EN - Integration to manual

Robus 600-1000

IT - Integrazione al manuale

Robus 600-1000

FR - Addenda au guide

Robus 600-1000

ES - Integración del manual

Robus 600-1000

DE - Vervollständigung des

Handbuchs Robus 600-1000

PL - Uzupełnienie do instrukcji

Robus 600-1000

NL - Aanvulling op de handleiding

Robus 600-1000

RB400 - RUN1500

For sliding gates

Codice: ISTRB2A.4865 Rev. 01 del 22 - 06 - 2009

DICHIARAZIONE CE DI CONFORMITÀ / CE DECLARATION OF CONFORMITY

Nota - Il contenuto di questa dichiarazione corrisponde a quanto dichiarato nell’ultima revisione disponibile, prima della stampa di questo manuale, del documento ufficiale deposi-

tato presso la sede di Nice Spa. Il presente testo è stato riadattato per motivi editoriali. / Note - The contents of this declaration correspond to those of the last revision available

of the official document, deposited at the registered offices of Nice S.p.a., before printing of this manual. The text herein has been re-edited for editorial purposes.

Numero / Number: 210/ROBUS Revisione / Revision:2

Il sottoscritto Luigi Paro in qualità di Amministratore Delegato, dichiara sotto la propria responsabilità che il prodotto: / The undersigned Luigi Paro, managing director, declares

under his sole responsibility that the following product:

Nome produttore / Manufacturer’s name: NICE s.p.a.

Indirizzo / Address: Via Pezza Alta 13, 31046 Z.I. Rustignè, Oderzo (TV) Italia / Italy

Tipo / Type: Motoriduttore elettromeccanico con centrale incorporata / Ac electromechanical gearmotor with built-in control unit

Modello / Models: RB600, RB600P, RB1000, RB1000P, RB400KIT, RUN1500

Accessori / Accessories: Ricevente radio SMXI, SMXIS; batteria di emergenza PS124 /Radio receiver SMXI, SMXIS; buffer battery PS124

Risulta conforme a quanto previsto dalla direttiva comunitaria: / Satisfies the essential requirements of the following Directives:

• 98/37/CE (89/392/CEE modificata) / 98/37/EC (89/392/EEC amended).

Come previsto dalla direttiva 98/37/CE si avverte che non è consentita la messa in servizio del prodotto sopra indicato finché la macchina, in cui il prodotto è incorporato, non sia

stata identificata e dichiarata conforme alla direttiva 98/37/CE / As specified in the directive 98/37/CEE use of the product specified above is not admitted until the machine on

which it is mounted has been identified and declared as conforming to the directive 98/37/CEE.

Inoltre il prodotto risulta conforme a quanto previsto dalle seguenti direttive comunitarie, così come modificate dalla Direttiva 93/68/CEE del consiglio del 22 Luglio 1993: / Further-

more, the product complies with the specifications of the following EC directives:

• 2006/95/CEE(ex direttiva 73/23/CE) . / 2006/95/EEC (ex directive 73/23/EC).

Secondo le seguenti norme armonizzate: / According to the following harmonised standards: EN 60335-1:1994+A11:1995+A1:1996+A13:1998

+A14:1998+A15:2000+A2:2000+A16:2001

• 2004/108/CEE(ex direttiva 89/336/CEE) / 2004/108/EEC (ex directive 89/336/EEC).

Secondo la seguente norma armonizzata: / According to the following harmonised standards:

EN 61000-6-2:2001; EN 61000-6-3:2007

Inoltre risulta conforme, limitatamente per le parti applicabili, alle seguenti norme: / Furthermore, complies with the specifications, limitedly for the applicable the following standards:

EN 60335-1:2002+A1:2004+A11:2004+A12:2006+ A2:2006, EN 60335-2-103:2003, EN 13241-1:2003; EN 12453:2002; EN 12445:2002; EN 12978:2003

Oderzo, 8 Maggio 2009 / Oderzo, 8 May 2009 Luigi Paro

(Amministratore Delegato / Managing Director)

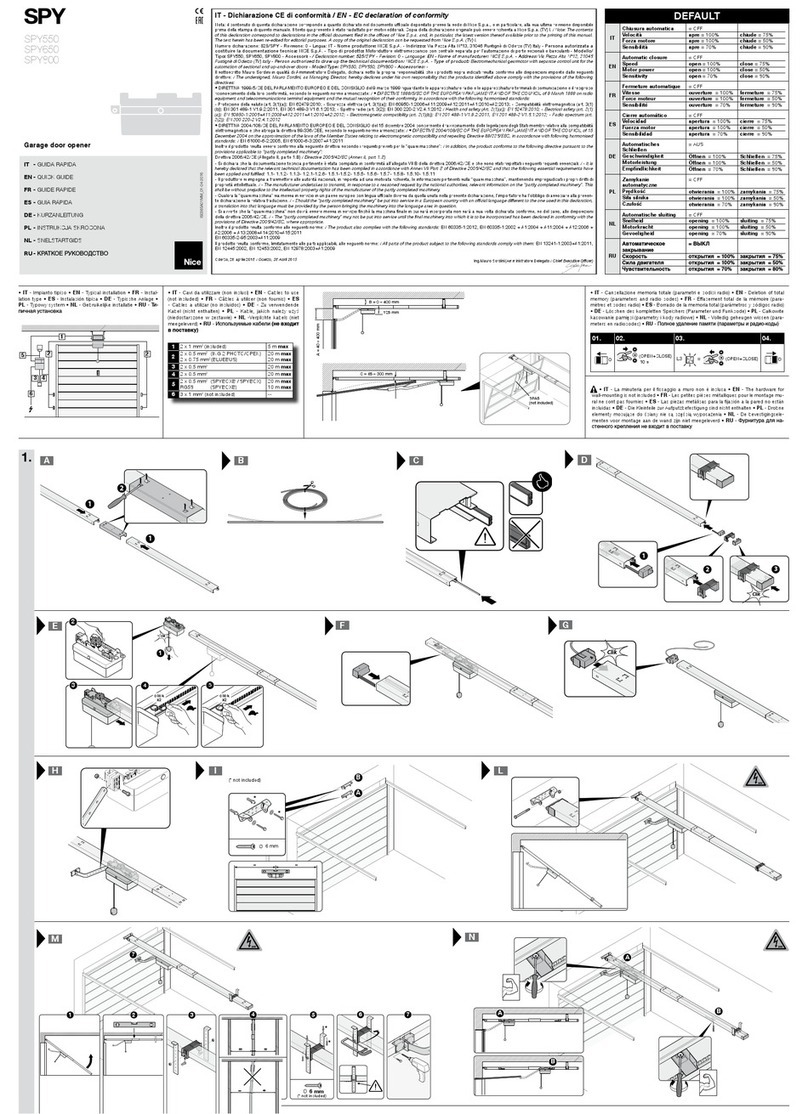

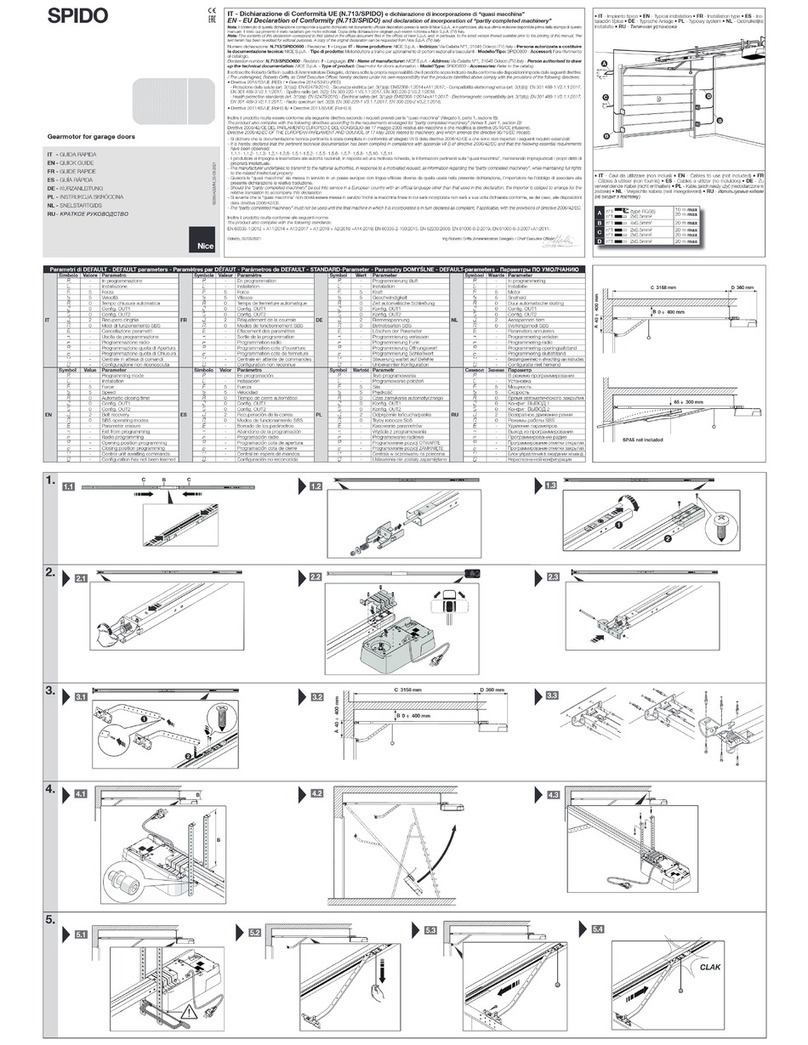

This Addendum provides the specific data of products RB400 and RUN1500; tables 2 and 3 also contain data specified in the reference

manual of the product Robus 600-1000.

APPLICATION LIMITS: in general, RB400 is designed for the automation of gates with weights up to 400 Kg and lengths up to 7 m,

while RUN1500 is designed for the automation of gates with weights up to 1500 Kg and lengths up to 14 m; see table 1 and 2.

The length of the leaf enables the calculation of the maximum number of cycles per hour and the maximum number of consecutive cycles,

while the weight enables calculation of the percentage of reduction in the number of cycles at the maximum admissible speed.

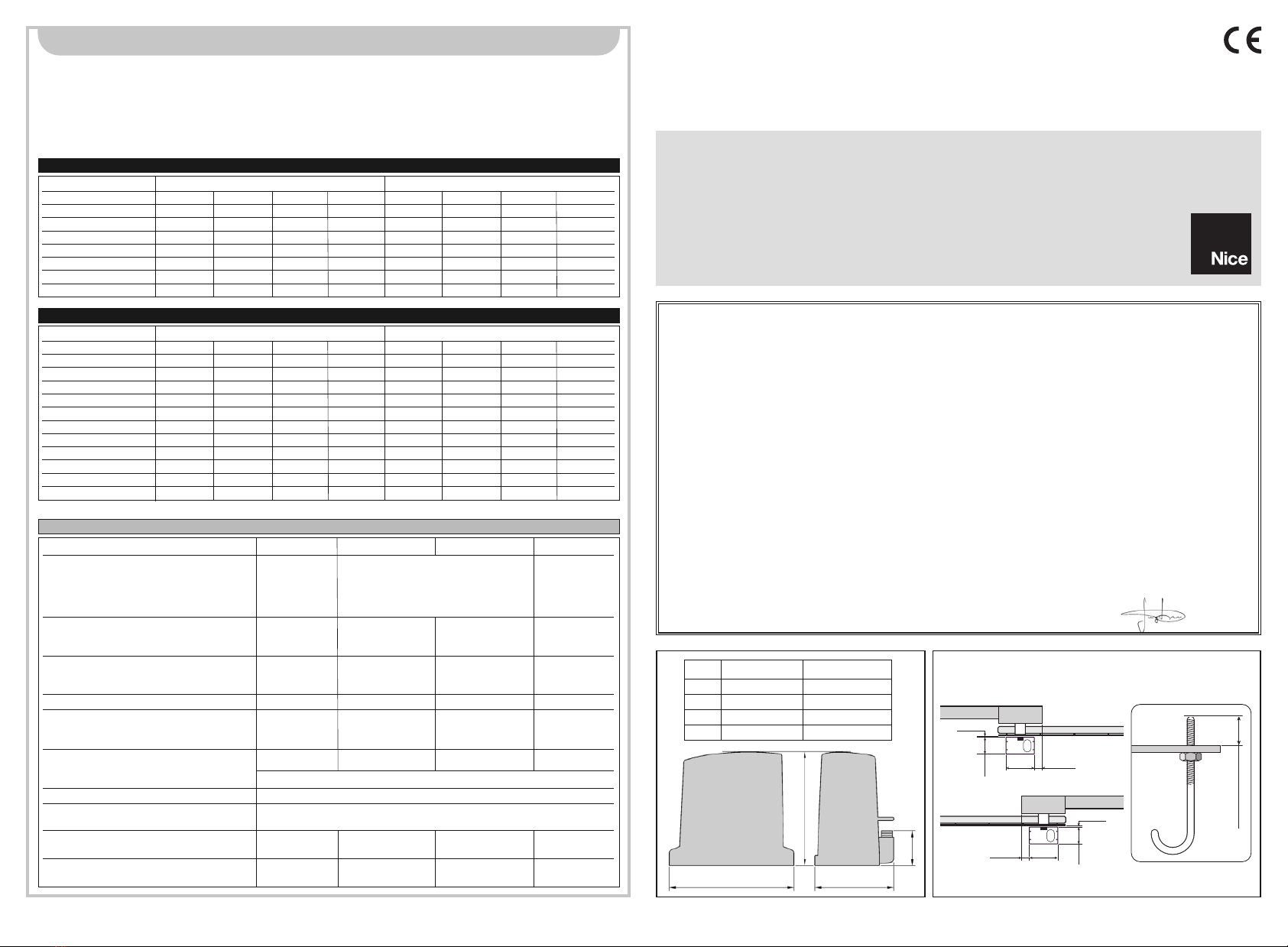

Table 2: limits in relation to the leaf length

ENGLISH

Leaf length (m) maximum cycles/hour maximum consecutive cycles

RB400 RB600 RB1000 RUN1500 RB400 RB600 RB1000 RUN1500

Up to 4 35 40 50 60 14 20 25 30

4 - 6 23 25 33 40 11 13 16 20

6 - 7 20 23 28 34 10 11 14 17

7 - 8 - 20 25 30 - 10 12 15

8 - 10 - - 20 24 - - 10 12

10 - 12 - - 16 20 - - - 10

12 - 14 - - - 17 - - - 8

TECHNICAL SPECIFICATIONS

RB400 RB600-RB600P RB1000-RB1000P RUN1500

Pinion Z: 15; Pinion Z: 15; Module: 4; Pinion Z: 18,

Module: 4; Pitch: 12,6 mm; Module: 4;

Pitch: 12,6 mm; Primitive diameter: 60 mm Pitch: 12.6 mm;

Primitive Primitive

diameter: 60 mm diameter: 72 mm

12 Nm 18 Nm 27 Nm 35 Nm

[400 N] [600 N] [900 N] [1000 N]

6 Nm 9 Nm 15 Nm 20 Nm

[200 N] [300 N] [500 N] [560 N]

0,18 m/s 0,15 m/s 0,14 m/s 0,18 m/s

0,34 m/s 0,31 m/s 0,28 m/s 0,25 m/s

35 40 50 60

The control unit limits the number of cycles tothe maximum value as stated in tables 2 and 3

10 minutes

In general Robus and Run are designed for the automation of gates with

weights and lengths within the limits specified in tables 2, 3 and 4

330 W 515 W [2,5 A] 450 W [2,3 A] 400 W

[4,8 A version/V1] [4,4 A version/V1]

330 x 195 h 277 330 x 120 h 303 330 x 210 h 303 400 x 255 h 390

8 Kg 11 Kg 13 Kg 19 Kg

Table 3: limits in relation to the leaf weight

Leaf weight (kg) percentage of cycles maximum admissible speed

RB400 RB600 RB1000 RUN1500 RB400 RB600 RB1000 RUN1500

Up to 200 100% 100% 100% 100% V6 V6 V6 V6

200 - 400 50% 80% 90% 100% V5 V5 V5 V6

400 - 500 - 60% 60% 95% - V4 V4 V6

500 - 600 - 50% 100% 90% - V3 V4 V5

600 - 700 - - 50% 85% - - V3 V5

700 - 800 - - 47% 80% - - V3 V5

800 - 900 - - 45% 75% - - V3 V5

900 - 1000 - - 40% 70% - - V3 V4

1000 - 1200 - - - 60% - - - V4

1200 - 1350 - - - 65% - - - V3

1350 - 1500 - - - 60% - - - V3

MODEL:

Pinion

Maximum start-up torque

[corresponding to the capacity to generate a

set force to move the gate leaf]

Nominal torque

[corresponding to the capacity to generate a

set force to move the gate leaf]

Speed at nominal torque

Speed under no load

(the control unit enables programming of six

speeds at approx.: 100, 85, 70, 55, 45, 30%)

Maximum frequency of cycles per hour of

operation

[on a standard gate of 4 m]

Maximum continuous operation time

Application limits

Maximum power absorption on start-up

[corresponding to Amps]

Dimensions (mm) and weight

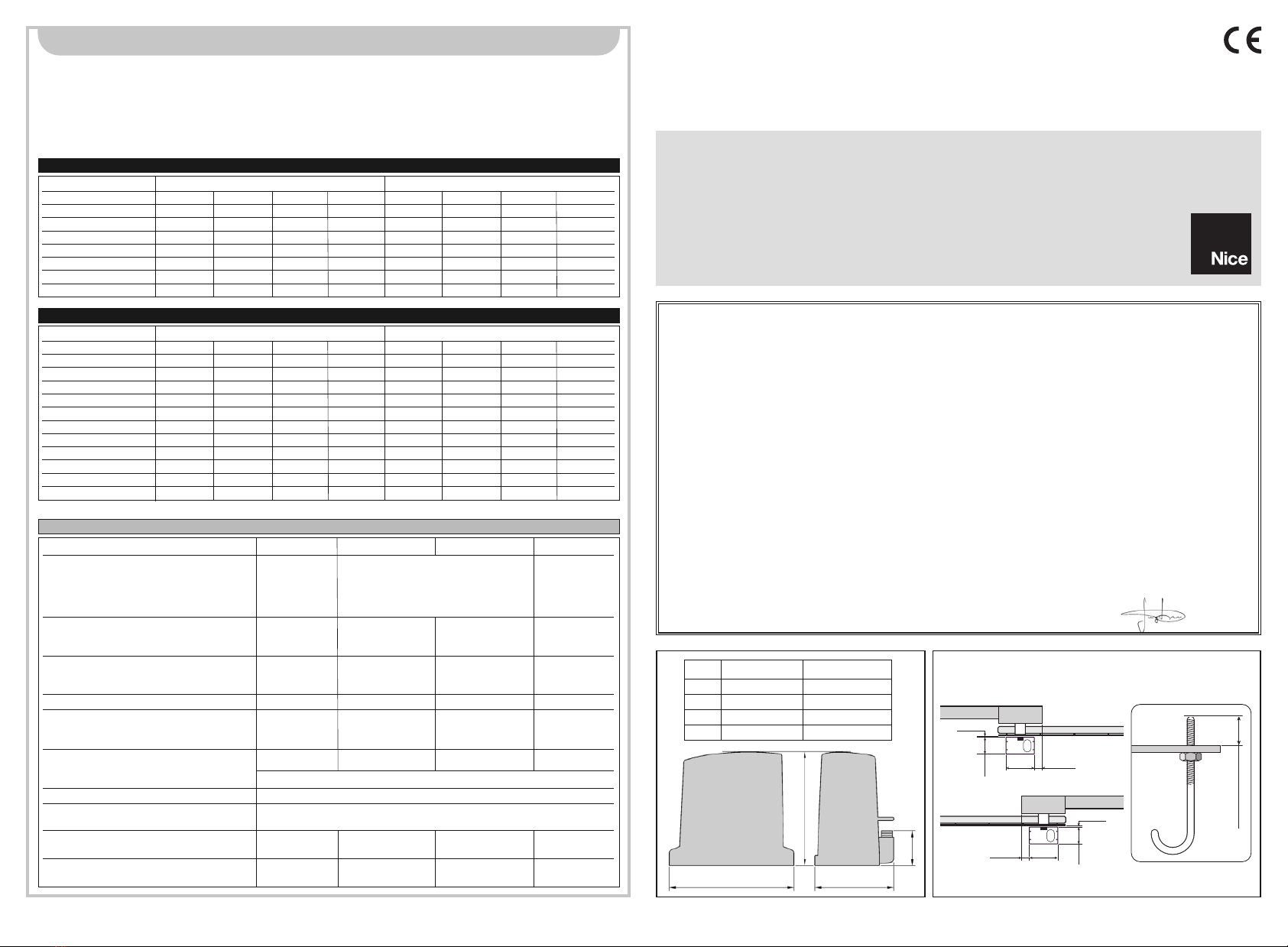

RUN1500

RB400 RUN1500

a330 mm 400 mm

b277 mm 390 mm

c195 mm 255 mm

d85 mm 108 mm

ac

b

d

400 0÷50

0÷10

240

4000÷50

0÷10

240