erkodent Erkopress 240 User manual

Instruction:

Content:

Page

1

Safety, Usage as directed,

Installation instruction

2

Declaration of Conformity

3

Start up, maintenance

4

Technical Data

5

Unit components, handling

6

Switch on the unit,

select language

7

Select foil

8

Save favourites

9

Thermoforming

10

Enter new foil

11

Delivery form,

available foil

material

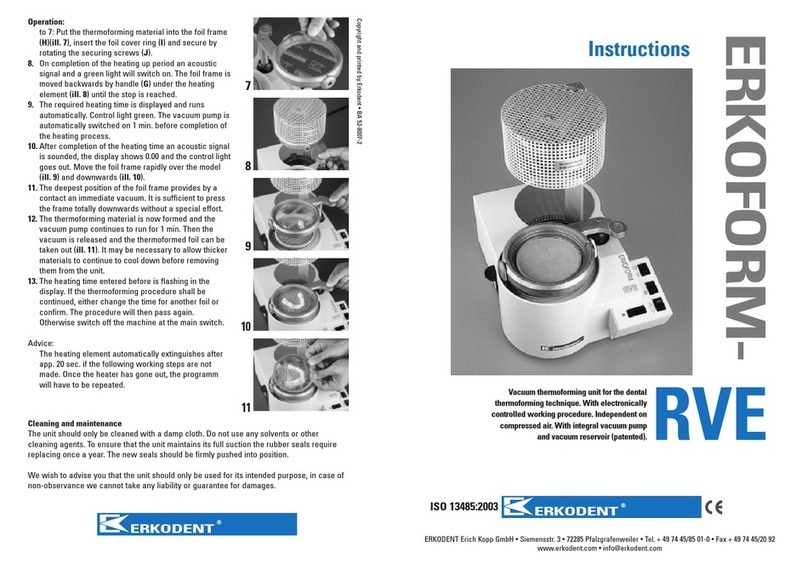

Pressure forming unit with automated thermoforming process

to connect to the existing compressed air system.

The Erkopress 240 unit is in accordance with the respective

legal standards that are listed in the declaration of conformity

on page 2 of this operating manual.

Instruction:

Erkopress 240

Safety:

• Before starting carefully read this operating manual.

• The operating company has to ensure that the operator has read and understood the

operating manual.

• The operational safety of the unit is only guaranteed when it is used in accordance with the legal

accident prevention and the safety guidelines are observed by the operator.

• Do not keep highly inflammable materials in direct area of the machine.

• Only operate the unit under supervision.

• The voltage of the power source has to be identical to the voltage indicated on the type plate.

• Attention hot, do not touch the heating element.

• Do not reach into the unit.

• Unplug the appliance when not in use.

• Before cleaning, maintenance and repairing always unplug the unit and allow to cool down.

• The unit should only be cleaned with a damp cloth. Do not use any solvents or other cleaning agents.

• Maintenance see page 3.

• Repairs of the units must only be carried out by trained personnel using original spare parts.

Otherwise the manufacturers liability and warranty expire.

Usage as directed:

• The units are intended for the use in the dental thermoforming technique.

• They must only be operated by instructed personnel and only using thermoforming material in

Ø 240 mm and up to 2.0 mm thickness to adapt on suitable models.

Otherwise the product liability expires.

Installation instructions:

• Place the unit on a plane ground. Pay attention to the fact that the weight of the unit with

accessories is approx. 47 kg.

• Install the unit in a dry and low-dust environment.

• Avoid draught (air-conditioning, ventilator, open window) at the installation place since this might

cause errors during the temperature measurement by the sensor.

• The Erkopress 240 is connected to the compressed air equipment available (mains pressure > 6 bar,

inner diameter of the feed cable at least 4 mm) and to electricity.

• A reliable operation of all functions is only guaranteed at a unit temperature of 15 °C.

Erkodent Erich Kopp GmbH

Siemensstraße 3 • 72285 Pfalzgrafenweiler • Germany

Tel.: +49 (0) 74 45 85 01-0 • Fax: +49 (0) 74 45 85 01-15

1

• DE: EG-Konformitätserklärung

• EN: EC Declaration of Conformity

• FR: Déclaration de conformité pour la CE

• ES: CE Declaración de Conformidad

• IT: Dichiarazione CE di conformità

• entsprechend der EG-Richtlinie Maschinen 2006/42/EG

• according to directives for machines 2006/42/EC

• conforme aux directives pour des machines de la CE 2006/42

• según las normativas para máquinas 2006/42/CE

• secondo la direttivam macchine CE 2006/42/CE

Wir • We • Nous • Nosotros • Noi

Erkodent Erich Kopp GmbH - Siemensstraße 3 - 72285 Pfalzgrafenweiler - Germany

• erklären in alleiniger Verantwortung, dass das Druck-Tiefziehgerät

• declare under our sole responsibility, that the pressure forming machine

• déclarons sous notre seule responsabilité que l’appareil de thermoformage à pression

• declaramos bajo propia responsabilidad que la máquina de presión para plastificación

• dichiara sotto la propria responsabilità che la termoformatrice a pressione

Type/Tipo:

Erkopress

Modell/ model/modèle/ modelo/modello:

240 (Seriennr.-Bereich / serial numbers / números de serie / numéros de série / numeri di seri: 95-500)

DE: den folgenden Bestimmungen in der jeweils aktuellen Version entspricht:

Richtlinie Maschinen 2006/42/EG • EMV-Richtlinie 2014/30/EU • DIN EN 12100 Sicherheit von Maschinen •

EN 13849-1 Sicherheitsbezogene Teile von Steuerungen • DIN EN ISO 14120 Sicherheit von Maschinen - Trennende

Schutzeinrichtungen • Richtlinie 2011/65/EU (gefährliche Stoffe, RoHS)

EN: complies with the following regulations:

guideline 2006/42/EC • guideline 2014/30/EC • EN 12100 • EN 13849-1 • EN ISO 14120 • guideline 2011/65/EC

FR: est conforme aux normes suivantes:

directive 2006/42/CE • directive 2014/30/CE • norme européenne EN 12100 • norme européenne EN 13849-1 • norme

européenne EN ISO 14120 • directive 2011/65/CE

ES: está en conformidad con las prescripciones siguientes:

normativas 2006/42/CE • normativas 2014/30/CE • EN 12100 • EN 13849-1 • ISO 14120 • normativas 2011/65/CE

IT: è conforme secondo le normative seguenti:

direttive 2006/42/CE • direttive 2014/30/CE • EN 12100 • EN 13849-1 • EN ISO 14120 • direttive 2011/65/CE

Unterlagenbevollmächtigte Person • authorized person for documents • agent pour les documents • comisionado para

documentos • persona autorizzata per i documenti

Hans-Peter Kopp, Siemensstraße 3, 72285 Pfalzgrafenweiler, Germany

Pfalzgrafenweiler, 01.08.2020

Hans-Peter Kopp

Geschäftsführer • Managing director • Gérant de société • Gerente

2

Erkopress 240, Start-up:

(Pay attention to the installation

instructions page 1)

Connect to the compressed air

system.

Connect to the power supply

system.

Attention:

leave at least 20 cm free space in

the area of the fans!

Erkopress 240

Maintenance:

To ensure that the unit maintains

its full function, the rubber seals

require replacing once a year when

the unit is permanently in use.

The new sealing rings should be

firmly pushed into position.

Sealing foil securing ring,

179 025

Sealing cylinder,

179 030

3

Main switch

Touchpanel

Medium-wave infrared heater

Foil reception with foil

securing ring

Insertion ramp for foil reception

Sensor window

Model disc

Form pot

Technical data, Erkopress 240:

temperature sensor: touchless infrared sensor, measuring range up to 240 °C

foil dimensions: Ø 240 mm, thickness 0 - 2.0 mm

operating pressure 4.5 bar, (factory setting), required supply pressure > 6 bar,

noise level < 80 dB(A)

Dimensions: height 40 cm, width 34.5 cm, depth 59 cm, weight 47 kg

Electrics: ~220 - 240 (100, 110 - 120) Volt, 50 - 60 Hertz max. 1100 W

Fuse: 230/240 V, 2 x T-5 A, • 100/115 V, 1 x T-12 A, H

Heating: medium wave infrared radiator, 1000 Watt

Erkopress 240

4

Mains connection • Compressed air connections

Handling of form pot, model disc and the placement of the models:

5

Form pot with carrying

cross for model discs

Use model disc only

with carrying cross!!

Bottom side of the form

pot with transverse

groove

Foil-reception (1) and

foil securing ring (2)

2 Model discs

*Note page 11!

Model disc with screws

for positioning models

Counterpart to the

groove on the form

pot table

Form pot with model

disc

7 models,

6 are placed on screws

as shown and 1 in the

middle.

To place up to 9 small

models, insert the

model disc with the

screws facing down.

Make sure that the

distance between the

models is at least 1 cm

and do not exceed the

ring.

The models must not

extend beyond the

marked ring

The form pot must be placed on the forming

pot table with the transverse groove in the

counterpart

1

2

Erkopress 240 Unit components:

Main switch

Switch on the unit

Switch on the unit at the main switch.

The touchpanel first shows the Erkodent Logo and

then it requires to check if the sensor window is dusty

or dirty. If so, dust off or clean with a damp cloth.

The sensor window is located at the rear right in the

device.

After a few seconds the basic display automatically

appears.

The touchpanel responds in the framed function fields on slight pressure. For input the enclosed

brush is equipped with a rubber cap. However, input is also possible with ngers.

Basic display:

Select language, for any further use of the unit the language selected last time is used.

1. Select language

selection

2. Select language 3. Menu, selected

language

Note: The function field »X« inter-

rupts the respective process and

has to be confirmed.

Note: The function field »delete“ has

to be confirmed.

Note:

If within 10 seconds the next required working step will not be performed, the working program will be

switched off for safety reasons.

6

Select foil:

The list of foils contains all foils that can be used with this machine.

(Example, Erkodur, 0.8 mm )

1. Select list of foils 3. Select 0.8 mm

2. Select Erkodur

4. Selected foil Functions of this display

selected foil

rated temperature

cooling time

change rated temp.

and cooling time

save as favourite

menu

OK, next step

one step back

7

Save favourites:

To save a foil in the list of favourites, this foil is selected out of the list of foils as described under

“select foil“. New foils, either future Erkodent foils or foreign foils, are entered with the functional field

»New foil« and are saved in the list of favourites.

After the desired foil is selected from the list of foils, the display shown at point 1. will be visible.

1. Select add favourite

Delete favourite:

2. Add favourite and confirm

2. Select favourite1. Select favourites 4. Confirm delete

favourite

3. The favourite appears and

can be processed.

3. Select delete favourite

8

to 4. Only after

confirmation of 3.

the selected foil is

heated.

The further thermo-

forming process and

the movement of the

form pot are

automated.

to 3. Now place the

form pot with model

disc and the models

arranged on it on the

form pot table and

confirm (yes).

to 3. Air blowing noises

during the cooling time

serve for cooling.

to 7. ... and confirm.

*Note on page 11!

to 2. Place foil recep-

tion with foil onto the

insertion ramp and

push it thus far under

the heater that it clicks

into place.

to 5. Warning appears

shortly before and dur-

ing cylinder release.

to 1. Correct foil?,

if yes, confirm.

In the display further

working steps are indi-

cated. The visualisation

disappears with the next

step.

Put the selected foil

in the foil reception

and clamp with the foil

securing ring.

1. Selected foil

2. Insert foil reception

5. Risk of crushing

3. Form pot in place?

6. Cooling time

7. Remove models

4. Foil is heated

Await further device

function step.

Thermoforming:

9

Hint: The function icon „X“ stops the respective

process. Each abort must be confirmed.

to 2.

Enter new foil:

New foils are future Erkodent foils.

If Erkodent launches a new foil the necessary data will be found on

the label (example: Erko new, thickness 1.8 mm, rated temperature

150 °C, cooling time 1:40 min.).

After entering “New foil” the program guides you through the

individual necessary entries. The new foils can be saved in the

list of favourites and selected via this list.

Note: Max 240 °C can be entered as rated temperature. The cooling

time has to be at least 30 sec. Otherwise there might be

malfunctions.

Select new foil

10

Erkodent Erich Kopp GmbH

Siemensstraße 3 • 72285 Pfalzgrafenweiler • Germany

Tel.: +49 (0) 74 45 85 01-0 • Fax: +49 (0) 74 45 85 01-15 • www.erkodent.com • [email protected]

11

BA-Erkopress 240-EN-11-2020

Delivery form for Erkopress 240, please check concerning completeness

1 Erkopress 240, order no. 179 000, with

1 foil securing ring (179 015)

1 foil reception (179 010)

1 form pot with model disc support (179 005)

2 model discs (1 pcs. 179 020)*

1 power supply cable (170 001)

1 hose connection (179 025)

1 brush as an input pen (188 530)

1 foil test pack, Erkodur 240, 0.8 mm thickness, 10 pieces

machine documents (folder), instructions, guarantee card

Available foil material, Ø 240 mm:

Erkodur 240, 0.5 mm, Ø 240 mm, clear, 20 pieces, 529505

Erkodur 240, 0.6 mm, Ø 240 mm, clear, 20 pieces, 529506

Erkodur 240, 0.8 mm, Ø 240 mm, clear, 20 pieces, 529508

Erkodur 240, 1.0 mm, Ø 240 mm, clear, 20 pieces, 529510

Erkoflex-bleach 240, 1.0 mm, Ø 240 mm, transparent, 20 pieces, 589510

Erkoloc-pro 240, 1.0 mm, Ø 240 mm, transparent, 20 pieces, 599510

Erkoloc-pro 240, 1.3 mm, Ø 240 mm, transparent, 20 pieces, 599513

Erkoloc-pro 240, 2.0 mm, Ø 240 mm, transparent, 10 pieces, 599520

* Note:

The two model discs supplied are

are used alternately.

The model disc absorbs heat during each

thermoforming process. To allow it to cool

down, the second model disc is used for the

following thermoforming process.

For easier changing, the model disc remains on the

thermoformed foil when removing the models.

After removal, separate the model disc from the models

and the foil.

Other manuals for Erkopress 240

2

Table of contents

Other erkodent Dental Equipment manuals