Introduction

2

Introduction

We are confident that you will be delighted with your PARAMOUNT MIXER, and it will become a most

valued appliance in your commercial kitchen.

A new mixer can seem very complex and confusing at first glance. To ensure you receive the utmost

benefit from your new Paramount Mixer, there are two important things you can do:-

Firstly

Please read the instruction book carefully and follow the directions given. The time taken will be well

spent.

Secondly

If you are unsure of any aspect of the installation, instructions or performance of your appliance, contact

your Paramount dealer promptly. In many cases a phone call could answer your question.

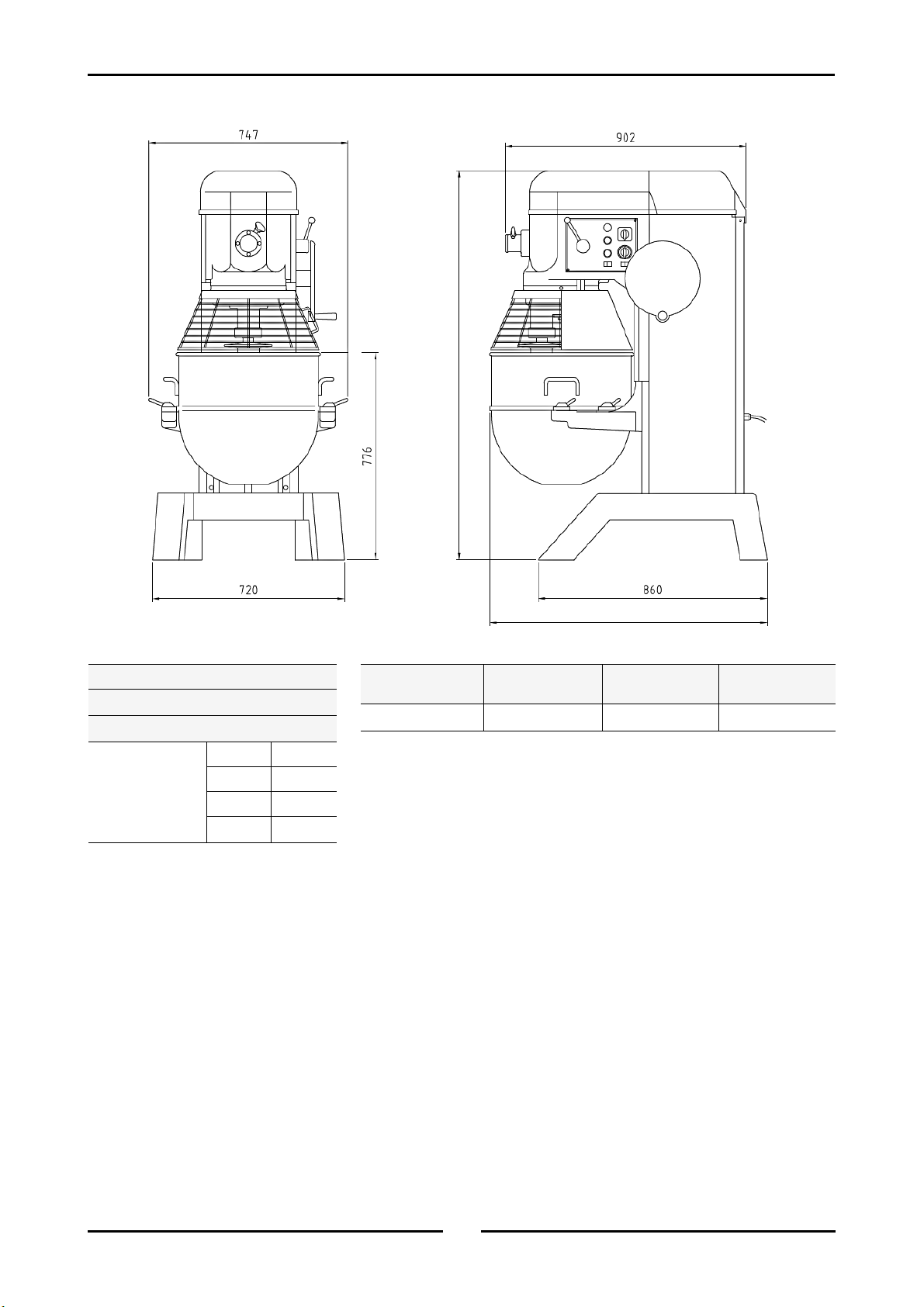

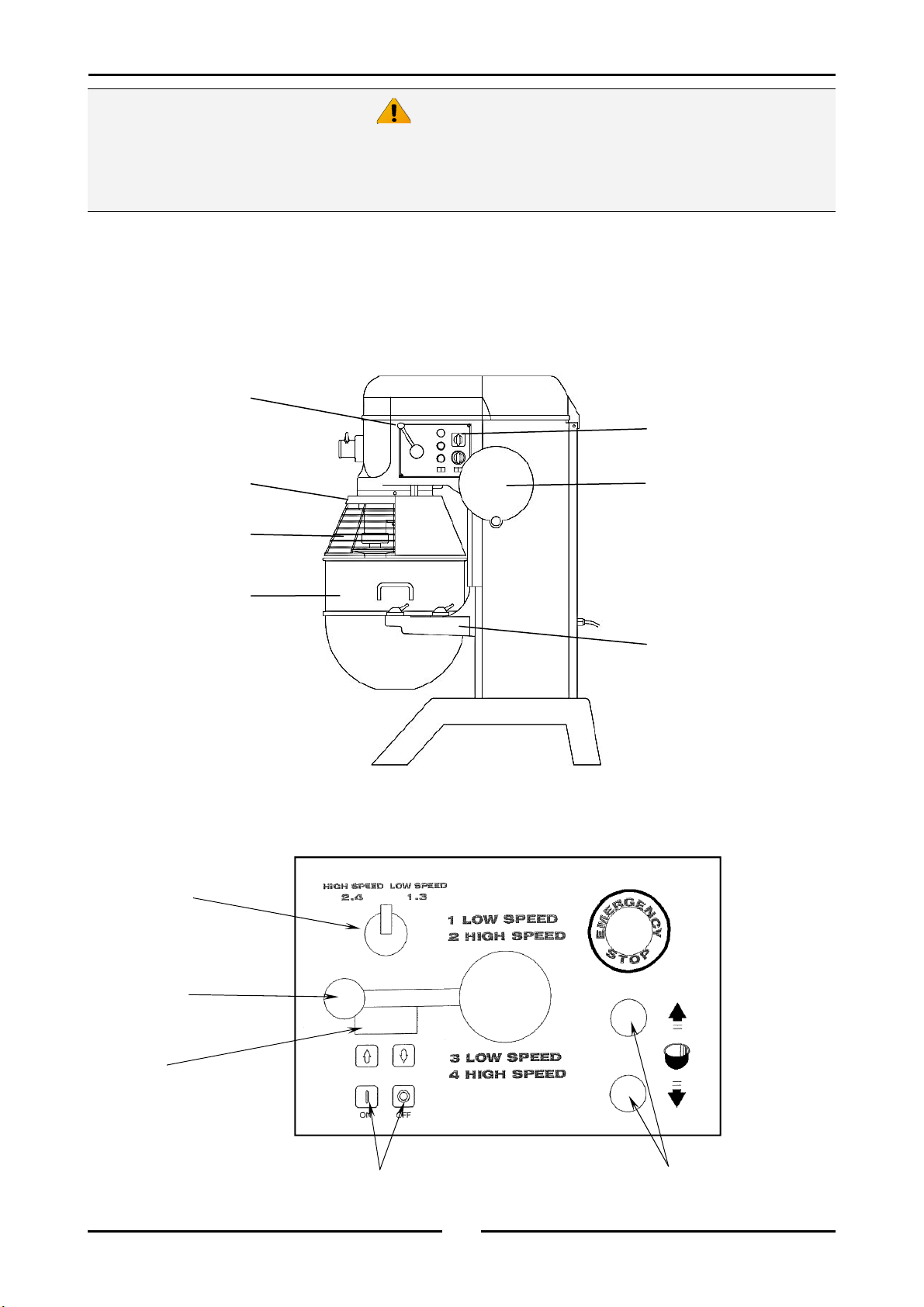

The Paramount BM80 is a dependable mixer for kneading and mixing all kinds of dough. The mixer has 4

speed selections and an electronic timer. The mixer comes with various style attachments which can be

used to obtain the best results. These are made of alloy aluminum or of a food hygiene standard material.

This model Mixer is equipped with a powerful 3HP, 2 speed motor and a 2 speed gear drive design which is

driven through ‘Vee’ drive belts. The constant mesh helical gears are made of hardened alloy steel and are

continually oil lubricated. The oil level can be monitored through an easy view sight glass.

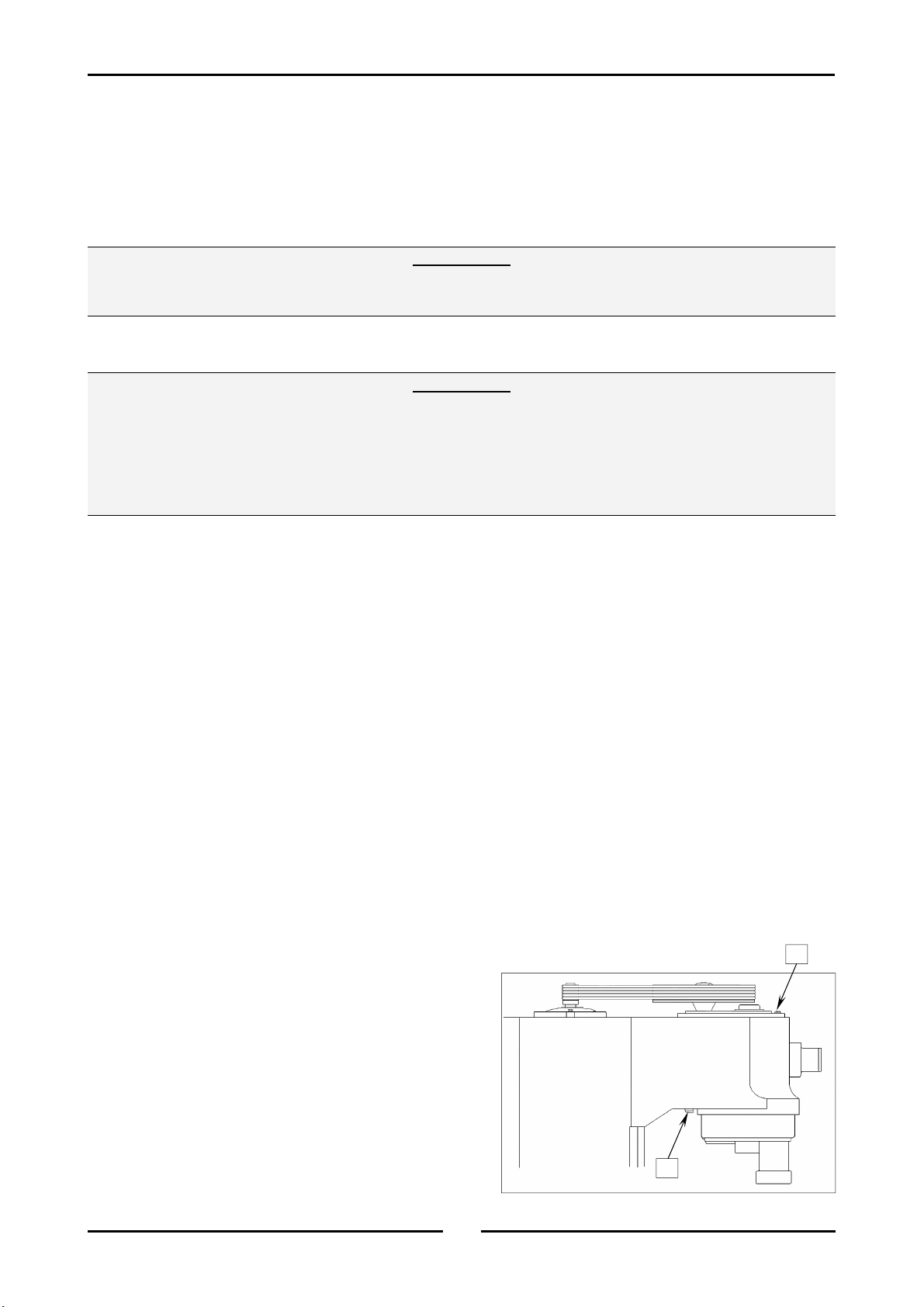

A stainless steel safety guard is optional and is fitted with a limit switch to turn ‘Off’ power when the guard

is in the ‘Open’ position.

With proper operation and maintenance this mixer will give you years of service, and obtain the best

results.

Safety Precautions

• Keep hands and clothing away from the bowl and hub attachments when in operation.

• Keep rigid objects away from the bowl and hub attachments when in operation.

• Do not use this machine for any applications other than food processing.

• Use the machine only with the electrical supply specified on the rating plate.

• Disconnect the machine from its power source before carrying out any maintenance.

• Do not disable or remove any of the safety mechanisms included with this machine.

• Do not leave the machine in operation unattended.

• Observe all maintenance and safety inspection schedules.

• Ensure the appliance and any accessories / attachments are in a stable, upright position before

operating.

• Ensure all safety features of the machine are fitted and operate correctly within the safety

requirements and procedures before operating the appliance.

Improper installation, adjustment, alteration, service or maintenance can cause property damage,

injury or death.

Read the installation, operating and maintenance instructions thoroughly before installing or

servicing this equipment. Failure to do so may result in serious injury or damage.

Caution