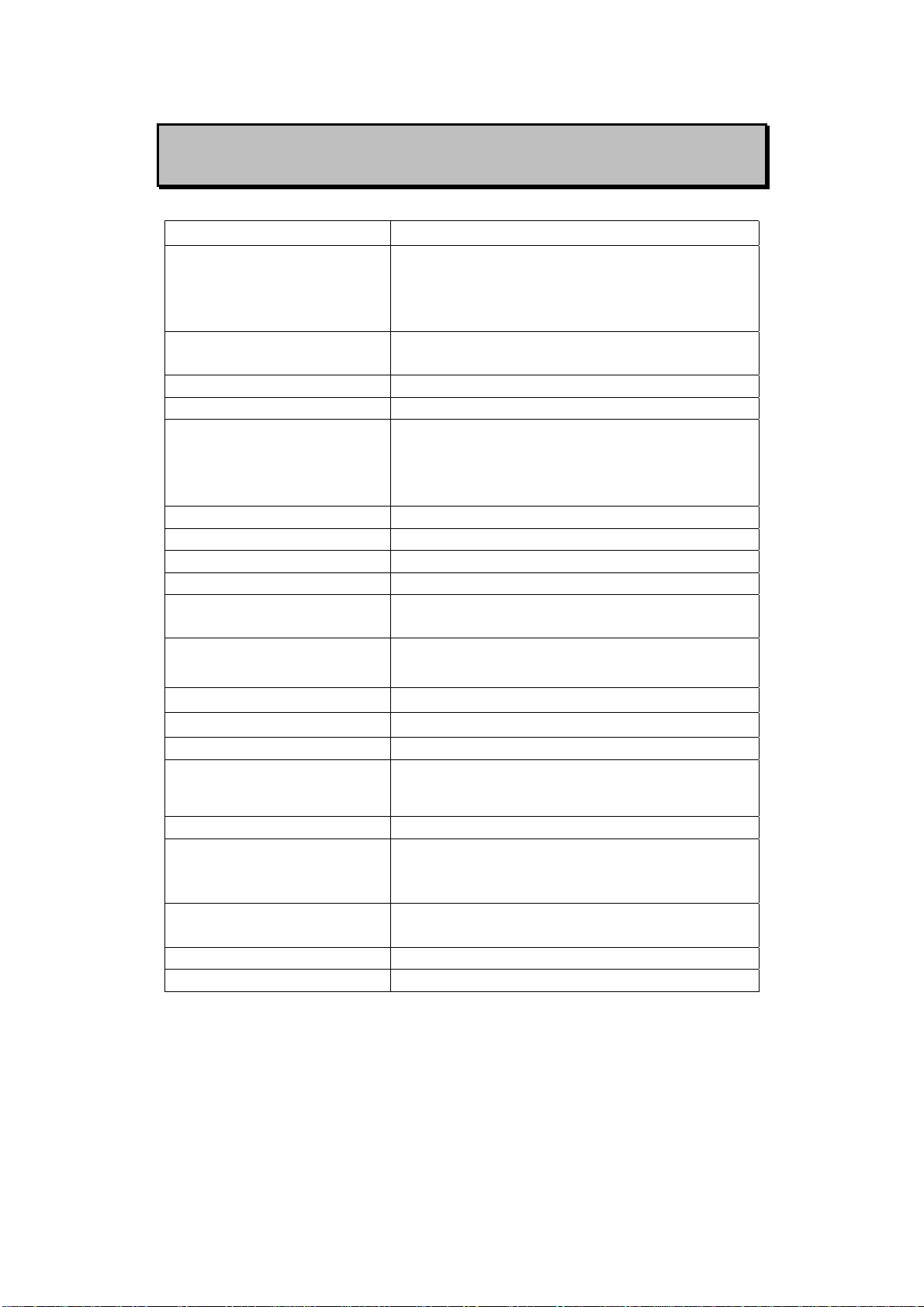

SAFETY INFORMATION

In this manual, "WARNING", is reserved for conditions and actions that

pose hazard(s) to the user; "CAUTION", is reserved for conditions and

actions that may damage your meter. Before using the meter, read the

following safety information carefully.

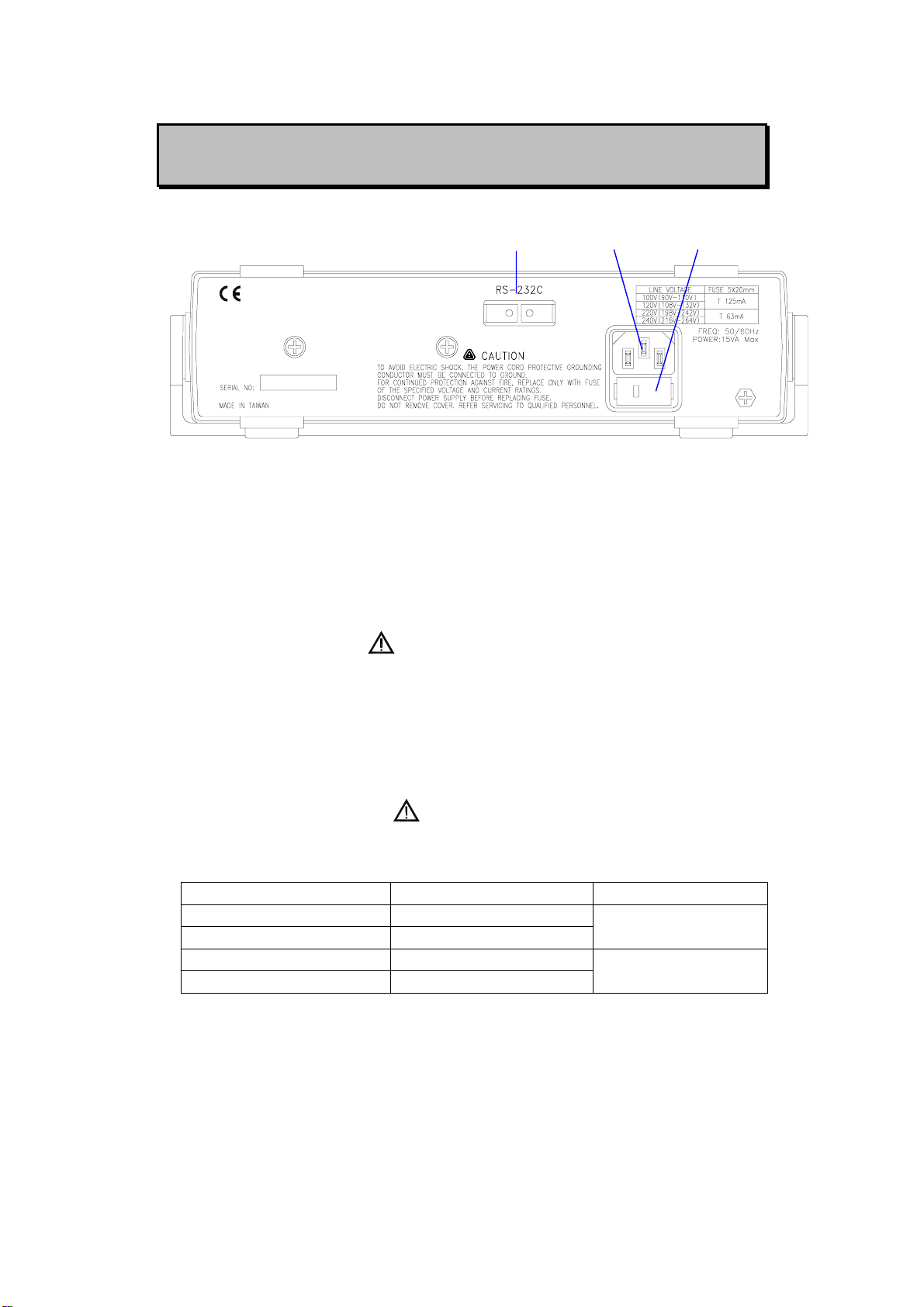

1. Before applying power, ensure that power cord and the proper line

voltage indicated for power source being used.

2. This product is grounding through the grounding conductor of the

power cord. To avoid electric shock, the grounding conductor must

be connected to earth ground. Before making any connections to the

input terminals of the products, ensure that the properly grounded.

3. To avoid personal injury, never operate the instrument without

covers or panels removed.

4. Do not operate this product in wet, damp or explosive atmosphere.

5. This meter is for indoor use, altitude up to 2,000 m.

6. The warnings and precautions should be read and well understood

before the instrument is used.

7. Use this device only as specified in this manual; otherwise, the

protection provided by the meter may be impaired.

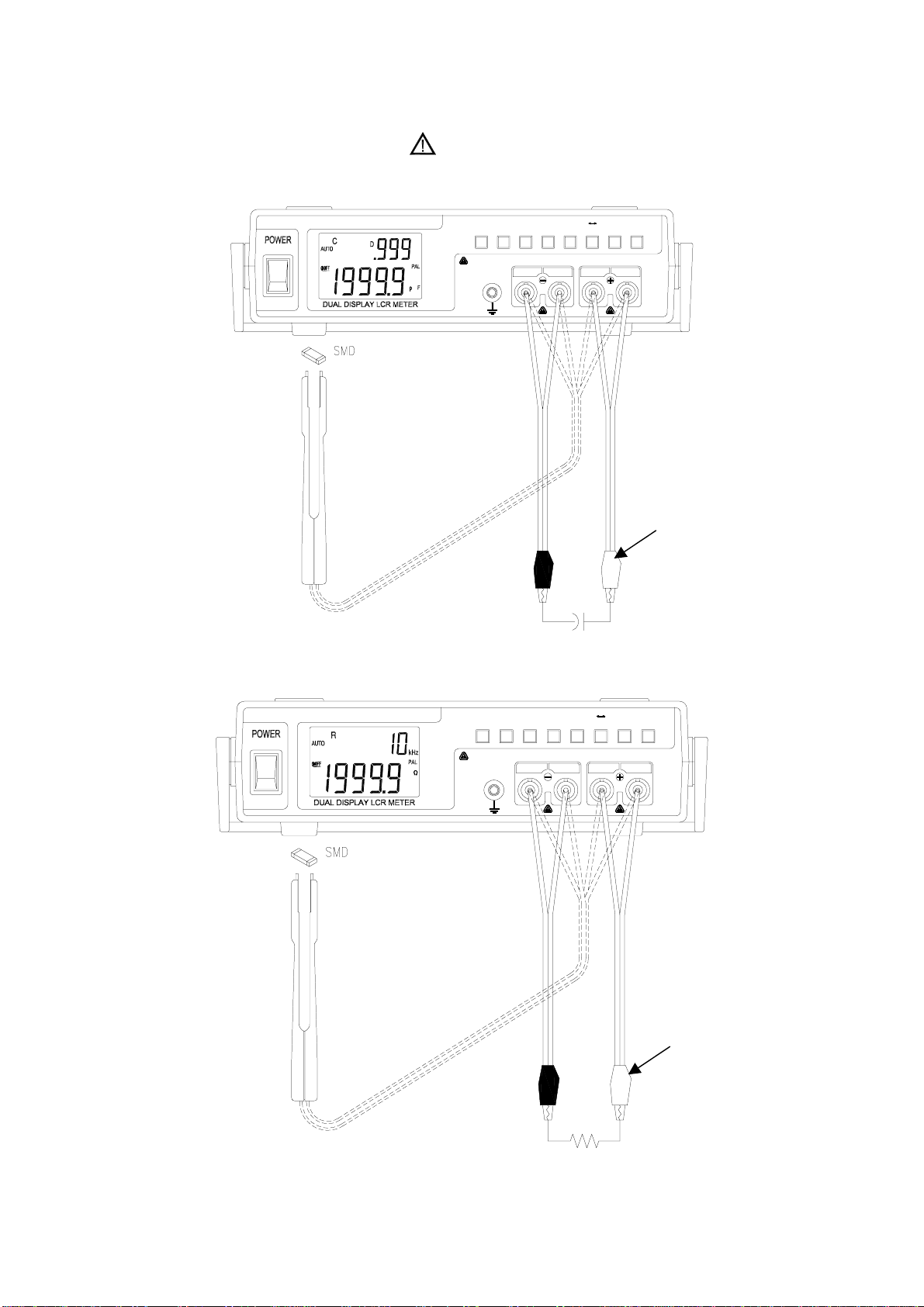

8. When measuring in-circuit components, first de-energize the circuits

before connecting to the test leads.

9. Discharge the capacitor before testing.

10.The meter is safety-certified in compliance with EN61010 (IEC

1010-1). EMC is certified in compliance with EN61326-1.

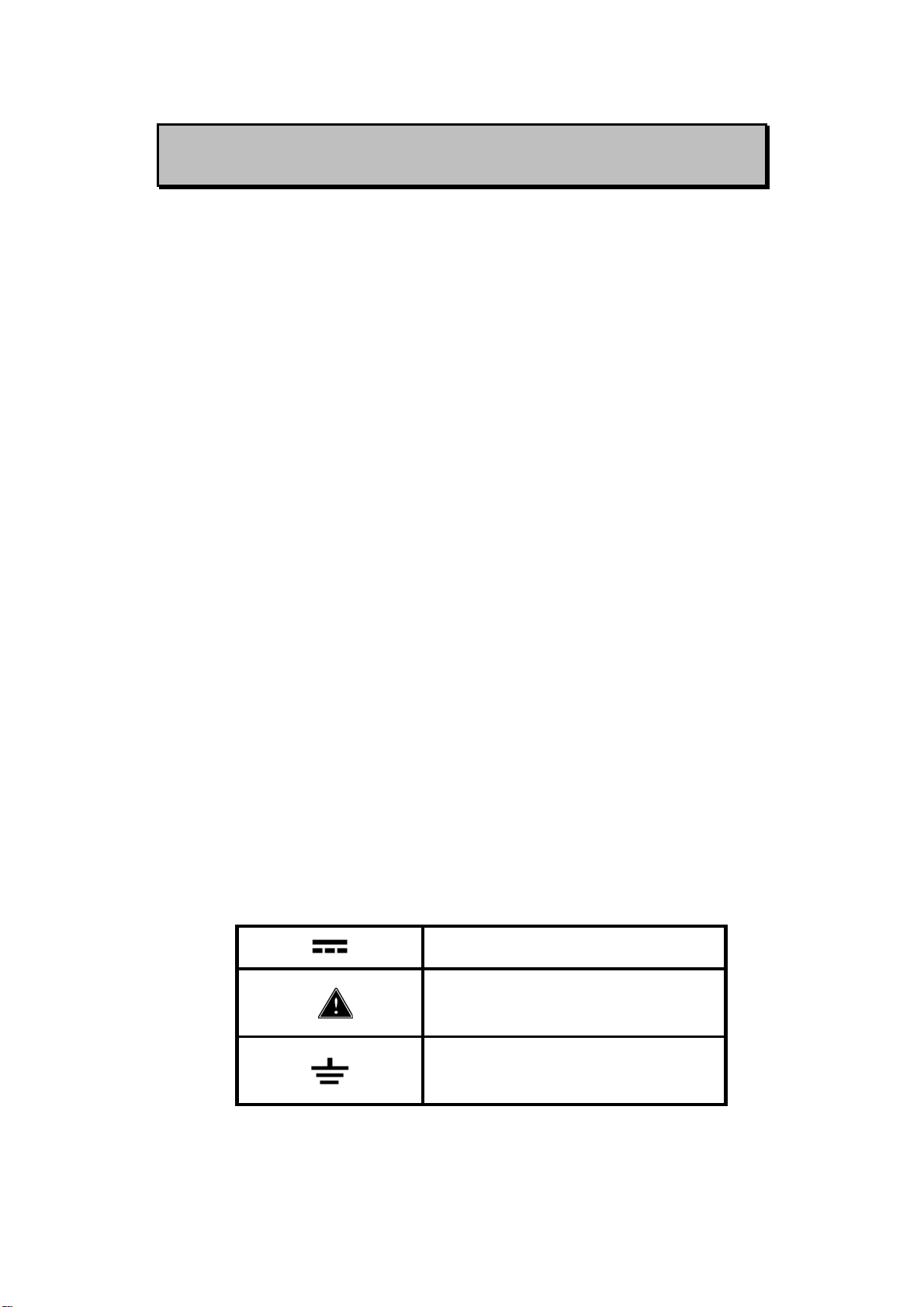

11. International electrical symbols used in this manual as follows:

DC - Direct Current

See Explanation In The Manual

Protective conductor terminated.

Table-1. International Electrical Symbols

2