TABLE OF CONTENTS

1First Start-up of the Software................................................................................ 4

2Operation of the CDI Crystal Touch Software ...................................................... 5

2.1 The user interface.........................................................................................................5

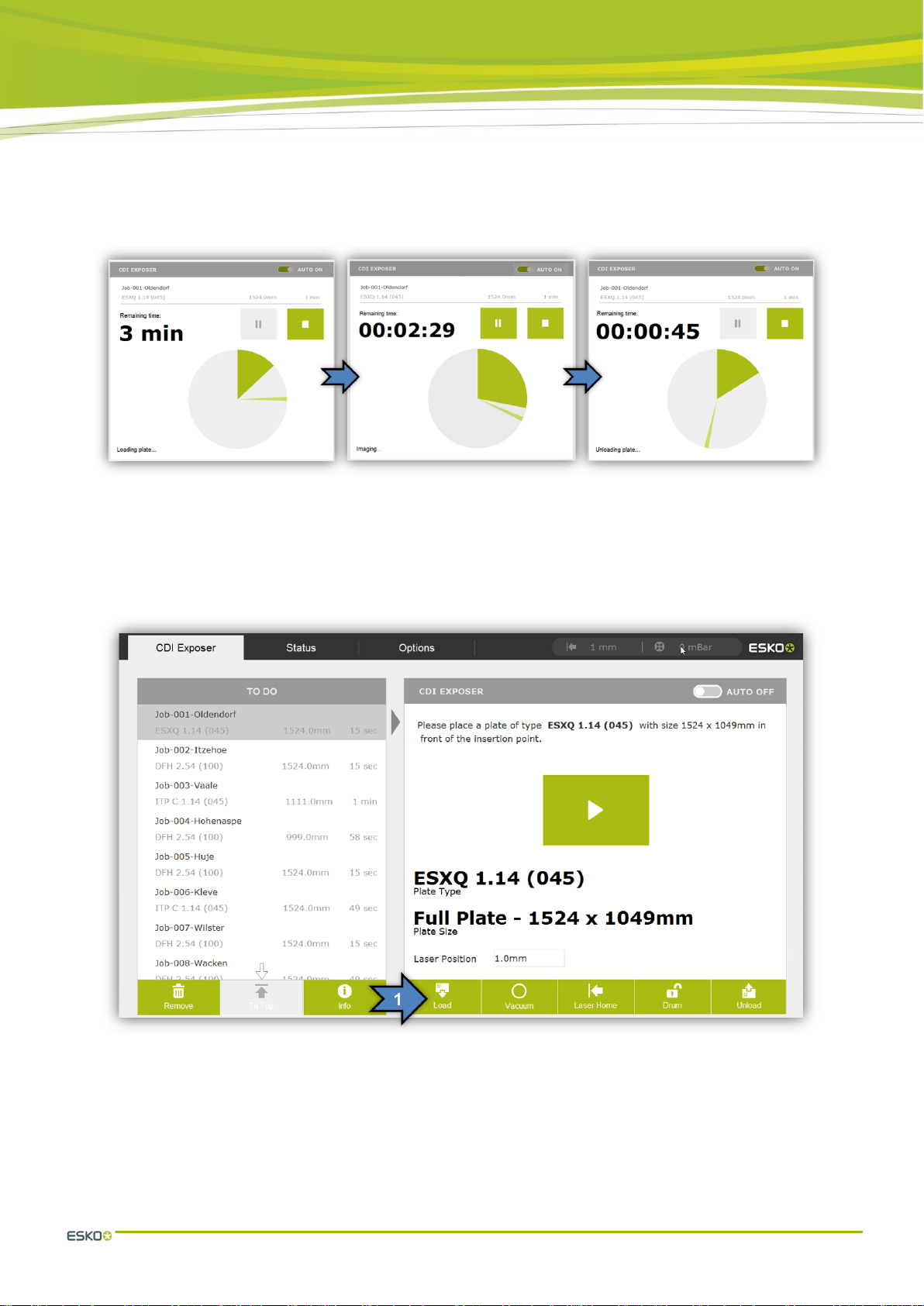

2.2 Automatically starting a job...........................................................................................6

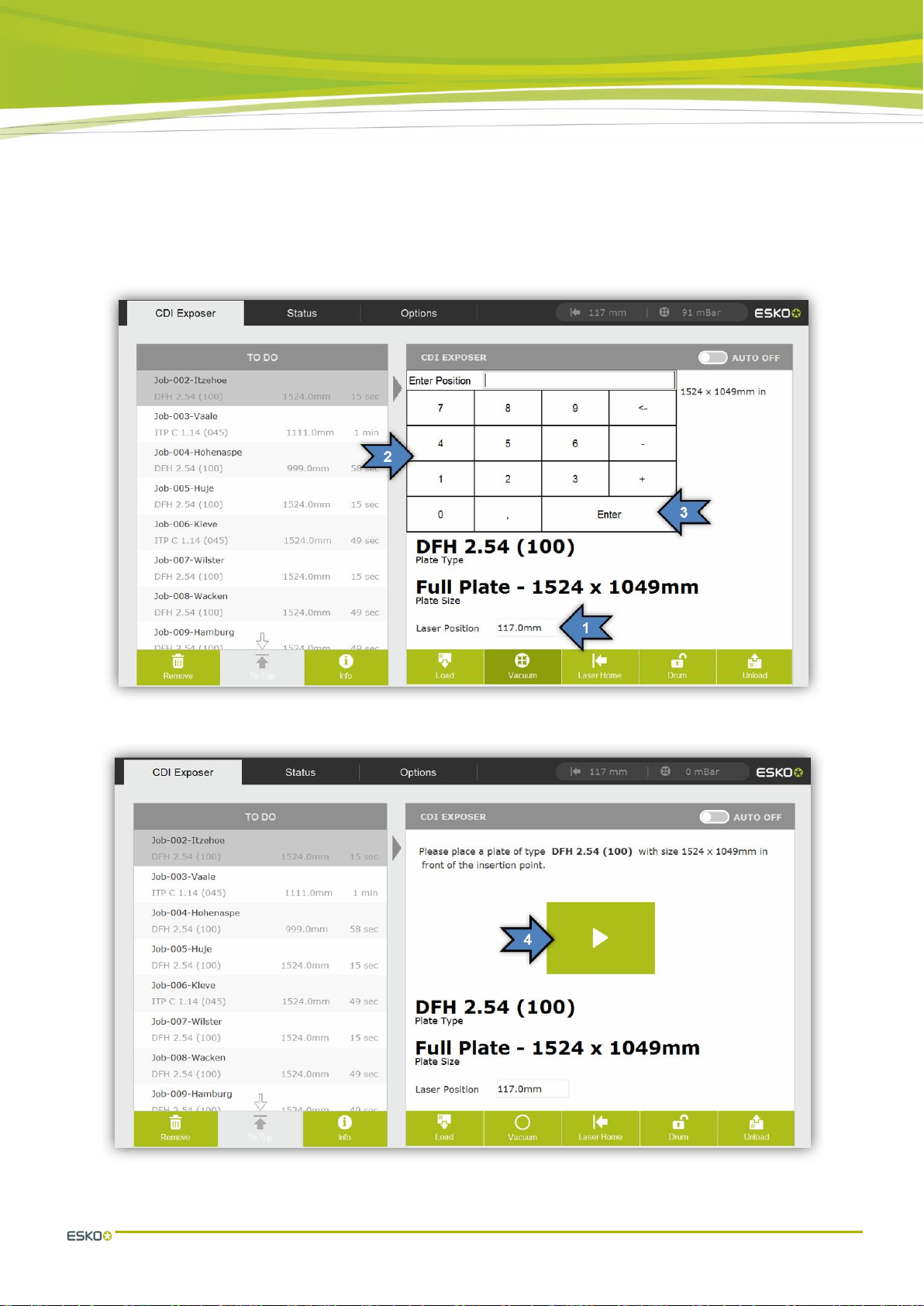

2.3 Automatically loading a plate ........................................................................................7

2.4 Automatically unloading a plate ....................................................................................8

2.5 Manually starting a job................................................................................................10

2.6 Deleting the job...........................................................................................................11

2.7 Re-ordering the job.....................................................................................................12

2.8 Displaying the information for a job.............................................................................12

2.9 Shutting down the CDI................................................................................................13

3Focus Search..................................................................................................... 13

3.1 Advanced settings ......................................................................................................15

3.2 Evaluation of the regular focus search........................................................................16

3.3 Evaluation of the simple focus search.........................................................................17

4Adjusting the Pixel-Boost parameters................................................................. 18

5Managing the plate list........................................................................................ 19

5.1 Adding a New Plate....................................................................................................20

6Operation of the CDI Crystal Touch Software with Plate Feeder........................ 22

6.1 The user interface with Plate Feeder ..........................................................................22

6.2 Selecting the loading level..........................................................................................23

6.3 Automatically starting a job from the "Plate Feeder" ...................................................23

6.4 Parallel operation with the "Plate Feeder"...................................................................24

7Machine status and data .................................................................................... 24

8Changing the basic settings ............................................................................... 25

8.1 Change language .......................................................................................................25

8.2 Show time...................................................................................................................26

8.3 Set date and time........................................................................................................26

8.4 Switch units (inch/mm)................................................................................................27

8.5 Changing the laser park position.................................................................................28

8.6 Changing the laser position for the automatic process................................................28

8.7 Changing the Pixel-Boost values for the "Step Test"...................................................29

9Support............................................................................................................... 29