Erbauer EBP28 User manual

Petrol Blower

(27.6 cm3)

Original Instructions – EBP28_V10322

WARNING: Read the instruction handbook thoroughly

before using the machine!

EBP28

EAN: 5059340256375

BX220IM/B3

2

EBP28

Let’s

get started...

These instructions are for your safety. Please read through

them thoroughly before use and retain them for future

reference.

Getting Started... 02

Safety information 03

Your machine 13

Technical specication 15

Before you start 16

Quick start 22

In more detail... 24

Machine functions 24

Operation 25

Care and maintenance 31

Troubleshooting 40

Recycling and disposal 41

Guarantee 42

Customer care and technical helpline 43

Availability of spare parts 44

UK declaration of conformity 45

EU declaration of conformity 46

3

EBP28

Getting Started . . .

Safety warnings

IMPORTANT

READ CAREFULLY BEFORE USE

KEEP FOR FUTURE REFERENCE

> This machine is not intended for use by children and persons with reduced physical,

sensory or mental capabilities, or lack of experience and knowledge.

> Children should be supervised to ensure that they do not play with the machine.

WARNING! Your safety and the safety of others is very important. Of course,

it is not practical or possible to warn you about all the hazards associated with

operating or maintaining this machine. At all times you must use your own

good judgment.

Training

Read the instructions carefully. Be familiar with the controls and the proper use of the

machine.

Petrol powered blower safety warnings

> Read all instructions carefully. Be familiar with the controls and the proper use of

the machine.

> Never allow children, persons with reduced physical, sensory or mental capabilities

or lack of experience and knowledge or people unfamiliar with these instructions to

use the machine. Local regulations can restrict the age of the operator.

> Keep children, other bystanders and pets away from the machine while operating.

> The operator or user is responsible for accidents or hazards occurring to other

people or their property.

> While operating the machine always wear substantial footwear and long trousers.

Do not operate the machine when barefoot or wearing open sandals. Avoid wearing

clothing that is loose tting or that has hanging cords or ties.

> Do not wear loose clothing or jewellery that can be drawn into the air inlet. Keep

long hair away from the air inlets.

> Operate the machine in a recommended position and only on a rm, level surface.

> Do not operate the machine on a paved or gravel surface where ejected material

could cause injury.

> Before using, always visually inspect to see that the fasteners are secure and the

housing is undamaged. Replace worn or damaged components in sets to preserve

balance. Replace damaged or unreadable labels.

> Running this machine in a conned or badly ventilated area can result in death due

to asphyxiation or carbon monoxide poisoning. The machine is for outdoor use only.

Safety information

4

EBP28

Getting Started . . .

> Take extreme care in wet and freezing weather conditions. Do not work in rain,

windy or stormy weather.

> Wear a dust mask. The use of this machine can generate exhaust gases, lubrication

oil mist and dust containing chemicals known to cause respiratory damage.

> Wear slip-resistant footwear, snug-tting clothing, protective gloves, eye or face

and hearing personal protective equipment (PPE).

> The machine is extremely noisy when in use. Wear hearing protection at all times

while operating the machine.

> Always visually check the machine before use.

> Do not attempt to tackle any job that you are not adequately trained for.

> Do not operate the machine if it has faulty safety equipment or damaged parts.

> Do not under any circumstances modify the machine. Modications can result in

serious personal injury or death.

> All machine servicing and maintenance, other than the items listed in this manual,

should be performed by an authorised service centre.

> First time user should have practical instruction in the use of the machine and

protective equipment from an experienced operator.

> National regulation can restrict the use of the machine.

Clothing and personal protective equipment (PPE)

> Secure long hair so that they are above the shoulder level.

> Do not wear loose tting clothing or jewellery as those could be drawn into the

engine or blower outlet.

> Use the following safety clothing and personal protective equipment (PPE) when

operating the machine:

• Wear hearing/ear protection (compliant to EN 352-1)

• Wear eye protection (compliant to EN 166)

• Wear face protection (compliant to EN 166)

• Wear protective gloves (compliant to EN ISO 21420 Class 0)

• Wear safety steel toe capped footwear (complaint to EN ISO 20345 Class 2)

• Wear protective leggings (compliant to EN ISO 11393-2, EN ISO 13688 Class 1)

• Wear dust mask

• First aid kit in case of injury

• Dry powder re extinguisher readily available

Safety information

5

EBP28

Getting Started . . .

Fuel handling

> Always switch the machine off, disconnect the spark plug connector and let the

machine cool down before refuelling it.

> Fuel vapour pressure may build up inside the fuel tank depending on the fuel used,

weather conditions and the tank venting system. To reduce the risk of burns and

other personal injuries, remove the fuel tank cap carefully to allow any pressure

build up to release slowly.

> Fuel and fuel vapour are highly ammable. Take care when handling fuel.

> Be aware of re risks, explosion and inhalation risks.

> Do not smoke while operating the machine, handling fuel or near fuel.

> Ensure the spark plug connector is secure. Loose connector may cause electrical

arcing that could ignite combustible fumes and cause a re or explosion.

> Always use suitable aids such as funnels and ller necks. Do not spill any fuel on

the machine or its exhaust system. There is a risk of ignition. Remove spilled fuel

carefully from all parts of the machine. Any residue which may be present must

have completely volatilised, before the machine is put into operation!

> Never refuel indoors.

> Never use the machine in environments where there is a risk of explosion. Exhaust

gases and fuel fumes are noxious. Fuel fumes can ignite.

> Avoid skin contact with petrol.

> Do not eat or drink, while you are refuelling the machine. If you have swallowed

petrol or oil, or if petrol or oil has got into your eyes, then seek the advice of a doctor

immediately.

> Check regularly for leaks from the fuel tank cap, oil tank cap and fuel lines.

> Use caution when handling fuel. To avoid any accidental res, move the machine at

least 3 metres from the fuelling point before starting the engine.

> Tighten the fuel tank cap thoroughly after relling the fuel tank.

> Do not operate the machine if it is leaking fuel.

> Do not remove the fuel tank cap while the engine is running.

> Do not store cans of fuel or rell the fuel tank in any place where there is a boiler,

stove, wood re, electrical sparks, welding sparks, or other sources of heat or re

which might ignite the fuel.

> If any fuel spillage occurs during refuelling, use a dry rag to wipe up spills and allow

remaining fuel to evaporate before starting the engine on again.

> If you have spilt fuel on yourself or on your clothes, change your clothes and wash

any part of your body that has come in contact with fuel before turning the engine

on again.

> If fuel has ignited, put out the re with a dry powder re extinguisher.

Safety information

6

EBP28

Getting Started . . .

Getting started

> Do not operate the machine indoors. The machine produces poisonous exhaust

fumes whilst the engine is running which may be colourless and odourless.

> Do not wrap the recoil starter rope around your hand whilst starting the machine.

This may result in injuries to your hand or ngers.

> Always hold the machine by the main handle (5) with the right hand. Keep handles

dry, clean and free from oil and grease. Greasy, oily handles are slippery and may

cause loss of control.

> To reduce the risk of stumbling and loss of control, do not walk backward while

operating the machine.

> Stop the engine and wait until the moving parts come to a complete stop before

placing the machine down.

> Check for signs of wear or damage before each use, after any impact or if the

machine has been dropped. Repair the machine if necessary.

Operation

> Before starting the machine, make certain that the tube and nozzles are empty.

> Keep your face and body away from the blower outlet.

> Do not allow hands or any other part of the body or clothing inside the tube or

nozzles, or near any moving part.

> Keep proper balance and footing at all times. Do not overreach. Never stand at a

higher level than the base of the machine when feeding material into it.

> Always stand clear of the discharge zone when operating this machine.

> Do not touch moving hazardous parts before they have come to a complete stop.

> Do not operate the machine near open windows or doors.

> Do not blow hard objects such as nails, bolts and rocks.

> Apply extra care when cleaning debris from stairs or other tight areas.

> Keep all parts of your body away from the blower outlet. Do not remove blockages

or jams when the machine is switched on. Stop the engine and wait until the moving

parts come to a complete stop when clearing jammed material. One moment of

inattentiveness while operating the machine may result in serious personal injury.

> Carry the machine by the handles with the engine off. Handling the machine

properly reduces the possibility of personal injury.

> Never operate the machine on a ladder or other insecure support. Do not work

above shoulder height.

> If the machine starts to vibrate abnormally, check it immediately. Excessive vibration

can cause injury.

> Always ensure the machine is fully assembled before using it. Never attempt to use

an incomplete machine or one tted with an unauthorised modication.

> Do not operate the machine if you are tired or ill.

> Do not operate the machine under the inuence of drugs, alcohol or medication.

> Use rakes and brooms to loosen debris before blowing.

Safety information

7

EBP28

Getting Started . . .

> Operate the machine only in daylight or in good articial light.

> Slightly dampen surfaces in dusty conditions.

> Operate the machine only at reasonable hours – not early in the morning or late at

night when people might be disturbed.

> Make sure that the air vents are kept clear of debris.

> Make sure that the air intake of the combustion engine is clear. Keep the air intake

free of dust, dirt particles, gases and fumes.

> Never use the machine without the air lter installed.

> Check for signs of wear or damage before each use, after any impact or if the

machine has been dropped. Repair the machine if necessary.

> Stop the engine, disconnect the spark plug connector:

• before clearing blockages;

• before cleaning or servicing the machine;

• if the machine starts to vibrate abnormally (check immediately);

• whenever you leave the machine unattended;

• before refuelling.

> Do not operate the machine if you have any medical conditions that might be

aggravated by strenuous work. Consult a doctor before operating this machine.

> Do not touch the exhaust during use - IT GETS VERY HOT during use.

> Do not operate the machine near or around ammable liquids or gases.

> Do not grip the handle with constant or excessive pressure. This might increase

the feeling of vibration and the risk of “Vibration White Finger (VWF)” disease. To

minimize vibration exposure, use the lock-on lever to lock the throttle trigger for

continuous operation.

Transport and storage

> Stop the engine and let the engine come to a complete stop before transporting the

machine.

> Carry the machine with the engine stopped the blower outlet away from the body.

> Allow the engine to cool before storing in any enclosure.

> Secure the machine when transporting in a vehicle to prevent turnover, fuel spillage

and damage to the machine. Use line or ratchet tie-down if necessary.

> Store the machine and fuel so that there is no risk of leakages or fumes coming into

contact with sparks or naked ames from electrical equipment, electric engines,

relays/switches, boilers etc.

> For longer periods of storage or transportation the fuel and tanks must be emptied.

Dispose of waste oil and fuel at a local petrol station, local authority centre or where

facilities exist.

> Store fuel and oil in an approved container specically designed for that purpose.

> Clean the machine and have it serviced before any long-term storage.

Safety information

8

EBP28

Getting Started . . .

Vibration and noise reduction

To reduce the impact of noise and vibration emission, limit the time of operation, use

low-vibration and low-noise operating modes as well as wear personal protective

equipment.

Take the following points into account to minimise the vibration and noise exposure

risks:

> Only use the machine as intended by its design and these instructions.

> Ensure that the machine is in good condition and well maintained.

> Use correct attachments for the machine and ensure they in good condition.

> Keep a tight grip on the handles/gripping surfaces.

> Maintain this machine in accordance with these instructions and keep it well

lubricated (where appropriate).

> Plan your work schedule to spread any high vibration tool use across a longer

period of time.

Emergency

Familiarise yourself with the use of this machine by means of this instruction

manual. Memorise the safety directions and follow them to the letter. This will

help to prevent risks and hazards.

> Always be alert when using this machine, so that you can recognise and

handle risks early. Fast intervention can prevent serious injury and damage to

property.

> Stop the engine and disconnect the spark plug connector if there are

malfunctions. Have the machine checked by a qualied professional and repaired,

if necessary, before you operate it again.

> In case of re stop the engine and disconnect the spark plug connector.

Take re-extinguishing measures immediately if the machine switch is no longer

accessible.

WARNING! Never use water to extinguish the machine on re. Burning fuel

must be extinguished with special extinguishing agents! We recommend

that you keep a suitable re extinguisher within reach in your work area! We

recommend to have dry powder re extinguisher always available.

Safety information

9

EBP28

Getting Started . . .

Residual risks

Even if you are operating this machine in accordance with all the safety

requirements, potential risks of injury and damage remain. The following dangers

can arise in connection with the structure and design of this machine:

> Health defects resulting from vibration emission if the machine is used over long

periods of time or not adequately managed and properly maintained.

> Injuries and damage to property due to broken application tools or the sudden

impact of hidden objects during use.

> Danger of injury and property damage caused by ying objects.

> Burns, if touching hot surfaces.

WARNING! This machine produces an electromagnetic eld during operation!

This eld may under some circumstances interfere with active or passive

medical implants! To reduce the risk of serious or fatal injury, we recommend

persons with medical implants to consult their doctor and the medical implant

manufacturer before operating this machine!

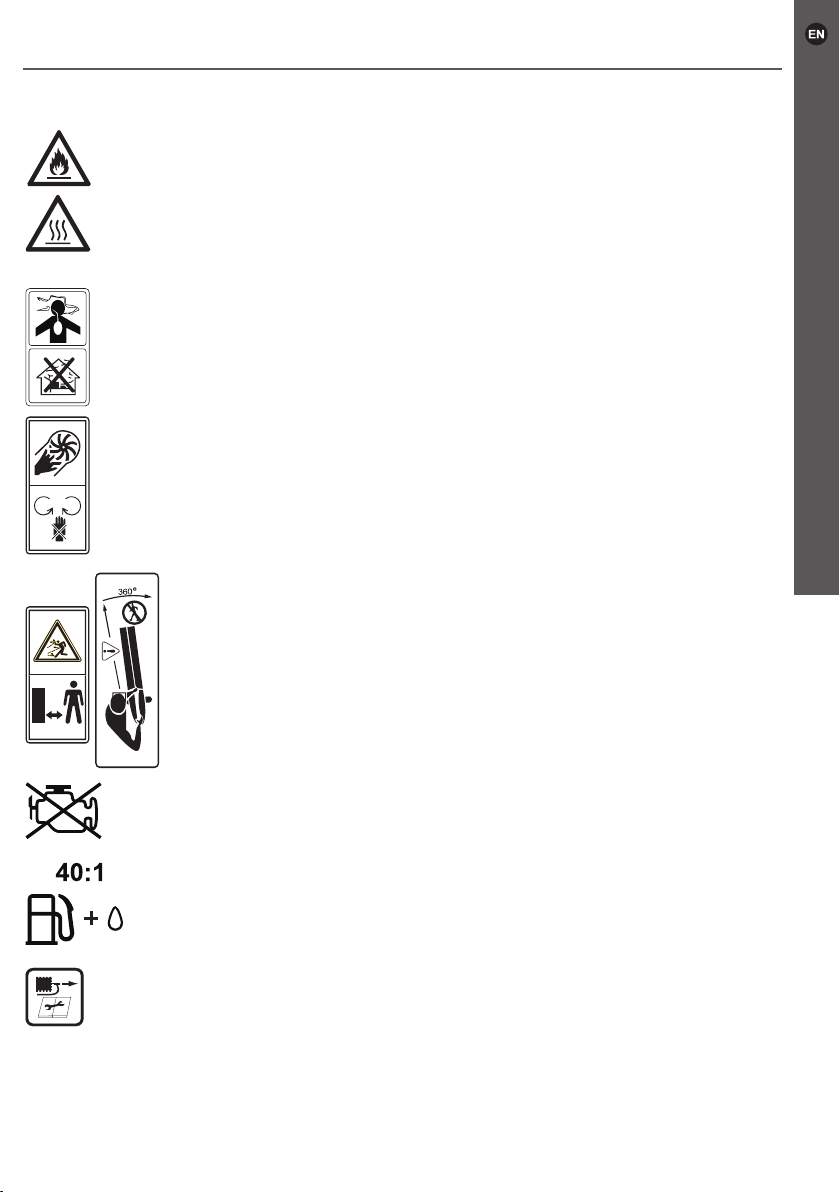

Symbols

On the machine, the rating label and within these instructions you will nd among others

the following symbols and abbreviations. Familiarise yourself with them to reduce

hazards like personal injuries and damage to property.

kW Kilowatt l Litre

cm3Cubic centimetre ml Millilitre

/min or min-1 Per minute °C Degree Celsius

mm Millimetre dB(A) Decibel (A-rated)

cm Centimetre m/s2Metres per second squared

kg Kilogram g/kWh Gram per kilowatt per hour

kg/h Kilogram per hour m/s Metres per second

yyWxx Manufacturing date code; year of manufacturing (20yy) and week of

manufacturing (Wxx)

Safety information

10

EBP28

Getting Started . . .

Safety information

Description of signal words:

DANGER! The signal word that indicates a hazard with a high level of risk

which, if not avoided, will result in death or serious injury.

WARNING! The signal word that indicates a hazard with a medium level of

risk which, if not avoided, could result in death or serious injury.

CAUTION! The signal word that indicates a hazard with a low level of risk

which, if not avoided, could result in minor or moderate injury.

NOTE! Indicates a practical tip, advice or practice not related to personal

injury.

Caution/Warning.

Read the instruction

manual.

Note/Remark.

Wear eye protection (compliant to EN 166).

Wear hearing/ear protection (compliant to EN 352-1).

Wear face shield (compliant to EN 166).

Wear safety steel toe capped footwear (compliant to EN ISO 20345

Class 2).

Wear protective gloves (compliant to EN ISO 21420 Class 0).

Do not expose the machine to rain or wet conditions.

Open ames in the work area, around the machine and in the vicinity

of ammable materials are prohibited!

Do not smoke in the work area, around the machine and in the vicinity

of ammable materials!

11

EBP28

Getting Started . . .

Risk of re/ammable materials.

Hot surface, do not touch! High temperatures on the machine’s

surfaces and structural parts that could cause burns, if they are

touched. The machine can also stay hot for a longer period of time

after the operation!

Petrol engines produce toxic carbon monoxide exhaust fumes.

Breathing carbon monoxide can cause nausea, fainting or even death.

Do not operate the engine indoors!

Keep hands out of the openings while the machine is running.

Objects thrown by the machine could hit the operator or other

bystanders. Always ensure that other people and pets remain at a

safe distance from the machine when it is in operation. In general,

children must not come near the area where the machine is operating.

Stop the engine before refuelling. Never refuel the machine while the

engine is running.

Only refuel unleaded petrol and oil mixture in ratio 40:1. Do not use

any other mixture ratio.

Stop the engine and disconnect the spark plug connector before

assembly, cleaning, adjustments, maintenance, storage and

transportation.

HHigh-speed mixture adjuster for adjusting fuel delivery at full throttle.

LLow-speed mixture adjuster for adjusting fuel delivery at idling speed.

Safety information

12

EBP28

Getting Started . . .

Safety information

Choke – CLOSED position.

Choke – OPEN position.

Engine manual start; recoil starter.

Guaranteed sound power level value in dB.

The machine complies with the applicable European directives and an

evaluation method of conformity for these directives was done.

The machine complies with the conformity requirements of the

applicable UK regulations.

EBP28 Designation of the tool

(E_Brand Name; BP_Petrol Blower; 28_Engine size in cc)

1E35F Engine brand logo, Family-Type and model number

SHA1/P V-0012 EU type-approval for the engine

13

EBP28

Getting Started . . .

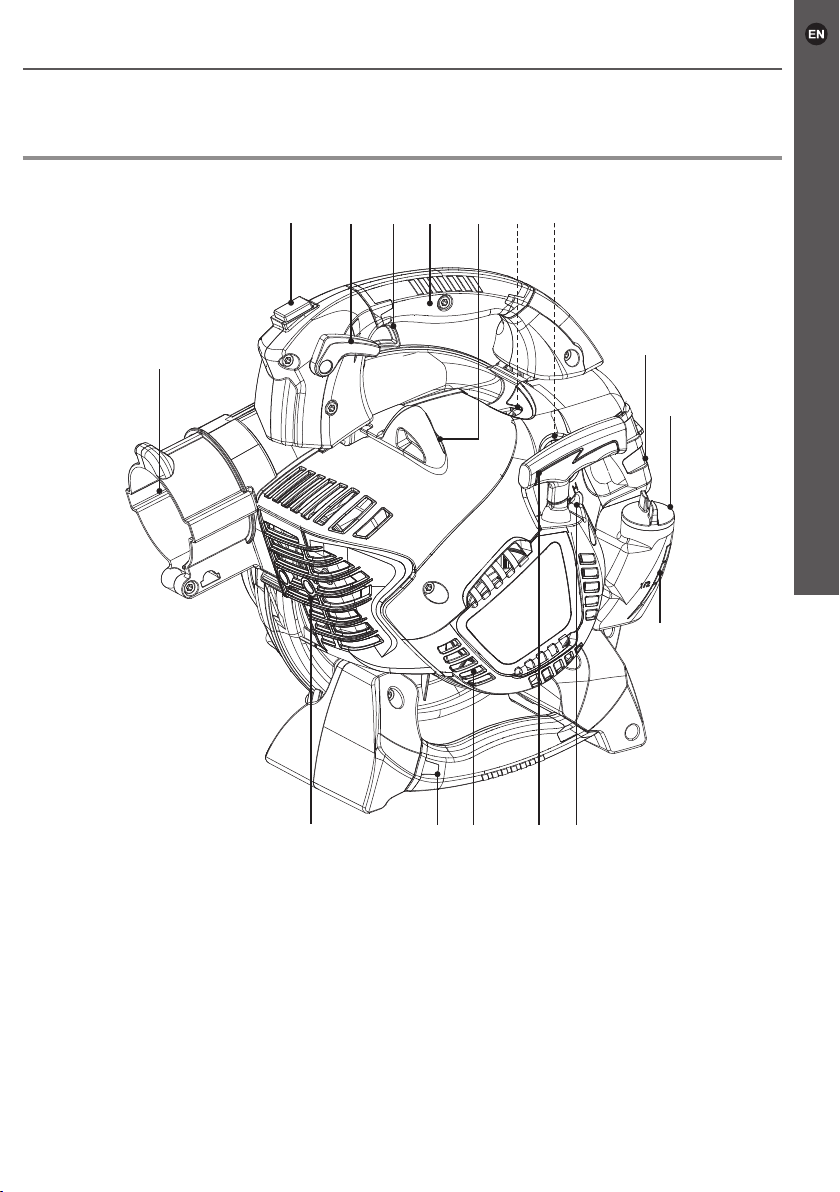

Your machine

Main unit

1

34 87

12

6

25

9

10

11

1316 1415

1. Blower outlet

2. Ignition switch (I / O)

3. Lock-on lever (throttle locking device)

4. Throttle trigger

5. Main handle

6. Spark plug connector

7. Primer

8. Choke

9. Air lter case

10. Fuel tank cap

11. Fuel tank

12. Adjusting screws for carburetor (H/ L)

13. Recoil starter handle

14. Air vents

15. Auxiliary handle

16. Exhaust

Your machine

14

EBP28

Getting Started . . .

Your machine

Blower assembly

17 18 19

17. S-shaped tube

18. Flat nozzle

19. Round nozzle

Accessories

20 21 22 23

20. Multi-tool

21. Torx key

22. Screwdriver

23. Fuel mixing bottle

15

EBP28

Getting Started . . .

Technical specications

Technical specications

General

> Dimensions (without tubes): approx. 35 x 25 x 35 cm

> Weight: approx. 4.7 kg

> Fuel tank capacity: 400 ml

> Petrol type: Octane rating of at least 90, unleaded,Octane rating of at least 90, unleaded,

Maximum 10% renewable ethanol (E10 orMaximum 10% renewable ethanol (E10 or

below)below)

> Engine oil type: Top quality synthetic oil specically for Top quality synthetic oil specically for

two-stroke engines, of JASO FC minimumtwo-stroke engines, of JASO FC minimum

specication. specication.

> Fuel-oil ratio: 40:1

> Specic fuel consumption at

maximum engine power:

550 g/kWh

> Fuel consumption at maximum

engine power:

0.44 kg/h

Engine

> Engine model: 1E35F

> Engine type: Air cooled, 2-stroke engine

> Engine displacement: 27.6 cm3

> Maximum engine power: 0.8 kW

> Maximum operating engine speed: 8300 min-1

> Maximum air velocity: 83 m/s

> Spark plug type: NGK BPMR7A

> Spark plug gap: 0.6-0.7 mm0.6-0.7 mm

Sound emission level

> Sound pressure level at operator

position: 93.9 dB(A)

> Uncertainty K: 3 dB(A)

> Measured sound power level LWA:106.6 dB(A)

> Uncertainty K: 3.0 dB(A)

> Guaranteed sound power level LWA 109 dB(A)

Vibration emission level

> Hand-arm vibration ahw:2.06 m/s2

> Uncertainty K: 1.5 m/s2

16

EBP28

Getting Started . . .

Technical specications / Before you start

The sound values have been determined according to noise test code given in

EN 15503, using the basic standards EN ISO 3744 and EN ISO 11201.

Wear ear protection, especially when sound pressure is over 70 dB(A).

The declared vibration value has been measured in accordance with a standard test

method (according to EN 15503) and may be used for comparing one machine with

another. The declared vibration value may also be used to evaluate the exposure for

the user caused by vibration in advance.

WARNING! Depending on the actual use of the machine the vibration values

can differ from the declared total. Adopt proper measures to protect yourself

against vibration exposures. Take the whole work process including times

the machine is running under no load or switched off into consideration!

Proper measures include among others regular maintenance and care of

the machine and accessories, keeping hands warm, periodical breaks and

proper planning of work processes!

Unpacking

1. Unpack all parts and lay them on a at, stable surface.

2. Remove all packing materials and protective shipping materials, if applicable.

3. Make sure the delivery contents are complete and free of any damage. If you nd

that parts are missing or show damage do not use the machine and contact your

dealer. Using an incomplete or damaged machine represents a hazard to operators

and property.

4. Ensure that you have all the accessories and tools needed for assembly and

operation. This also includes suitable personal protective equipment.

WARNING! The machine and the packaging are not children’s toys! Children

must not play with plastic bags, sheets and small parts! There is a danger of

choking and suffocation!

17

EBP28

Getting Started . . .

Before you start

You will need

(items not supplied)

> Suitable personal protective

equipment

> Fuel funnel with lter

> Suitable 2-stroke engine oil for air-

cooled engines, high quality

> Suitable fuel (unleaded petrol)

> Container to collect fuel

> First aid kit

> Dry powder re extinguisher readily

available

> Soft absorbent cloth (for fuel spills)

(items supplied)

> Multi-tool (20)

> Torx key (21)

> Screwdriver (22)

> Fuel mixing bottle (23)

Assembly

WARNING! The machine must be fully assembled before operation!

Do not use a machine that is only partly assembled or assembled with

damaged parts!

Follow the assembly instructions step-by-step and use the pictures provided

as a visual guide to assemble the machine easily!

Disconnect the spark plug connector before assembly! Reconnect it after

assembly (see "Maintenance").

NOTE: Take care of small parts that are removed during assembly or when

making adjustments. Keep them secure to avoid loss. Complete the assembly

on a at and stable surface.

18

EBP28

Getting Started . . .

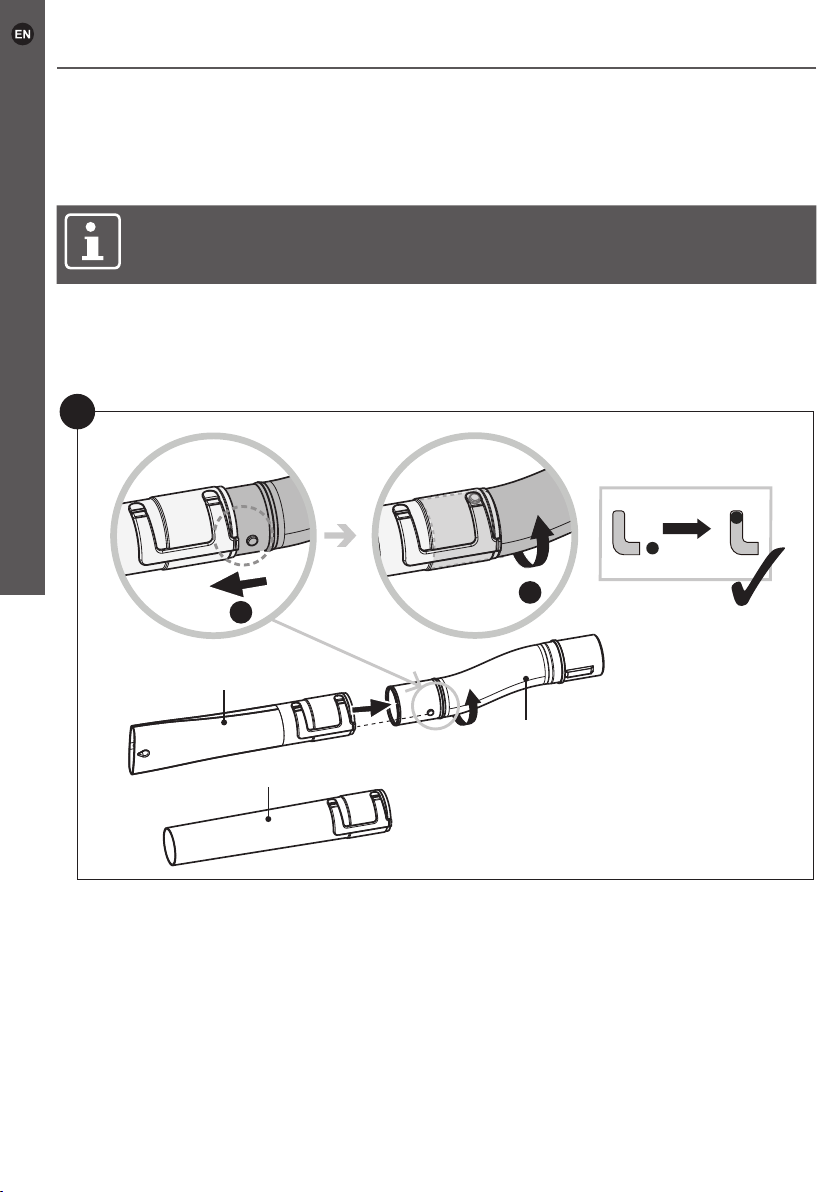

Blower assembly

1. Select the at nozzle (18) or round nozzle (19) for the desired application.

NOTE: Flat nozzle (18) offers higher air speed for more demanding tasks and

for heavier debris. Round nozzle (19) offers greater air volume for general

blowing tasks in a larger area and for lightweight debris.

2. Align the slot of nozzle (18/ 19) with the pin on the S-shaped tube (17). Insert

the S-shaped tube (17) into the nozzle (18/ 19) (Step 1, Fig.1). Turn the S-shaped

tube (17) clockwise until the pin reaches end of the slot (Step 2, Fig. 1).

1

18

19

17

1

2

Before you start

19

EBP28

Getting Started . . .

Before you start

3. Align the tabs on the other end of the S-shaped tube (17) with the slots on the

blower outlet (1). Insert the S-shaped tube (17) into the blower outlet (1) all the way

until it clicks into place (Fig. 2).

2

17

1

NOTE: To detach the S-shaped tube (17) from the blower outlet (1), use the

multi-tool (20) to depress the red locking lever, and pull the S-shape tube (17)

(Fig. 3).

3

Locking lever

20

1

20

EBP28

Getting Started . . .

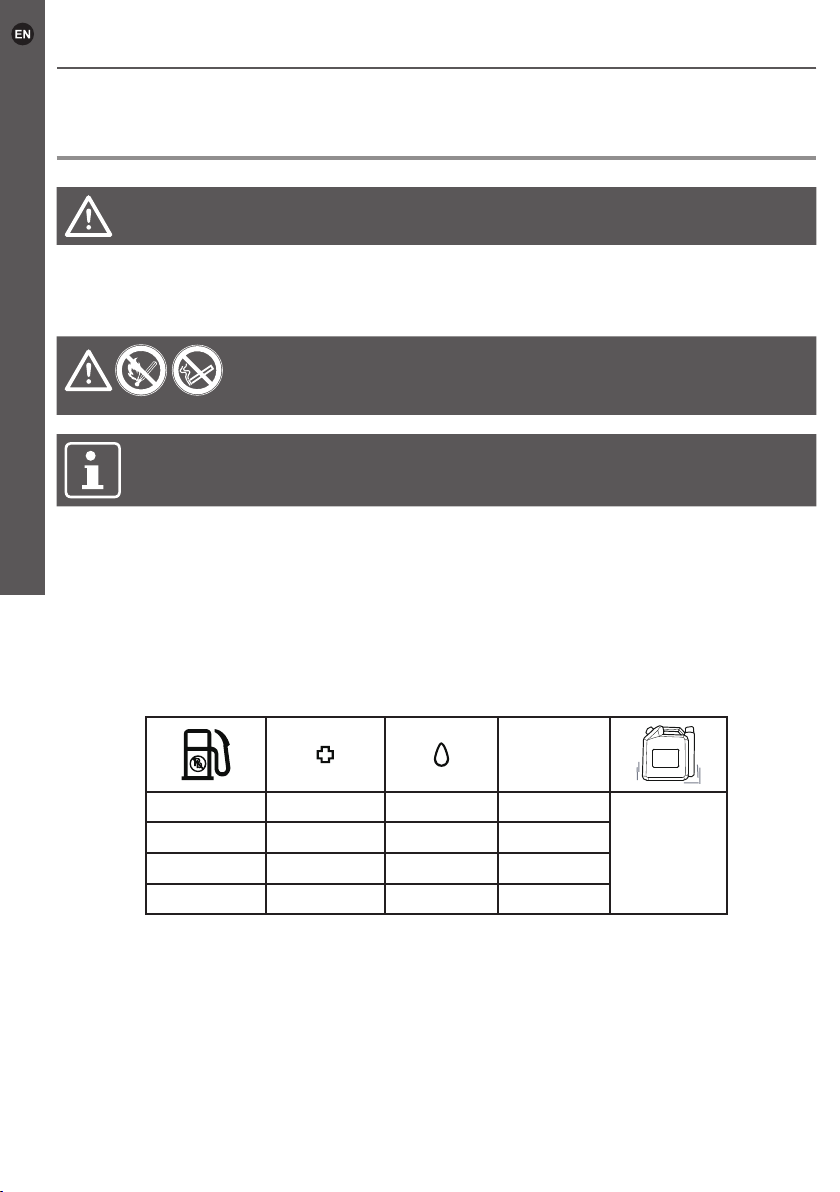

Filling up fuel and oil

WARNING! This machine is not supplied with petrol-oil mixture in the engine!

Before operating this machine it is essential to ll it with petrol-oil mixture!

This machine is equipped with a 2-stroke engine, the fuel and oil tank are combined

and it is essential to ll a fuel-oil mixture before operating this machine. Observe the

technical specications for suitable fuel and engine oil.

WARNING! Fuel and oil are highly inammable! Fumes will

explode if lit! Ensure that there are no naked ames around the

machine! Do not smoke while lling fuel and oil!

NOTE: To avoid spillage and to lter out debris, use a funnel with lter to ll

the fuel mixing bottle (23) and the fuel tank (11).

1. Place the machine on a stable, level surface with the fuel tank cap (10) facing

upwards. We recommend laying a non-ammable sheet under the machine.

2. Pour a regular-grade unleaded petrol and a quality engine oil for air cooled 2-stroke

engines in the supplied fuel mixing bottle (23) respectively via the 2 openings.

Use the scale markings on different sides for your desired ratio for petrol:oil. For

example, ll petrol to scale marking “10” rst, and then ll 2-stroke oil to scale

marking “10”. This indicates a correct ratio of 40:1 when using the scale 40:1.

=

100 ml + 2.5 ml =

40:1

200 ml + 5 ml =

300 ml + 7.5 ml =

400 ml + 10 ml =

3. Tilt and shake the fuel mixing bottle (23) thoroughly to make the fuel.

Before you start

Table of contents

Other Erbauer Blower manuals

Popular Blower manuals by other brands

Minuteman

Minuteman Kleen Sweep 40 quick start guide

Graphite

Graphite 58G031 Translation of the original instructions

Zenoah

Zenoah HBZ2602 owner's manual

Makita

Makita GBU01 instruction manual

Maruyama

Maruyama MD830 Owner's/operator's manual

Heatcraft Refrigeration Products

Heatcraft Refrigeration Products 4346B001 Installation & operation manual

Central Machinery

Central Machinery 61162 Owner's manual & safety instructions

Meec

Meec 721-322 User instructions

SNOWJOE

SNOWJOE sunjoe 20ViONLT-BLW-RM Operator's manual

Tanaka

Tanaka TBL7800/7800R owner's manual

Grizzly Tools

Grizzly Tools ALB 2020 Lion Set Translation of the original instructions for use

Ryobi

Ryobi RBL36 Operator's manual