MATERIALS

frame, platform or shroud through general use may create an audible sound.

TOLERANCE

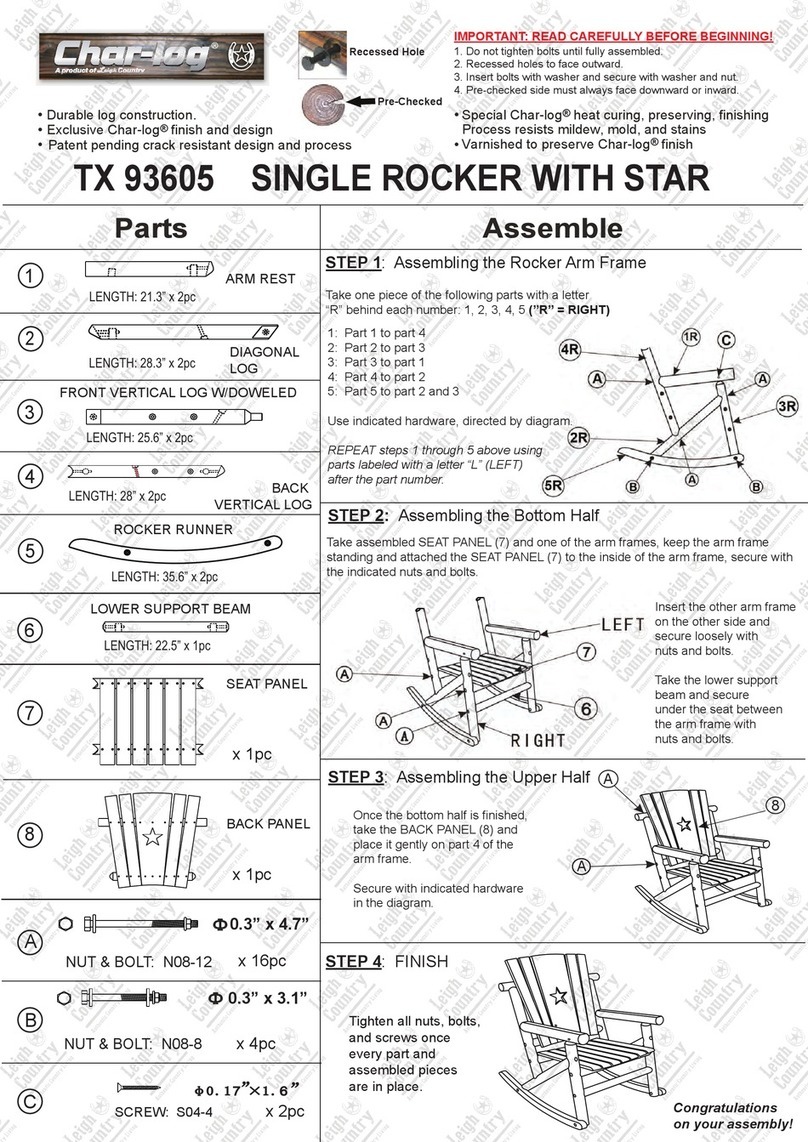

All Ergo adjustable foundations, depending on make and model, are designed

and manufactured to perform and function within designated quality control

parameters. Bases are subject to meticulous and rigorous inspections during

the quality control process to ensure bases will operate within these standards

during normal operating use. Normal operating use is defined as the following:

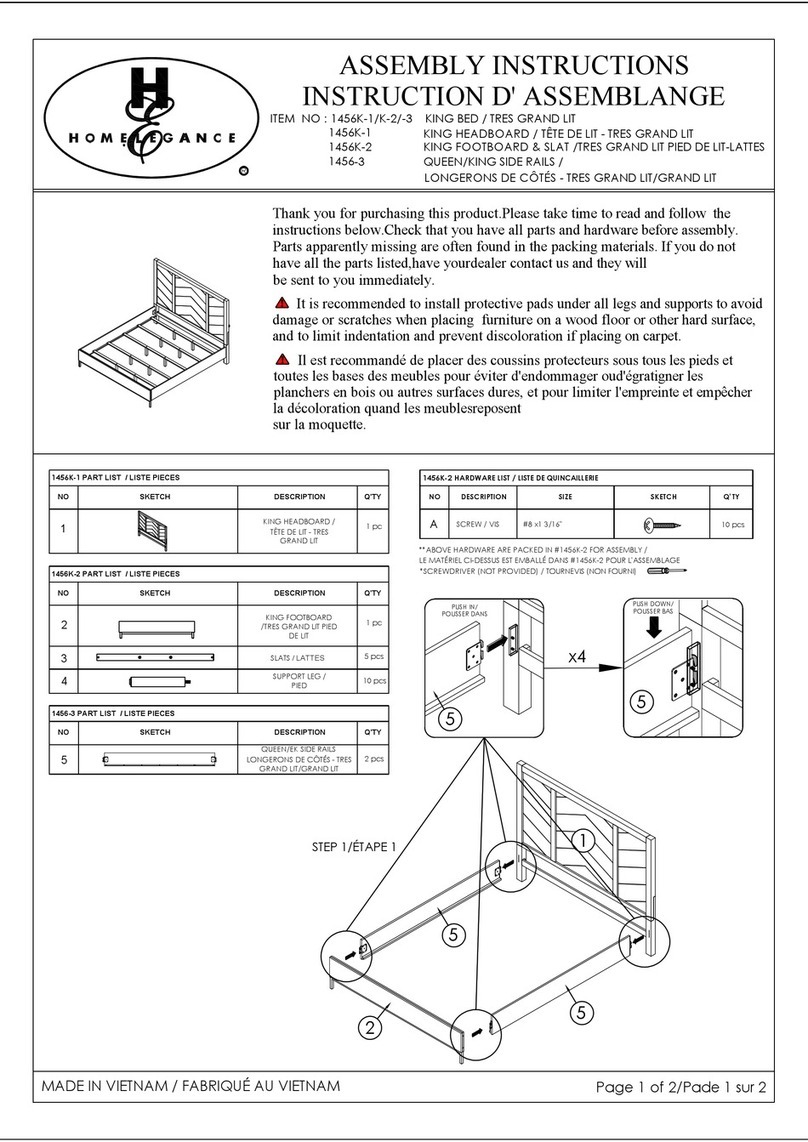

Adjustable foundation is to be operated with a mattress and load. Testing

procedures require lifetime cycle tests with up to 120kg distributed load. The

angle (designated “α” in illustration) between the back section and the flat

section for various configurations of the mattress support platform shall be ± 3°,

which translates to a tolerance of up to 1 ½”. The angle (designated “β” in

figure 1) between the flat section and foot

section for various configurations of the

mattress support platform shall be ± 3°,

which translates to a tolerance of up to ¾”.

Any adjustable foundation deemed to be within

these allocated tolerances is considered to

have met the manufacturer’s quality control

standards.

THAT “NEW PRODUCT” SMELL:

providing

adequate ventilation of the product and the environment.

BREAK IN PERIOD:

You can speed up the break-in period by simply spending time in the

adjustable bed through activities such as reading, watching TV or playing with

the kids or grandkids. The extra movement will help the adjustable base

respond to weight and temperature changes. Some of the materials in our

adjustable bases such as the woods, metals and plastics used in the platform,

frame and components are sensitive to moisture content and temperature

and may make sounds in colder environments.

PAIRED OPERATION:

When operating a “paired” split base setup there may be a time latency up to

1.5 seconds between each bases articulation.

WEAR AND TEAR:

Wear and tear is damage that naturally and inevitably occurs as a result of

normal use or aging.

FABRIC CARE:

To prolong the life of your fabric, protect from direct sunlight whenever

possible. For spot cleaning, wipe area with a light damp sponge or vacuum

with a soft brush attachment to remove particles. Keep at a minimum of

30cm (12 inches) away from direct heat sources. For a deeper cleaning, blot

liquid spills with a clean dry cloth. Wipe with a clean cloth dampened with

warm water. Do not wet excessively. A soft bristle brush may be used to

remove ingrained soil. Avoid scratching by gentle brushing. Wipe with a clean

cloth dampened with warm water to remove residues. Dry in shade away

from direct heat. If persistent marks remain visible after cleaning, seek

professional advice.

Adjustable

Bed Tolerance

Ergomotion Inc. | ph 1-888-550-3746 | fx 805-979-9399 | www.ergomotion.com

All Ergomotion adjustable foundations, depending on make and model, are designed and manufactured to perform and

function within designated quality control parameters. Bases are subject to meticulous and rigorous inspections during

the quality control process to ensure bases will operate within these standards during normal operating use.

Normal operating use is defined as the following:

-Adjustable foundation is to be operated with a mattress and load. Testing procedures require lifetime cycle

tests with up to 120kg distributed load.

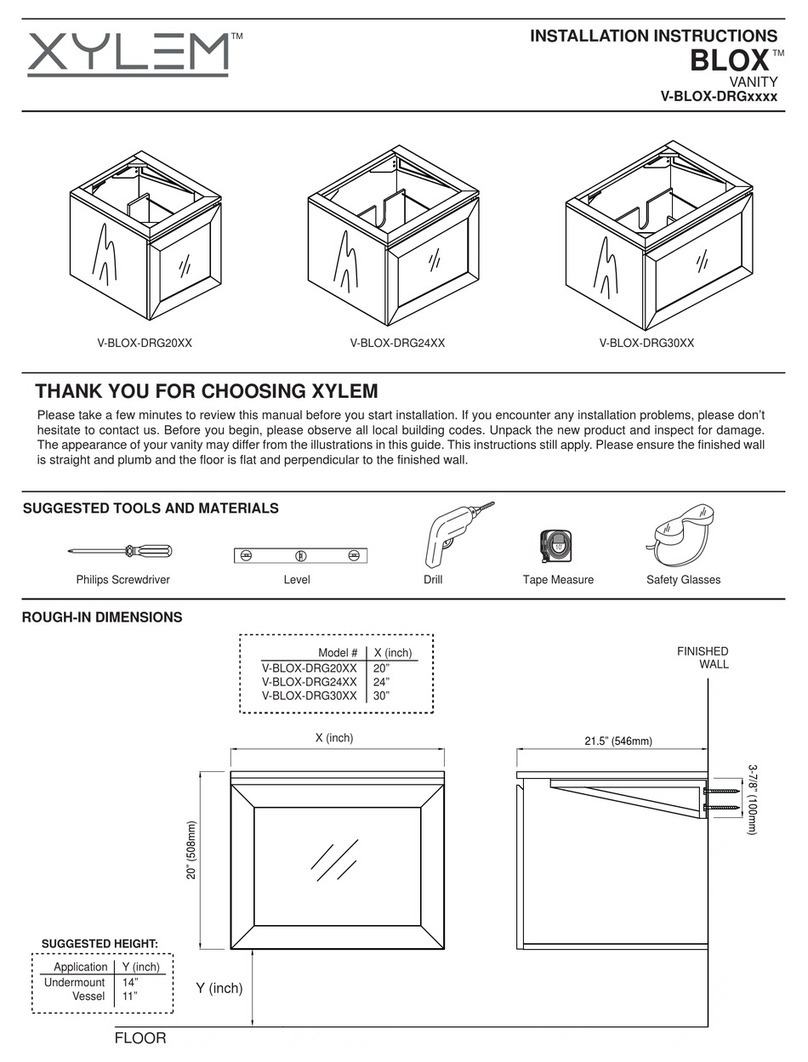

The angle (designated “α” in figure 1) between the back section and the flat section for various configurations of the

mattress support platform shall be ± 3°, which translates to a tolerance of up to 1 ½”.

The angle (designated “β” in figure 1) between the flat section and foot section for various configurations of the mattress

support platform shall be ± 3°, which translates to a tolerance of up to ¾”.

Any adjustable foundation deemed to be within these allocated tolerances is considered to have met the manufacturer’s

quality control standards.

(α°)

(β°)

When operating a "paired" split base setup there may be a time latency up to 1.5 seconds between each bases articulation.

Blake Pettit

Quality Assurance Manager

Ph 805-979-3875

Fx 805-979-9399

www.ergomotion.com