Erbauer ERB666GRD User manual

Table of contents

Other Erbauer Grinder manuals

Erbauer

Erbauer ERB371GRD User manual

Erbauer

Erbauer ERB612GRD User manual

Erbauer

Erbauer EQSS240 User manual

Erbauer

Erbauer EAG2200 User manual

Erbauer

Erbauer EAG18-Li User manual

Erbauer

Erbauer ERB8DLC User manual

Erbauer

Erbauer ERB564GRD User manual

Erbauer

Erbauer ERB013GRD User manual

Erbauer

Erbauer ERB112BTE User manual

Erbauer

Erbauer ERB017GRD User manual

Popular Grinder manuals by other brands

VERTO

VERTO 51G091 instruction manual

DR

DR PRO XL-SP Safety & Operating Instructions

Rikon Power Tools

Rikon Power Tools 80-805 Operator's manual

Jet

Jet IBGM-8 Operating instructions and parts manual

Resson Technologies

Resson Technologies RD-14G Operation manual

DeWalt

DeWalt XR DCG409VS Original instructions

Festool

Festool DSG-AG 125 Original operating manual

Makita

Makita 9500D instruction manual

Coleman

Coleman Powermate Professional P024-0101SP instruction manual

DuraTech Industries

DuraTech Industries 6010 operating instructions

niteo

niteo DS0096-23 instruction manual

DeWalt

DeWalt XR DCG416VS Original instructions

Ryobi

Ryobi R18AG-0 Original instructions

Parkside

Parkside 102876 translation of original operation manual

Lux Tools

Lux Tools WS 230 Original operating instructions

TYROLIT Hydrostress

TYROLIT Hydrostress FGE400B operating instructions

Bosch

Bosch PWS 20-230 J Professional Original instructions

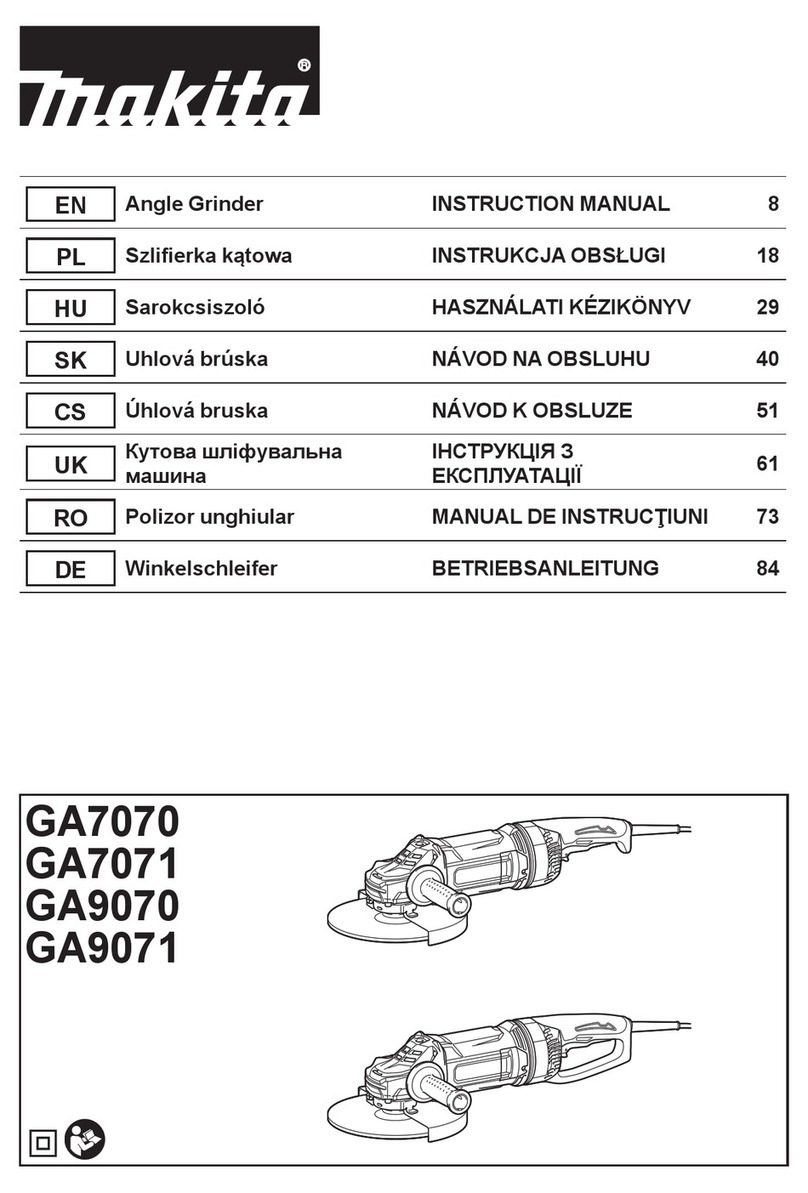

Makita

Makita GA9071 instruction manual