For more information please call

your Account Manager or 1-800-BAKERS-1.

Headquarters

AMF Bakery Systems

2115 West Laburnum Avenue

Richmond, Virginia 23227

1-800-225-3771 or 804-355-7961

FAX: 1-804-342-9724

www.amfbakery.com sales@amfbakery.com

European operation

West Park Ring Road

Leeds LS16 6QQ England

Tel.: 1132-787110

Fax: 1132-741415

STATIONARY BOWL MIXER

•Nema 12 remote enclosure (painted steel) including:

Square D main breaker.

Full voltage magnetic Nema rated starters.

Pre-wired terminal strip.

•Operator panel contains the following:

Eagle digital plug-in timers for high and low speed.

Eagle digital plug-in refrigeration timer.

Digital bowl temperature indicator.

Allen Bradley push-buttons for the following functions:

Mixing (slow, fast, stop)

Door (up, down, stop)

Flour gate (open, close)

Refrigeration selector OFF/ON/AUTO

Alarm (acknowledge/reset)

Safety/jog

Emergency stop

•Nema 1 Gemco cam switch.

•Nema 12 junction box, terminal blocks, prewired motors

and controls.

•Bowl door gearhead motor with electric brake and components.

•Weg drive motor (copper rotor) integral mount with

NORD Gear reducer.

•Motor overheat protection installed in stator winding.

•High/low speed jog operation with special anti-jog function.

•CAD produced electrical wiring diagram.

•Equipment meets OSHA requirements.

Bowl And Cooling Jacket

•All stainless steel one piece bowl construction.

•Bowl plate 5/16”thick.

•Bowl end plate 3/8”thick jacketed.

•Bowl jacket 1/4”“L”type breaked & welded.

•Reinforcement belts are added to the bowl jacket for

maximum resistance to shock.

•Refrigerated bowl sides.

•Bowl insulated with urethane foam.

•Stainless steel bowl drain valve.

•D.X. expansion valves or Glycol valves are included.

•Bowl tested at 250 PSI.

Top Assembly

•Solid stainless steel.

•The 12”diameter pneumatic sliding flour gate

•Two 2”stainless steel sanitary liquid inlets.

Door and Door Shaft Assembly

•Reinforced stainless steel door.

•Air operated door seals.

•Door racks and pinions.

Agitator and Drive Assembly

•Solid stainless steel “Y”type spiders split at main shaft and

agitator bars.

•Stainless steel primary agitator bars mounted on lubrication

free U.H.M.W. bushings.

•Stainless steel secondary agitator bars mounted on lubrication

free U.H.M.W. bushings.

•Solid stainless steel main shaft mounted on spherical bearings.

•Sanitary split seal assembly.

•Agitator is chain and sprocket driven.

•Chain lubrication by oil bath.

•Standard agitator RPM 35/70 (consult for other RPM available).

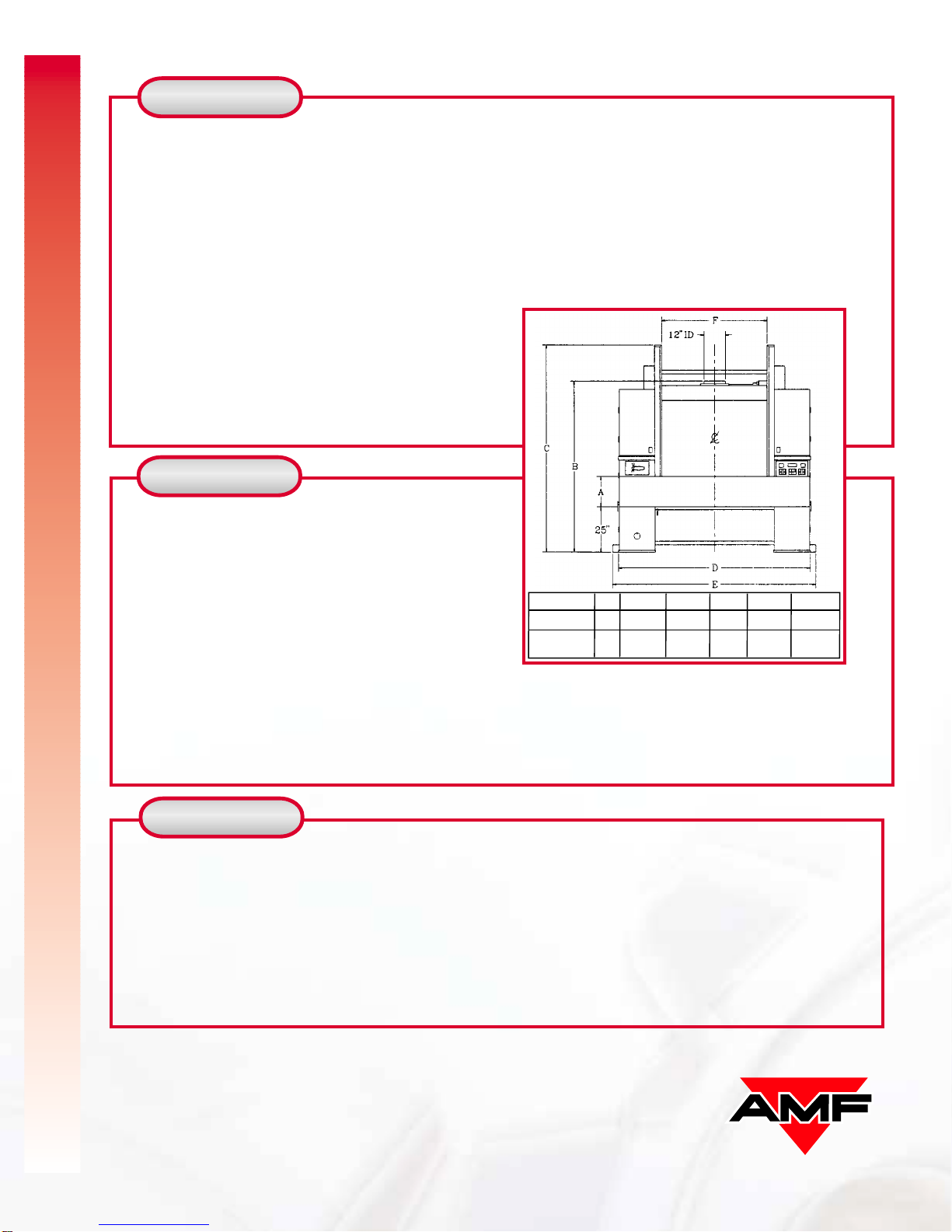

MIXER

59-1/8"

9' - 0"

9' - 6 3/4" 9' - 6 1/4"

7' - 10 5/8"

17"

2000 &

2400 lb.

54-1/8"

8' - 7"

9' - 5 3/4" 9' - 1 1/4"

7' - 7 5/8"

16"

1600 lb.

AB C D E F

Mechanical Options

•Extra liquid inlet.

•12”O.D. butterfly valve in lieu of sliding flour gate.

•Stainless steel air operated front sliding type sponge door.

•Stainless steel air operated rear hinge type sponge door.

•Stainless steel ingredient door with safety bars.

•Stainless steel refrigerated door (with hoses and valves).

•Double extra heavy stainless steel primary agitator bars

(5/8”wall) 4”O.D.

•Anti-vibration pad.

•Belt drive.

Electrical Options

•Eagle digital salt timer with alarm.

•Newport digital thermometer.

•Ampmeter.

•Total time clock (mounted in remote enclosure).

•Nema 4 gemco cam switch in lieu of Nema I.

•Allen Bradley programmable controller SLC 500 series.

•Allen Bradley PanelView 550 operator interface.

•Ampmeter (displayed on operator interface).

•Wattmeter (displayed on operator interface).

Mechanical

Specifications

Electrical

Specifications

Options

08/2002

13-K-07

AMF’s continuing engineering is constantly improving product performance. Consequently machinery specifications are subject to change without notice.

For more information please call

your Account Manager or 1-800-BAKERS-1.

Headquarters

AMF Bakery Systems

2115 West Laburnum Avenue

Richmond, Virginia 23227

1-800-225-3771 or 804-355-7961

FAX: 1-804-342-9724

www.amfbakery.com sales@amfbakery.com

European operation

West Park Ring Road

Leeds LS16 6QQ England

Tel.: 1132-787110

Fax: 1132-741415

STATIONARY BOWL MIXER

•Nema 12 remote enclosure (painted steel) including:

Square D main breaker.

Full voltage magnetic Nema rated starters.

Pre-wired terminal strip.

•Operator panel contains the following:

Eagle digital plug-in timers for high and low speed.

Eagle digital plug-in refrigeration timer.

Digital bowl temperature indicator.

Allen Bradley push-buttons for the following functions:

Mixing (slow, fast, stop)

Door (up, down, stop)

Flour gate (open, close)

Refrigeration selector OFF/ON/AUTO

Alarm (acknowledge/reset)

Safety/jog

Emergency stop

•Nema 1 Gemco cam switch.

•Nema 12 junction box, terminal blocks, prewired motors

and controls.

•Bowl door gearhead motor with electric brake and components.

•Weg drive motor (copper rotor) integral mount with

NORD Gear reducer.

•Motor overheat protection installed in stator winding.

•High/low speed jog operation with special anti-jog function.

•CAD produced electrical wiring diagram.

•Equipment meets OSHA requirements.

Bowl And Cooling Jacket

•All stainless steel one piece bowl construction.

•Bowl plate 5/16”thick.

•Bowl end plate 3/8”thick jacketed.

•Bowl jacket 1/4”“L”type breaked & welded.

•Reinforcement belts are added to the bowl jacket for

maximum resistance to shock.

•Refrigerated bowl sides.

•Bowl insulated with urethane foam.

•Stainless steel bowl drain valve.

•D.X. expansion valves or Glycol valves are included.

•Bowl tested at 250 PSI.

Top Assembly

•Solid stainless steel.

•The 12”diameter pneumatic sliding flour gate

•Two 2”stainless steel sanitary liquid inlets.

Door and Door Shaft Assembly

•Reinforced stainless steel door.

•Air operated door seals.

•Door racks and pinions.

Agitator and Drive Assembly

•Solid stainless steel “Y”type spiders split at main shaft and

agitator bars.

•Stainless steel primary agitator bars mounted on lubrication

free U.H.M.W. bushings.

•Stainless steel secondary agitator bars mounted on lubrication

free U.H.M.W. bushings.

•Solid stainless steel main shaft mounted on spherical bearings.

•Sanitary split seal assembly.

•Agitator is chain and sprocket driven.

•Chain lubrication by oil bath.

•Standard agitator RPM 35/70 (consult for other RPM available).

MIXER

59-1/8"

9' - 0"

9' - 6 3/4" 9' - 6 1/4"

7' - 10 5/8"

17"

2000 &

2400 lb.

54-1/8"

8' - 7"

9' - 5 3/4" 9' - 1 1/4"

7' - 7 5/8"

16"

1600 lb.

AB C D E F

Mechanical Options

•Extra liquid inlet.

•12”O.D. butterfly valve in lieu of sliding flour gate.

•Stainless steel air operated front sliding type sponge door.

•Stainless steel air operated rear hinge type sponge door.

•Stainless steel ingredient door with safety bars.

•Stainless steel refrigerated door (with hoses and valves).

•Double extra heavy stainless steel primary agitator bars

(5/8”wall) 4”O.D.

•Anti-vibration pad.

•Belt drive.

Electrical Options

•Eagle digital salt timer with alarm.

•Newport digital thermometer.

•Ampmeter.

•Total time clock (mounted in remote enclosure).

•Nema 4 gemco cam switch in lieu of Nema I.

•Allen Bradley programmable controller SLC 500 series.

•Allen Bradley PanelView 550 operator interface.

•Ampmeter (displayed on operator interface).

•Wattmeter (displayed on operator interface).

Mechanical

Specifications

Electrical

Specifications

Options

08/2002

13-K-07

AMF’s continuing engineering is constantly improving product performance. Consequently machinery specifications are subject to change without notice.