88

5. Description

5.1. General

The eVD4 series of vacuum circuit-breakers are apparatus

for indoor installation. For the electrical performances, please

refer to the corresponding technical catalogue.

For special installation requirements, please contact ABB.

The following versions are available:

– fixed

– withdrawable for UniGear ZS1 switchgear and PowerCube

units.

Vacuum circuit-breakers have particular advantages when

used in systems with a high operation frequency and/or which

involve a certain number of short-circuit interruptions. The

eVD4 vacuum circuit-breakers comprise the circuit-breaker,

sensor, protection and control functions in a single solution.

eVD4 circuit-breakers include an RBX615 relays and current

and voltage sensors. The multi-function RBX615 unit is

an Intelligent Electronic Device (IED), has a vast range of

protection and control functions and makes the eVD4 a

complete product, able to satisfy the needs of modern electric

installations.

The “combisensor” version sensors allow simultaneous and

precise measurements of both current and voltage. Integration

of the multi-purpose electronics and of the sensors on board

the circuit-breaker is done in the factory and is followed

by a careful testing stage which allows the functionality

of the whole system to be checked before the product is

sold. These checks, together with the many self-diagnosis

functions of the IED make the eVD4 stand out for their highly

reliable operation and low maintenance required.

eVD4 vacuum circuit-breakers are derived from the VD4

series of which they possess the same reliability and sturdy

construction.

5.2. Reference standards

The eVD4 vacuum circuit-breakers conform to the

specifications of the following Standards:

– IEC 62271- 100 VDE 0670 part 1000

– IEC 62271-1 DIN VDE 0670 part 104

– IEC 61000-4 DIN VDE 0847 part 4

– IEC 60255-26

– IEC 60044 -7 -8

5.3. Composition

The eVD4 circuit-breaker is a system consisting of:

– vacuum circuit-breaker with mechanical stored energy and

free release operating mechanism (5)

– RBX615 electronic unit to carry out the protection, control,

measurement, monitoring and self-diagnosis functions (3)

– embedded sensors for current and voltage measurement (2)

– Human Machine Interface (HMI), allowing all the RBX615

functions to be managed from the low voltage compartment

door.

– Web HMI, allowing most of the HMI functions to be used by

means of

a web browser.

The actuator works on the circuit-breaker poles by means of

special kinematics. The operating mechanism springs provide

the energy needed to activate the driving gear.

The circuit-breaker operating position is monitored thanks to

two inductive sensors

The basic circuit-breaker version also has the following

instruments:

– manual device for loading the operating mechanism

– mechanical open/closed state indicator

– mechanical indicator of springs loaded

– mechanical operation counter

– opening and closing pushbuttons.

The withdrawable version has a truck (15), either manual or

motorized, consisting of a steel sheet structure with wheels,

on which the circuit-breaker is installed with the relative

auxiliary components, the isolating contacts for electric

connection with the switchgear and the multi-pole connector

for connection of the circuit-breaker auxiliary circuits.

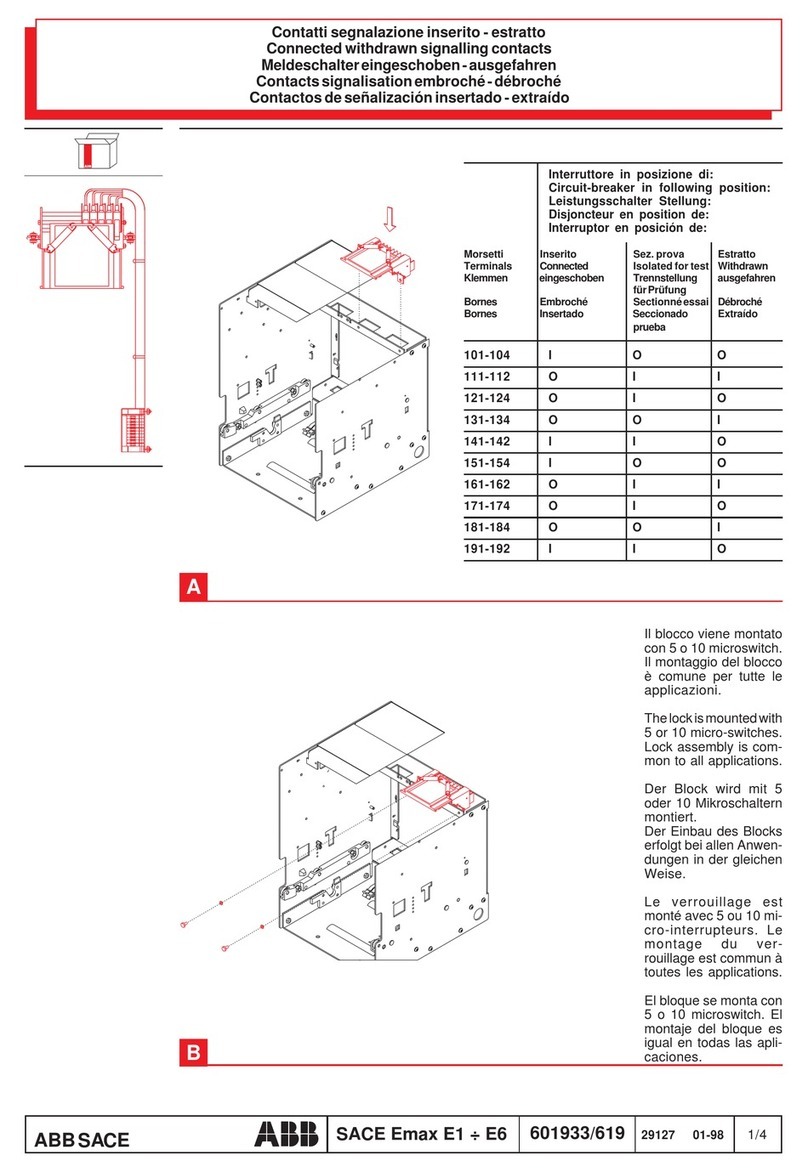

After being racked into the switchgear and hooked up,

the withdrawable circuit-breaker functions in the following

positions: racked-out, isolated for test (with the connector

inserted) and racked-in.

The racked-in circuit-breaker is automatically earthed by

means of the truck wheels.

The mechanical actuator of the circuit-breaker and the relative

operating pushbuttons are accessible from the front.

Withdrawable circuit-breakers of the same type and

characteristics are interchangeable, but the connector coding

prevents incorrect combinations between circuit-breaker and

switchgear.

5.3.1. Structure

Fixed circuit-breaker (fig. 4/a)

Withdrawable circuit-breaker (fig. 4/b).