter range attention transducer designed parallel on the centre

line of installing the pipeline.

The spacing value shown on menu window M25 refers to the distance of inner spacing

between the two transducers. The actual transducers spacing should be as close as possible to

the spacing value. The transducer spacing is from the end of one transducer to another sensor.

The transducer mounting spacing is very important for Transit-time meters, and users need

mount transducers exactly according to the spacing distance value M25 displays after users

input proper parameter settings. M91 is only for reference, and just keep it within 97--103%

value range.

As the above figure shows, the normal transducer spacing refers to the distance between the

ends of the two transducers (as the two red lines indicate). And this spacing should be exactly

according to the value in M25. Note that this method suits for normal Small, Std. M and Large

transducer.

For Magnetic transducers, the definition of transducer spacing is the distance between the two

scale lines, just as showed bellow:

11

ULTRA-E-F

The value displayed in M25 for magnetic transducer spacing refers to the distance showed in

the above figure. (Note: The displayed value in M25 is larger than the distance between the

ends of the two magnetic transducers.) Users should mount the magnetic transducers with the

above showed spacing exactly according to the M25 value.

Z-Mode Installation

Z-mode installation method is suitable for S-Transducer, L-Transducer and the condition of

weak signal strength and/or inaccurate readings. The section below details a method for

properly locating the transducers on larger pipes. This method requires a roll of paper such as

freezer paper or wrapping paper, masking tape and a marking device.

1.

Wrap the paper around the pipe in the manner shown in Figure 2.4. Align the paper ends

to within 6 mm.

2.

Mark the intersection of the two ends of the paper to indicate the circumference. Remove

the template and spread it out on a flat surface. Fold the template in half, bisecting the

circumference. See Figure2.5.

3.

Crease the paper at the fold line. Mark the crease. Place a mark on the pipe where oneof

12

ULTRA-E-F

the transducers will be located. See Figure 2.1 for acceptable radial orientations. Wrap the

template back around the pipe, placing the beginning of the paper and one corner in the

location of the mark. Move to the other side of the pipe and mark the pipe at the ends of the

crease. Measure from the end of the crease directly across the pipe from the first transducer

location) the dimension derived in Step 2, Transducer Spacing. Mark this location on the

pipe.

4.

The two marks on the pipe are now properly aligned and measured.

If access to the bottom of the pipe prohibits the wrapping of the paper around the

circumference, cut a piece of paper to these dimensions and lay it over the top of the pipe.

Length = Pipe O.D. x 1.57; width = Spacing determined on Menu 25.

Mark opposite corners of the paper on the pipe. Apply transducers to these two marks.

5.

Place a single bead of couplant, approximately 0.5 inch [15 mm] width, on the flat face of

the transducer. See Figure 2.2. Generally, a silicone-based grease is used as an acoustic

couplant, but any grease-like substance that is rated to not “flow” at the temperature that the

pipe may operate at, will beacceptable.

a)

Place the upstream transducer in position and secure with a stainless steel strap or other.

Straps should be placed in the arched groove on the end of the transducer. A screw is

provided

b)

Try to help hold the transducer onto the strap. Verify that the transducer is true to the pipe

- adjust as necessary. Tighten transducer strap securely. Larger pipes may require more than

one strap to reach the circumference of the pipe.

6.

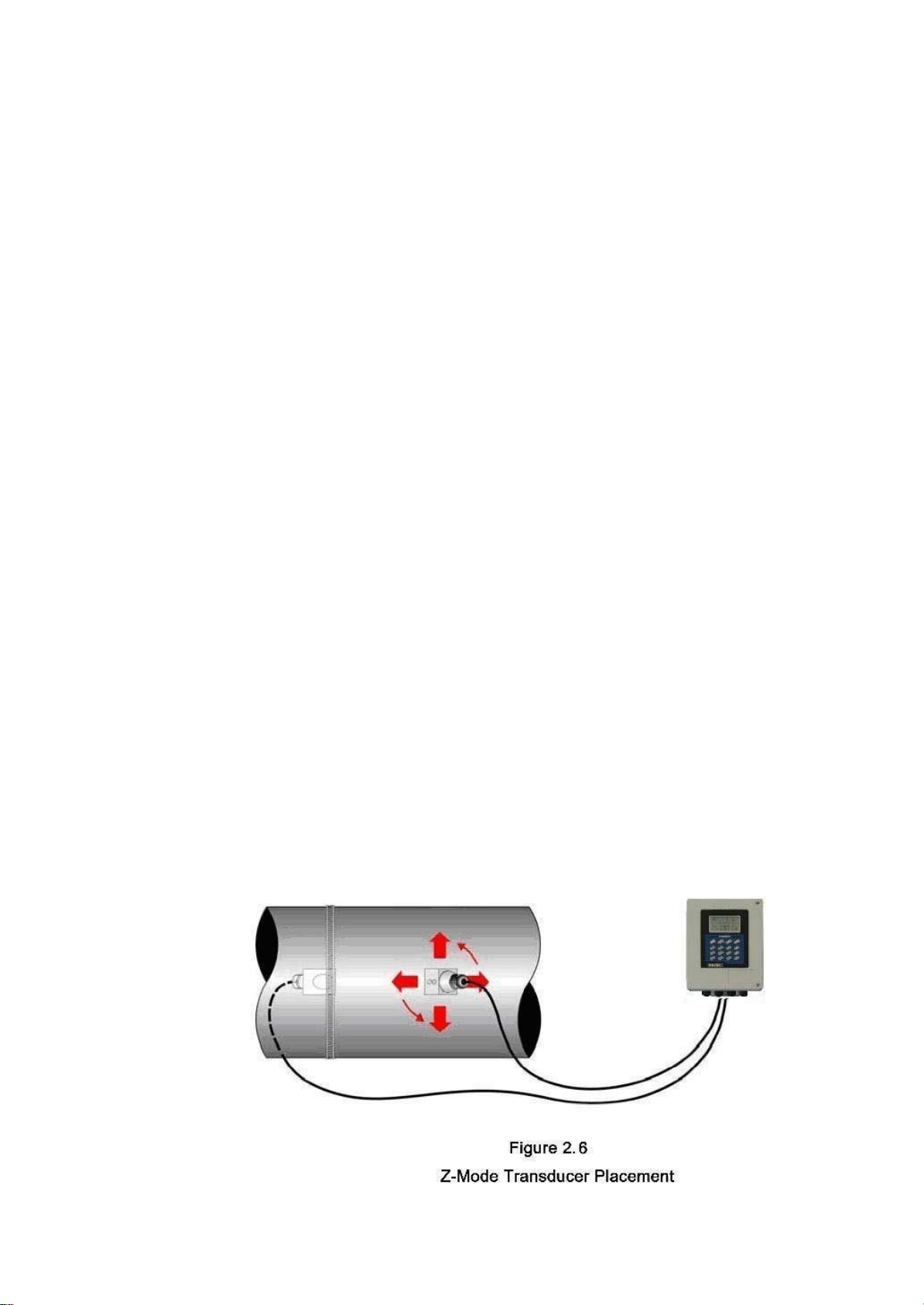

Place the downstream transducer on the pipe at the calculated transducer spacing. See

Figure 2.6. Using firm hand pressure, slowly move the transducer both towards and away

from the upstream transducer while observing Signal Strength. Clamp the transducer at the

position where the highest Signal Strength is observed. Signal Strength of between 60 and 95

percent is acceptable. On certain pipes, a slight twist to the transducer may cause signal

strength to rise to acceptablelevels.

7.

Secure the transducer with a stainless steel strap or other.

13

ULTRA-E-F

TransducerMounting Inspection and CouplantApplication

2.5.1 Transducer Mounting Inspection

It is very important to use menu operations for TRANSDUCER MOUNTING INSPECTION

and Estimation, Refer to 6.1, Use menu windows for Transducer Mounting Inspection.

2.52 Couplant Application

A, It is also very important for couplant application.

When mounting the transducers, apply just enough pressure so that the couplant fills the gap

between the pipe and transducer. Commonly, the Dow 732 for permanent and Dow 111 for

temporary installations, but Dow 111 has a better coupling effect. If Dow 732 was used,

ensure that no relative movement between the transducer and the pipe takes place during the

setting time and do not apply instrument power for at least 24 hours, Dow 111 also be used for

permanent installations(avoid rain or water etc.), setting time is not necessary. We recommend

using Dow 111 for permanent installing, and then use Dow732 around the transducer in order

to fix the transducer, waterproof cloth is recommended if the Transducers are installed outdoor.

Dow 112 for high temperatureapplication.

B, Transducers for High Temperature

Mounting of high temperature transducers is similar to ULTRA-E-F standard transducers; High

temperature installations require acoustic couplant Dow Corning 112 that is rated not to flow

at the temperature that will be present on the pipe surface.

14

ULTRA-E-F

PART-3 TRANSMITTER INSTALLATION AND OPERATION

INSTRUCTIONS

TransmitterInstallation

After unpacking, it is recommended to save the shipping carton and packing materials in case

the instrument is stored or re-shipped. Inspect the equipment and carton for damage. If there is

evidence of shipping damage, notify the carrier immediately.

The enclosure should be mounted in an area that is convenient for servicing, calibration or for

observation of the LCD reading.

1 Locate the transmitter within the length of transducer cable that was supplied with the

ULTRA-E-F system. If this is not possible, it is recommended that the cable be exchanged for

one that is of proper length. Transducer cables that are up to 990 feet [300 meters] may be

accommodated.

2.

Mount the ULTRA-E-F transmitter in a location that is:

♦

Where little vibrationexists.

♦

Protected from falling corrosivefluids.

♦

Within ambient temperature limits -40 to 131°F [-40 to 55°C]

♦

Out of direct sunlight. Direct sunlight may increase transmitter temperature to above the

maximum limit.

3.

Mounting: Refer to Figure 3.1 for enclosure and mounting dimension details. Ensure that

enough room is available to allow for door swing, maintenance and conduit entrances.

Secure the enclosure to a flat surface with four appropriate fasteners.

Figure 3.1 Mechanical Dimensions

15

ULTRA-E-F

4.

Conduit holes. Conduit hubs should be used where cables enter the enclosure. Holes not

used for cable entry should be sealedwith plugs.

NOTE: Use NEMA 4 [IP65] rated fittings/plugs to maintain the water tight integrity of the

enclosure. Generally, the left conduit hole (viewed from front) is used for line power; the

center conduit hole for transducer connections and the right hole are utilized for OUTPUT

wiring.

5 If additional holes are required, drill the appropriate size hole in the enclosure’s bottom.

Use extreme care not to run the drill bit into the wiring or circuit cards.

TransmitterWirings

Figure 3.2 Transmitter Wirings

To access terminal strips for electronic connectors, loosen the two screws in the enclosure door

and open the door. Guide the transducer terminations through the transmitter conduit hole

located in the bottom-center of the enclosure.

The terminals within ULTRA-E-F are a pluggable type - they can be removed wired and then

plugged back in. Connect the appropriate wires to the corresponding screw terminals in the

transmitter.

XDCR UP “+ - GND” is used to connect upstream transducer (Marked with a red sign),

16

ULTRA-E-F

.

∧

MENU

XDCR DN “+ - GND” is used to connect downstream transducer (Marked with a blue sign).

Connect line power to the screw terminals N, Land GND in the transmitter. The ground terminal

grounds the instrument, which is mandatoryfor safe operation.

DC Power connection: The ULTRA-E-F may be operated by a 12-36 VDC source, which is

capable of supplying a minimum of 3 Watts.

NOTES:

1)

The transducer cable carries low level high frequency signals. In general, it is not

recommended to add additional cable to the cable supplied with the transducers. If

additional cable is required, contact the factory to arrange an exchange for a transducer

with the appropriate length of cable. Cables to 300 meters are available.

2)

This instrument requires clean electrical line power. Do not operate this unit on circuits

with noisy components (i.e., fluorescent lights, relays, compressors, or variable frequency

drives). It is recommended not to run line power with other signal wires within the same

wiring tray orconduit.

Keypad Configuration

Keypad functions

After transducer and connection of appropriate power supply to ULTRA-E-F, keypad

configuration of the instrument can be undertaken. Generally, there should be no display of

error messages, and the flow meter will go to the most commonly used Menu Window Number

01 (short for M01) to display the Velocity, Flow Rate, Positive Totalizer, Signal Strength and

Signal Quality, based on the pipe parameters entering by the user or by the initial program.

The ULTRA-E-F contains a 16-key tactile keypad, allows the user to view and change

configuration parameters as shown below.

Follow these guidelines when using ULTRA-E-F

keypad:

0~ 9 and to input numbers anddecimal.

to backspace or delete characters to the left.

The arrow keys and

∨

To return to the last

menu or to open the next menu, are used to scroll

through menu configuration parameters; also acts

as “+” and “-” functions when entering numbers.

to select a menu. Press this key first,

input two menu numbers and then enter the

selected menu. For instance, to input a pipe Outside diameter, press MENU

1keys,

◀

1

17

ULTRA-E-F

∧

8

1

1

∧

,

∨

2

1

8

6

1

4

1

MENU

MENU

1

1

ENTER

ENTER

where “11” is the window Address to display the pipe outside diameter.

Keypad Operation

With all of the parameters entered, the instrument setup and measurement displays are

subdivided or consolidated into more than 100 independent windows. The user can view the

window menu, input parameters, modify settings or display measurement results. These

windowsarearrangedby2-digitserialnumbers(including

∧

sign)from00~94, thento

∧

0 ,

, etc.. Every window serial number, or so-called window Address code, has a defined

meaning. For instance, Window No.11 indicates the parameter input for pipe outside diameter,

while Window No.25 indicates the mounting distance between the transducers, etc. (Refer to

Part 4 –Windows Display Explanations).

The keypad shortcut to visit a specific window is to press the MENU key at any time, then

input the 2-digit window Address code. For instance, to input or check the pipe outside

diameter, justpress the keys for window Address code11.

Anothermethodto visit a particularwindow is to press

∨

and ENTER keys to scrollthe

menu. For instance, if the current window Address code is 66, press

∧

key to enter Window

No.65, press the again to enter Window No.64; then, press the key to back Window

No.65, and press the key again to enter WindowNo.66.

Example 1. To enter a pipe outside diameter of 218.6, the procedure is as follows:

Press keys to enter Window No.11 (the numerical value displayed currently

is a previous value). Now press ENTER key. The symbol ﹥and the flashing cursor are

displayed at the left end of the second line on the Screen. The new value can be entered by

press . .

Example 2. If the pipe material is “Stainless Steel”, press keys MENU to enter

Window No.14 first. Then press key to modify the options. Now, select the “1.

Stainless Steel ” option by pressing and keys, and then press key to confirm the

selection. It is possible to press the key to change the selection and wait until “1.

Stainless Steel” is displayed on the second line of the screen. Then press the ENTER key to

confirm.

M11

Outer Diameter

108 mm

M11

Outer Diameter

108 mm

﹥218.6

∧

∨

∧

∨

ENTER

Table of contents