erkodent Erkoform-3dmotion User manual

Erkodent Erich Kopp GmbH • Siemensstraße 3 • 72285 Pfalzgrafenweiler • Germany

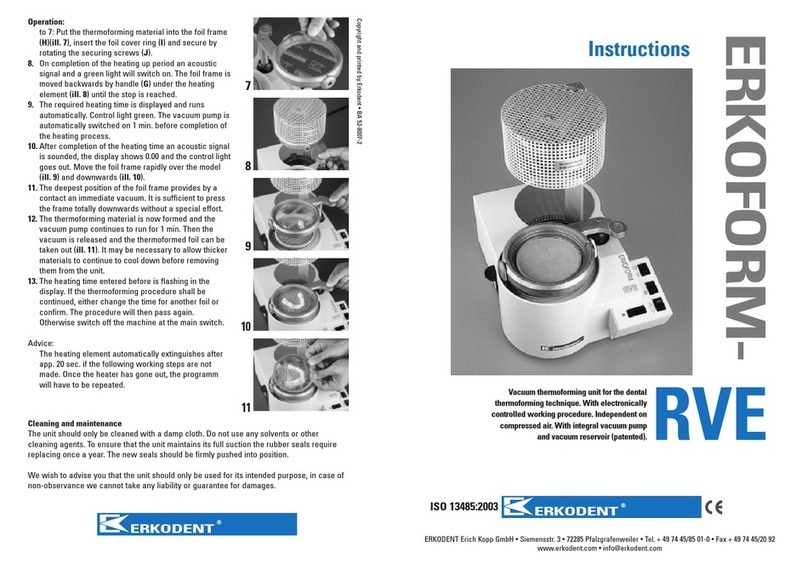

Erkoform-3dmotion

Medium-wave infrared

heater with cover

Form pot for reception of

granules pot, model plate

and Occluform-3 model pot

(Occluform-3, 188 580)

Foil reception handle with

cavity for good grip

Column for movement of

foil reception

Sensor window for

temperature registration

Mains connection (back)

Foil reception with

foil securing ring

Main switch

Touchpanel to operate all

functions

Granules collecting device

Erkoform-3dmotion

Vacuum thermoforming

unit with touchless

temperature control

(EP 1 905 380),

pre-vacuum, touchpanel

and automated

thermoforming process

Model plate* for very flat trimmed models

*also included

Granules pot*, Øinside 97 mm

height inside 40 mm

Instructions

Security

Before starting, please read instructions for use. The operator of the machine is

responsible for the complying with regulations for accident prevention concerning

technical security.

The construction of the Erkoform-3dmotion unit complies to the applicable legal standards.

Security hints

ATTENTION! Risk of burns, do not touch heater, housing of the heater and hot foils!

ATTENTION! Risk of crushing during the automated thermoforming process!

Keep free range of motion!

Only operate the machine under supervision. Do not keep highly inflammable materials near

the machine. Heat and work only with suitable thermoforming materials.

Usage as directed

The Erkoform-3dmotion unit must only be used with suitable dental thermoforming material

in diametre 120 mm and thickness of up to 6 mm for forming on suitable models. In case of

non-observance we cannot take any liability or guarantee for damages.

Cleaning and maintenance

The unit should only be cleaned with a damp cloth.

Do not use any solvents or other cleaning agents. To ensure

that the unit maintains its full function the sealing rings require

replacing once a year when the unit is consistently in use.

New seals should be firmly pushed into position.

Installation instructions

In order to avoid humidity and dirt entering the unit install and store it in a dry and low-dust

environment. Allow a cold unit (after transportation, storage or similiar) to warm up for 2

hours at minimum 15 °C room temperature to avoid condensed water.

Putting into operation

Fit in the supplied plug in the rear socket of the machine and plug in at the wall socket.

Unplug the machine when not in use.

Technical data:

Measurement: height 315 mm

width 350 mm

depth 370 mm

weight 13.9 kg

Foil measures: diameter 120 mm

thickness 0 - 6 mm

Form pot: inner Ø101 mm

inner height 42 mm

Electricity: volt: 230/240/115/100

watt: 360 (incl. heater)

Fuse: 2 x T- 2 A (230/240 V) or

2 x T- 4 A (100/115 V)

Heater technique: medium-wave round-pipe

infrared heater

volt 230/240/115/100

watt 280

Sensor: touchless infrared

temperature sensor, pro-

grammable measuring

range up to 240 °C

Vacuum technique: with pre-vacuum

vacuum 0.8 bar

litre capacity 6 l/min

noise level < 70 db(A)

Spare sealing

foil reception

188 011

Spare sealing

form pot

188 017

1

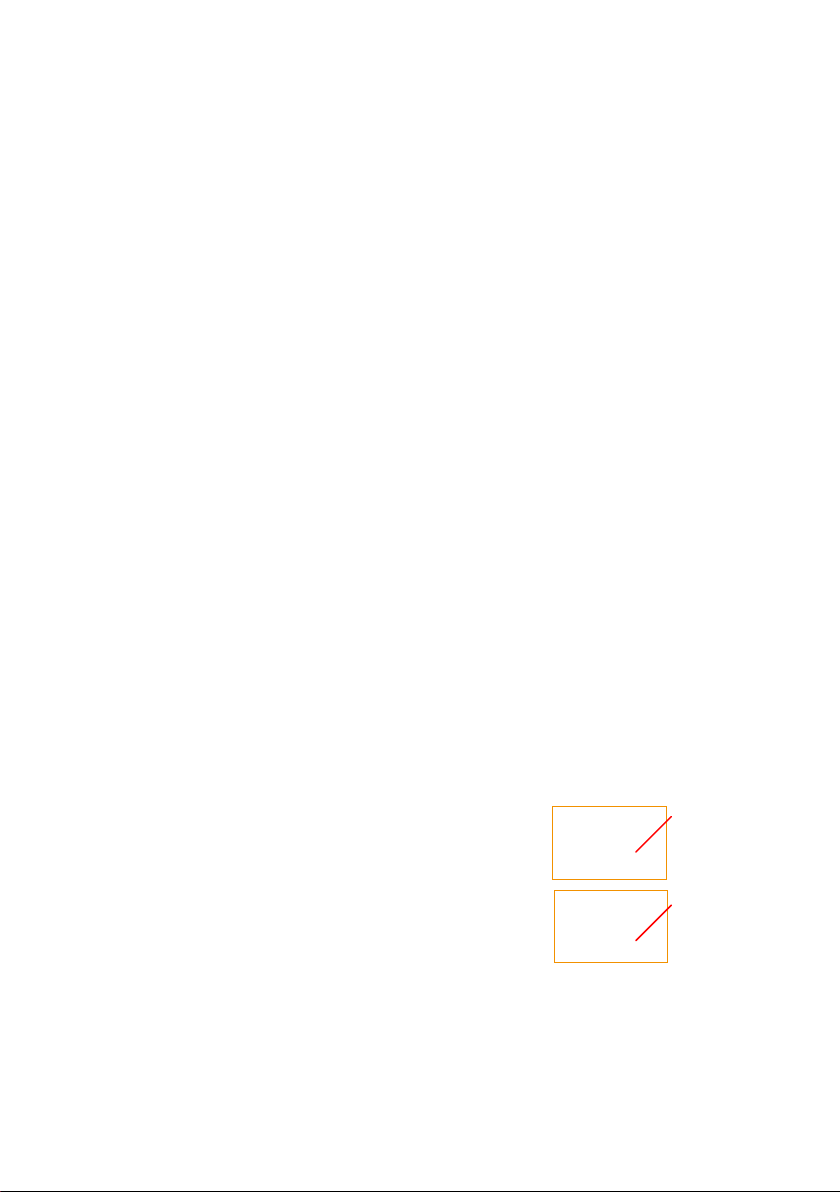

Recommendation:

Operate the machine only with granules (illustr.) To fill the

granules pot move the foil reception in the upper right position.

Smooth the granules, excessive granules will fall in the

surrounding chanel and can be swept with the brush in the

granules collecting device. Ensure that no granules remain on

the sealings.

The symbols of the touchpanel:

Switch unit on

Switch the unit on at the main switch.

A picture in the touchpanel reminds to

clean the sensor window.

A dirty sensor window leads to mea-

surement errors. If necessary, dust off

or clean with a damp cloth (no clean-

ing agents!).

After a few seconds the basic display

automatically appears.

The touchpanel responds in the

framed function fields on slight pres-

sure.

sensor window

main switch

2

refer to

instructions

main menue

foil thickness

risk of crushing

continue

foil temperature

list of foils

back

cooling time

favourites

ok continue

rated temperature

new foil

abort

delete

special functions

add favourite

heating off

language selection

change presettings

heating on

For input, the enclosed brush for

granules is equipped with a rubber cap.

Input is also possible with fingers.

Select language: (The unit retains the language selected)

1. Change selected language 2. Select language 3. Menu, selected language

Select foil example, Erkodur, thickness 1 mm

The list of foils contains all foils of the Erkodent range of

products that can be used with this machine and that have

been available at the time of production of this unit.

Add new foil, page 6 Save favourites, page 5

1. Select list of foils 3. Select 1.0 mm2. Select Erkodur

4. Selected foil

3

Thumb list of foils

back menu continue

Functions of this indication selected foil

rated temperature

cooling time

work with Occluform-3

change rated tempera-

ture and cooling time

save as favourite

menu

OK, next step

one step backwards

1. Select Occluform-3

and confirm

2. As above 3. As above, the

thermoforming pro-

cess runs after the

rated temperature is

reached.

4. Request to close the

Occluform-3.

Afterwards the cooling

time is indicated.

Thermoforming (see also page 10)

Thermoforming with Occluform-3

1. Correct foil (?),

confirm.

As soon as the foil

is confirmed the dis-

play shows the fur-

ther working steps.

Further functions of

this indication (see

page 10).

Hint:

Press abort: X

2. Foil will be heated.

As soon as the foil

reception clearly

clicks into place

under the heating,

the display shows

the foil temperature.

70 °C before the

rated temperature is

reached the vacuum

pump switches on to

built up the pre-vac-

uum.

3. Attention!

Thermoforming pro-

cess

10 °C before the

rated temperature is

reached there will

be an audibly and

visual warning of the

automated thermo-

forming process.

Attention, risk of

crushing! Do not

reach into motion

area!

4. Cooling time

After the thermoform-

ing process the

cooling time runs.

to 2. and 3.

During the heating

process the foil recep-

tion can shortly (max.

3 sec.) be swivelled

towards the starting

position without inter-

rupting the program.

Hint: When thermoforming Playsafe triple the

machine requires to close the Occluform-3 only

1 min. after the thermoforming process.

4

Save favourites

The list of favourites allows a quicker selection of often used foils. To save a foil in the list of

favourites, this foil is selected out of the list of foils as described under ”select foil“. New foils,

either future Erkodent foils or foreign foils, are entered with the functional field ”new foil“ and

are saved in the list of favourites.

After having selected the desired foil from the list of foils the display 1. will be visible. To save

the foil as favourite, select „to favourites“.

Recommendation: If an Erkodent foil will be saved with the factory parameters and as a favou-

rite with changed parameters, the changed one should be saved as new foil with a different

name in order to avoid any mix-up.

1. Select

add favourite

2. Confirm

add favourite

3. The favourite appears

and can be processed

1. Select

favourites

2. Select

favourite

3. Select

delete favourite

4. Confirm

delete favourite

Delete favourite

5

Enter new foils

New foils can be future Erkodent foils or foreign foils.

If Erkodent launches new foil the necessary data will be found on the label

(example: Erko new, thickness 1.8 mm, rated temperature 150 °C, cooling time 1:40 min.).

The foil can be saved under input „New foils“. In case of foreign foils the rated temperature

and the cooling time have to be determined with the help of the special functions.

The new foils will be saved in the list of favourites and selected via this list.

Hint: Max. 240 °C can be entered as rated temperature. The cooling time has to be at least

30 sec. Otherwise there may be malfunctions.

1. Select

new foils

5. Enter

cooling time

2. Enter

foil name

6. Select

favourite

3. Enter

foil thickness

7. Select

new foil

4. Enter

rated temperature

8. Thermoform new

foil

To 2., the new foil is saved as favourite,

the menu appears

6

Change factory settings for foils

The rated temperature and cooling time can be changed for one single thermoforming process

or constantly as a favourite. The rated temperature (factory presetting) can only be changed

by maximum +/- 5 °C. The changes are done in the window „selected foil“ or „favourite“, also

see “select foil” and “save favourite”.

1. Select change 2. Change rated tem-

perature and cooling

time

3. Thermoform or save

as favourite

Abort Save Thermoform once

with the changed

data

Save as favou-

rite.

As favourite the

changed data

and the foil name

will remain .

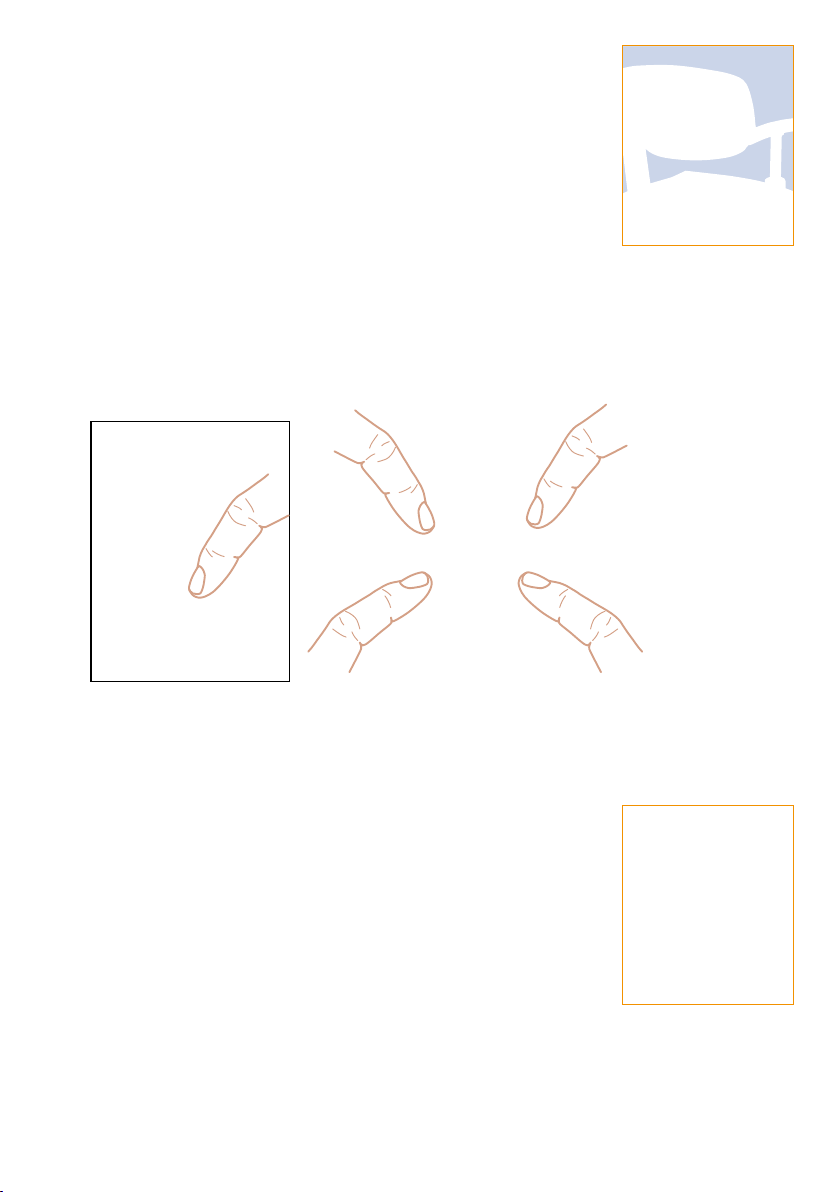

Optional Occluform-3 device (188 580) to imprint the opposing bite.

The construction is based on a Bonwill triangle with a side length of 11.5 cm and a

Balkwill angle of 20 °.

Occluform-3

7

8

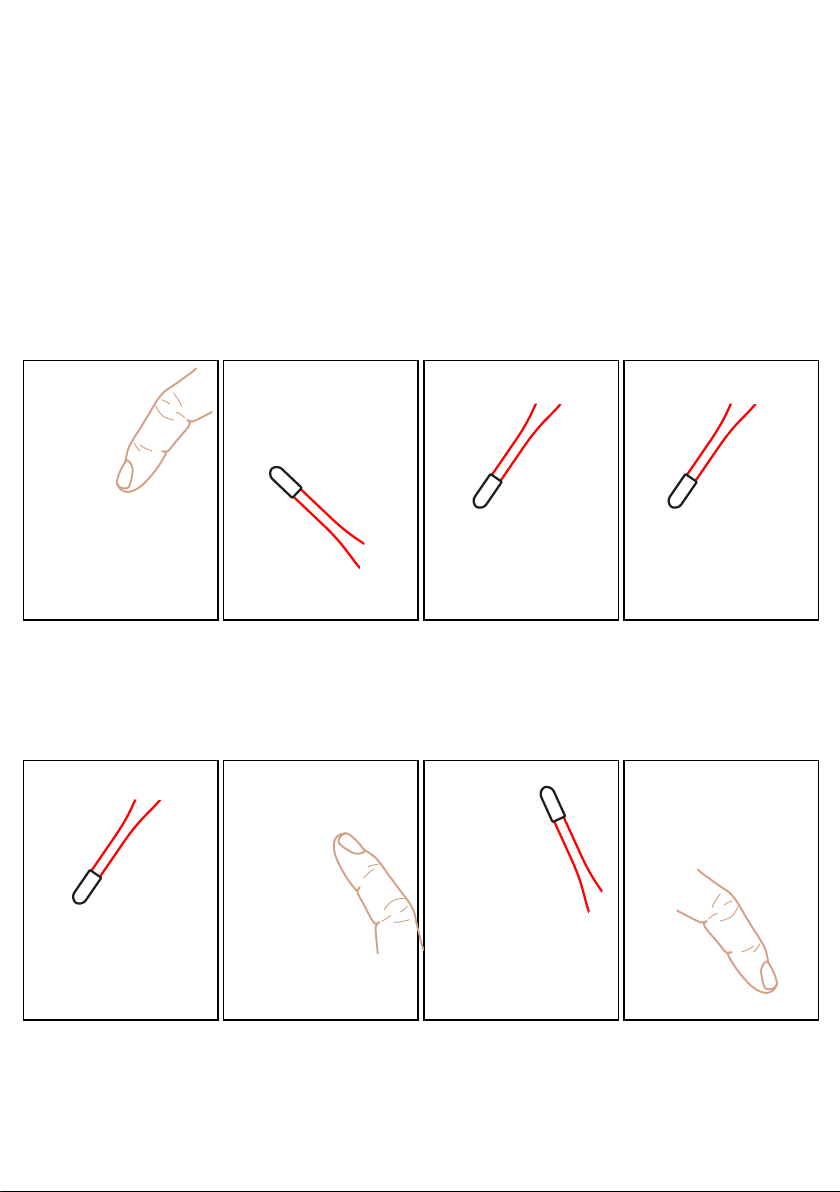

Special functions

Using special functions the heating and the vacuum pump can be

switched on and off independently of the program.

To determine the rated temperature (thermoforming temperature)

of an unknown foil, select „heating on“ and clamp the foil in the foil

frame as mentioned under „thermoforming“. As soon as the foil frame

is swivelled under the heating (a), it will be switched on and the

sensor will measure the temperature of the foil. If the foil shall be

thermoformed afterwards, select „pump on“.

Note, switch on the vacuum pump only with the foil reception in the

upper position.

Select special functions Heating off Heating on

Vacuum pump off vacuum pump on

a

To check the thermoformability, swivel the foil towards outside (b)

and check with a blunt instrument. If permanent impressions result,

generally the foil is ready for thermoforming.

The heating switches off if: the foil is swivelled out of the heating

area, “heating off“ is selected or the sensor measures > 240 °C.

The temperature shown on the display is the temperature measured

at last. If the foil is ready for thermoforming, this temperature

corresponds to the rated temperature.

To determine the cooling time, the time beginning with the adaptation

is measured. For the first time check the foil temperature manually

app. after 1 minute (earlier: risk of burning!). The correct cooling time

is achieved if the foil on the surface has app. room temperature. The

foil can now be saved as described under „enter new foil“.

b

9

Trouble shooting:

error

machine not ready to use,

no display in the touchpanel

heating does not switch on

program reacts absurdly

absurd temperature

indication

vacuum not sufficient

vacuum pump does not

function

automated thermoforming

action clamps

” ” ”

foil reception moves

upwards again (Error 001)

possible reason

wall socket, machine plug or

fuses defective

foil reception not in the

correct position

heater, switch for heater or

circuit board defective

system crash,

program faulty

sensor window soiled,

sensor defective

granules on the sealings,

hole in the foil, sealings

used, vacuum pump soiled or

defective

membrane clotty,

menbrane too hard at room

temperature below 15 °C

attachment got stuck

foil reception not correctly

positioned under the heating

motion area not free

elimination

(after sales service = ass)

check wall socket, machine

plug, fuses (at the machine plug)

foil reception has to clearly click

into place under the heating,

exchange heater, switch for

heater or circuit board (ass)

switch machine on and off,

deploy program again (ass)

clean sensor window,

exchange sensor (ass)

remove granules from sealings,

check foils concerning holes,

exchange sealings, clean or

exchange vacuum pump (ass)

clean membrane (ass)

allow machine to warm up for

app. 2 hours at room tempera-

ture to avoid condensed water

switch machine off, wait for 5

seconds, switch the machine on

again, swivel foil reception up to

the right

restart thermoforming process

and turn foil reception in the

engagement position under the

heating

do not reach into the motion

area and keep it free

10

1. Select list of foils

Thermoforming with Occluform-3

4. Select thickness 3.0 mm

7. ... until it clicks into

place (!). The heating

switches on.

10. Close the Occluform-3

to the stop, wait for the

cooling time

2. Thumb list of foils

5. Select Occluform

8. Attention, the automat-

ed thermoforming process

starts. Risk of crushing!

11. Release foil securing

ring, remove the Occlu-

form model pot with the

foil

3. Select Erkoloc-pro

6. Continue, thermoform-

ing*, swivel foil reception

under the heating ...

* the working steps

required before thermo-

forming will be shown in a

repeating animation.

All animations will be

stopped with the next

working step.

9. Animated request to

close the Occluform-3.

Delivery form for Erkoform-3dmotion

please check concerning completeness

Piece: Article: Order number:

1 Erkoform-3dmotion 188 400

with accessories as follows:

1 foil securing ring 188 550

to fix the foils in the foil reception

1 granules collecting device 188 570

1 model plate 188 507

1 granules pot 188 593

1 brush for filling granules with rubber cap 188 530

can also be used as input pen

1 on-off magnet red or green red, 110 890

to collect filling granules green, 110 891

1 power supply cable 188 001

1 filling granules 110 852 (1.3 kg)

(supplied with the Erkoform-3d motion 1.8 kg)

high-grade steel filling granules (magnetic) with

rounded edges

1 foil trial package

1 machine documents (folder)

instructions, thermoforming technique manual,

material card, Erkodent program,

guarantee card, declaration of conformity (if applicable)

Other erkodent Dental Equipment manuals