Ergon Crafco Patcher I Diesel User manual

Patcher I Diesel

PART MANUAL - 56933

Rev. 0

2

Revised: 02/06

3

Patcher I Diesel

Part Number 56900 (Skid Mount)

4

TABLE OF CONTENTS

PatcherI............................................................................................................................... 5

SafetyPrecautions...............................................................................................................6-7

LimitedWarranty.................................................................................................................. 8

WarrantyClaimInstructions.................................................................................................9

Specifications.......................................................................................................................10

Introduction............................................................................................................................11

OperatingInstructions

MachineStartUp..........................................................................................12

Figures1and2............................................................................................ 13

Figures3and4............................................................................................ 14

Figures5and6............................................................................................ 15

Figures7and8............................................................................................ 16

Caution..........................................................................................................17

ShutdownProcedure................................................................................... 17

StoringMachine........................................................................................... 17

TroubleShootingChart............................................................................... 18

ServiceInstructions..................................................................................... 18

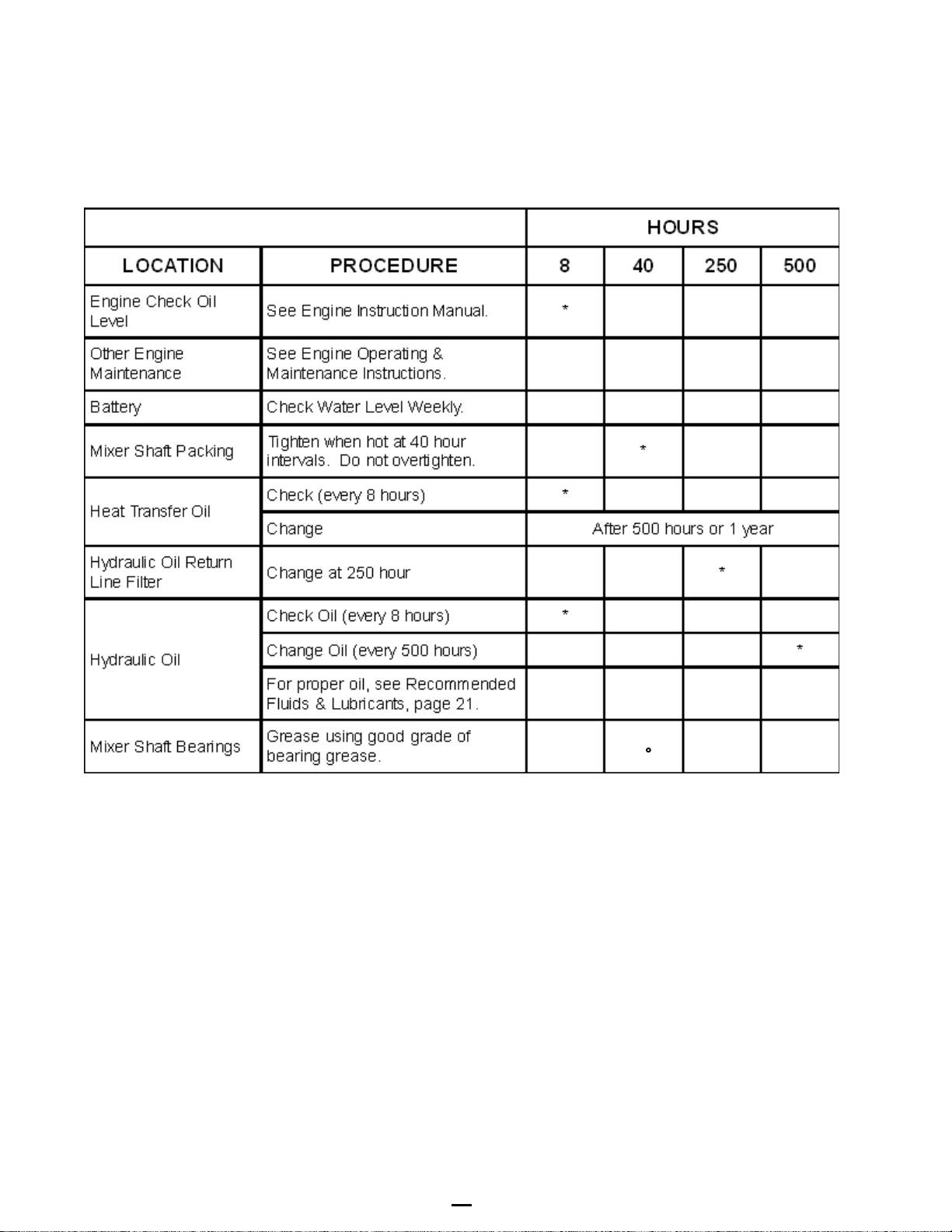

Maintenance MaintenanceInstructions............................................................................ 19

MaintenanceChart...................................................................................... 20

RecommendedFluids&Lubricants.......................................................... 21

TypicalSpecifications..................................................................................21

GeneralMaintenanceItems........................................................................ 22

InstructionsforOrdering Parts.................................................................... 22

PatchingMaterialPlacement......................................................................23

ApplicationSteps.........................................................................................23

ApplicationofthePatchingProduct........................................................ 24

BurnerTroubleShooting..............................................................................25

DieselBurnerElectrodeAdjustment..........................................................26

DieselBurnerSettings.................................................................................26

RTDSensor-Ohmsvs.Temperature........................................................27

Parts PatcherIDiagramsandParts....................................................................28-32

PlaceforNoted.............................................................................................33

HydraulicDiagramandParts..................................................................... 34-36

5

Patcher I Diesel

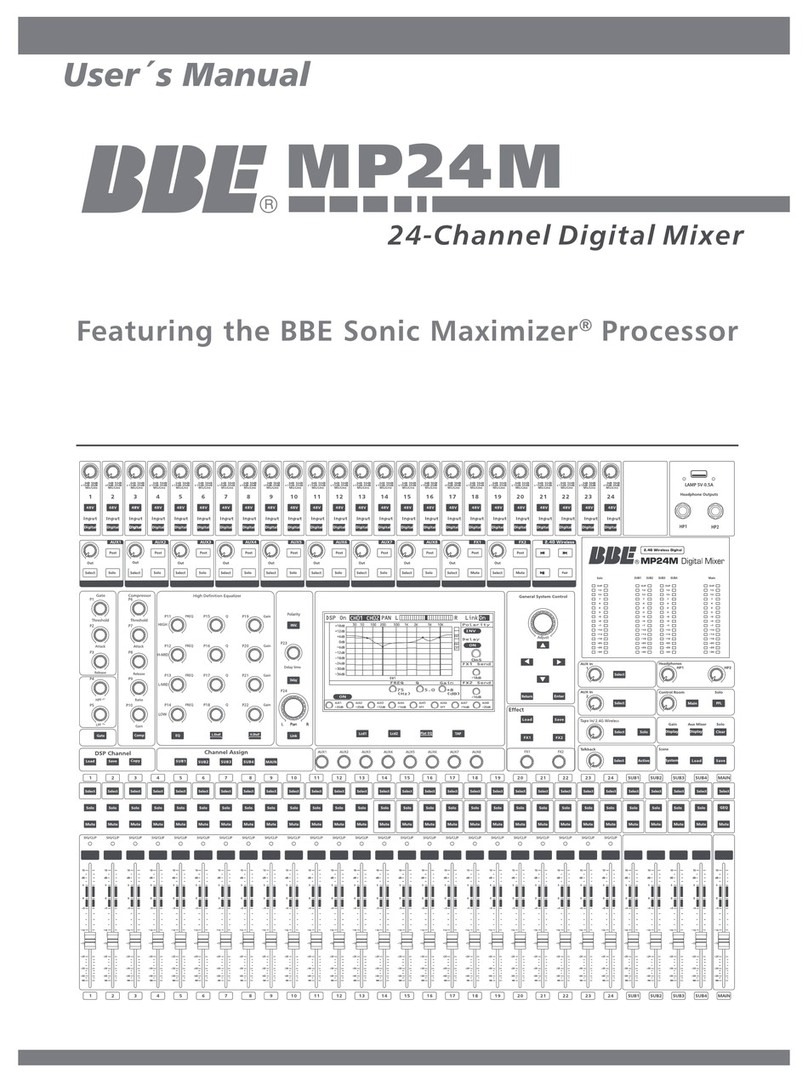

Thismanualisfurnishedwitheachnew CRAFCO Patcher I Diesel MIXER. Themanual will

helpyour machine operatorslearntorunthe mixer properly andunderstanditsmechanical

functionsfor trouble-freeoperation.

Your CRAFCO Patcher I Diesel MIXER is designed to give excellent service and save

maintenanceexpense. However,aswith all specifically engineered equipment, youcanget

bestresultsatminimumcostsif:

1. Youoperateyourmachine as instructedinthismanual, and

2. Maintainyourmachine regularly asstatedinthis manual.

WARNING: The engine exhaust from this product containschemicals

known to theStateof California to cause cancer, birth defectsor other

reproductiveharm. Operate in well ventilatedareaonly. Engineexhaust

isdeadly.

6

SAFETY PRECAUTIONS

•Highoperatingtemperatures of product and machine require protective clothing, long sleeve

shirt,long pants/coveralls, hat or hard hat (ifrequired)andflameresistantglovesbe worn by

operator.

•Alwaysweareyeprotection (goggles or faceshield) when operating hotcompressedair

lance,airgaslance and when applying material. Faceshield is tobeworn when adding mate-

rialto the Patcher I.

•Observe all CAUTIONAND WARNING signs posted on machine.

•Avoidthe entrance of water into any partofthemachine. Water will displace heat transferoil

ormelted material when it reaches operating temperatures which could be hazardous to

personnelsurroundingthemachine.

•Avoidbodily contactwith hot applied patchingmaterial or heat transfer oil;seriousburnsmay

result.

•ReadOperatorManualthoroughlybeforeoperatingmachine.

•Makesure operator is familiar with machine operation.

•Do not operate in closed building or confined areas.

•Shut-downburner and engine prior to refilling diesel tank.

•When adding material to material tank, stop mixer, lift lid, add material and close lid before

restartingmixer. Hotmaterial could splashandcauseseriousburnsifthis procedure is not

followed.

•Keephands,feet,andclothingaway from all moving parts.

•Alwayskeepafireextinguisherneartheunit. Maintainextinguisher properly and be familiar

withits use.

•Donotexceed525OF. for heat transfer oil temperature.

•Donot overfill heat transfer oil level. Expansionofoilduringheatupcouldcause overflow.

Check oil each day before starting burner, add oil to touch bottom of dipstick if required (at

70OF.) Useonly recommended heat transfer oil and change after500hoursof operation or

oneyear,whicheveroccursfirst.

7

SAFETY PRECAUTIONS continued

•Followoperating instructions forstartingandshut-downofburner. Instructionsaremounted

oncontrolbox.

•Replaceanyhoseswhichshowsignsofwear,fraying, or splitting. Be sure all fittings and

jointsare tight and leak-proof.

•Precautionisthebest insurance against accidents.

•ThePatcher I mixershouldnot be leftunattendedwithburner lit.

•Tightenallboltsandscrewsafterevery100hoursofoperation.

•Crafco,Inc. assumesnoliabilityforanaccidentor injury incurred through improper use of the

machine.

8

Patcher I Diesel

LIMITED WARRANTY

Crafco,Inc., through itsauthorized distributor,will replace for the original purchaserfreeof

chargeany partsfounduponexaminationbythefactory at Mesa,Arizona, to bedefectivein

materialorworkmanship. Thiswarrantyis for a period within 60 days of purchase date, but

excludesengineorcomponents,tires,andbatteryastheseitemsaresubjecttowarranties

issuedby theirmanufacturers.

After60 days,Crafco,Inc.warrants structuralparts,excludingheating system,hydrauliccom-

ponents,and electrical componentsfor a periodofone(1) year from date of delivery. Crafco,

Inc.,shallnot be liable for parts that have been damaged by accident, alteration, abuse, im-

properlubrication/maintenance, normal wear,orothercausebeyondour control.

Thewarranty provided herein extends onlytotherepairand/orreplacement of those compo-

nentsontheequipmentcoveredaboveanddoesnotcover labor costs. The warranty does

notextendtoincidentalorconsequentialdamagesincurredasaresultofanydefectcovered

bythiswarranty.

Alltransportationandlaborcostsincurred by the purchaser in submitting or repairing covered

componentsmust be incurredbythepurchaser.

Crafco,Inc. specifically disavows any otherrepresentation,warranty, or liabilityrelatedtothe

conditionoruseof the product.

WARNING: Useofreplacement parts other than genuine Crafcoparts

mayimpair the safety orreliabilityofyourequipment and nullifies anywarranty.

9

WARRANTY CLAIM INSTRUCTIONS

Pleasefollow the instructions statedbelowwhencallingin a WarrantyClaim. Failuretofollow

theseprocedures may be cause to void the warranty.

1. Callyour local Crafco Distributor. Ifyoudonot know who your local distributor is, call

aCrafcoCustomerServiceRepresentative,(tollfree 1-800-528-8242) for name,

location,andtelephonenumber.

2. OncontactingtheDistributor,be preparedtoidentifythe machine type, model number,

andserialnumber,also the date of purchase if available.

3. Shouldthecauseofthemalfunction be a defective part, the Distributor will advise you

oftheprocedure to follow for a replacement.

4. Thewarrantyis valid only for parts which havebeensuppliedorrecommendedby

Crafco,Inc.

Ifyou have any additional questions regarding warranty repairs and parts, please do not

hesitatetocalltoll free 1-800-528-8242.

CRAFCO,INC.

235SOUTH HIBBERT

MESA, AZ 85210

480-655-8333

480-655-1712 (FAX)

TollFree 1-800-528-8242

10

SPECIFICATIONS

VatCapacity............................................................. 95 gallons

HeatTransferOilRequired..................................... 17 gallons at 70OF.

TankConstruction.................................................... Double boiler type

TankOpeningSize(2)............................................. 14.25” x 17.88” (each)

MaximumHeatInput.................................................260,000B.T.U.

Burner&TemperatureControl................................Automatic-Digitalreadout.

Hotoilandmaterial.Autoflame

shutdown.

Engine-Yanmar SingleCylinder(Max. Output)

ModelL100V- DieselFueled............................. 9.1 BHP @ 3600 rpm

DriveMechanism.....................................................Allhydraulic with two speed forward

andreverse action.

Mixer..........................................................................Horizontalshaftwith4sweep paddles

DryShippingWeight(Skid)....................................Approximately3,000lbs.

MaximumEquippedWeight(Skid)........................Approximately4,850 lbs.

DryWeightTrailer(IfEquipped).............................900lbs.

11

Patcher I Diesel

OPERATING INSTRUCTIONS

INTRODUCTION

TheCrafcoPatcherIDiesel Mixer was developed to melt patching material.

DO NOT operatemachinewithoutfollowingthese instructions:

1. Checkenginecrankcaseoillevel(referto Engine OperatorManual).

2. Checkhydraulic fluid level, at ambient temperature. Add fluid ifnecessary to bring to

correctlevel (approximately 3” below top of filler tube).

3. Checkheattransferoil level (see Fig. 4). At 70OF.,the oilshouldtouchthedipstick.

DO NOT overfillor spillage may occur when oil is heated and expands.

NEVER REMOVE DIPSTICK WHEN OIL IS HOT.

4. ThereardischargematerialvalveshouldbeintheclosedpositionandtheBurner

Controltoggle switch “OFF.”

5. Fill engine tank with diesel fuel - DO NOT FILL ENGINE FUEL TANK WHEN

BURNERS ARE LIT (see Fig. 7).

6. Lubricate mixer bearingsweekly(see Fig. 1).

7. Make sure discharge gate is in the closed position (see Fig. 2).

8. Placethehydrauliccontrol valve switch in the neutral position(seeFig.3).

12

MACHINE START UP

1. Startengine. To startengine, insert key into the control panel. Turnkeytofirstposition.

Warninglightsshouldturn“ON.” Turnkeyto second position. Engineshould start.

Releasekey when engine is running. Leave at idle for a few minutes. Move throttle

levertoset engine at desired speed (see Fig.5). Makesure hydraulic control valve

switchis in the neutral position.

2. Settemperaturedialstodesiredtemperature. Hot oil temperature should not exceed

525OF. and material 410OF. (see Fig. 6).

3. Turntoggleswitch“ON”(seeFig. 6).

CAUTION

Ifburners do not ignite thefirsttime,turntoggle switch “OFF.” Turntoggleswitch “ON.” Burner

shouldignite. If burner still does not ignite, determinecauseofmalfunction(seeTrouble

ShootingGuide,page 25).

4. Allowtheheatingoilto continue to heat. Place bags of material in the mixerandheat.

Start the mixer as soon as possible to break up the bags. When loading solid material

intothemixer tank, the mixer will stop when lifting the lid (if equipped with lid switchs),

addmaterialand close the lid again to startthe mixer. Followingthisprocedurewill

preventthe hot material from splashingandcausingseriousburns to personnel.

Engagethe mixer by moving the mixer hydraulic controltoggleswitchtoforwardor

reverserotation. When changing the speed of mixing, movebothbypasshydraulic

valvessimultaneously. Ifmixer jams, switch maybemovedforoppositerotation.The

speedofmixingiscontrolledbythepositionofthe 2 bypass hydraulic valves

(seeFig.8). Thevalvesshould be moved together (either in or out)notoneatatime.

Theminimumamountof material needed for proper mixer operation is400lbs.

5. Temperaturereadouton burner control box indicatesmaterialtemperature. When

patchingmaterialreachescorrectapplicationtemperature,materialmaybedrawnoff

as desired. Discharge gate is opened by moving handle down. Drain material into

pourbucket.

Removeexcess patching material from chute with scrapingtool.

CAUTION: Be sure discharge gate is completely closed after each draw off. Lock

handlewithsafetychainifmachineis transported (see Fig. 2).

13

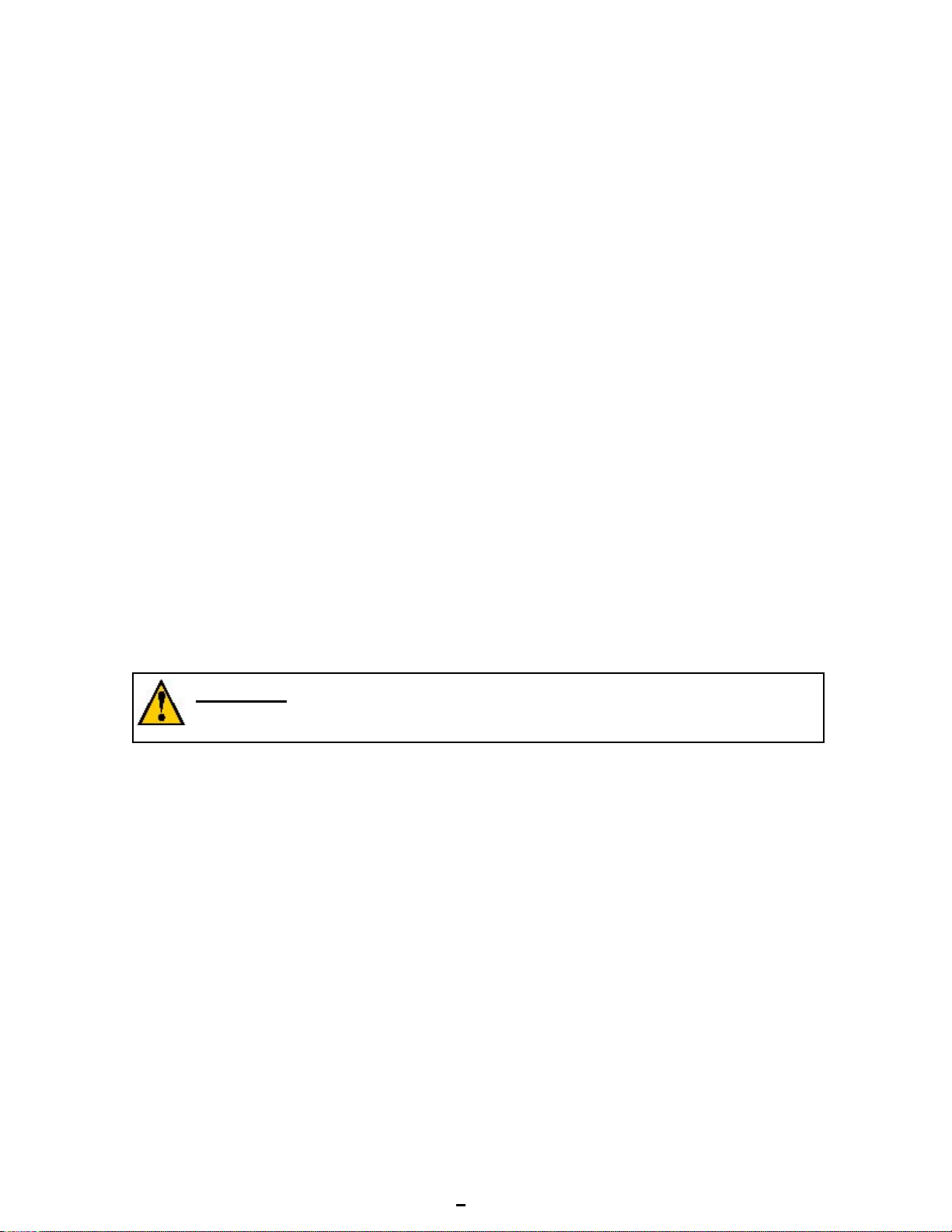

Fig. 1

Fig. 2

grease fitting

safety chain

discharge

gate

14

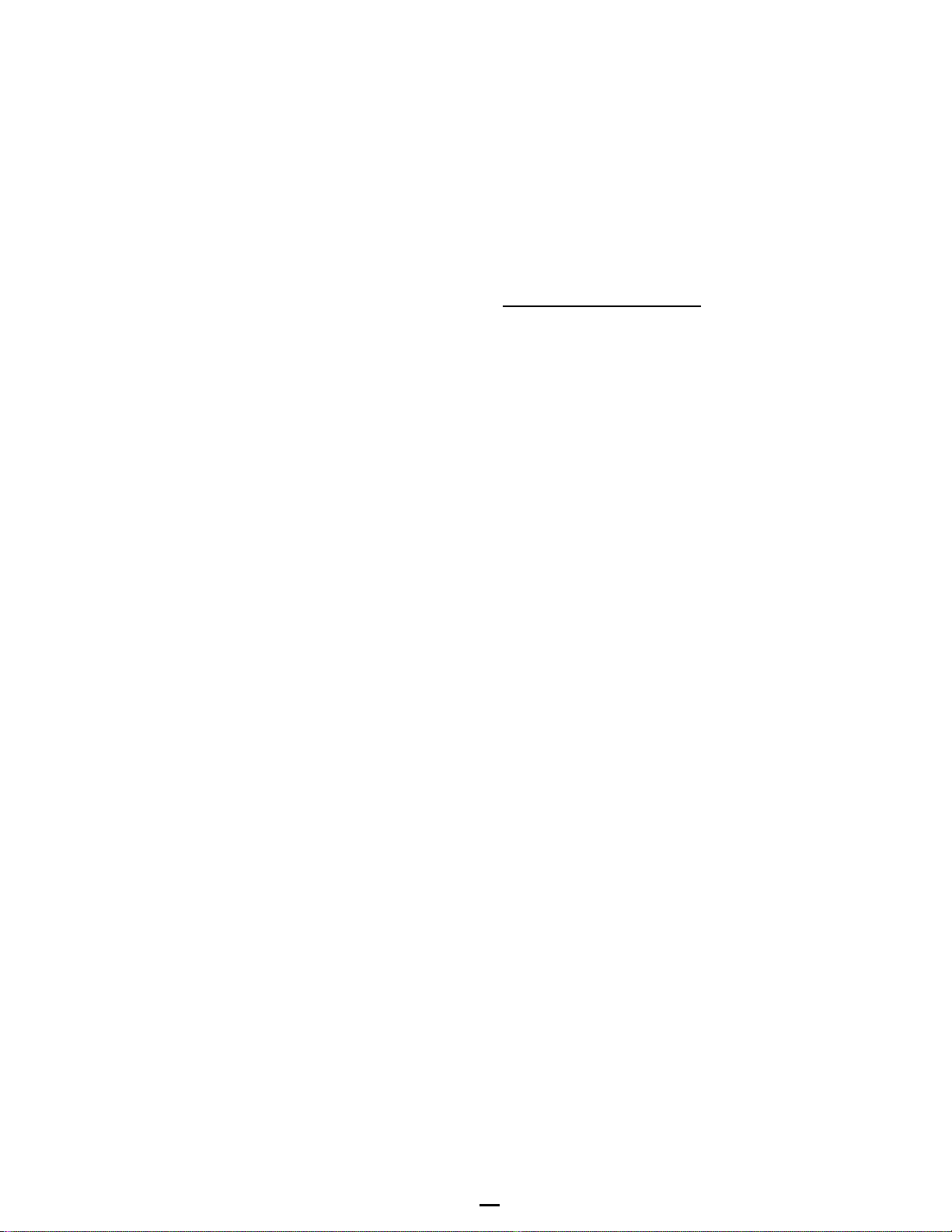

Fig. 3

Fig. 4

heat transfer dipstick

mixer control switch

15

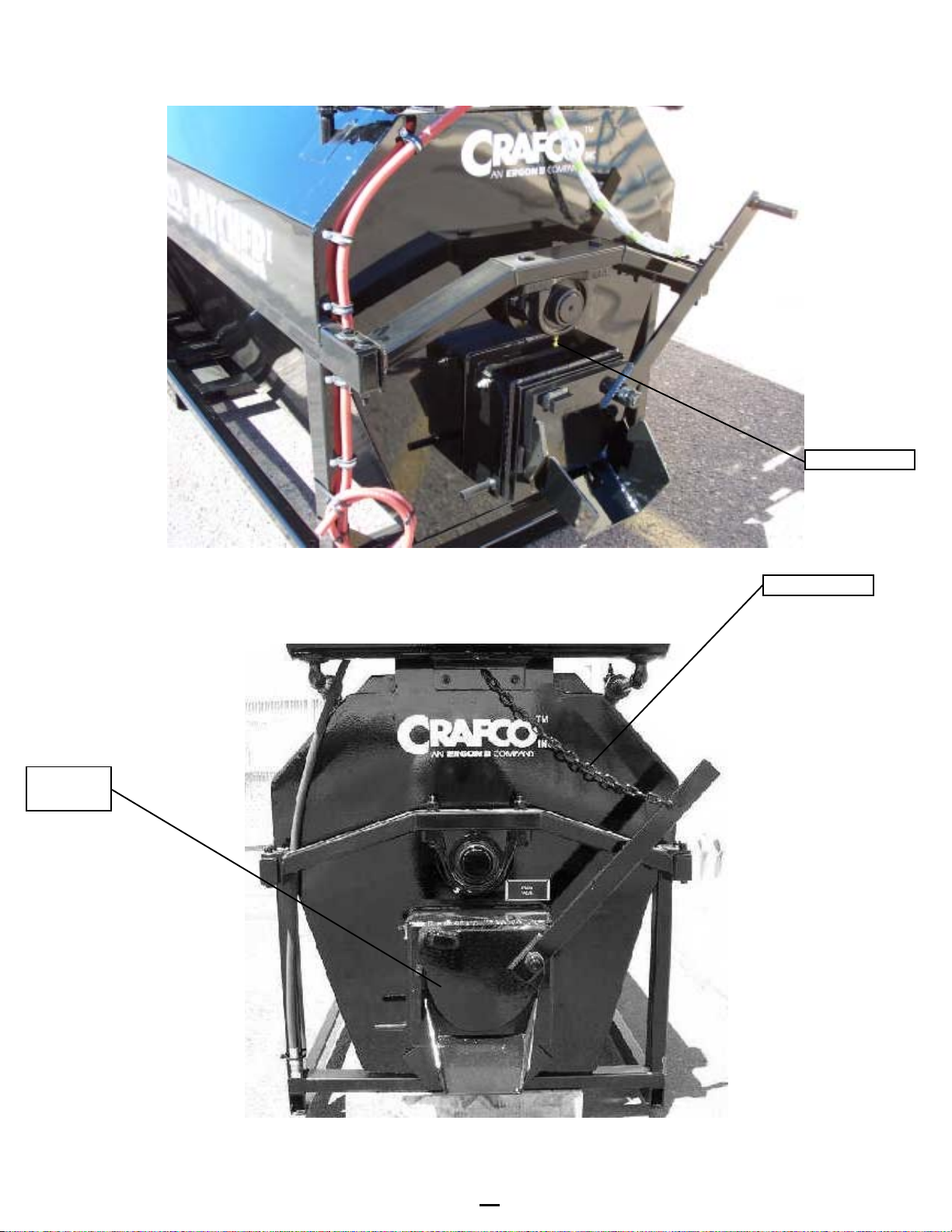

Fig. 5 temperature dials

Fig. 6

throttlelever

toggle

switch

16

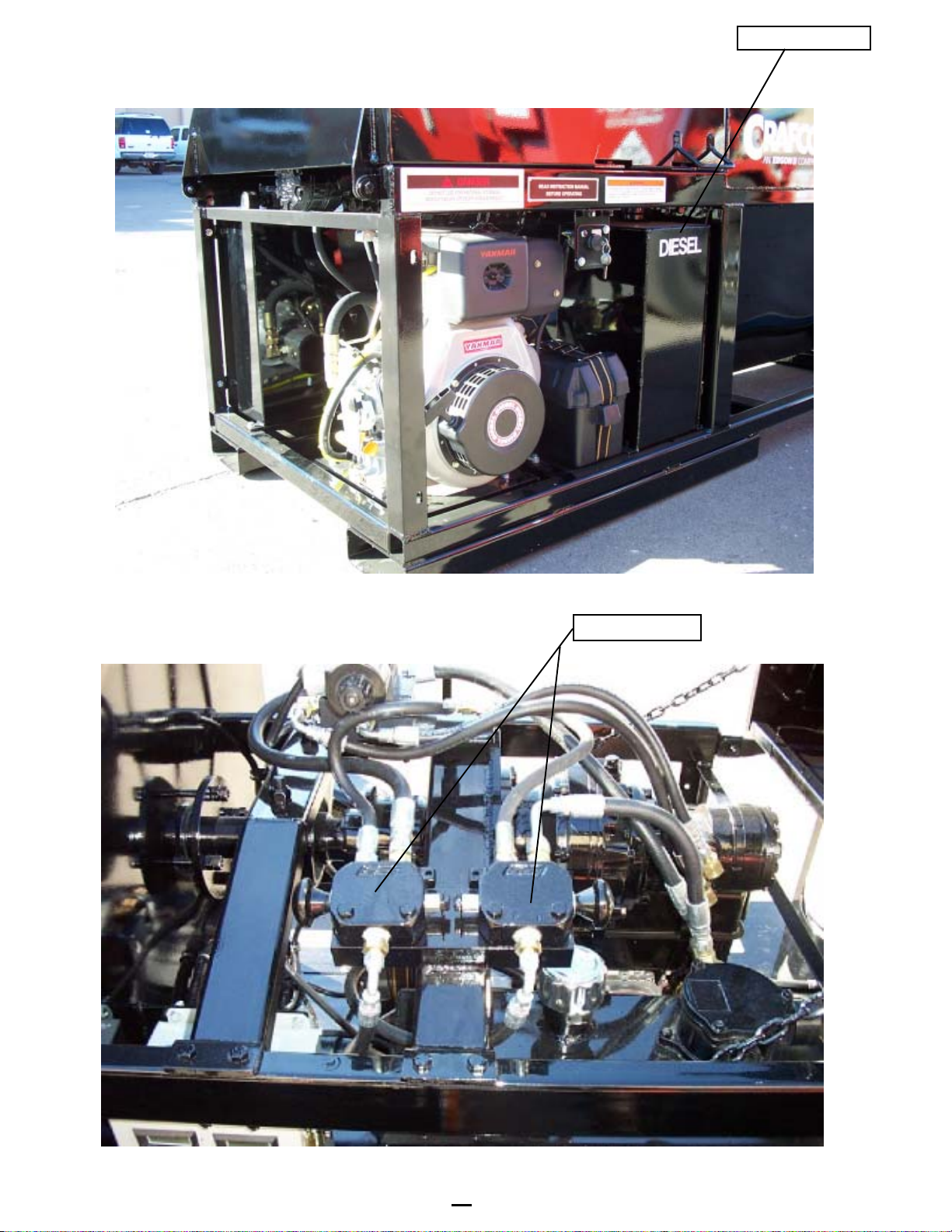

Fig. 7

Fig. 8

by-pass valves

enginefuel tank

17

SHUTDOWN PROCEDURE

1. Turnburnertoggleswitchto“OFF.”

2. Returnmixerhydraulic control switchto“OFF”position.

3. Turnoffengineby closing stop leverandturnoffkey.

STORING MACHINE

ThePatcherIDiesel shouldbestoredinanareawheremoisturecannotentermachine.

Extendeddowntimecancausemoisturebuildupinheatingoiltank.

Ifthere is any suspicion moisture thatmayhavecollectedinheat transfer oil, warm heat

transferfluidto300OF. for 2 to 3 hours to evaporate the moisture.

CAUTION

Extremecaremustbeusedwhenoperatingthis equipment. Safety is the result of being

carefulandpayingattentiontodetails. Certainexposedpartsofthismachine,whenoperat-

ing,reach500OF.; the material as high as 400OF. and the hydraulic fluid may reach 200OF.

Always wearprotectiveclothingandeyeprotection. Besure that all joints and fittings are tight

andleakproof. Immediately replace any hose which show signs of wear,fraying or splitting.

Tightenallbolts,nutsand screws every100hours.

18

TROUBLE SHOOTING CHART

SERVICE INSTRUCTIONS

1. Conductageneralinspectionof your machine at least once a week. Replace all worn

ordamaged parts, make any necessary adjustments and tighten all loose nuts or

screws.

2. Keep regular replacement items instockforemergencyrepairs,toavoid costly “down”

time. Refertogeneralmaintenanceitems.

3. Watchfor leaks - tighten packingon mixer if necessary.

4. Cleanmachineexternally periodically. Check with material manufacturerfor

recommendation.

5. Follow“RecommendedMaintenanceProcedures”perMaintenance Chart, page 20.

MELBORPESUACYDEMER

etatortonlliwrexiM

.wolooterutarepmettnalaeS lairetamtaehoteunitnoC

.emitenotadecalpskcolbynamooT gnisrev

eryrt&lairetamtaehoteunitnoC .rexim

erusserp/wolfciluardyhetauqedanI .leveldiulfciluardyhkcehC .yrassecenfiwolfkcehc/erusserpteseR

tnalesfoputaehwolS

foedisniehtnolairetamdezillatsyrcrodekocfopudliuB .knatlair

etam .loocotenihcamwollA .tnevloshtiwhsulfdnastisopedevomeR

gnitarepotonrenruB .ediuGgnitoohSelbuorTrenru

BeeS

levelliognitaehwoL tcerrocsileveldiulferusekaM

erutarepmetliognitaehwoL erutarepmetdednemmocertaeeS

d

ezillatsyrcsahrodloliognitaeH sruoh005yrevedednemmocersatiecalpeR

etatortonlliwrexiM

ffodenruthctiwselgg

otrexiM hctiwselggotnonruT

noitcennoceriwdaB riaperdnadniF

evlavlortnocdaB evlavecalpeR

eruliafegdritraccil

uardyH ecalperdnaevomeR

eruliafliocciluardyH ecalperdnaevomeR

19

MAINTENANCE INSTRUCTIONS

ENGINE:

Checkoildaily. Service engine perYanmar owners manual. See engine owners

manualfor additional operating andmaintenanceinstructions.

HYDRAULIC SYSTEM:

Checkhydraulic fluid daily. Change hydraulic filter after250 hours. Change hydraulic

fluidevery 500 hours of operation.

MIXER PACKING GLAND/SEALS:

Tightenglandwhile hot at40hourintervals. Do not overtighten.

MIXER SHAFT BEARINGS:

Lubricateweeklyusinga good grade of high temperature grease.

HEAT TRANSFER OIL:

Checkleveldaily. Oil should touch dipstick when 70OF. Donot overfill (see Fig. 4).

TEMPERATURE CONTROL CALIBRATION

Checkcontrolknobcalibrationweekly. Calibratebyaligningthelineonthecontrolknob

withthecalibrationlineonthescaleplate(seebelow).

20

MAINTENANCE CHART

Table of contents

Popular Mixer manuals by other brands

Paramount Fitness

Paramount Fitness BM80 Installation & operation manual

Holstein Housewares

Holstein Housewares HH-09149005 manual

Linea 2000

Linea 2000 DOMO DO9180M Instruction booklet

Univex

Univex Swing Ring SRMF20 Maintenance & parts manual

Ametek

Ametek Chandler Engineering 3260 instruction manual

Russell Hobbs

Russell Hobbs THE SLICK STICK Instructions & warranty