ERMCO AHT-1 Guide

1

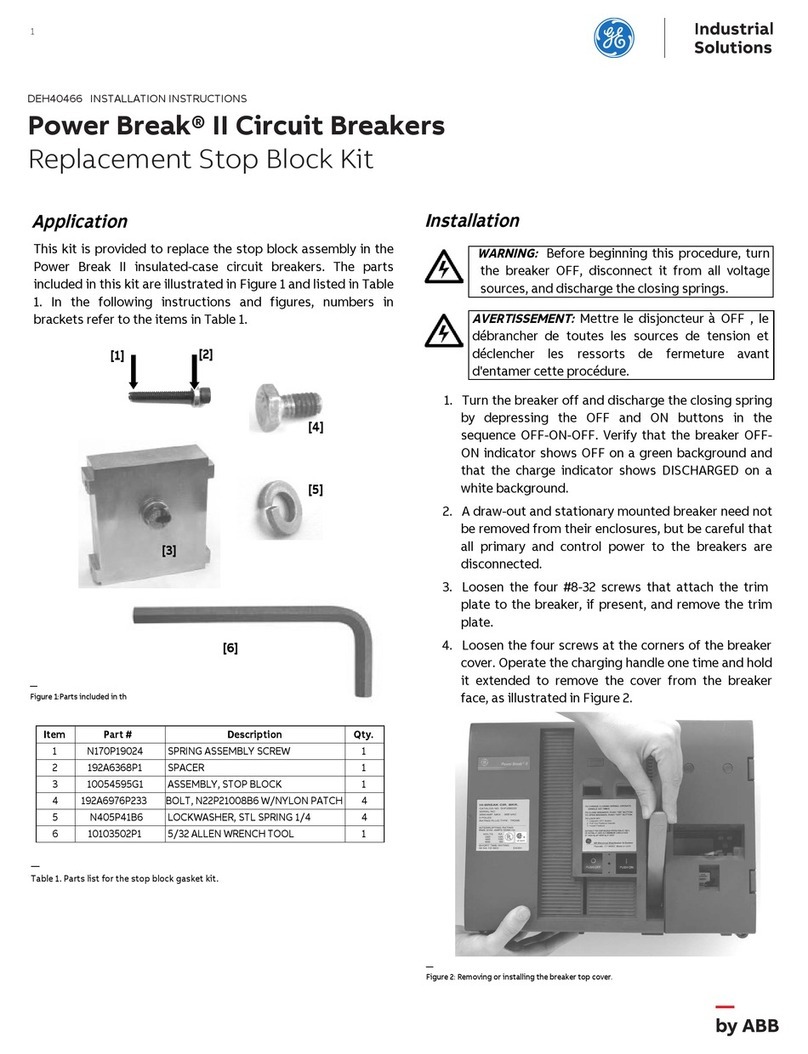

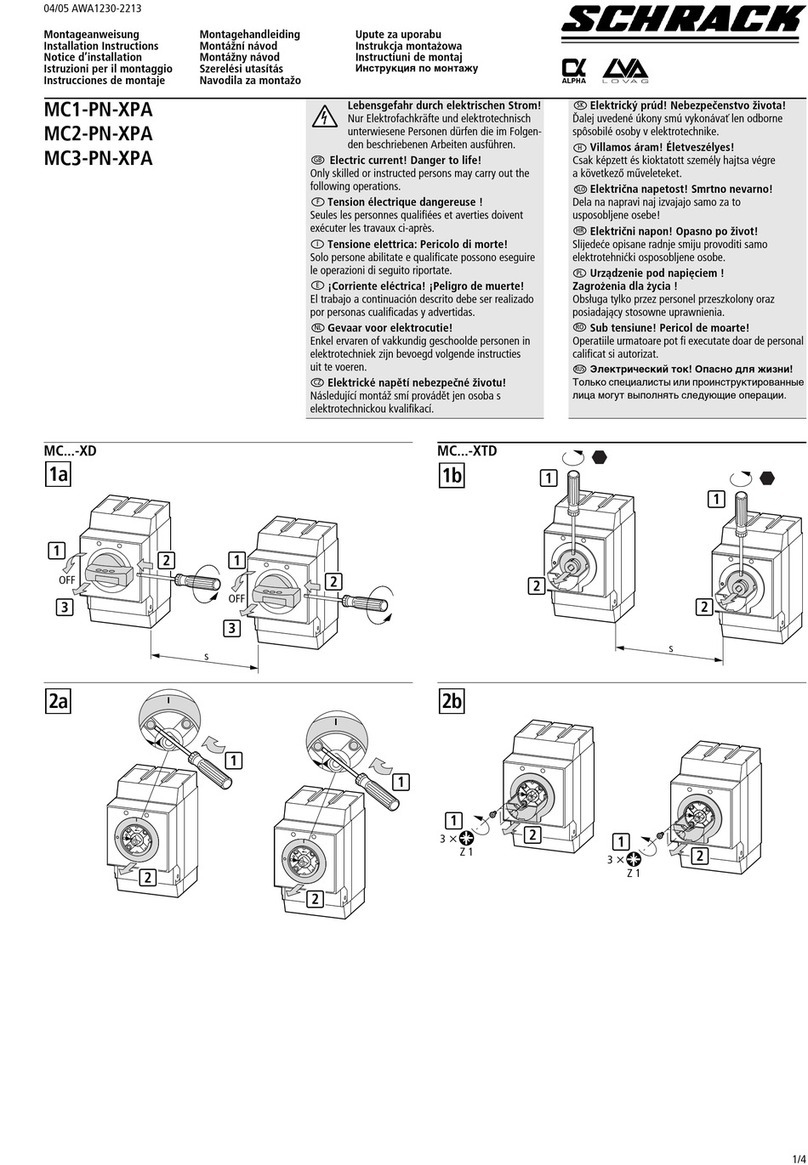

CIRCUIT BREAKER OPERATION & ADJUSTMENT (AHT‐1 & T‐12)

Preliminary factory adjustment of the breakers is expected to give

signal light contact connuity under the following four condions:

1. When the cocking lever is moved beyond the open posion.

2. When the cocking lever is moved beyond the closed posion.

3. When the trip bar is moved, but before the breaker contacts are

tripped.

4. When the breaker has tripped completely.

To achieve these condions, the posion of the two signal light

contacts and the calibrang screw are factory preset. To obtain light

indicaon from the reset posion, the cocking lever must be moved

toward the light tower when the contacts are open. To obtain light

indicaon from the closed posion, the cocking lever must be moved

toward the contacts when the contacts are closed. This allows the

light switch operaon to be checked outside the tank.

Following this preliminary adjustment, the breakers are calibrated

and packaged.

To obtain the same condions when the breaker is installed in a

transformer requires the correct amount of free travel at each end of

the operang handle moon.

Obtaining the correct free travel is oen a cut‐and‐try procedure due

to variaon in the handle locaon, breaker locaon and tank

dimensions. To facilitate this adjustment the following steps may

prove useful.

1. Bolt breaker to support, ghten screws firmly and back offthe

screw under the trip bar ½ turn.

2. Install the operang handle assembly in the tank and ghten

the clamping nut unl the gasket stop booms out. Further

ghtening is undesirable.

3. Posion the operang handle to align the yellow arrow with the

“R” on the bearing, allowing about ¼” clearance between the

handle stop and the bearing stop. Posion breaker in the

cocked posion with the contacts open.

4. Screw the connecng rod (link arm) in to the cocking lever unl

the holes in the rod and operang arm mate. Insert a coer pin

in the holes, hold coer pin in place and move the operang

handle to check for the following operaons:

a. Close and open the breaker.

b. Close breaker, trip light contact manually (avoid tripping

main breaker contacts). Reset light by moving operang

handles to the “L” posion.

c. Trip breaker contacts and try reseng the breaker. A

properly adjusted breaker will have approximately ¼” of

travel lebetween the handle and bearing stops. If

breaker fails to operate properly, adjust connecng rod

unl the above operang condions are obtained.

FOR MORE INFORMATION VISIT ermco‐eci.com

ERMCO COMPONENTS, INC | 1607 Industrial Road | Greeneville, TN 37745

5. Install coer pin permanently; avoid binding between rod and

lever.

6. Install signal light in tank wall; ghten clamping nut only enough

to compress the gasket. Avoid over‐ghtening.

7. Posion calibraon control mechanism (overload lever) on the

breaker at the “normal” posion. Insert the preformed end

control wire into the breaker overload lever and thread the

control cable (sheath) into the support on the breaker and lock

the connecon by pinching the support around the cable

sheath.

8. Posion the calibraon control mechanism (overload lever) on

the breaker in the “normal” posion. Hold the control assembly

lever on the operang handle bearing in the “normal” posion.

Thread the control cable through the hole in the cable support

and lock the connecon by pinching the support around the

cable sheath. Twist the control wire into and around the

emergency overload control lever as show below.

9. Connect signal light winding to terminal on the breaker.

10. Connect signal light winding to the signal light.

11. For breakers without emergency overload and signal light, the

following procedure is recommended to make the breaker

assembly adjustment in the transformer tank:

a. Place breaker in the cocked posion with the contacts

open.

b. Adjust threaded connecng rod (link arm) so that the

yellow arrow on the operang handle is aligned with the

“O” on the bearing.

c. Check breaker for proper reset and close operaons.

Adjust connecng rod (link arm) to achieve proper

operaon, if required.

ECI

A1‐15

11/04

A1‐16

10‐21

2

STANDARD OPERATING INSTRUCTION GUIDE FOR LOW‐VOLTATE BREAKER & SIGNAL LIGHT

WARNING : ON SINGLE PHASE & THREE PHASE TRANSFORMERS

WITH THE SECONDARY CIRCUIT BREAKER OPEN, THERE MAY BE

SUFFICIENT COUPLING TO THE WINDING SO THAT PERCEPTIBLE

SHOCK MIGHT BE OBTAINED FROM THE SECONDARY TERMINALS.

A circuit breaker when provided is mounted inside the tank, under

the liquid level. The funcon of this breaker is to open the low‐

voltage circuit and protect the transformer from faults or severe

overloads. A red signal light, when provided, gives the warning that

the load has reached a value near the tripping point of the breaker.

The signal light remains lighted unl reset (turned off) by means of

the breaker‐operang handle. Transformers should not be operated

under load condions that will cauase the red light to appear

frequently, since it indicates an overload on the transformers. When

such a condion exists, it is recommended that a larger transformer

be substuted to avoid impairing the life of the smaller unit.

The circuit breaker operang handle and posion indicator are

shown in Figure 1. Transformers are shipped with the circuit

breakers closed. To open the low voltage circuit manually, move the

handle so that the pointer moves from “C” (closed) to “O” (open), at

which point the circuit is open. Verify that the circuit breaker is

latched in the “open” posion.

To insure that the discharge of the stac charge, which is somemes

present in the low voltage winding due to capacitance, it is

recommended that the low voltage be grounded aer opening the

circuit breaker unl the high voltage is disconnected.

To close the breaker aer manual opening move the handle so the

arrow points towards “C”. If the breaker has been tripped it is

necessary to move the arrow towards “R” to reset the breaker

before closing the breaker by moving the arrow towards “C”.

If a fault exists or and excessive load exists at the me the breaker is

closed, the breaker will reopen even though the operang handle is

held in the “C” (closed) posion.

To reset the signal light, rotate the handle to the “L” (light), and then

return to “C” (close). If the light fails to go out, the transformer is sll

over heated.

Provision is made for checking the signal light bulb when the

transformers is in service, to do this, rotate the handle to “L” (light)

FOR MORE INFORMATION VISIT ermco‐eci.com

ERMCO COMPONENTS, INC | 1607 Industrial Road | Greeneville, TN 37745

and the light should come on. If it does not, the bulb should be

replaced. The bulb is a standard six‐volt, GE bulb No. 44, and is

replaceable from outside the transformer and by removing the signal

light lens. Aer checking return the operaon handle to “C”. Faulty

bulbs should be replaced, since operang the transformer with the

faulty bulb or without a bulb may result in radio noise.

Some circuit breakers are equipped with emergency overload

devices, which can be used to restore service following a circuit

breaker operaon due to overload. With the emergency lever in the

normal posion the breaker will trip at its normal sengs as

calibrated at the factory. Moving the lever in clockwise direcon (see

Figure 1) increases the seng so that a higher temperature is

required to trip the breaker. This emergency seng provides extra

load capacity and sll permits manual breaker operaon, and also

retains short circuit protecon of the transformer. It is important

that the emergency seng be used only when and as long as

absolutely necessary, because its use will result in a reducon of

transformer life.

A meter seal is provided on the emergency lever to prevent

tampering. It is recommended that a new seal be applied when it is

returned to the normal posion aer emergency operaon.

ECI

7‐7D

A1‐17

3/02

3

CIRCUIT BREAKER APPLICATION

ECI

7‐7D

A1‐12

02/05

4

CIRCUIT BREAKER APPLICATION

ECI

7‐7D

A1‐13

01/99

5

CIRCUIT BREAKER APPLICATION

ECI

7‐7D

A1‐14

11/01

This manual suits for next models

1