Ericsson GE LBI-4622B User manual

Mobile Communications

MASTR II

MAINTENANCE MANUAL

406-420 & 512 MHz,

40-WATT TRANSMITTER

Maintenance Manual

LBI-4622B

Printed in U.S.A.

Copyright © 1974 GeneralElectric Company

TABLE OF CONTENTS

Page

DESCRIPTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

CIRCUIT ANALYSIS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Exciter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

ICOMS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Audio IC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Buffer, Phase Modulators & Amplifiers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Buffer,Multipliers & Amplifier . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Power Amplifier . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

RF Amplifiers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Power Control Circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Carrier Control Timer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Disassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

PATransistor Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Alignment Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Test Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Power Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Tone Deviation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Voice Deviation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

OUTLINE DIAGRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

SCHEMATIC DIAGRAMS

Exciter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Power Amplifier . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

PARTS LIST AND PRODUCTION CHANGES

Exciter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Power Amplifier . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20 thru 23

ILLUSTRATIONS

Figure 1 - Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Figure 2 - Typical Crystal Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Figure 3 - Equivalent ICOM Circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Figure 4 - Simplified Audio IC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Figure 5 - Disassembly Procedure (Top View) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Figure 6 - Disassembly Procedure (Bottom View) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Figure 7 - PATransistor Lead Identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Figure 8 - PATransistor Lead Forming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Figure 9 - Frequency Characteristics Vs. Temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Figure 10 - 40-Watt Power Output Setting Chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Figure 11 - 38-Watt Power Output Setting Chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Figure 12 - 35-Watt Power Output Setting Chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

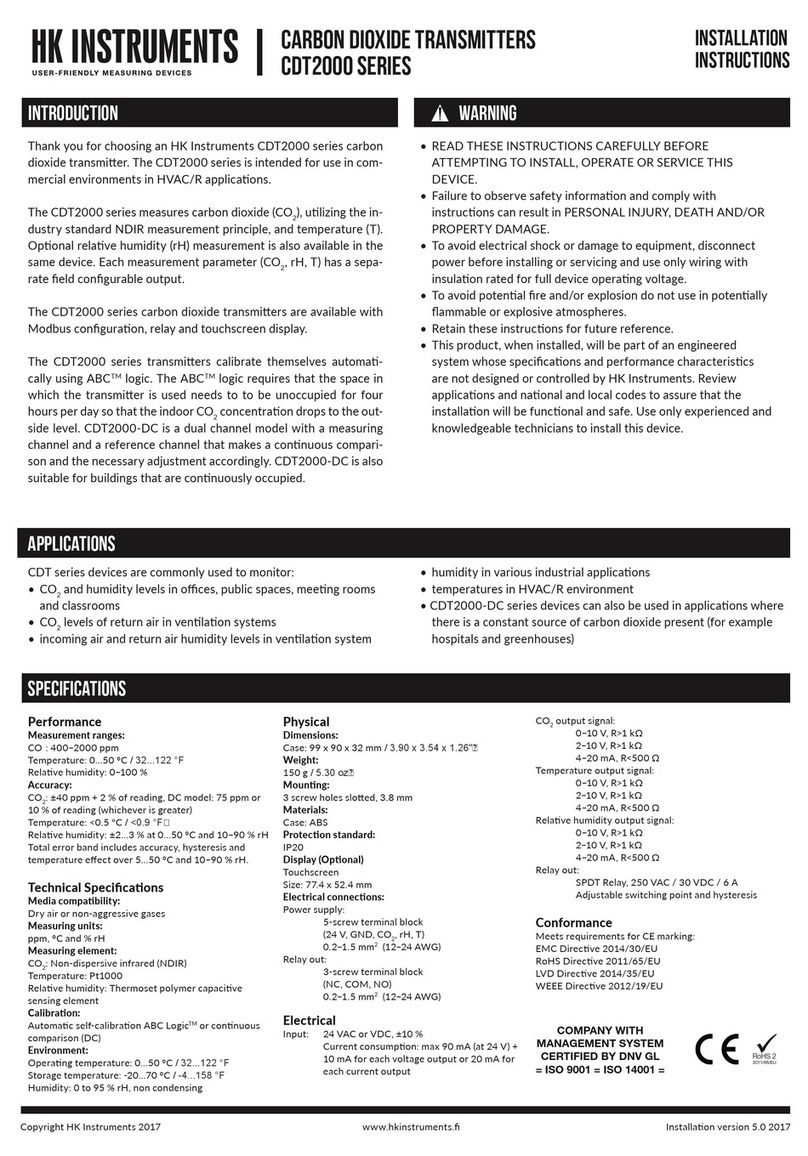

SPECIFICATIONS *

Power Output

406-420 MHz & 450-470 MHz 40 Watts (Adjustable from 12 to 40 Watts)

470-494 MHz 38 Watts (Adjustable from 12 to 38 Watts)

494-512 MHz 35 Watts (Adjustable from 12 to 35 Watts)

Crystal Multiplication Factor 36

Frequency Stability

5C-ICOM with EC-ICOM ±0.0005% (-40°C to +70°C)

5C-ICOM or EC-ICOM ±0.0002% (0°C to +55°C)

2C-ICOMS ±0.0002% (-40°C to +70°C)

Spurious and Harmonic Emission At least 80 dB below full rated power output.

Modulation Adjustable from 0 to ±5 kHz swing with instantaneous

modulation limiting.

Modulation Sensitivity 75 to 120 Millivolts

Audio Frequency Characteristics Within +1 dB to -3 dB of a 6-dB/octave pre-emphasis from

300 to 3000 Hz per EIA standards. Post limiter filter per FCC

and EIA.

Distortion Less than 2% (1000 Hz)

Less than 3% (300 to 3000 Hz)

Deviation Symmetry 0.5 kHz maximum

Maximum Frequency Spread (2 to 8 channels) Full Specifications 1 dB Degradation

406-420 MHz 2.75 MHz 6.00 MHz

450-470 MHz 2.75 MHz 9.00 MHz

470-494 MHz 2.90 MHz 9.50 MHz

494-512 MHz 3.00 MHz 9.75 MHz

Duty Cycle EIA 20% Intermittent

RF Output Impedance 50 Ohms

* These specifications are intended primarily for the use of the serviceman. Refer to the appropriate Specification Sheet for the

complete specifications.

Although the highest DC voltage in MASTR II Mobile Equipment is supplied by the vehicle battery, high currents

may be drawn under short circuit conditions. These currents can possibly heat metal objects such as tools, rings,

watchbands, etc., enough to cause burns. Be careful when working near energized circuits! High-level RF energy in

the transmitter Power Amplifier assembly can cause RF burns upon contact. KEEP AWAY FROM THESE CIR-

CUITS WHEN THE TRANSMITTER IS ENERGIZED!

WARNING

LBI-4622 LBI-4622

1

DESCRIPTION

MASTR II transmitters are crystal controlled, phase

modulated transmitters designed for one through eight-fre-

quency operation in the 406 to 420 and 450 to 512 mega-

hertz band. The solid state transmitter utilizes both

integrated circuits (ICs) and discrete components, and con-

sists of the following assemblies:

Exciter Board; with audio, modulator, amplifier and mul-

tiplier stages

Power Amplifier Assembly; with amplifier, driver, PA,

power control, filter and antenna switch.

CIRCUITANALYSIS

EXCITER

The exciter uses seven transistors and one integrated cir-

cuit to drive the PA assembly. The exciter can be equipped

with up to eight Integrated Circuit Oscillator Modules

(ICOMs). The ICOM crystal frequency ranges from ap-

proximately 11.3 to 14.2 megahertz, and the crystal fre-

quency is multiplied 36 times.

Audio, supply voltages and control functions are con-

nected from the system board to the exciter board through

P902.

Centralized metering jack J103 is provided fro use with

GE Test Set Model 4EX3A11 or Test Kit 4EX8K12. The

test set meters the modulator, multiplier and amplifier stages,

and the regulated 10-Volts.

ICOMS

Three different types of ICOMs are available for use in

the exciter. Each of the ICOMs contains a crystal-controlled

Colpitts oscillator, and two of the ICOMs contain compensa-

tor ICs. The different ICOMs are:

5C-ICOM - contains an oscillator and a 5 part-per-mil-

lion (±0.0005%) compensator IC, Provides compensa-

tion for EC-ICOMs.

EC-ICOM - contains an oscillator only. Requires exter-

nal compensation from a 5C-ICOM.

2C-ICOM - contains an oscillator only. 2 PPM

(±0.0002%) compensator IC. Will not provide compen-

sation for an EC-ICOM.

The ICOMs are enclosed in an RF shielded can with the

type ICOM (5C-ICOM, EC-ICOM or 2C-ICOM) printed on

the top of the can. Access to the oscillator trimmer is ob-

tained by prying up the plastic tab on the top of the can. The

tabs can also be used to pull the ICOMs out of the radio.

Frequency selection is accomplished by switching the

ICOM keying lead (terminal 6) to A- by means of the fre-

quency select or switch on the control unit. In single-fre-

quency radios, a jumper from H9 to H10 in the control unit

connects terminal 6 of the ICOM to A-. The oscillator is

turned on by applying a keyed +10 Volts to the external oscilla-

tor load resistor.

In Standard 5 PPM radios using EX-ICOMs, at least one

5C-ICOM must be used. The 5C-ICOM is normally used in

the receiver Fl position, but can be used in any transmit or re-

ceive position. One 5C-ICOM can provide compensation for

up to 15 EC-ICOMs in the transmit and receiver. Should the

5C-ICOM compensator fail in the open mode, the EC-ICOMs

will still maintain 2 PPM frequency stability from 0°C to 55°C

(+32°F to 131°F) due to the regulated compensation voltage (5

Volts) from the l0-Volt regulator IC. If desired, up to 16 SC-

ICOMs may be used in the radio.

The 2C-ICOMs are self-compensated at 2 PPM and will

not provide compensation for EC-ICOMs.

Oscillator Circuit

The quartz crystals used in ICOMs exhibit the traditional

"S" curve characteristics of output frequency versus operating

temperature.

At both the coldest and hottest temperatures, the frequency

increases with increasing temperature. In the middle tempera-

ture range (approximately 0°C to 55°C), frequency decreases

with increasing temperature.

Since the rate of change is nearly linear over the mid-tem-

perature range, the output frequency change can be compen-

sated by choosing a parallel compensation capacitor with a

temperature coefficient approximately equal and opposite that

of the crystal.

Figure 2 shows the typical performance of an uncompen-

sated crystal as well as the typical performance of a crystal

which has been matched with a properly chosen compensation

capacitor.

At temperatures above and below the mid-range, additional

compensation must he introduced. An externally generated

compensation voltage is applied to a varactor (voltage-variable

capacitor)which is in parallel with the crystal.

A constant bias of 5 Volts (provided from Regulator IC

U901 in parallel with the compensator) establishes the varactor

capacity at a constant value over the entire mid-temperature

range. With no additional compensation, all of the oscillators

will provide 2 PPM frequency stability from 0°C to 55°C

(+32°F to 131°F).

Compensator Circuits

Both the SC-ICOMs and 2C-ICOMs are temperature com-

pensated at both ends of the temperature range to provide in-

stant frequency compensation. An equivalent ICOM circuit is

shown in Figure 3.

The cold end compensation circuit does not operate at tem-

peratures above 0°C. When the temperature drops below 0°C,

the circuit is activated. As the temperature decreases, the

equivalent resistance decreases and the compensation voltage

increases.

The increase in compensation voltage decreases the capac-

ity of the varactor in the oscillator, increasing the output fre-

quency of the ICOM.

The hot end compensation circuit does not operate at tem-

peratures below +55°C. When the temperature rises above

+55°C, the circuit is activated, As the temperature increases,

the equivalent resistance decreases and the compensation volt-

age decreases. The decrease in compensation voltage increases

the capacity of the varactor, decreasing the output frequency of

the ICOM.

SERVICE NOTE: Proper ICOM operation is dependent on

the closely-controlled input voltages from the 10-Volt

regulator. Should all of the ICOMs shift off frequency, check

the 10-Volt regulator module.

Figure 1 - Transmitter Block Diagram

All ICOMs are individually compensated at the factory

and cannot be repaired in the field. Any attempt to re-

pair or change an ICOM frequency will void the war-

ranty.

CAUTION

Figure 2 - Typical Crystal Characteristics

LBI-4622 LBI-4622

2

Audio IC

The transmitter audio circuitry is contained in audio IC

U101. A simplified drawing of the audio IC is shown in Fig-

ure 4.

Audio from the microphone at pin 12 is coupled through

pre-emphasis capacitor C1 to the base of Q1 in the opera-

tional amplifier-limiter circuit. Collector voltage for the

transistorized microphone preamplifier is supplied from pin

11 through microphone collector load resistor R18 to pin 12.

The operational amplifier-limiter circuit consists of Q1,

Q2 and Q3. Q3 provides limiting at high signal levels. The

gain of the operational amplifier circuit is fixed by negative

feedback through R19,R20 and the resistance in the network

(Pin 9).

The output of Q3 is coupled through a de-emphasis net-

work (R10 and C3) to an active post-limiter filter consisting

of C4, C5, C6, R11, R12, R13, R15, R17 and Q4.

Following the post-limiter filter is class A amplifier Q5.

The output of Q5 is coupled through MOD ADJUST poten-

tiometer R104 and resistor R125 to the phase modulator.

SERVICE NOTE: If the DC voltages to the Audio IC are

correct and no audio output can be obtained, replace U101.

For radios equipped with Channel Guard, tone from the

encoder is applied to the phase modulator through CHAN-

NEL GUARD MOD ADJUST potentiometer R105, and re-

sistor R127. Instructions for setting R105 are contained in

the modulation adjustment section of the Transmitter Align-

ment Procedure.

Buffer, Phase Modulators & Amplifiers

The output at pin 3 of the selected ICOM is coupled

through buffer-amplifier Q101 to the modulator stage. The

phase modulator is varactor (voltage-variable capacitor)

CV103 in series with tunable coil T103. This network ap-

pears as a series-resonant circuit to the RF output of the os-

cillator. An audio signal applied to the modulator circuit

through blocking capacitor C107 varies the bias of CV103,

resulting in a phase modulated output. A voltage divider

network (R110 and R111) provides the proper bias for varac-

tor CV103.

The output of the modulator is coupled through blocking

capacitor C150 to the base of Class A amplifier Q104. The

output of the modulator is metered through C123, R128 and

CR104, and is applied to the base of buffer Q105. Diodes

CR105 and CR106 remove any amplitude modulation in the

modulator output.

Buffer, Multipliers & Amplifier

Buffer Q105 is saturated when no RF signal is present,

Applying an RF signal to Q1O5 provides a sawtooth wave-

form at its collector to drive the class C tripler, Q106. The

tripler stage is metered through R138, The output of Q106 is

coupled through tuned circuits T104and T105 to the base of

doubler Q107. The doubler stage is metered through R141.

The output of Q107 is coupled through tuned circuits

T106 and T107 to the base of second doubler Q108. Q108

is metered through R146

The output of Q108 is coupled through three tuned cir-

cuits (T108, T109 and T110) to the base of amplifier Q109.

Q109 is a Class C amplifier, and is metered through

R148. The amplifier collector circuit consists of T111,

C154, C155, T112 and C157, and matches the amplifier out-

put to the input of the power amplifier assembly.

POWER AMPLIFIER

The PA assembly uses seven RF power transistors and

seven transistors in the Power Control circuitry to provide

rated power output. The broadband PA has no adjustments

other than Power Control potentiometer R226.

Supply voltage for the pA is connected through power

leads from the system board to feed through capacitors C297

and C298 on the bottom of the PA assembly, C297, C298,

C299, L295 and L296 prevent RF from getting on the power

leads. Diode CR295 will cause the main fuse in the fuse as-

sembly to blow if the polarity of the power leads is reversed,

providing reverse voltage protection for the radio.

Centralized metering jack J205 is provided for use with

GE Test Set Model 4EX3A11 or Test Kit 4EX8K12. The

Test Set meters the Tripler drive (exciter output), Amp1-2 in-

put, Driver and PAcurrent.

TRIPLER & RF AMPLIFIERS

The exciter output is coupled through an RF cable to PA

input jack J201. The 50-ohm RF input is coupled through a

matching network (C206 and w209) to the base of the broad-

band tripler stage, Q201.

Part of the RF input is rectified by CR201 and is used to

activate the Power Control circuit. Another portion of the

rectified RF is applied to J205 for metering the tripler drive.

Figure 3 - Equivalent ICOM Circuit

Figure 4 - Simplified Audio IC

LBI-4622 LBI-4622

3

The output of Q201 is coup led through a 20-ohm collec-

tor matching network (C212, C213, C4219 and L203) to the

input of a high-pass filter consisting of C217 through C225,

and w210 through w213.

Following the high-pass filter is a low-pass filter consist-

ing of w214 through w219, C226 through C230 (and C4214

through C4217 in the 406-420 MHz band). The two filter

sections combine to act as a bandpass filter providing a

minimum of 60 dB rejection below 300 megahertz and 30

dB rejection above 600 megahertz.

In 450 to 512 megahertz transmitters, the filter output is

coupled through a matching network (C231, C232, C233

and w220) to the base of Class C amplifier Q207. Collector

voltage to Q207 is coupled through collector stabilizing net-

work L220, R216 L219 and C234. The output of Q207 is

coupled through a matching network (w221, C236, C237

and w222) to the base of the second Class C amplifier Q202.

Drive to Q202 is metered at J205 (Amp1-2 Input) through

metering network C238, CR202, C239 and R205.

In 406 to 420 megahertz transmitters, Q207 and its asso-

ciated circuitry is removed, and the filter output is coupled

through C285 to the base of second amplifier Q202,

Collector voltage for Q202 is coupled through stabilizing

network L206, R206, L205 and C240. Matching network

w223,C241, C242, C243 and W224 matches the output of

Q202 to the base of third amplifier Q203.

Collector voltage for Q203 is applied through stabilizing

network R207, L209, and C246.

The output of Q203 is coupled through a matching net-

work (w225, C247, C248, C249 and w226) to the base of

Class C driver Q204. Collector voltage for Q204 is applied

through collector stabilizing network C201, L211 and C267.

Collector current for Q204 is metered across tapped

manganin resistor R214 at J205 (Driver Current). The read-

ing is taken on the one-Volt scale with the High Sensitivity

button pressed, and read as 10 amperes full scale.

Following Q204 is a matching network (w227 and C253)

that matches the driver output to the 50-ohm impedance of

power divider network W228 and R209.

The power amplifier stages consist of two identical par-

alleled Class C PAcircuits (Q205 and Q206). One output of

the power divider network is applied to the base of Q205

through matching network W229 and C268

Supply voltage for Q205 is coupled through collector

stabilizing network L213, R210, L214 and C255. The out-

put of Q205 is coupled through a matching network (W231

and C258) and added to the output of Q206 in power com-

biner network R212 and W233. The combined collector cur-

rent for Q205 and Q206 is metered across tapped manganin

resistor R213 at J205 (PA Current). The reading is taken on

the one-Volt scale with the High Sensitivity button pressed,

and read as 10 amperes full scale.

The PA output is coupled through a low-pass filter to the

antenna through antenna switch K201. Capacitors C214,

C270 through C4218 provide DC ground isolation for ±

ground operation.

POWER CONTROL CIRCUIT

When the transmitter is keyed, rectified RF from CR201

is applied to the base of switch Q208, turning it on. Turning

on Q208 turns on voltage regulator Q210, supplying a con-

stant voltage to Power Adjust potentiometer R226.

Q212, Q213 and Q215 operate as an amplifier chain to

supply voltage to the collector of Q202 (Amp1-2). The set-

ting of R226 determines the voltage applied to the base of

Q212. The higher the voltage at the base of Q212, the

harder the amplifiers conduct, supplying more collector volt-

age to Q202. The lower the voltage at the base of Q212, the

less collector voltage is supplied to Q202. Reducing the

supply voltage to Q202 reduces the drive to Q203 and Q204,

thereby reducing the power output of the PA. The power

output can be adjusted by R226 from approximately 12 to 40

Watts.

Temperature protection is provided by Q209, Q211 and

thermistor RT201 which is mounted in the PA heatsink. Un-

der normal operating conditions, the circuit is inactive

(Q209 is on and Q211 is off). When the heatsink tempera-

ture reaches approximately 100°C, the resistance of RT201

decreases. This increases the base voltage applied to Q209,

turning it off. Turning off Q209 allows Q211 to turn on, de-

creasing the voltage at Power Adjust potentiometer R226.

This reduces the base voltage to Q212 which causes Q213

and Q215 to conduct less, reducing the collector voltage to

Q202 (Amp1-2) . This reduces the transmitter output power,

keeping the heatsink at a maximum of approximately 100°C.

When the heatsink temperature decreases below 100°C, the

temperature control circuit turns off, allowing thenormal trans-

mitter power output.

CARRIER CONTROL TIMER

The Carrier Control Timer option shuts off the transmitter

on each transmission after a one-minute timing cycle, and

alerts the operator that the transmitter is off by means of an

alarm tone in the speaker. The transmitter can be turned on

again by releasing and rekeying the push-to-talk switch on the

microphone.

The timing cycle (transmitter keyed time) is normally set at

the factory for a duration of one minute. Apotentiometer per-

mits the timing cycle to be adjusted from approximately 15

second to 3 minutes.

MAINTENANCE

DISASSEMBLY

To servicethe transmitter from the top:

1. Pull the locking handle down,then pry up the cover at

the front notch and lift off the cover.

To service the transmitter from the bottom:

1. Pull the locking handle down and pull the radio out of

the mounting frame.

2. Remove the top cover, then loosen the two bottom

cover remaining screws and remove the bottom cover

(see Figure 5).

3. To gain access to the bottom of the exciter board, re-

move the six screws holding the exciter board

and its bottom cover to the module mounting frame,

and remove the bottom cover.

To remove the exciter board from the radio:

1. Unplug the exciter/PA cable

2. Remove the six screws holding the exciter board

and its bottom cover to the module mounting frame

(see Figure 6).

3. Press straight down on the plug-in exciter from the

top to avoid bending the pins when unplugging the

board from the system board jack.

The stud mount RF Power Transistors used in the

transmitter contain Beryllium Oxide, a TOXIC Sub-

stance. If the ceramic, or other encapsulation is

opened, crushed, broken or abraded, the dust may be

hazardous if inhaled. Use care in replacing transis-

tors of this type.

WARNING

Figure 5 - Disassembly Procedure Top View Figure 6 - Disassembly Procedure Bottom View

LBI-4622 LBI-4622

4

To remove the PAassembly:

1. Remove the PA top cover and unplug the exciter/PA

cable , the antenna, receiver and PTT cables

2. Remove the four side-rail screws , and unsolder

the power cables from the bottom of thePA assembly

if desired.

To remove the PAboard:

1. Remove the PA top cover and unplug the exciter/PA

cable

2. Unsolder the two feed through coils and the ther-

mistor leads

3. Remove the PA transistor hold-down nuts and spring

washers on the bottom of thePA assembly.

4. Remove the four PA board mounding screws , the

five screws in the filter casting , and the retaining

screw in Q215 , and lift the board out.

PA TRANSISTOR REPLACEMENT

To replace the PA RF transistors:

1. Unsolder one lead at a time with a 50-Watt soldering

iron. Use a scribe to hold the lead away from the

printed circuit board until the solder cools.

2. Turn the transmitter over.

3. Hold the body of the transistor to prevent it from turn-

ing. Remove the transistor hold-down nut and spring

washer through the hole in the heats ink with am

11/32-inch nut-driver. Lift out the transistor, and re-

move the old solder. from the printed circuit board

with a de-soldering tool such as a SOLDA PULLT®.

Special care should be taken to prevent damage to the

printed circuit board runs because part of the match-

ing network is included in the base and collector runs.

4. Trim the new transistor leads (if required) to the lead

length of the removed transistor. Cut the collector

lead at a 45° angle for future identification (see Figure

7). The letter "C" on the top of the transistor also in-

dicates the collector.

5. Applying a coating of silicon grease around the tran-

sistor mounting surface, and place the transistor in the

mounting hole. Align the leads as shown in the Out-

line Diagram. Then hold the body of the transistor

and replace the holding-down nut and spring-washer,

using moderate torque (8 inch-pounds). A torque

wrench must be used for this adjustmentsince transis-

tor damage can result if too little or too much torque

is used.

6. Make sure that the transistor leads are formed as

shown in Figure 8 so that the leads can be soldered to

the printed circuit pattern, starting from theinner edge

of the mounting hole.

7. Solder the leads to the printed circuit pattern. Start at

the inner edge of mounting hole and solder the re-

maining length of transistor lead to the board. Use

care not to use excessive heat that causes the

printed wire board runs to lift up from the board.

Check for shorts and solder bridges before applying

power.

MODULATION LEVEL ADJUSTMENT

The MOD ADJUST (R104) was adjusted to the proper

setting before shipment and should not normally require re-

adjustment. This setting permits approximately 75% modu-

lation for the average voice level. The audio peaks which

would cause overmodulation are clipped by the modulation

limiter. The limiter, in conjunction with the de-emphasis

network, instantaneously limits the slope of the audio wave

to the modulator, thereby preventing overmodulation while

preserving intelligibility.

TEST EQUIPMENT

l. An audio oscillator (GE Model 4EX6A10)

2. A frequency modulation monitor

3. An output meter or a VTVM

4. GE Test Set Model 4EX3A11 or 4EX8K12

PROCEDURE

l. Connect the audio oscillator and the meter across

audio input terminals J10 (Green-Hi) and J11

(Black-Lo) on GE Test Set, and connect red Test

Set plug to the System red metering plug. If not us-

ing GETest Set, connect audio oscillator and meter

across P902-6 (Mike High) through a 0.5 micro-

farad (or larger) DC blocking capacitor, and P902-5

(Mike- Low) on the System Board

2. Adjust the audio oscillator for 1-Volt RMS at 1000

Mz.

3. For transmitters without Channel Guard, set MOD

ADJUST R104 for a 4.5-kHz swing with the devia-

tion polarity which gives the highest reading as in-

dicated on the frequency modulation monitor.

4. For transmitters with Channel Guard, set Channel

Guard MOD ADJUST R105 for zero tone devia-

tion. Next, with the l-Volt signal at 1000 Hz ap-

plied, set MOD ADJUST R104 for 3.75 kHz

deviation. Then remove the signal from the audio

oscillator and set Channel Guard MOD ADJUST

R105 for 0.75 kHz tone deviation.

5. For multi-frequency transmitters, set the deviation

as described in Steps 3 or 4 on the channel produc-

ing the largest amount of deviation.

PA POWER INPUT

For FCC purposes, the PA power input can be deter-

mined by measuring the PA supply voltage and PA current,

and using the following formula:

Pi= PA voltage x PA current

where:

Piis the power input in Watts,

PA voltage is measured with Test Set Model4EX3A11 in

Position G on the 15-Volt range (read as 15 Volts full

scale), and with the polarity switch in the (-) position.

With Test Set Model 4EX8K12, use the H+ position and

the l-Volt range (read as 15 Volts full scale), with the

HIGH SENSITIVITY button pressed and the polarity

switch in the (-) position.

PA current is measured with the Test Set in Position G in

the Test l position, and with the HIGH SENSITIVITY

button pressed (10 amperes full scale)

Example:

Pi= 12.6Volts x 3.4 amperes = 43 Watts

ICOM FREQUENCY ADJUSTMENT

First, check the frequency to determine if any adjustment

is required. The frequency should he set with a frequency

meter or counter with an absolute accuracy that is 5 to 10

times better than the tolerance to be maintained, and with the

entire radio as near as possible to an ambient temperature of

26.5°C (79.8°F)

The stud mount RF Power Transistors used in the

transmitter contain Beryllium Oxide, a TOXIC Sub-

stance. If the ceramic, or other encapsulation is

opened, crushed, broken or abraded, the dust may be

hazardous if inhaled. Use care in replacing transistors

of this type.

WARNING

Figure 7 - Lead Identification

Figure 8 - Lead Forming

Failure to solder the transistor leads as directed may

result in the generation of RF loops that could dam-

age the transistor or may cause low power output.

CAUTION

LBI-4622 LBI-4622

5

MASTR II ICOMs should be reset only when the fre-

quency shows deviation in excess of the following limits:

A. ±0.5 PPM, when the radio is at 26.5°C (79.8°F).

B. ±2 PPM at any other temperature within the range

of -5°C to +55°C (+23°F to +131°F)

C. The specification limit (±2 PPM or +5 PPM) at any

temperature within the ranges of -40°C to -5°C (-

40°F to +23°F) or +55°C to +70°C (+131°F to

+158°F)

If an adjustment is required, pry up the cover on the top

of the ICOM to expose the trimmer, and use one of the fol-

lowing procedures

If the radio is at an ambient temperature of 26.5°C

(79.8°F), set the oscillator for the correct operating fre-

quency.

If the radio is not at an ambient temperature of 26.5°C

setting errors can be minimized as follows:

A. To hold the setting error to ±0.6 PPM (which is

considered reasonable for 5 PPM ICOMS):

l. Maintain the radio at 26.5°C (±5°C) and set the

oscillator to desired frequency, or

2. Maintain the radio at 26.5°C (±10°C) and off-

set the oscillator, as a function of actual tem-

perature, by the amount shown in Figure 9.

B. To hold setting error to +0.35 PPM (which is con-

sidered reasonable for 2 PPM ICOMs) Maintain

unit at 26.5°C (+5°C) and offset the oscillator as a

function of actual temperature, by the amount

shown in Figure 9.

For example: Assume the ambient temperature of the radio

is 18.5°C (65.4°F). At that temperature, the curve shows a

correction factor of 0.3 PPM. (At 406 MHz, 1 PPM is 406

Hz. At 512 MHz, 1 PPMis 512 Hx).

With an operating frequency of 450 MHz, set the oscilla-

tor for a reading of 135 Hz (0.3 x 450 Hz) higher than the li-

censed operating frequency. If a negative correction factor is

obtained (at temperatures above 26.5°C), set the oscillator

for the indicated PPM lower than the licensed operating fre-

quency.

Figure 9 - Frequency Characteristics Vs. Temperature

LBI-4622 LBI-4622

6

TRANSMITTER ALIGNMENT

EQUIPMENT REQUIRED

1. GE Test Set Model 4EX3A11 or Test Kit 4EX8K12.

2. A50-ohm wattmeter connected to antenna jack J906.

3. A frequency counter.

PRELIMINARY CHECKS AND ADJUSTMENTS

1. Place ICOMs on Exciter Board (crystal frequency = operating frequency 36).

2. For a large change in frequency or badly mis-aligned transmitter, pre-set the slugs in T104 and T105 to the bottom of the

coil form. Pre-set all of the other slugs to the top of the coil form.

3. For multi-frequency transmitters with a frequency spread less than that specified in column (1) tune the transmitters to the

lowest frequency. For a frequency spread exceeding the limits specified in column (1) tune the transmitters usinga center

frequency tune up ICOM. Except the maximum frequency spread can be extended to the limits specified in column (3)

with l dB degradation.

For tuning L101, L102, and L103, always tune L101, L1O2, and L1O3 on the lowest frequency.

Multi-frequency Transmitter Tuning

TRANSMITTER

FREQUENCY RANGE MAXIMUM FREQUENCY SPREAD

(1) Without center tuning With center tuning With center tuning (1 dB degradation)

406-420 MHz

450-470 MHz

470-494 MHz

494-512 MHz

2.75 MHz

2.75 MHz

2.90 MHz

3.00 MHz

5.50 MHz

5.50 MHz

5.80 MHz

6.00 MHz

6.00 MHz

9.00 MHz

9.50 MHz

9.75 MHz

4. Connect the red plug on the GE Test Set to the System Board metering jack, and the black plug to the Exciter metering

jack. Set the polarity to +, and set the range to the Test 1 position (l-Volt position for 4EXBK12)for all adjustments.

NOTE: With the Test Set connected to the PAmetering jack, the voltage reading at position "F" with the HIGH SENSI-

TIVITY button pressed may be converted to driver collector current by reading the current as 10 amperes full scale. The

voltage reading at position "G" with the HIGH SENSITIVITY button pressed may be converted to PA collector current by

reading the current as 10 amperes full scale.

5. All adjustments are made with the transmitter keyed. Unkey the transmitter between steps to avoid unnecessary heating.

The tuning frequency for multi-frequency transmitters is determined by the operating frequency and the frequency

spread between transmitters. Refer to the table below for maximum frequency spread.

NOTE

STEP METER

POSITION TUNING

CONTROL METER

READING PROCEDURE

1. B

(MOD-1) T103 See Procedure Tune T103 for the maximum meter reading on the

lowest frequency, After tuning T103 for maximum,

turn the slug 1/8 of a turn clockwise (increasing

inductance).

2. C

(MULT-1) T104 Minimum Tune T104 for a dip in meter reading.

3. D

(MULT-2) T105, T104

& T106 See procedure Tune T105 for maximum meter reading and re-adjust

T104 for maximum meter reading. Then tune T106 for

a dip in meter reading.

4. F

(MULT-3) T107, T106,

T108 & T109 See procedure Tune T107 for maximum meter reading and re-adjust

T106 for maximum meter reading. Then tune T108 for

a dip in meter reading and T109 for maximum meter

reading.

5. G

(AMPL-1) T110, T108 Maximum Tune T110 for maximum meter reading. and then re-

adjust T108 and T109 for maximum meter reading.

6. D

(AMPL-1 DRIVE

on pA)

T111 & T112 Maximum Move the black detering plug to the power Amplifier

metering jack and tune T111 and then T112 for

maximum meter reading. Then alternately tune T111

and T112 for maximum meter reading.

7. G

(AMPL-1) T108, T109

& T110 Maximum Move the black metering plug hack to the exciter meter

ing jack and re-adjust T108, T109 and T110 for

maximum meter reading.

8. D

(AMPL-1 DRIVE

on PA)

T111 & T112 Maximum Move the black metering plug back to the Power

Amplifier metering jack and re-adjust Till and T112 for

maximum meter reading.

9. R226 With tire battery voltage at 13.6 volts or the PA

collector voltage at 13.0 volts, set Power Adjust

potentiometer R226 on the PAhoard for the desired

power output (from 12 to 40 Watts).

If the battery voltage is not at 13.6 volts or the

collector voltage at 13.0 volts and full rated outputs

desired (40,38 or 35 Watts at 13.6 volts), set R226 for

the output power according to tie battery voltage or

collector voltage shown in Figures 10, 11 or 12.

ADDITIONAL STEPS FOR TRANSMITTERS USING CENTER FREQUENCY TUNE-UP ICOM

10. D

(MULT-2) T105 See procedure Move the black metering plug to the exciter metering

jack and re-adjust T105 for equal drive on the highest

and lowest frequency.

11. G

(AMPL-1) T110 & T108 Maximum Re-adjust T110 and then T108 for maximum meter

reading on the lowest frequency.

The PA collector voltage is measured as described

in the PAPOWER INPUT section.

NOTE

LBI-4622 LBI-4622

7

TEST PROCEDURES

TheseTest Procedures are designed to assist you in serv-

icing a transmitter that is operating-- but not properly. Prob-

lems encountered could be low power output, tone and voice

deviation, defective audio sensitivity, and modulator adjust

control set too high. Once a defect is pin-pointed, refer to

the "Service Check" and the additional corrective measures

included in the Transmitter Troubleshooting Procedure. Be-

fore starting with the Transmitter Test Procedures, be sure

the transmitter is tuned and aligned to the proper operating

frequency.

TEST EQUIPMENT REQUIRED

for test hookup as shown:

l. Wattmeter similar to:

Bird # 43

Jones # 711N

2. VTVM similar to:

Triplett # 850

Heath # IM-21

3. Audio Generator similar to:

GE Model 4EX6A10

4. Deviation Meter (with a .75 kHz scale) similar to:

Measurements # 720

5. Multimeter similar to:

GE TEST SET MODEL 4EX3A11,

MODEL 4EX8K12 or

20,000 ohms-per-Volt voltmeter

POWER MEASUREMENT

TEST PROCEDURE

1. Connect transmitter output from the antenna jack to

the wattmeter through a 50-ohm coaxial cable. Make

sure the wattmeter is terminated into a 50-ohm load.

2. Key the transmitter and check the wattmeter for the

desired power output.

SERVICE CHECK

Check the setting of the Power Adjust Control (R226).

Refer to the QUICK CHECKS on the Transmitter Trou-

bleshooting Procedure.

VOICE DEVIATION SYMMETRY AND

AUDIO SENSITIVITY

TEST PROCEDURE

l. Connect the test equipment to the transmitter as

shown.

2. In radios with Channel Guard, set Channel Guard

Mod Adjust R105 for zero tone deviation.

3. Set the Audio generator output to 1.0 VOLTS RMS

and frequency to 1 kHz.

4. Key the transmitter and adjust Deviation Meter tocar-

rier frequency.

5. Deviation leading should be ±4.5 kHz in radios with-

out Channel Guard, and ±3.75 kHz in radios with

Channel Guard.

6. If necessary, adjust MOD ADJUST control R104 for

the proper deviation on plus (+) or minus (-) devia-

tion, whichever is greater.

NOTES:

MASTR II transmitters are adjusted for 4.5 kHz deviation

at the factory. The factory adjustment will prevent the

transmitter from deviating more than 5.0 kHz under the

worst conditions of frequency, voltage and temperature.

7. If the deviation reading plus (+) or minus (-) differs

by more than 0.5 kHz, recheck Steps 1 and 2 as

shown in the TransmitterAlignment Chart.

8. Check Audio Sensitivity by reducing generator output

until deviation falls to 3.0 kHz for radios without

Channel Guard, or 2.25 kHz for radios with Channel

Guard. Voltage should be LESS than 120 millivolts.

If not, refer to the Transmitter Troubleshooting Proce-

dure.

TONE DEVIATION WITH CHANNEL

GUARD TEST PROCEDURE

TEST PROCEDURE

1. Set up the Deviation Meter and monitor the output of

the transmitter.

2. Remove the 1000 Hz signal from the audio generator.

3. Key the transmitter and check for 0.75 kHz deviation.

If the reading is low or high, adjust Channel Guard

MOD ADJUST R105 for a reading of 0.75 kHz.

NOTES:

1. On units supplied with Channel Guard, the Phase

Modulator Tuning should be adjusted Carefully to in-

sure proper performance. (Refer to Step 1 in the

Transmitter Alignment Chart).

2. The Tone Deviation Test Procedures should be re-

peated every time the Tone Frequency is changed.

Figure 10 - 40-Watt Power Output Setting Chart

Figure 11 - 38-Watt Power Output Setting Chart

Figure 12 - 35-Watt Power Output Setting Chart

Before bench testing the MASTR II Mobile Radio,

be sure of the output voltage characteristics of your

bench power supply.

To protect the transmitter power output transistors

from possible instant destruction, the following in-

put voltages must not be exceeded:

Transmitter unkeyed: 20 Volts

Transmitter keyed (50 ohm resistive load): 18

Volts

Transmitter keyed (no load or non-resistive load):

15.5 Volts

These voltages are specified at the normal vehicle

battery terminals of the radio and take the voltage

drop of standard cables into account. The voltage

limits shown for a non-optimum load is for "worst

case" conditions. For antenna mis- matches likely to

be encountered in practice, the actual limit will ap-

proach the 18 Volt figure.

Routine transmitter tests should be performed at EIA

Standard Test Voltages (13.6 VDC for loads of 6 to

16 amperes: 13.4 VDC for loads of 16 to 36 am-

peres). Input voltages must not exceed the limits

shown, even for transient peaks of short duration.

Many commonly used bench power supplies cannot

meet these requirements for load regulation and tran-

sient voltage suppression. Bench supplies which

employ "brute force" regulation and filtering (such

as Lapp Model 73) may be usable when operated in

parallel with a 12-Volt automotive storage battery.

CAUTION

LBI-4622 LBI-4622

8

LBI-4622 LBI-4622

9

TROUBLESHOOTING PROCEDURE

STEP1 - QUICK CHECKS

METER

POSITION GE

TEST SET

PROBABLE DEFECTIVE STAGE

HIGH

METER

READING

LOW METER

READING ZERO

METER

READING

EXCITER

B

(MOD-1) Q102, 10-

Volt Regulator T103,

CV103, C104 T103,

CV103,

CR104, Q104

C

(MULT-1) Q105, Q106,

T104 Q105, Q106 Q105, Q106,

T104

D

(MULT-2) Q107, T106 T104, T104,

Q107 T104, T105,

Q107, T106

F

(MULT-3) Q108, T108 T106, T107,

Q108 T106, T107,

Q108, T108

G

(AMPL-1) Q109, C157 T108, T109,

T110, Q109 T108, T109,

T110, Q109,

L106

POWER AMPLIFIER

"C"

(TRIPLER

DRIVE)

Low Output

from Exciter No output

from Exciter

CR201

"D"

(AMPL-2

INPUT)

Q207 Q207 Q207, Q201

"F"

(DRIVER

CURRENT)

Q204 Q204, Low

Output from

Q201, Q207,

Q202, Q203

Q203, Q202,

Q207, Q201.

Check Pos. C

& D

"G"

(PA CURRENT) Q205, Q206 Q201, Q207,

Q202, Q203,

Q204, Q205,

Q206

Q206, Q205,

Q204, Q203,

Q202, Q207,

Q201, Q215

LBI-4622 LBI-4622

10

406-512 MHz, 40-WATT TRANSMITTER

Issue 2

TROUBLESHOOTING PROCEDURE

LBI-4622 LBI-4622

11

406-512 MHz, 40-WATT TRANSMITTER

OUTLINE DIAGRAM

EXCITER BOARD

SOLDER SIDE

(19D416850, Sh. 2, Rev. 3)

COMPONENT SIDE

(19D416850, Sh. 2, Rev. 3)

(19D416850, Sh. 3, Rev. 3)

LBI-4622 LBI-4622

12

PA BOARD

OUTLINE DIAGRAM

(19D417162, Sh. 2, Rev. 3)

(19D417162, Sh. 3, Rev. 5)

COMPONENT SIDE

(19D417162, Sh. 2, Rev. 3)

SOLDER SIDE

LBI-4622 LBI-4622

13

PARTS LIST

LBI-4622 LBI-4622

14

PARTS LIST

LBI-4622 LBI-4622

15

406-512 MHz, EXCITER BOARD

19D416859G5-G8

SCHEMATIC DIAGRAM

LBI-4622 LBI-4622

16

406-512 MHz, EXCITER BOARD

19D416859G5-G8

SCHEMATIC DIAGRAM

LBI-4622 LBI-4622

17

406-512 MHz, 40-WATT POWER AMPLIFIER

19C320620G5-G8

SCHEMATIC DIAGRAM

LBI-4622 LBI-4622

18

406-512 MHz, 40-WATT POWER AMPLIFIER

19C320620G5-G8

SCHEMATIC DIAGRAM

LBI-4622 LBI-4622

19

This manual suits for next models

1

Table of contents